Grating Catalog Meiser

-

Upload

adrian-leonas-ionita -

Category

Documents

-

view

212 -

download

17

description

Transcript of Grating Catalog Meiser

-

Grating

-

I n t roduc t i on 2

- Abou t ME I SER 4

- ME I SER p re ss l o c ked g ra t i ng 6

- Te chn i ca l t e rms 10

- Ma te r i a l 14

- Ga l van i s i ng P l an t 15

- Su r fa ce r e f i n emen t 16

P ress l o c ked g ra t i ng 18

- App l i ca t i ons 22

- Fu l l g ra t i ng 24

- Heav y du t y g ra t i ng 25

- L ouv re g ra t i ng 26

- Fu l l p re s s l o c ked l ou v re g ra t i ng 26

- Pa t en t G ra t i ng 28

- U l t r a g ra t i ng 29

She l f g ra t i ng 30

- L oose - f i t t i ng des i gns 34

- I n s e r t ed des i gns 36

- Check l i s t 38

P ress we l ded g ra t i ng 40

- App l i ca t i ons 44

- P re s s we l ded g ra t i ng 46

- O f f s ho re p re ss we l ded g ra t i ng 47

- P re s s we l ded g ra t i ng w i t h

smoo t h round ba r s 47

Spec i a l g ra t i ng 48

- App l i ca t i ons 52

- F i nned g ra t i ng 54

- Ba re foo t g ra t i ng 54

- Comb g ra t i ng 55

- To l sun 56

- F ences 58

S ta i r t r eads 60

- App l i ca t i ons 64

- S t a i r t r eads t y pes 66

- Ra i s ed sa fe t y nos i ng 67

F i x i ng C l i p s 68

P roduc t range 74

- S t a i r cases 76

- P ro f i l e g ra t i ng 77

- S ca f fo l d i ng 78

- GRP 79

- D ra i nage channe l s 80

- Heav y du t y channe l s 82

- Spec i a l s e c t i ons 84

- Ga l van i s ed s t r i p /ba r re l hoop 84

- V i n eya rd f ence pos t s 84

- F a l l p ro t e c t i on ma t s and

s po t -we l ded w i re meshes 84

S tock p rog ramme 86

S ta t i c s and l oad t ab l e s 96

- L oad t ab l e s f o r s t a i r t r eads 98

- L oad t ab l e s f o r g ra t i ng 100

Sa fe t y 110

- An t i - s k i d - p rope r t i e s 114

- S l i p p ro t e c t i on s e r ra t i on t y pes 116

Se r v i c e / S t anda rds and c e r t i f i c a t e s 118

- S e r v i c e 120

- E x t e r na l s a l e s f o rc e 121

- S e r v i c e / comp la i n t s managemen t 122

- Qua l i t y and env i ronmen t 123

- Manu fac t u r i ng t e chno l ogy s k i l l s 124

- Check l i s t f o r g ra t i ng 126

- S t anda rds and Ce r t i f i c a t e s 128

- ME I SER i n t e r na t i ona l 132

Mas t head 135

Intro-duction

-

4

-

5TOP LEFT: LIMBACH SITE

TOP RIGHT: OELSNITZ SITE

BOTTOM, FROM LEFT TO RIGHT: WOLFGANG MEISER,

EDMUND MEISER, ULRICH MEISER

MEISER,foundedin1956,isamedium-sized,owner-managed

family business with its company headquarters in Schmelz-

Limbach in theSaarland. In the fieldofgratingMEISERhasa

leadingpositionworldwide.Theproduct range issupplemen-

tedbyotherbusinesssegments.

This includesthefieldofsteelprocessingwith itsownslitting

plantsandcoldrollingcentres.Furthermore,MEISERoperates

traditional hot dip galvanising plants and a strip galvanising

plant. The diversification is rounded off by the production of

sheet metal profile grating, staircase systems, special sec-

tions,scaffoldingsystemsandbarrelhoops.

MEISER employs 2,400 people worldwide, 1,700 of whom

workatthelocationsinGermany.Thetwomainproductionfa-

cilitiesintheSaarlandandSaxonyaresupplementedbymanu-

facturing facilities in France,Belgium,Hungary,Dubai, Egypt,

BrazilandMorocco.Withnumerousotherbranches,MEISERis

representedalmostallovertheworld.Personalsupportforour

customersonsiteisthereforeguaranteed.

50yearsafter thecompanywas foundedbyEdmundMeiser,

westillremaintruetoouroriginsandtraditionalvaluesasafa-

milybusiness.Long-termplanningandreliabilitycharacterise

ourdailywork,whichissupportedbyflexibleandenthusiastic

employeesaswellasmodernandhighlyefficientmachinery.

Forus,economicactivity isassociatedprimarilywithpeople.

That iswhyweplace special emphasisonourpersonal and

individualcontactwithyou,ourbusinesspartnersandcusto-

mers.Wearealwaysavailabletodiscussyourrequirement.

Weareonlyabletomakeprogressifyouourcustomeris

satisfiedoverthelongterm.Themanyunusualprojectsthatwe

have implementedtogetherwithourcustomersconfirmtous

thatthisistherightrouteforustotake.Wewouldbedelighted

toincludeyouamongourcustomersyoucandependonus!

Edmund,WolfgangandUlrichMeiser

Intro-duction

A B O U T M E I S E R

-

6 T H E G R A T I n G

M E I S E R P r e s s L o c k e d G r a t i n g

Grating is a structural element that has a high load-

bearing capacity with a low dead weight and a high

level of transparency. The positive-fitting connection of

thebearingbarsandcrossbarswiththesurroundmake

the grating not only a very stable, but also visually at-

tractive product. The applications are very diverse, as

gratingisusedeverywhereinindustryandarchitecture.

Asanextremely robust, safeyet lightplatform flooring,

thegratingisindispensableinallareasofheavyindus-

try.Gratingisinstalledinrefineries,powerstations,steel

mills,minesandonoilplatforms.Everysteelworker,me-

talworker and fitter needs grating in his trade. Grating

isbeingusedincreasinglymoreinthelogisticsindustry

asplatformflooringandshelves.Architectsandbuilding

owners appreciate the grating as a product which is

bothaesthetically pleasingand functionalbe thisas

decorativefacadecladding,asuspendedceilingorsun

shield.

-

7EUROPEAN COURT OF JUSTICE, LUxEMBOURG

MEISERoffersthelargestrangeofgratingworldwide.The

diversityofpossibleapplicationsalsorequiresanunusu-

allylargevarietyofproducts.Togetherwithourcustomers

weselecttherightgratingfromourrange.Gratingisalmost

alwaysrelevanttosafety,andwearewellawareofthisre-

sponsibility.Whenone isstandinghighuponabreezy

platform made of MEISER grating, one understands the

importance of quality and reliability. We set the highest

standards forourproducts from theplanningstage to

delivery.MEISERgratingis100%madebyMEISER.More

than80%ofallgratingaremadetomeasureatourtwo

factoriesintheSaarlandandVogtlandforourcustomers.

Our employees will be pleased to support and advise

youwith planning your projects. Static calculations and

quantitysurveysalso formpartofourscopeofservices.

MEISER grating sustainable concepts.

Intro-duction

-

8 T H E G R A T I n G

-

9Intro-duction

TOP: OIL AND GAS MANUFACTURING COMPANy, KATAR

BOTTOM, FROM LEFT TO RIGHT:

PEDESTRIAN BRIDGE, EMMENDINGEN; MULTI-STOREy CARPARK,

BIELEFELD; PORSCHE HIGH-BAy WAREHOUSE, AUSTRIA

-

10

a

b

cc

c=centre

T E C H n I C A L T E R M S

Bea r i n g b a r s

Bearingbarsareload-bearing,verticalflatbarswhichrun

paralleltooneanotherfromonesupporttothenext.

C r o s s b a r s

The cross bars run at right angles to the bearing bars,

connecting them together through compression and/or

weldingatthecrossoverpoints.

E d g e b a n d i n g

Allgratingisbandedasarulebyflatbars,T-shapedsec-

tionsorU-shapedsections.

M e s h w i d t h

(a) the clear distance between the bearing bars or the

crossbars.

M e s h s p a c i n g

(b)distance fromcentre tocentreofbearingbarsor the

crossbars.

BB BB CBCB

33,3mm

33,3mm

11,1mm

11,1mm

Me s h s i z e

Themeshsizeislargelydeterminedbythemeshspacing,

wherebythedistancebetweenthebearingbars(BB)and

crossbars(CB)canbedifferent.Inalltablesthefirstvalue

is thedistancebetweenof thebearingbars, the second

value is thedistancebetween thecrossbars.Wewould

liketoillustratethishereusinganexampleof33.3x11.1

and11.1x33.3(distancefromthecentreofthebartothe

centreofthebar).

BB CB

-

11

min.30mm

Supportbeamcentres

ClearSpan

S u p p o r t b e am c e n t r e s

Isthecentre-to-centredistanceofthesupportinthedirec-

tionofthebearingbar.

C l e a r S p a n

Isthecleardistancebetweentwosupports.

G r a t i n g l a n d i n g

Thetermgrating landing isusedtodescribethe length

ofthebearingbarendswhichlieonthesupportstructure.

Itshouldcorrespondtotheheightofthebearingbars,but

alsobeatminimumof30mm.

I n s t a l l a t i o n / E r e c t i o n c l e a r a n c e

The installation clearance is used during assembly to

compensate for tolerances between the steel structure

andgrating.

C u t - o u t s

Ifthetotallengthofthecutoutislessthan0.5mm,wecall

thisaSmallCut-Out.

A n g l e c o l l a r

A bracket welded on one or more sides to the grating.

Thespanofthebracketshouldcorrespondatleasttothe

heightofthebearingbarinthisversion.

Z - s h a p e d s e c t i o n / M E I S E R s p e c i a la n g l e c o l l a r

Angle sectionwith two folds, similar to the angle collar,

inwhichthesectionprotrudesintoanotchinthebearing

bar.

Intro-duction

-

12 T E C H n I C A L T E R M S

De e p B a n d i n g

Reinforcedandraisededgesurrounddownwards,e.g.in

ordertoachieveacertaininstallationheight.

K i c k P l a t e

A raised surround plate, also known as a toe plate, is

welded on, increases safetywhenwalked on and pro-

tectsagainstslidingatthegratingedge.Thisisnecessa-

ryiftheclearancebetweenthegratingandtheadjacent

componentismorethan30mm.

-

13

no t c h e d b e a r i n g b a r

Specialnotchingof thebearingbarsand thepanelban-

dingbars local to thesupport structure (notchesshould

benotmorethanhalftheheightofthebearingbars).

A n t i - s k i d - p r o p e r t i e s ( S e r r a t i o n s )

notchingofbearingandcrossbarstoincreaseslipresis-

tance.

Intro-duction

OFFICE BUILDING, AUSTRIA

-

14 M AT E R I A L

S t e e l g r a d e s

S235JR(DInEn10025-2)S235JRhasprovenitsworthduetoitsgoodweldability,mallea-bilityandstrength.

S275JR(DInEn10025)S275JRdisplayscomparableproductcharacteristicstoS235,although it stands out due to its somewhat higher tensilestrengthandresilience.

S355JR(DInEn10025)Themost importantsteels in thebuilding industryarenotonlythewell-knownconcretesteels,butalsothesteelgradesS235JRandS355JR.

Allof thematerials referred tohavenopassive layerand thereforehave tobeprotectedagainstcorrosion.Indoorsaprimerwithanadditionalcoatofpaintissufficientforthis.Atleasthotdipgalvanisationisrequiredoutofdoors.

H i g h - g r a d e s t e e l

Thematerialnon-rustinghigh-gradesteelcombinesbeneficialpropertieswhichhave todaybecome indispensable formanyfields of application. nevertheless, it is important to knowwhich types of high-grade steel are particularly suitable fortheintendedpurpose,sincethereisnouniversalmaterialthatcanbeusedeverywhere.TwogenerictermsaregenerallyusedinGermany:V2Aor1.4301 isahigh-gradesteel that isoftenfoundineverydayuse,forexampleintheconstructionofbani-

sters,vehiclesandsinks.V4Aor1.4571issimilartoV2A,butis additionally alloyedwith 2%molybdenum (Mo). Thisme-ans that thehigh-gradesteel ismoreresistant tocorrosion inchloride-containingmedia.V4Ahigh-gradesteelisusedinare-as,forexample,whichcomeintopermanentcontactwithsaltwater,inswimmingbathsandthechemicalindustry.Itisalsopossible to pickle and polish the surface of high-grade steel.Thisprocessisdescribedindetailonthefollowingpage.

A l um i n i um

Aluminiumhasbeenincreasinglyusedoverthepastfewyearsasaconstructionmaterial.Itsnumerousbeneficialpropertiesmakealuminiuman interestingandcompetitivealternative tosteel, and in the list of themost commonly usedmetals it isbehindsteelinsecondposition.

The specificweight of aluminium is only2.7 kg/dm (approx.1/3of theweightofsteel),which inconjunctionwith its rela-tivelyhighstrengthandgoodweldingpropertiesmeansthatinmanyapplications itenablessignificantweightsavingscom-paredtosteelstructures.

Materialno. Tensilestrength Yieldstrength Elongationatrupture*

Rmn/mm2min. ReLn/mm2min.

1.0038 360-510 235 26%

Materialno. Tensilestrength Yieldstrength Elongationatrupture*

Rmn/mm2min. ReLn/mm2min.

1.0044 430-580 275 23%

Materialno. Tensilestrength Yieldstrength Elongationatrupture*

Rmn/mm2min. ReLn/mm2min.

1.0045 510-680 355 22%

MEISERhasitsownslittingplants,wiredrawingdevicesandcoldrollingcentres.Wearethereforeabletodesignagratingexactlyinaccordancewiththerequirementsandwishesofourcustomers.Here,oversizingmakeslittlesense,whileundersizingmustbeavoidedunderallcircumstances.Theidealcombinationofmaterialthicknessandheight,associatedwiththematchingsteelquality,ensuresthegreatestpossibleeconomicbenefits.Thatisouraspiration-notmoreandnotless.Wewouldliketoexplainthebest-knownversionstoyoubelow:

COR - T EnUndertheactualrustlayer,COR-TEnsteelsformaparticularlydensebarrier layerasa result ofweathering,whichconsistsofadhesivesulphatesorphosphatesandprotectsthecompo-nentagainst furthercorrosion.Adistinction ismadebetweenCorten A and Corten B. Corten B ASTM A 588 material no.1.8963,En10027-1:S355J2Wisnotphosphorus-alloyed,ap-

provedby thebuildingauthorities,canbereadilyweldedandoffersgoodcoldandhotworkability.Owingto its insensitivitytotheeffectsoftheweatheranditscharacteristicpatina,COR-TEnsteelisalsousedtoprovidehighlightsinarchitecture,forexampleinthecaseoffacadecladding.

*Dataapplicableforproductthicknessfrom3mmto40mmandlongitudinaltestspecimenwithL

0=5,65*S

0

-

15

Intro-duction

G A L V A N I S I N G P L A N T

G a l v a n i s i n g P l a n t a t S c h m e l z - L i m b a c h

With the commissioning of the new hot dip galvanising plant

we began a new chapter in the summer of 2011. Hot dip gal-

vanising is the last but an important step in the production

of the grating and guarantees the long-term corrosion pro-

tection of MEISER products without any special maintenance

measures. Our new building combines attractive industrial

architecture with state-of-the-art technology. The environment

and the employees benefit from pollutant-free operations and

exemplary working conditions, which in no way resemble the

conventional image of a galvanising plant. Behind the beautiful

facade, many areas of the building accommodate automated

processes which ensure the highest possible level of efficiency

and quality.

Each individual grating is loaded according to schedule into

the galvanisation process and can be tracked from the time it is

hung up on the cross member to when it is taken down on the

lifting and lowering stations. There is therefore no danger that

grating will get lost in the galvanising process. Chemical pre-

treatment, an environmentally sensitive process, is performed

in a fully enclosed area which passes the emissions produced

through an extraction system to a filter system, so that our envi-

ronment is not polluted in any way. Using a very powerful dryer,

we produce very clean and preheated surfaces before the gal-

vanising process. This also has a very positive effect on the

consumption of zinc and the surface quality. Zinc is a valuable

raw material which has to be handled with care.

P l a u e n G a l v a n i s i n g P l a n t

The Plauen Galvanising Plant (Verzinkerei Plauen) has be-

longed to MEISER for some years now and enables us to also

offer quality from a single source in the Vogtland region. Ori-

ginally designed as a galvanising plant for steel components

and locksmiths products, after the reunification of Germany

a major conversion was carried out with the focus on scaffol-

ding, which was pushed through by the then operator Thyssen

Hnebeck.

Subsequently the focus has increasingly been on MEISER pro-

ducts, which make up more and more of the product range in

Plauen. With the takeover of all of the shares in the galvanising

plant in Plauen, this became an integral part of MEISER in the

Vogtland. Today the production is dominated by grating, sheet

metal profile grating, staircase systems and special profiles.

-

16 S U R F A C E R E F I n E M E n T

S u r f a c e r e f i n e m e n t

MEISERgratingischaracterisedbydurabilityandhighquality.

Thiscruciallydependsonthecorrectsurfacetreatment.Inthis

respectweofferourcustomersnumerouspossibilities-bethis

with thefocusonfunctionalityoraesthetics.For theselection

ofthesurfacetreatmenttherearevariousfactorswhicharede-

cisive: thepersonalpreferencesofourcustomer, theirbudget

andquestionsofcorrosionprotection.

H o t d i p g a l v a n i s i n g

MEISERgratingmanufacturedfrommildsteelisusuallyhotdip

galvanised. In our new plant,whichwe put into operation in

2011,thisiscarriedoutinaccordancewiththespecifications

of DIn En ISO1461. State-of-the-art galvanising and environ-

mental technology guarantee long-term corrosion protection

whichisabletowithstandtheusualmechanicalandchemical

stresseswithoutproblems.

P owd e r c o a t i n g

Ifyouwouldliketohaveyourgratingsuppliedinvariouscolours,

powdercoatingisthe leastexpensiveandmostdurablesoluti-

on.Inthisprocessthegratingisinitiallydegreasedinimmersion

baths, pickled and zinc-phosphated. Then the powder coating

materialisappliedelectrostaticallyandbakedatapproximately

180C.

Particularly durable corrosion protection is offered by the

MEISERDUPLEXcoating,whichconsistsofhotdipgalvanising

withsubsequentpowdercoating.Thepowdercoatingisavailab-

leinallpossibleRALcoloursinvariousdegreesofglossandsur-

facestructures.Moreover,weareabletoprovidethenecessary

layerthicknessesforallfeasibleapplicationsfromC1toC5-M.

P i c k l i n g ( h i g h - g r a d e s t e e l )

MEISERhigh-gradesteelgratingisusuallypickledafterproduc-

tion,asduringmanufacturetheweldingprocessresultsinsca-

leanddiscolouration,which inturnrepresentpotentialpoints

of attack for corrosion. In the pickling process the grating is

immersedinapicklingbath,asaresultofwhichtheyareprovi-

dedwithametallicallypureandprotectedsurface.

-

17

E l e c t r o - c h em i c a l - p o l i s h i n g ( h i g h - g r a d e s t e e l )

The electropolishing process represents a reversal of the

electroplating process. Under the influence of direct current,

metal is removed inanelectrolyte from theanodicsurfaceof

theworkpiece.Theresultissmoothandshinysurfaceswhich

displayahighlevelofcorrosionresistanceandisveryeasyto

clean.

G l a s s b e a d b l a s t i n g

Through theuseofglassbeadsasblastingmaterial,MEISER

gratingmade of chrome steel and aluminium are further re-

fined.Blasting techniquesserve tospecificallycreatemattor

semi-gloss surfaces and to cover surface defects in thema-

terial.Theresultingsemi-glosseffect ispermanently retained.

Thesurface iscleanedofadhesive foreignparticlesandalso

strengthened, as a result of which its durabilitymay be pro-

longed.

A n o d i s i n g ( a l um i n i um )

MEISERgratingmadeofaluminiumisanodisedasstandardin

ordertopreventoxidation.Intheanodisingprocess,whichasa

ruleiscarriedoutinanimmersionbath,thematerialisinitially

degreasedandpickledbeforetheactualanodisingprocessis

performed.Here,thechemicalprocessofelectrolysisisused,

with an oxidised protective layer being created on the alumi-

nium.Thiscanbecoloured if thenaturalaluminiumcolour is

notdesired.

C a t h o d i c imme r s i o n b a t h c o a t i n g ( CDC )

CDC is a good combination of corrosion protection, quality,

cost-effectiveandenvironmentalfriendly.Corrosionprotection

thatoffersgoodresistancetomechanicalandchemicalstress.

Theunderlyingphysicalprincipleinelectro-coatingconsistsin

attractingmaterialswithoppositechargesandproducingvery

goodadhesionasaresult.

Before the coating process a direct current is applied to the

workpiece,whichissubsequentlyimmersedinacoatingbath

withoppositelychargedcoatingparticles. Inorder toachieve

maximumresistanceofthecoating,thefilmsubsequentlyhar-

densatapproximately180Celsiusinthebakingoven.Vario-

us layer thicknesses are possible, although the colour selec-

tionislimited.

Intro-duction

-

18

-

19

BMW, VLIZy

P R E S S L O C K E D

G R AT I n G

Presslockedgrating

-

20 P R E S S L O C K E D G R A T I n G

M E I S E R P r e s s L o c k e d G r a t i n g

Thepress lockedgrating is themost commonlyused typeof

gratinginmanyEuropeancountriestoday.Thankstoaproduc-

tion technologywhich differs significantly from that used for

thepressweldedgrating,andwhichenablesamuchgreater

varietyofproducts,thistypeofgratingprovidesforanalmost

unlimited number of applications. Its design allows for great

flexibilityregardingthemeshsizeandtheheightandthickness

of the bearing bars. In combinationwith the variety ofmate-

rials fromwhich press locked grating can bemanufactured,

weproducegratingthatareexactlyinlinewiththecustomers

wishesand the intendeduse.Wedonotclaim that thepress

lockedgratingisthebettergrating,butit iscertainlythemore

attractiveandindividuallycustomisedgratingcomparedtothe

pressweldedgrating.

Forapresslockedgrating,thecrossbarswhichasaruleare

madeofcold-rolledflatsteelarepressedintothepreviously

punched-outbearingbars.Thebandingbarsaredesignedas

T-shapedorflatsections,andareattachedbymeansofauto-

matic resistancewelding. If there isan increased riskof slip-

ping,presslockedgratingcanbemanufacturedinananti-skid

design.Forthis,thebearingand/orcrossbarsarenotchedon

the upper side. With press locked grating, the opposite end

meshesareusuallyofequalsize.Buthere, too,applieswhat

hasbeensaidabove:thereisalmostnolimittotheimaginable

usesanddesignsofpresslockedgrating.

500 to

GERMAN HyGIENE MUSEUM, DRESDEN

BearingbarBearingbar2mm 3mm

Bearingbar4mm

Bearingbar5mm

20/2 20/3 - -

25/2 25/3 25/4 25/5

30/2 30/3 30/4 30/5

35/2 35/3 35/4 35/5

40/2 40/3 40/4 40/5

45/2 45/3 45/4 45/5

50/2 50/3 50/4 50/5

- 60/3 60/4 60/5

- 70/3 70/4 70/5

- 80/3 80/4 80/5

- 90/3 90/4 90/5

- 100/3 100/4 100/5

- - - 110/5

- - - 120/5

- - - 130/5

- - - 140/5

- - - 150/5

- - - 160/5

- - - 170/5

Commonmeshspacingforbearingbarsfrom2to3mm

Bearingbar Crossbar

11,1 11,1 16,65 - 22,2 33,3 44,4 49,95 66,6 99,9

15 11,1 16,65 - 22,2 33,3 44,4 49,95 66,6 99,9

21 11,1 16,65 21,0 22,2 33,3 44,4 49,95 66,6 99,9

22,2 11,1 16,65 21,0 22,2 33,3 44,4 49,95 66,6 99,9

33,3 11,1 16,65 21,0 22,2 33,3 44,4 49,95 66,6 99,9

44,4 11,1 16,65 21,0 22,2 33,3 44,4 49,95 66,6 99,9

55,5 11,1 16,65 21,0 22,2 33,3 44,4 49,95 66,6 99,9

66,6 11,1 16,65 21,0 22,2 33,3 44,4 49,95 66,6 99,9

99,9 11,1 16,65 21,0 22,2 33,3 44,4 49,95 66,6 99,9

Commonmeshspacingforbearingbarsfrom4to5mm

Bearingbar Crossbar

21 16,65 22,2 33,3 44,4 50 66,6 99,9

25 16,65 22,2 33,3 44,4 50 66,6 99,9

33,3 16,65 22,2 33,3 44,4 50 66,6 99,9

50 16,65 22,2 33,3 44,4 50 66,6 99,9

66,6 16,65 22,2 33,3 44,4 50 66,6 99,9

99,9 16,65 22,2 33,3 44,4 50 66,6 99,9

S t a n d a r d b e a r i n g b a r p r o f i l e s

Wewillofcoursebepleasedtofulfilanyspecialwishesthatyoumayhave!

-

21

Presslockedgrating

-

22 A P P L I C A T I O n S

Bringingnaturetolife-isthemottoofthetreetopwalkatEder-

see(LakeEder).MEISERpresslockedgratingenablevisitorsto

walkalongtherouteinsafetyandharmoniseperfectlywiththe

architecturalconcept,which isbasedonnaturalshapes.The

gratingofferasafepaththroughthetreetopsinallweathers.

AnodisedMEISERpresslockedgratingcontributetothedesign

oftheshowroomatthePorscheCentreinLbeck.Cleverlyhigh-

lightedwithcolouredlight,thegratingunderlinetheexclusivityof

thevehiclesonshow.

-

23

Presslockedgrating

The walkways across the Saarbrucken extinguishing water

ponds are covered with MEISER press locked grating in an

antiskiddesign.As inallpubliclyaccessibleareas, itmustbe

ensuredherethatthesurfaceisslip-proofinallweathers.

Whenthewalkwaysandgratingwerebeingdesigned,themo-

dern style of the surrounding building complexes was taken

intoconsideration.

AtthewastewatertreatmentplantintheDresdensuburbofKaditz,

MEISERpresslockedgratingprovidetheconnectionbetweenthe

twodigestiontowersandthefunctiontoweroftheplant.

Thegratingequippedwithanti-skidprotectionprovideacrossover

whichisbothsafeandindependentoftheweather.

-

24

F u l l G r a t i n g

Full grating bear this name because the bearing and cross

barshave the samecross-sectionandare thereforeof equal

height. Abearingbar is onewhoseendsareboth supported

andwhoseundersideisnotslotted.Theadvantagecompared

to the normal press locked grating is its improved screening

andtheattractivedesign.

P R E S S L O C K E D G R A T I n G T Y P E S

Bearingbar 2mm

Bearingbar3mm

Bearingbar5mm

20/2 20/3 -

25/2 25/3 25/5

30/2 30/3 30/5

35/2 35/3 35/5

40/2 40/3 40/5

45/2 45/3 45/5

50/2 50/3 50/5

- 60/3 60/5

- 70/3 70/5

- 80/3 -

- 90/3 -

- 100/3 -

Commonmeshspacingforbearingbarsfrom2to3mm

Bearingbar Crossbar

22,2 16,65 22,2 - 44,4 66,6

33,3 16,65 22,2 33,3 - 66,6

44,4 16,65 22,2 - 44,4 -

66,6 16,65 22,2 33,3 - 66,6

Commonmeshspacingforbearingbarsfrom5tomm

Bearingbar Crossbar

33,3 16,65 33,3 66,6 99,9

66,6 16,65 33,3 66,6 -

99,9 16,65 33,3 - 99,9

S t a n d a r d b e a r i n g b a r p r o f i l e s

Thepossibleusesofgratingisveryvaried.Itispossibletofind

asuitabledesignforeveryapplication.Besidestheconventio-

nalpresslockedgratingorpressweldedgrating,thereisalso

agreatvarietyofspecialsolutions,whichwewouldliketopre-

senttoyouingreaterdetailbelow.Heavydutygratingcanbe

driven over by heavy equipment, while full grating or finned

grating are increasingly finding favour among architects, as

with this type of grating it is possible to create certain high-

lights in the design of the facade. The possible applications

andthedesignofgratingisalmostlimitless.Wewillbepleased

toadviseyousothattogetherwecanfindtheperfectsolution

foryourapplication.

-

25

H e a v y d u t y g r a t i n g

Fromthenameyoucanguesstheintendedapplicationofthe

MEISER heavy duty grating. This is press locked gratingwith

particularlydeepand/or thickbearingbars. Thedimensions

ofthecrossbarareadaptedaccordingly.

Counter gear teeth during the pressing process gives the

MEISERheavydutygratingadditionalstability,sothatsurface

loadsofmore than50 tonnesandwheel loadsof10 tonnes

canbewithstoodwithoutdifficulty.

Weadapttheexactdesignfromcasetocasetothewidthbet-

weensupportsandtheintendeduse.Productioninhigh-grade

steelisalsopossible.

Bearingbar8mm Bearingbar10mm Bearingbar12mm

80/8 80/10 -

90/8 90/10 -

100/8 100/10 100/12

110/8 110/10 110/12

120/8 120/10 120/12

130/8 130/10 130/12

140/8 140/10 140/12

150/8 150/10 150/12

- - 160/12

- - 170/12

- - 180/12

- - 190/12

- - 200/12

Commonmeshspacing

Bearingbar Crossbar

25 50 75 100

50 50 75 100

75 50 75 100

100 50 75 100

S t a n d a r d b e a r i n g b a r p r o f i l e s

Presslockedgrating

-

26

L o u v r e G r a t i n g

Less transparency is sometimes what is required. In these

casesthe louvregrating isused.Therearea largenumberof

applications,whicharenotrestrictedonlytofloorcoveringsin

thecaseofbridges,walkwaysandcrossovers.Asasunshield

orcladdingelement,thelouvregratingisalsousedinthecase

ofventilationgrilles,facadesandsuspendedceilings.

MEISER offers louvre grating in steel, aluminium and high-

gradesteel. Thecrossbarscanbepressed inatanangleof

15,30or45,sothatvaryingdegreesoftransparencycan

beachieved.Pleasenote inyourplanningthat for this typeof

gratingweareonlyabletoproducecrossbarlengthsofupto

1,500mm.

F u l l P r e s s L o c k e d L o u v r e G r a t i n g

Thisspecialdesignofthelouvregratingcombinesthetechni-

calpropertiesofaconventionalpress lockedgratingand full

gratingwith theattractive designof a louvregrating. The full

presslockedlouvregratingisparticularlysuitablenotonlyas

facadecladding,butalsoasacrossoverorwalkwaycovering

duetoitsstaticadvantages.

Theangleof thecrossbarscanbe freelyselected in thisver-

sion.The load-bearingcapacityof thefullpress locked louvre

gratingbenefitsfromtheverysmallpunchdepthofthebearing

bars,whichisonly10mm.MEISERoffersthefullpresslocked

louvregratinginsteel,aluminiumandhigh-gradesteel.Anot-

chinginthebearingbarsispossible,sothatthisversionalso

offersahighlevelofslipresistance.Pleasenote inyourplan-

ningthatforthistypeofgratingwecanonlyproducecrossbar

lengthsupto1,250mm.

Firstsizementioned=bearingbardirection;externalgratingdimensions

2mm 3mm

25/2 25/3

30/2 30/3

35/2 35/3

40/2 40/3

45/2 45/3

50/2 50/3

- 60/3

- 70/3

- 80/3

- 90/3

- 100/3

2mm 3mm

25/2 25/3

30/2 30/3

35/2 35/3

40/2 40/3

45/2 45/3

50/2 50/3

Commonmeshspacing

Bearingbar Crossbar

33,3 16,65 22,2 33,3 66,6

66,6 16,65 22,2 33,3 66,6

99,9 16,65 22,2 33,3 66,6

Commonmeshspacing

Bearingbar Crossbar

22,2 16,65 22,2 33,3 44,4 66,6

33,3 16,65 22,2 33,3 44,4 66,6

44,4 16,65 22,2 33,3 44,4 66,6

66,6 16,65 22,2 33,3 44,4 66,6

99,9 16,65 22,2 33,3 44,4 66,6

S t a n d a r d b e a r i n g b a r p r o f i l e s

S t a n d a r d b e a r i n g b a r p r o f i l e s

P R E S S L O C K E D G R A T I n G T Y P E S

MULTI-STOREy CAR PARK, BIELEFELD

-

27

Presslockedgrating

-

28 P R E S S L O C K E D G R A T I n G T Y P E S

P a t e n t G r a t i n g

TheMEISERpatentgratingisproducedwithapatentedpunch

pressconnection,surroundedwithaU-shapedsectionandhot

dipgalvanised. TheV-shapedcrossbarsproduceahighde-

greeofstiffnessandanoutstandingwipingeffect.

Thepatentgratingisthereforeprimarilyusedasahigh-quality

boot scraper and an extremely stable and resilient light well

grating.Asuitableangleframewithpunchedwallanchorscan

besupplieduponrequest.

ThepatentgratingisproducedexclusivelybyMEISER.

Meshwidth Gratingheight Bearingbar

31/24mm 20mm 2mm

-

29

500 to

Presslockedgrating

U l t r a G r a t i n g

MEISER developed the ultra gratingmany years ago in order

tooffercut-to-sizecompaniesanalternative to theconventio-

nal pressweldedmats in the form of a press locked grating

design. Specially developed joining technology guarantees a

solidconnectionbetweenthebearingandcrossbars.Thiscan

evenbesupplementedbyspotweldinguponrequest.Theultra

gratingmat is therefore ideally suited for further processing,

as it isalmost impossible for thecrossbarstobecomeloose

duringsawing.

Theultragratingmatisalsoavailableincrossbarlengthsup

to 1,500mm, so that the offcuts are significantly smaller in

comparisontothepressweldedmat.Theultragratingmat is

alwaystrimmedandavailableinourstockprogrammeinvari-

ousmeshspacingandsizes.Uponrequest,thecrossbarside

canalsobeedged.

2mm 3mm

25/2 25/3

30/2 30/3

35/2 35/3

40/2 40/3

Commonmeshspacing

Bearingbar Crossbar

34,3 33,3 66,6 99,9

68,6 33,3 66,6 99,9

S t a n d a r d b e a r i n g b a r p r o f i l e s

-

30

-

31

HIGH-BAy WAREHOUSE, DACHAU

S H E L F G R AT I n G

Shelfgrating

-

32 S H E L F G R A T I n G

M E I S E R S h e l f G r a t i n g

MEISER shelf grating offers decisive advantages within logi-

sticssystemscomparedtoothershelfcoverings.Inadditionto

theirdurability,theyareaboveallpermeabletolightandwater.

Thisisakeyfeaturewhensprinklersystemsareused.Thehigh

degreeoftransparencyofthegratingmeansthatplentyoflight

isabletoenter,thusprovidinghighbrightnesslevelsinthelogi-

sticssystem;moreover,theitemsstoredontheshelvescanbe

identifiedfrombelow.

Ingenious detailed solutions mean that the grating is easily

installedandoffers theadditional integratedbenefits. Onthe

following pages we present our solutions, which have been

developed together with the leading suppliers of logistics

systems.

-

33

Shelfgrating

-

34

Sh e l f g r a t i n g w i t h n o t c h e d T - s h a p e d s e c t i o nb a n d i n g b a r s

This is the standard design, which can be manufactured at

lowcostandwhichissuitableforvariousshelvesofthesame

depth,butwithdifferentcross-members.

S h e l f g r a t i n g , b e a r i n g b a r w i t h r a i s e d e d g es u r r o u n d

Thisgratinghasaraisededgesurround,albeitonlyattheends

ofthebearingbars.Thelockingfunctionistherefore lesspro-

nounced, but the possible applications are somewhat more

flexible,asit isnotnecessarytouseaspecificcross-member

width.

S H E L F G R A T I n G

L o o s e - F i t t i n g Ve r s i o n

These versions of the MEISER shelf grating can be easily

lockedinplaceonthecross-membersoftheshelfstructure.To

thispurpose,theT-shapedsectionsurround,whichisextended

downwards, isprovidedwithnotches thatarespecificallyad-

aptedtothewidthofthecross-member.

Thenotchesarepuncheduptotheheightofthebearingbars,

sothatthebearingbarsarelocatedflushonthecross-member

andhelp to improve the statics. Further specific adjustments

canbecarriedout,whicharedescribedbelow.

-

35

Sh e l f g r a t i n g , n o t c h e d w i t hp u s h - t h r o u g h p r o t e c t i o n

Push-throughprotectionisanimportantsafetyelementinshelf

systems. If thishas tobe installedseparately, it isassociated

withconsiderablecosts.

MEISERhasashelfgratingwith integratedpush-throughpro-

tectioninitsrange.Therearisedgedwithareinforcedflatbars,

theheightofwhichcanbefreelyselected.

S h e l f g r a t i n g w i t h a d d i t i o n a l n o t c h e s i n t h ea r e a o f t h e r e s t s f o r d o u b l e s h e l v e s

For so-called double shelves, MEISER has also developed a

specialtypeofgrating.Additionalnotchesallowacontinuous

connectionacrossthedoubleshelves.Thisgratingcanalsobe

quicklyinstalled.

Shelfgrating

-

36 S H E L F G R A T I n G

I n s e r t e d D e s i g n s

In addition to the loose-fitting versions, MEISER has also de-

veloped thissolution. Here, theendsof thebearingbarsare

enclosedwithaZ-shapedspecialsectionthatisconnectedto

thebearingbarsbymeansofanautomaticresistancewelding

process.Thisshelfgratingisalsoveryresilientasaresult.

An important advantage of the inserted shelf grating is the

improvedeffectiveheightof theshelfspaces.Since thisshelf

grating issuspendedbetweenthe longitudinalgirders, the in-

sertionheightofashelfisnotreducedbythegratingitself.

S h e l f g r a t i n g w i t h Z - s h a p e d a n g l e s e c t i o ns u r r o u n d / M E I S E R s p e c i a l a n g l e c o l l a r

This isthemostcommondesignoftheinsertedshelfgrating.

The angle collar used is a rolled section of our own design,

whichisinsertedintothebearingbarsandadditionallywelded.

-

37

Shelfgrating

S h e l f g r a t i n g w i t h U - s h a p e d s e c t i o n s u r r o u n d

Inthisversion,arolledU-shapedsectionisweldedtotheends

ofthebearingbars.Thegratingthereforelieswithintheshelves

and is also lockedwith the cross-members bymeans of the

U-shapedsection.Additionalsafetywillthereforebeprovidedif

theshelvesaresubjectedtoexcessiveloads.

G r a t i n g f o r D o u b l e S h e l v e s

Thisshelfgratingelementconsistsoftwogratingpanelswhich

are connected by a U-shaped section in the central area of

thereststoformaunit.Thiscreatesacontinuousconnection

across thedoubleshelves,with the full shelf heightbeing re-

tained.

S h e l f g r a t i n g s w i t h Z - s h a p e d a n g l e s e c t i o ns u r r o u n d a n d p u s h - t h r o u g h p r o t e c t i o n

The insertedshelfgrating isalsoavailablewithpush-through

protection. In this case the Z-shaped special section is sup-

plementedbyanadditionalsection,whichpreventsthegoods

frombeingpushedthrough.

-

38 S H E L F G R A T I n G

C h e c k l i s t

Shelf GratingPleaseusethechecklistasafaxtemplatetofacilitatetheorderingprocess.

Offer number/Project number

1 2

SHE L F GRAT I nG I n S ER T EDSHE L F GRAT I nG LOOS E - F I T T I nG

Project dataPostcode/ZIParea Deliverydate Contactperson Date

Grating Versions Mesh widths Loose-fittinggratingwithdisplacementprevention 30x30mm Withspecification

Insertedgratingwithanglecollar 30x60mm nospecification,tobeoptimised

Load Bearing Bearing bar BB pershelf(framedepth mmxbeamlength mm) BBspecification:

kgshelfload BBoptimisedaccordingtoload

perm

Pointloading

Dimensions

Shelfload Framedepth Beamlength Quantity

www.meiser.co.uk

Bearingbarsize Bearingbarsize

BeamdistanceFramedepth

Beamdistance

Framedepth

-

39

Shelfgrating

-

40

-

41

HEATING PLANT, FREIHAM

P R E S S W E L D E D

G R AT I n G

PressWeldedGrating

-

42 P R E S S W E L D E D G R A T I n G

P r e s s We l d e d G r a t i n g

MEISER press welded grating is traditionally used in many

areas of industry. The continuouswelding of each individual

intersectionpointofthebearingbarandcrossbarproducesan

extremely stable and hard-wearing structure. The cross bars

normallyusedinthepressweldedgratingaretwistedsquare

wires,whichareresistanceweldedtothebearingbars.

This is carried out under high pressure usingautomatic resi-

stancewelding.Manufactureiscarriedoutonproductionlines

thathavebeendevelopedbyourselves,wherewecanproduce

made-to-measuregratingpanelswithoutwasteandinaccor-

dancewithourcustomerwishes.This isachievedby the fact

thatourmachinescanproducepanelswithcrossbarlengths

ofupto1,250mm,whilstothermoreconventionalmachines

are restricted to 1,000mm. Utilising our larger panel widths

cangivesavingsofupto20%inthenumberoffixingsrequired

which obviously translates into bigger savings in installation

timeandlabourcosts.MEISERpressweldedgratingisprima-

rily used in the oil andgas industry, petro-chemical industry,

Commonmeshspacing

Bearingbar Crossbar

15,08 - - - 38,1 50,8 76,2 101,6

17,15 - - - 38,1 50,8 76,2 101,6

20,77 - 24,0 - 38,1 50,8 76,2 101,6*

23,69 - 24,0 - 38,1 50,8 76,2 101,6*

25,00 - - - - - 76,2 101,6

30,15 - - - 38,1 50,8 76,2 101,6

33,00 - - 31,75 - - - -

34,30 19,25 24,0 - 38,1 50,8 76,2 101,6

41,45 - 24,0 - 38,1 50,8 76,2 101,6

45,23 - 24,0 - 38,1 50,8 76,2 101,6

51,45 - 24,0 - 38,1 50,8 76,2 101,6

60,30 - 24,0 - 38,1 50,8 76,2 101,6

68,60 - 24,0 - 38,1 50,8 76,2 101,6

*availablewithrestrictions

-

43

CELLULOSIC ETHANOL PLANT, STRAUBING

PressWeldedGrating

miningindustryandinpowerstations.Wherestrongshearing

forcesoccurandplatformflooringhastobechangedfrequent-

ly, the superiority of the presswelded grating comes into its

own.Steel fabricators alsoappreciate thepressweldedgra-

ting,whosestabilityisideallysuitedtothesubsequentworking

ofmaterials.MEISERpressweldedgratingpanelsarenormally

bandedwithflatsectionsandcanbeproducedinV2AandV4A

withroundorribbedcrossbars.Uponrequest,forgratingma-

nufacturedinmildsteel,thecrossbarscanbesuppliedinthe

size7mm(twisted)or8mm(ribbed).

Bearingbar2mm

Bearingbar3mm

Bearingbar4mm

Bearingbar5mm

- 20/3 20/4 20/5

25/2 25/3 25/4 25/5

30/2 30/3 30/4 30/5

35/2 35/3 35/4 35/5

40/2 40/3 40/4 40/5

45/2 45/3 45/4 45/5

- 50/3 50/4 50/5

- 60/3 60/4 60/5

- 70/3 70/4 70/5

- 80/3 80/4 80/5

S t a n d a r d b e a r i n g b a r p r o f i l e s

-

44 A P P L I C A T I O n S

Verynarrowmeshspacing,lessthan15.08mm,whichissome-

times required for safety reasons, cannot be produced for the

pressweldedgrating.Ifitisimportanttopreventthepassageof

smallpartsfromplatforms,aclose-meshpresslockedgratingis

thefirstchoice.However,MEISERcanaddressthisrestrictionwith

respect topressweldedgratingbysupplementingthestandard

pressweldedgratinguponrequestwithperforatedsheets.These

arearrangedbetweenthebearingbarsandweldedtothecross

bar.Aballwithadiameterof9mm, i.e.a referencesize that is

oftenused,cannotfallthroughsuchagrating.SaarbahnGmbH

inSaarbrckenhasinstalledthistypeofpressweldedgratingin

itstwo-storeyworkshophallsinordertoprotectemployeesonthe

lowerflooragainstfallingobjects.

TheSunliquid demonstrationplant ofClariant AG is currently

thelargestplantinGermanyfortheproductionofbio-ethanol.

The hazards associated with the production of bio-ethanol

requirehigh safety standards,whichare fullymetbyMEISER

pressweldedgrating.notonlytheirlowflammability,butalso

their resistance to chemicals speak in favour of the use of

MEISERpressweldedgratingintheproductionofbio-ethanol.

-

45

Theproductionofpolysiliconrequiresstrictsafetyprecautions

and is associatedwith a potential hazard to employees and

theenvironment.AtthePVCrystaloxSolarPLCfactory,MEISER

pressweldedgratingformsthe idealbasis,particularly inthe

outdoor area, for safe working and the safe handling of ha-

zardoussubstances.

Inside Rgen Bridge, MEISER press welded grating used as

safe walking routes. The good anti-skid properties and high

torsional stiffnessof thepress lockedgrating is ideal foruse

inbridgebuilding.

PressWeldedGrating

-

46 P R E S S W E L D E D G R A T I N G T Y P E S

M E I S E R P r e s s W e l d e d G r a t i n g

In the case of press welded grating, it is not possible to pro-

duce very small mesh widths for technical reasons. If the

customer requires the use of press welded grating but would

nevertheless like to ensure that the grating is 8 mm ball

proof, then this is the grating that sould be used. By welding

perforated sheets with an aperture of not more than 8 mm

between the bearing bars, it is possible to produce a very

close-meshed grating for a reasonable cost. This grating

corresponds to the Spanish standard no. 486/1997 (BO 23rd

April 1997, no. 97/1997).

Common mesh spacing

Bearing bar Cross bar

34,30 38,1 50,8

Bearing bar 2 mm

Bearing bar 3 mm

25/2 25/3

30/2 30/3

40/2 40/3

S t a n d a r d b e a r i n g b a r p r o f i l e s

8 mm

As with the press locked grating, the press welded grating is

also available in numerous versions. We are aware of count-

ry and customer-specific requirements and are implemented

in accordance with the relevant standards. It is often the case

that the clear mesh width plays an important role from the as-

pect of safety. As the press welded grating cannot provide the

fine mesh grid of a press locked grating owing to the manufac-

turing process, other versions have been developed which take

into account the safety requirements. This guarantees that a

test ball with a specific diameter cannot fall through. Special

welding regulations can of course also be implemented by us.

-

47

M E I S E R P r e s s We l d e d G r a t i n g w i t h

S m o o t h R o u n d B a r s

The classical press welded grating is producedwith twisted

square bars, which offer a certain degree of slip resistance.

If aesthetic aspects are important, it is also possible to use

smoothroundbarsascrossbars.

Thisversionispossibleforallcommonmeshspacing.

PressWeldedGrating

M E I S E R O f f s h o r e P r e s s

We l d e d G r a t i n g

Thistypeofgratinghasbeenspeciallydesignedforuseinthe

offshoreoilandgasindustry.Thebackgroundtothisisthespe-

cificationisthatatestballwithadiameterof15mmmustnotfall

throughthegrating. Inorder toguarantee this,an intermediate

roundbarisweldedparallelandcentrallybetweenthebearing

barstotheundersideofthetwistedsquarecrossbarsusingthe

automaticresistanceweldingmethod.Thisprovidestheoffshore

gratingwithadditionalstability,whichisveryusefulintheharsh

conditionsonoffshoreoilrigs.

Bearingbar3mm

Bearingbar4mm

Bearingbar5mm

25/3 25/4 25/5

30/3 30/4 30/5

35/3 35/4 35/5

40/3 40/4 40/5

45/3 45/4 45/5

50/3 50/4 50/5

60/3 60/4 60/5

Commonmeshspacing

Bearingbar Crossbar

34,30 101,6

38,28 101,6

S t a n d a r d b e a r i n g b a r p r o f i l e s

Commonmeshspacing

Bearingbar Crossbar

15,08 - - - 38,1 50,8 76,2 101,6

17,15 - - - 38,1 50,8 76,2 101,6

20,77 - 24,0 - 38,1 50,8 76,2 101,6*

23,69 - 24,0 - 38,1 50,8 76,2 101,6*

25,00 - - - - - 76,2 101,6

30,15 - - - 38,1 50,8 76,2 101,6

33,00 - - 31,75 - - - -

34,30 19,25 24,0 - 38,1 50,8 76,2 101,6

41,45 - 24,0 - 38,1 50,8 76,2 101,6

45,23 - 24,0 - 38,1 50,8 76,2 101,6

51,45 - 24,0 - 38,1 50,8 76,2 101,6

60,30 - 24,0 - 38,1 50,8 76,2 101,6

68,60 - 24,0 - 38,1 50,8 76,2 101,6

*availablewithrestrictions

Bearingbar2mm

Bearingbar3mm

Bearingbar4mm

Bearingbar5mm

- 20/3 - -

25/2 25/3 25/4 25/5

30/2 30/3 30/4 30/5

35/2 35/3 35/4 35/5

40/2 40/3 40/4 40/5

45/2 45/3 45/4 45/5

- 50/3 50/4 50/5

- 60/3 60/4 60/5

- 70/3 70/4 70/5

- - 80/4 80/5

S t a n d a r d b e a r i n g b a r p r o f i l e s

-

48

-

49

S P E C I A L G R AT I n G

SpecialGrating

UNIVERSITy, ENSCHEDE

-

50 S P E C I A L G R A T I n G

-

51

S p e c i a l G r a t i n g

Over time,MEISERhasdevelopedandproducedmore than

5,000differenttypesofgrating.Mostoftheseversionswere

createdfromverydetailedspecificationsbythecustomer,ar-

chitectorplanningoffice.Oftenthemainfocusisonfunction-

ality,althoughitisnotunusualforaestheticstoplayacertain

role,withatightbudgetsometimessettingclearlimitations.If

everythingcomestogether,wespeakofspecialsolutionsor

specialgrating,whichwefindparticularlyappealing.

Imagination and technical expertise are required for comb

grating,finnedgratingorgratingonwhichyoucanwalkba-

refoot.

If load-bearingcapacity is less important thanvisual scree-

ning,MEISERlouvregratingareused.Therequirementscome

fromourcustomers,butthedevelopmentandthetechnically

reliablesolutionisprovidedbyus.

PEDESTRIAN ZONE, KAUFBEUREN

SpecialGrating

-

52 A P P L I C A T I O n S

MEISERcombgratingwasusedduringtherefurbishmentofthe

MoritzburginHalle.Thewestandnorthwingofthecastleare

connectedbya roof that is shapedbyskylightscoveredwith

aluminium,andnowfacedwithMEISERcombgrating.

Theirappearanceanddurabilityareachievedbyacathodicim-

mersionbathcoatingandasubsequentpowdercoating.This

adds a touch ofmodernity to the historic architectural styles

andshapesfromthevariousepoquesoftheMoritzburg.

Fencesareanimportantsafetyelementinsportsstadiums.As

can be seen here at the Stade de laMaladire in neuchtel,

MEISERpress lockedgrating (the termULTRAhasanegative

connotation in the fieldofsportsstadiums)providesastable

alternative toconventionalstadium fenceswhichareofequi-

valentvalueintermsofdesign.Differentmeshspacingandthe

freedom to choose the colour, aswell as production in high-

gradesteel,offerasuitablesolutionforeverypurpose.Painted

inthecoloursoftheclub,usedforseparatingtheblocksandas

aborderwiththeedgeof thesports field, theMEISERfencing

systemoffersmorethanjuststableprotection.

-

53

Every year the number of cars registeredonour roads incre-

ases.Thismeansthattheproblemofprovidingparkingspaces

forclinics,companies,theretailtrade,airports,publicfacilities

andmanyotherlocationscontinuestogrow.Oftenitisneces-

sary to successfully integrateamulti-storey car park into the

surroundings. The facade plays an important role, also with

respect to thebudget.Gratingoffernewoptionsfor thearchi-

tectureofthemulti-storeycarpark,aswellasfulfillingfunctio-

nalroles.Inthismulti-storeycarparkinRegensburgthegrating

concealtheheavystructureofthebuilding,providefallprotec-

tionandneverthelessenableextensiveventilation.

MEISER treegratingprotect the rootsofour trees, ensuringa

sufficient supply ofwaterwhile remaining architecturally ap-

pealing. Tree grating can be inserted into a group either un-

obtrusivelyandflushwiththesurface.Oryoucanemploythe

somewhat raised grating as a deliberate design element, as

showninourreferencephotograph.

SpecialGrating

-

54

B a r e f o o t G r a t i n g

Some locations such as swimming baths are places whereshoesarenotusuallyworn.Here,agratingcanbeveryuseful.Forthisreasonwehavedevelopedagratingwhichisalsoplea-sant whenwalked on barefoot. The cross bar is a U-shapedsectionthatispressedinataflatangle.Theclearancebetweenthese treads is approximately 9mm. They aremanufacturedfromsteelorhigh-gradesteel.

F i n n e d G r a t i n g

MEISERfinnedgratingstandsoutconsiderablycomparedtoaclassicalgrating.Thefunctionofthecrossbaristakenoverinthis versionbyapipe that is insertedcentrally in thebearingbars.Thisprovides the finnedgratingwithaveryhigh-qualityappearance, although this is less suitable for larger spanwidths.

Innormalcases the finnedgrating isnotprovidedwithasur-round,particularlyinordernottodisrupttheverycleardesign.Finned grating is often used as a high-quality ventilation co-verforuseindoors.Tothispurposetheycanbemanufacturedfromaluminiumandhigh-gradesteel,orofcourseintheclas-sical version of hot dip galvanised steel. They can be furtheradaptedtoindividualrequirementsthroughtheuseofspecialbearingbarprofilesanddifferentpipediameters.

Bearingbar2mm

Bearingbar3mm

Bearingbar4mm

Bearingbar5mm

25/2 25/3 25/4 25/5

30/2 30/3 30/4 30/5

35/2 35/3 35/4 35/5

40/2 40/3 40/4 40/5

45/2 45/3 45/4 45/5

50/2 50/3 50/4 50/5

Bearingbar2mm

Bearingbar3mm

25/2 25/3

30/2 30/3

35/2 35/3

40/2 40/3

45/2 45/3

50/2 50/3

- 60/3

Commonmeshspacing

Bearingbar Crossbar

11,10 50 100 150 200 250 300

21,00 50 100 150 200 250 300

22,20 50 100 150 200 250 300

25,00 50 100 150 200 250 300

33,30 50 100 150 200 250 300

44,40 50 100 150 200 250 300

66,60 50 100 150 200 250 300

Commonmeshspacing

Bearingbar Crossbar

22,20 8,25

33,30 8,25

66,60 8,25

S P E C I A L G R A T I n G

S t a n d a r d b e a r i n g b a r p r o f i l e s

S t a n d a r d b e a r i n g b a r p r o f i l e s

-

55

C om b G r a t i n g

MEISERcombgratingisapresslockedgratingwithcrossbarswhichprotrudeabovethetopsurfaceofthebearingbars.Thismakesthebearingbarsalmostinvisible,sothatthegratingnolonger lookslikeagrille,butmorelikeacomb.Theemphasison the cross bars produces a very elegant and light appea-rance.Theclearanceandnumberofbearingbarscanbeva-riedandareadaptedtothestaticrequirements.Therearealsoseveralpossiblevariationsfortheclearanceofthecrossbars.

MEISERcombgratingcanhaveavarietyofuses,althoughtheirmain application is usually where there are high aestheticaldemands on appearance. This grating is therefore frequentlyfoundasacovering indoors,e.g. forairconditioningsystemsandheatingducts,butalsoasahigh-qualitychannelgrateandfacade cladding in order to emphasise horizontal or verticallines.

Thespecialarrangementofthebearingandcrossbarsmeansthattheycanalsobereadilyusedassunshadeelements.Likethefinnedgrating,thecombgratingcanalsobeproducedwithdifferentmaterialsandsurfaces; furthermore,specialprofilescanbeusedasthecrossbarforthisspecialgratinginordertoprovideparticularlyattractiveeffects.

Bearingbar2mm

Bearingbar3mm

30/2 30/3

35/2 35/3

40/2 40/3

45/2 45/3

50/2 50/3

Commonmeshspacing

Bearingbar Crossbar

15,00 11,1 16,7 22,2 33,3

21,00 11,1 16,7 22,2 33,3

22,20 11,1 16,7 22,2 33,3

33,30 11,1 16,7 22,2 33,3

66,60 11,1 16,7 22,2 33,3

99,90 11,1 16,7 22,2 33,3

L I n E AR SHAP E

ROUnDED SHAP E

EDGED SHAP E

Y - SHAP E

SpecialGrating

S t a n d a r d b e a r i n g b a r p r o f i l e s

-

56 S P E C I A L G R A T I n G

To l s u n

TheMEISERTolsunisadesignergratingproducedexclusively

byMEISER.DevelopedbyourFrenchcolleagues,thenameex-

pressesoneofitsimportantadvantages,namelysunshielding.

Specially profiled aluminium fins,which aremodelled on the

wingsofanaeroplane,serveascrossbarsandgivetheTolsun

aspecialaesthetictouch.Asafacadeelement,theTolsungu-

aranteesexcellentsunshielding,butneverthelessanaturalair

supplyaswell,andtherebymakesasignificantcontributionto

anall-roundair-conditioningsystemandhighlevelsofthermal

comfort.

MEISERoffers the Tolsunwith awell thought-out idea for the

means of attachment as an all-round solution for the design

of the facadewithanairconditioningeffect.TheTolsun isan

architecturally appealing and very high-quality product. The

lightweight design and the possibility of producing one-part

andlarge-surfaceelementsprovidegoodvalueformoney.The

MEISERTolsunisonlyavailableinaluminium,butcanbecusto-

mised to your individualneedsbycolouranodisingorcolour

coating.

Te c h n i c a l D e t a i l s

Maximumformat1,500mm(bearingbardirection)

Maximumformat2,000mm(crossbardirection)

OFFICE BUILDING, BASSENS

TO L SUn A LUM I n I UM 5 0 x 3 3 00 / 60

TO L SUn A LUM I n I UM 5 0 x 3 3 00 / 120

Bearingbar50/3 Crossbar 100x1,5

300mm 60mm300mm 120mm300mm 180mm

-

57

SpecialGrating

-

58 S P E C I A LG R A T I n G

F e n c e s

MEISERfencegratingisfundamentallyagratingwithspecial

edgesurrounds.Dependingonthepurposeofthefence,the

designcanbeverylightandtransparent,butalsoverystable

andclose-meshed,e.g.asacrowdbarrieratevents.

The fenceheightand fieldsizecanbe individuallyselected,

ascan thematerialof the fenceand thesurfacedesign.As

arule,thefenceelementsareenclosedwithaflatbar,which

containsslottedholesforeasymountingtothefenceposts.

Uponrequest,MEISERcansupplyentirefencesystems,inclu-

dinginstallation.

BENEDICTINE ABBEy, THOLEy

-

59

SpecialGrating

FENCE, STADIUM

-

60

-

61

TOP, FROM LEFT TO RIGHT:

HOTEL ROOMERS, FRANKFURT;

TOWN HALL, KELKHEIM;

OFFICE BUILDING, MUNICH

BOTTOM: SKI JUMP, KLINGENTHAL

S TA I R T R E A D S

StairTreads

-

62 S TA I R T R E A D S

S t a i r t r e a d s

MEISERstairtreadsaremanufacturedfromgratingincorpora-

tingendplatesandnon-slipsafetynosingtotheirleadingedge.

The treadasan essential safety element of all typesof stair-

casesmustalwaysfunctioncorrectly,beitduringeverydayin-

tensiveuseontheaccesspathtoaskilift,orwheresubjected

toextremeloads,if,forexample,thestaircaseisusedinanun-

controlledmannerasanescaperoutebymanypeopleduring

afire.MEISERisawareofthisresponsibilityandhasdesigned

itsstairtreadsaccordingly.Theextended,perforatedsafetyno-

singfulfilsandevenexceedsthelatestregulations.Itprovides

additionalstability,reducesthemaximumdepthoftheopening

to 120mmand fulfils safety classR11. At the request of the

customer, thenosingcanalsobemadeofa special section,

e.g.anon-slipsteelflooringplateorasandedsteelangle.The

safety endplates have a pronounced bead, which interlocks

withthebearingbars.Thispreventstheendplatefromtearing

-

63

StairTreads

offprematurelyifitissubjectedtosignificantexcessloadsand

causingthetreadtofail.ThetreadsurfaceoftheMEISERstair

treads canbedesigned individually. Asamatter of principle,

stair treads can be produced as press locked grating treads

andpressweldedgratingtreads.Themeshspacingandheight

of the bearing bar are determined by the effectivewidth and

the customers requirements.Of coursewe knowwhat is re-

quired in thecaseofpubliclyaccessiblestaircases.Thestair

treadsareproduced inaccordancewith thespecificationsof

DIn24531-1andprovide foracorrespondingholepattern in

theendplates.Individualholepatternsareofcoursepossible,

aswell asnotchedbearingbarsandcrossbars, so that slip

resistanceuptoclassR13 ispossible. Itgoeswithoutsaying

thatstairtreadscanalsobedesignedinaluminiumandhigh-

grade steel; special designsallowstair treadwidthsof up to

4,000mm.

RED CROSS HEAD qUARTERS, ERLANGEN

-

64

Wind turbines are increasingly dominating our countryside.

Their share of regenerative energy sources is growing. Their

heightcanreachupto200metres. It isessential that ifsuch

turbines have to be serviced or repaired, they can be readily

and safely accessedon foot. Every turbine therefore requires

asmallaccessstaircasefromtheoutsideandfacilitiesinside

whicharenotvisibleexternally. Ineverycase thestepsarea

crucialsafetyelementforwhichnocompromisesarepossible.

Sometimesstairsareneverused,orareonlyusedinanemer-

gency.Thenthesearecalledemergencyescapestairs,suchas

inthiscaseatahotelinFrankfurt.Thegratingstairtreadsmust

beabletowithstandenormousloadsinthecaseofafire.They

are thereforedesignedwithdoubleanti-skidprotectionanda

largetreaddepth.

A P P L I C A T I O n S

-

65

Inthecaseoflargesilosystemsitisonlypossibletoaccessthe

externalshellbecauseasarulethesiloisfilledupwith-some-

timessensitive-material.Thestepsthenhavetofitexactlyon

theexternal radiusof the tanksystemandalsopossesshigh

torsionalstiffness.Thestepsat the fueldepot inHonauwere

thereforegivenananti-skiddesignbyMEISER.

TigerandTurtleMagicMountainisalandmarkintheAnger-

parkinDuisburg-Angerhausenthatismodelledonarollercoa-

ster. The largesculpture isaworkofartbyHeikeMutterand

UlrichGenth,whichwasdevelopedaspartoftheRuhrCapital

ofCultureRuhr2010.Thetotallengthof220metresiscovered

with 349MEISER grating stairtreads, ofwhich only 220 can

beaccessedonfoot,however,astheremainingareasaretoo

steep.

StairTreads

-

66

E n d p l a t e s

Forstandardstairtreads,thesafetyendplatewithbeadisge-

nerally used. However, upon request a special endplatewith

adifferentdrill-holesizecanbeattached.Fromabearingbar

heightof50x3mmupwardsthedrill-holesizeshouldbeco-

ordinatedinallcasesinordertoavoidinstallationproblems.

StairtreadendplateswithDInstandarddrill-hole

Length[mm] Drill-hole

240 120

270 150

305 180

S T A I R T R E A D S T Y P E S

P r e s s L o c k e d G r a t i n g T r e a d s

Presslockedgratingtreadscanbeproducedfrommildsteel,high-

gradesteelandaluminium.Theyareproducedinaccordancewith

the same principle as for press locked grating. It is possible to

providethesestairtreadswithanti-skid-propertiesuptoR13byin-

cludingspecialnotchesonthebearingbarsandcrossbars.Even

verylargetreadwidthscanbeproducedbydesigningthebearing

barsinthesamewayasheavydutygrating.Thusitispossiblefor

evenextremeloadstobereliablyabsorbed.

P r e s s We l d e d G r a t i n g T r e a d s

Presswelded grating treads can be produced frommild steel

andhigh-gradesteel.Heretoo,productionisbasedonthepro-

cessusedforthemanufactureofpressweldedgrating.Itispos-

sibletoprovidethistreaddesignwithanti-skid-propertiesupto

R12.

S A F E T Y E nDP L AT E W I TH B E AD

-

67

Safetynosing,perforated,note:safetynosing34mm

R a i s e d s a f e t y n o s i n g

For the purposes of slip resistance and in order to increase

their load-bearing capacity, stair treads are provided on the

front edgewithaperforated, specially shapedangle section.

Thisso-callednosingisweldedtogetherwiththeendplateand

thebearingbarandcontributestoreinforcingthestairtread.It

canalsobeproduced fromnon-slip steel flooringor checker

plate. We comply with specific customer wishes as well as

withdeviatingforeignstandards.

In the case of publicly accessible staircases, regulations are

increasinglyspecifyingamaximumclearanceof120mmbet-

weenthetreads.Wehavetakenthisspecificationintoaccount

witha70mm-highnosingandthereforefulfilnORMB5371,

whichinthecaseofpitchesofupto190mmpermitsamaxi-

mumstep-throughheightof120mm.

StairTreads

S t a b l e a n d s a f e :

t h e n e w M E I S E R s t a i r t r e a d

w i t h s a f e t y n o s i n g

HE I GH T O F T H E C L I P S 7 0 MM

Drill-hole

70

15 35

14

55

70 60

135

2

10

10

31

Safetynosing70mm

-

68

-

69

LUCERNE CANTONAL HOSPITAL,

SWITZERLAND

F I X I n G C L I P S

MEISERgratingfixingclipsareanimportantpartofourservice.Thegrating

canonly fulfil its functionproperly if it iscorrectlyattached,asotherwise

accidentscanquicklyhappen.MEISERhastheproperfixingclipforevery

application, fromthesimplestandardclamptothecustomisedindividual

solutionMEISERproducesmanyclampsitself,butalsoworkstogetherwith

well-knownfasteningspecialists.

Togetherwith theHILTI company, the XMGR clamp has been developed,

which is insensitive tovibrationsandoffersenormous installationadvan-

tages.On the followingpagesweshowyou themostcommonsafetysy-

stems,whichinmostcasesrepresentagoodandlow-costsolution.

FixingClips

-

70 F I X I n G C L I P S

galvanised V2A

Designation Meshwidth[mm] Meshwidth[mm]

M0531 33x33 33x33

M0531 34x38 34x38

M2231 33x21 33x21

C l amp B Consisting of a saddle top clip, clamp lower part,

M8x60hexagonscrewsandM8squarenut.

H e a d b o l t f a s t e n e rConsistingofheadboltsandretainingflange;forhigh-

ly corrosiveenvironments (e.g.offshore),alsoavaila-

bleasX-BT;pre-mountedversionX-GRRU.

Theillustrationsarenotassemblyinstructions.

notBG(SlipReviewGroup)-compliant.

C l amp B 10Consistingofastirruptopclip,hexagonsocketscrew,

cliplowerpartandnut.

galvanised V2A

Designation Meshwidth[mm] Meshwidth[mm]

M2331 33x11 33x11

galvanised V4A

Designation Meshwidth[mm] Meshwidth[mm]

X-FCM+X-M8 22x2266x66 22x2244x44

X-FCM+X-BT 22x2266x66 22x2244x44

X-GR-RU 33x33

C l amp SConsistingofaflatheadscrew,clamplowerpartand

squarenut

galvanised V2A

Designation Meshwidth[mm] Meshwidth[mm]

M2031 33x11 33x11

H EAD BO LT FA S T En ER

C L AMP B

C L AMP B 10

C L AMP S

-

71

galvanised V2A

Designation Meshwidth[mm] Meshwidth[mm]

M0833 34x38 34x38

galvanised V2A

Designation Meshwidth[mm]

XMGR 33x33/34x38/34x24

galvanised V2A

Designation Meshwidth[mm] Meshwidth[mm]

M0731 34x38 34x38

F I X I n G C L I P S F O R I n D U S T R I A L G R A T I n G

DOUBL E C L AMP B

H I LT I C L AMP XMGR

S A F E T Y C L AMP D

S A F E T Y C L AMP A

H i l t i c l amp XMGRConsistingofsaddletopclipandlowerpartconnected

tooneanother;highresistancetovibrations,easypor-

tability by 1 person and thereby significantly shorter

installationtimes.

maximumgratingheight40mm

Doub l e c l amp BConsistingof 2 saddle top clips, clamp lower part, 2

hexagonscrewsand2squarenuts.

S a f e t y c l am p AConsistingofsafetyupperpart,clamplowerpart,he-

xagonscrewandsquarenut.

S a f e t y c l amp DConsistingofsafetyupperpart,clamplowerpart,he-

xagonscrewandsquarenut.

Theillustrationsarenotassemblyinstructions.

galvanised V2A

Designation Meshwidth[mm] Meshwidth[mm]

M0540 33x33 33x33

M2240 33x22 33x22

M2340 33x11 33x11

FixingClips

-

72 F I X I n G C L I P S F O R I n D U S T R I A L G R A T I n G

We l d e d - i n H o l e d F i x i n g P l a t e s

consistingofwelded-inholedplateholesize isaccor-

dingtocustomersspecifications;screwsareprovided

bythecustomer.Thedesignandpositionofthewelded

inplatedependontheloadtowhichthegratingissub-

jectedandthefasteningpossibilitiesavailableonsite.

Theillustrationsarenotassemblyinstructions.

P a n e l A t t a c hmen t s(suppliedloose)

Galvanised

Designation

Safetychain

Hinge

Socketwrenchclasp

Welded-inperforatedplatesS A F E T Y CHA I n

H I nGE

SOCKE T WREnCH C L ASP

BMW, VLIZy

WELDED - I n HO L ED F I X I nG P L AT E S

-

73

FixingClips

-

74 P R O D U C T R A n G E

P R O D U C T R A n G E

MEISERisprimarilyknownasaleadingmanufacturerofopenbar

grating.Wecomplementour rangeof industrialfloorcoverings

withsheetmetalprofilegratingandGRPgrating.Channelgrates

are combinedwith channel bodies developed by us to form a

drainagesystemmadeofsteel.Furthermore,over thepast few

yearsMEISERhasdiversifiedevenmorestronglyandisparticu-

larlyactiveasaserviceprovider in thefieldofsteelprocessing

and hot dip galvanising.We havemadea name for ourselves

asaproviderofcompletestairwaysystems.Weofferslitstrips

inblackandgalvanisedform,whileinourformingplantwepro-

P RO F I L E GRAT I nG

GRP FA L L P ROT EC T I On MAT S

S TA I RCAS E S

-

75

duce vineyard fencepostsand supportingprofiles for open-air

solarmodules.Ourowntoolconstructionandmechanicalengi-

neeringfacilitiespositionustodevelopnewproductsthroughto

productionreadinessatlowcompetitivecost.Fromdiscussions

with our customers, items such as fall protection mats (spot-

welded wiremeshes), for example, have been created, which

areoften installedat factories in theautomotive industry.Many

manufacturersofhighqualitywoodenbarrelsrelyonthebarrel

hoopsmanufacturedbyMEISER,whicharecustomisedanddeli-

veredonajustintimebasis.

ProductRange

V I n E YARD F EnCEPOS T S DRA I nAGE CHAnnE L S

SCA F FO LD I nG BARRE L HOOPS

-

76 P R O D U C T R A n G E

S t a i r c a s e s

MEISERstaircasesarealmostalwaysmanufacturedontheba-

sisofarequestfromacustomerandoftenmakeasignificant

contribution to theaestheticappearanceofabuilding. Inad-

dition,aMEISERstaircasemustofcoursealsoreliablyfulfilits

functionandsatisfystatutoryrequirementstoalevelof100%.

This iseasiersaidthandone,asthespecificationsof theDIn

standards,Germanstatutoryaccident insurance,Germanac-

cidentpreventionregulationsetc.areveryextensiveanddiffer

fromstatetostate,alsowithinGermany.

ButyoucanrelyonMEISER,becauseweknowexactlywhich

regulationsareinforce,sothatyoudonotexperienceanasty

surprise during the acceptance test. MEISER staircases can

be constructed in a straight orwinding version,with the spi-

ralstaircasebeingaparticularlyappealingchallengeforMEI-

SER.Ultimatelyitispersonaltaste,thespaceavailableandthe

budgetwhichdeterminethedesignthatisselected.Wewillbe

pleased to advise you and also carry out themeasurements

onsite.

-

77

P r o f i l e G r a t i n g

MEISERsheetmetalprofilegratingisanalternativetostandard

MEISERgrating,especiallywhen largespanwidthshave tobe

bridgedor amore closed surface is required. The special em-

bossingandperforationof thesurfaceensure veryhigh levels

ofslipresistance.Everywhereinindustrywhereworkiscarried

outwithglide-enhancingsubstances,sheetmetalprofilegrating

isagoodchoice.

Thepossibilityofproducingelementsofup toa lengthof6,50

metres ensures fast installation, which is further accelerated

with innovative fixing clips that we have developed ourselves.

For indoor applications it is also possible to use sheet metal

profile grating consisting of sendzimir-galvanised steel strip.

This results in a significant cost advantage. One special field

is non-flammable sheetmetal profile grating. This version has

been testedand certifiedby theMFPA (Material Researchand

Testing Institute)and issuitable, forexample,asa transformer

traycovering.

TOP: STAIRCASE, RED CROSS HEADqUARTERS

BOTTOM: PROFILE GRATING, SAIL CITy

ProductRange

-

78 P R O D U C T R A n G E

S c a f f o l d i n g

The long-standing collaboration with ALFIX, a leading manu-

facturerof scaffolding systems, culminated in2012 inMEISER

purchasingaholdinginALFIX.Formorethan60yearsALFIXhas

stoodforscaffoldingsystemsMadeinGermany.Throughcon-

tinuous innovations and fair prices, ALFIX scaffolding systems

have become an established brand product on the European

market.

Both ALFIX andMEISER put their faith in committed and well-

trainedemployeeswhoensureproximity to the customerboth

in-house and in the external sales force. Through continuous

research anddevelopment, the products ofMEISERandALFIX

continue toset thestandards.With this typeofscaffoldingour

customerswillthereforealwaysbewellequipped.

Formoreinformationvisitwww.alfix.de.

-

79

G R P

MEISERGRPgratinggenerallyhaveasquaremeshsize,aswell

asbearingbarsandcrossbarsofthesameheight.Theappea-

rance is similar to that of aMEISER full gratingmadeof steel.

GRPgratingisindemandwhentheenvironmentisverycorrosi-

veorelectricalconductivityisnotdesired.

OurproductsarecertifiedbytheInstituteforOccupationalSafety

and guarantee extreme long-term slip resistance through their

resistancetovariousmedia.

TOP: STEEL PROFILE TUBE SCAFFOLDING, SHIPyARD;

BOTTOM: GRP GRATING,

KEOLIS TRAIN WASHING SySTEM

ProductRange

-

80 P R O D U C T R A n G E

D r a i n a g e C h a n n e l s

TheMEISERdrainagechannelisapuresteelchannel.Incom-

binationwithMEISERgrating,weofferaneconomicalandyet

very individual drainage system for sewage and rainwater.

Heretoo,youcanbenefitfromourextensiveknow-how.

A l l A d v a n t a g e s a t a G l a n c e

- Channelsmade-to-measurewithindividualpieces

upto5,000mminlength(allspecialdimensions)

- Stableedgesminimisetheneedforrepair

- Veryeasyinstallationowingtothelowweight

- Shortdeliverytimes

- Reliableanchoringwiththeconcretefoundation

bymeansoflateralanchorbrackets

- Frontordownwardpipeoutletavailable

- Custom-fitlayingbymeansofattachedU-shapedsection

- Tightnessofthejointsguaranteedbypermanently

elasticsealingcompound

- 5yearswarranty

- noformworkcosts

- nobreakoutoftheconcreteedges

- Deliverywithallgratingtypespossible

(bearingbarupto200x14mm)

- Trafficablebyforklifttrucksandheavyvehicles

F am i l i a r l y P r o g r e s s i v e

ThenewMEISERchannelwillinspireyou.Productioniscarried

outtomeasure.Expertadvice,verygoodvalueformoneyand

shortdeliverytimesareforareliableandinspiringpackage.

BENEDICTINE ABBEy, THOLEy

-

81

ProductRange

-

82 P R O D U C T R A n G E

M E I S E R H e a v y D u t y C h a n n e l s - D I nE n 14 3 3 S t a n d a r d

Drainagechannelsaretheoptimalsolutionfortakinguprain-

waterthataccumulatesfromadjacentpavedsurfacesoreven

facades,beforetransportingitawayanddischargingitintothe

sewers. TheMEISER steel channel is alsousedasan evapo-

rationchannelwithoutdrainage,e.g.inundergroundgarages.

P r o d u c t S t r u c t u r e

- Channelbody&gratingmadeofsteel,hotdip

galvanisedaccordingtoDInEnISO1461

- Perfectlyco-ordinatedwithoneanother,robust,

durableandlow-maintenance

- Availablecross-sections:

Dn100-->extendedlength339mm

Dn150-->extendedlength489mm

Dn200-->extendedlength639mm

- Squarecross-section(HW)ofthechannelbody

- Availableinlengthsof1,000mmand2,000mm

- Specialdimensionsonrequest

O p t i o n s

- Endcapswith/withouthorizontaloutlet

- Outletverticalwithsinktrap

- nominalwidthoftheoutletopeningsmin.

Dn100(-->contents8.7l/m)

- Alternativechannelwithowngradientanda

maximumlengthof3,000mm

Dn = nominal diameter, designation for the nominal width

(connectiondimension)ofpipes,fittingsandcomponents

-

83

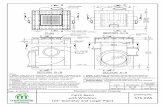

M E I S E R h e a v y d u t y c h a n n e l t y p e Ic o n f o r m s t o D I n E n 14 3 3w i t h C E m a r k i n g

C l a s s A 15 C l a s s B 12 5 C l a s s C 2 5 0 C l a s s D 4 0 0+Pedestrians +Pedestrians +Kerbs +Roadways

+Cyclists +Carparkingspaces/ +Hardshoulders +Pedestrianzones

+Greenspaces parkingdecks +Carparks +Carparks

+Vans

G r a t i n g q u i c k - r e l e a s e f i x i n g c l i p :

Thegratinginsertissecuredwithaspecial,non-rustingquick-

releasefasteneragainst lifting&moving.Thefastenerretains

itsfunctionevenwhensubjecttohighlevelsofsoiling.

ProductRange

-

84 P R O D U C T R A n G E

S p e c i a l s e c t i o n s

MEISERhasahighlyefficient tool constructionandmechani-cal engineering system at its disposal.We therefore operateourownmechanicalengineeringcompanyandknowthepro-blems in thedailyproductionprocess.Openspecialsectionswithamaterialthicknessofupto6mm,withorwithoutperfo-rationsandnotching,areourspecialfield-hotdipgalvanisedifrequired.Ifyouwouldliketotakeadvantageofourexperience,pleasecontactus.Weareproudofour long-standingcoope-rationwithHILTI,whereweact as a strategic partner for thesupplyofsupportingprofilesforopen-airsolarenergysystems.

G a l v a n i s e d s t r i p / b a r r e l h o o p

Inourstripgalvanisingplant,thesteelstripthatwehaveprevi-ouslyslitisgalvanisedinthecontinuousprocess.Wespeciali-seinthegalvanisingofnarrowstripswithagalvanisededge.Various zinc coatings are possible, as are different packingsizes.We supply galvanised slit coil from19 x1.3 to 90 x 5mm,ascoilgoodsorinbars.Ourspecialitiesincludeearthingstrapsandtheirfurtherprocessingintobarrelhoops.

V i n e y a r d f e n c e p o s t s

Theuseofmachineryandtheoptimisationofworkingroutinesinvineyardsarebecomingincreasinglyimportant.Specificallyfortheuseofharvesters,MEISERoffersavineyardfencepostsystemtogetherwiththedistributionpartnerartos.Itconsistsoffencepostswithhookslocatedontheinsideoroutside,aswellas restrainingposts,which togetherguaranteeoptimumcovering. Exactly how thisworks can be seen atwww.artos-weinbergpfahl.de.

F a l l p r o t e c t i o n m a t s a n d s p o t -

w e l d e d w i r e m e s h e s

Thepossibleusesforspot-weldedwiremeshesareveryvaried.Theyrepresentaconvenientsolutionforsecuringspecificare-asorplants.Theyare fastenedonsiteor togetherwithprefa-bricatedposts.Thewiremeshesconsistofsteelwiresweldedtogether crosswisewhose diameter - depending on the loadsituation-isbetween3and6mm.Thelengthandwidthoftheelementscanbefreelyselectedwithintheproductrange.

Intheautomotiveindustry,so-calledfallprotectionmatshavebecomepopularasasophisticatedsolution forsecuringandinspectingproduction lines.MEISERdelivers forallmajor carmanufacturers such as Audi, BMW,Mercedes, VW, in accor-dancewiththestandardsinforceineachcase.

BMW PLANT, DINGOLFING

-

85

ProductRange

-

86

-

87

GALVANISING PLANT AND LOGISTICS CENTRE

SCHMELZ-LIMBACH

COMPOUND LANDSCAPING By DUTT&KIST