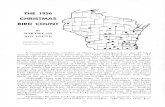

Global Hawk UAV - Materials Education (MatEdU) · PDF fileIntroduction to Advanced Composite...

Transcript of Global Hawk UAV - Materials Education (MatEdU) · PDF fileIntroduction to Advanced Composite...

An introduction to composites: ! modern composites defined matrix of resin +fiber ! advanced composites > strength : weight ratio specific purpose design ! composite history & evolution 60 yrs of accelerating advances fiberglass epoxy matrix carbon fiber aramid fibers advanced composites aircraft applications ceramic & metal matrix materials repair techniques

Composite applications ! Transportation

Ground, air, marine, space ! Military armor, weapons, containers ! Sporting goods golf, tennis, fishing, helmets,

wheels, skis/snow boards, kite and wind surfing, snow machines, gun components

! Building materials pipes, beams, panels, bridges,

roofing, decking, signs, furniture ! Medical prosthetic devices, braces,

enclosures, body moving aids

Other industries ! Electrical & electronics- standoffs, circuit boards, junction boxes, ladder rails, cherry picker buckets

! Corrosion resistant systems- oil field pipes, pump bodies, suction rods

! Appliances & equipment-compressor bases, washing machine gears and parts, power tool housings, computer housings

! Renewable Energy systems- wind, ocean, solar

Composite pros & cons ! advantages stiffness, TS/p, high fatigue life, corrosion resistant, complex shapes, smooth skin, stealth, multiple mfg methods ! Disadvantages high labor, material and capital costs, storage of materials damage and repairs safety concerns

Course Development

! Industry needs • workforce trained in composite usage • work experience using composites • design experience with composites • repair experience with composites

! Students needs • hands on experience with composites • Students who want to work in growing

advanced composite industries • Design experience using composites

! College needs • New technologies for students • New courses for program development • New laboratory ideas & equipment • Internships and industry partnerships

• •

Lay-Up with splice

Industry connections ! Training for new employees and educational upgrades ! Internships for students and faculty ! Research ideas for faculty and students ! Industry tours for processing classes ! Projects for capstone classes and senior projects ! Feedback from employed alumni ! Development of training programs ! Equipment and lab material donations ! Expertise for developing programs and ideas

Industry ideas ! Review product, processes. Materials, inspection and repair techniques • Cessna • Monaco and Country Coach • ECS Case • Bayliner • Boeing • Erickson Air Crane ! Tooling ! Lean ! GD&T ! Six sigma ! CAD/CAM ! Automated systems ! Communication skills ! Material conveyance ! Repair ! Testing and Inspection

Course Outline ! Introduction to composites ! Advanced composites ( high temp/high performance) ! Environmental effects on composites ! Fiber reinforcements ! Composite design considerations ! Tooling ! Inspection and testing ! Adhesive bonding ! Advanced composite assembly ! Liquid molding ! Industries and processes using advanced composites ! Repair of composites ! Nanocomposites

Laboratory Development

Laboratory experiments • Wet lay up-flat • Build a clip board • Build a mold & mold prep • Wet lay up with clocking in a

mold • Prepreg layup with clocking in

mold • De-bulking vac bag • Make a product (skate board

or surf board) • Resin transfer molding

experiment

Lab Equipment

• Benches • Freezer • Vacuum pump • Hand tools • Safety equipment • Furnace/autoclave • thermocouples

Safety

• Identify safety hazards and hazardous waste

• Illustrate use of safety equipment

• Encourage compliance of safety regulations

• List personal protective equipment

• Post Material Safety Data Sheets

• Location and use of fire extinguishers

Lab Material

• Woven material –fiberglass, carbon fiber & aramid

• Resin fast and slow • Vac bagging materials • Mixing materials

• VISUAL INSPECTION DEFECTS DEFECT LAY-UP

SEQUENCE BAGGING FIBERS RESIN CURE TOOL

Bubbles Wrinkles Loose Fibers Resin Starved Areas

Ply Orientation Porosity Surface Defects Inclusions Fiber Distortion Voids Contamination FOD - FOE Burned Resin Burned Bag Vacuum Leak Delamination Ply Gaps TC Problems Bridging De-Bonds Damaged Plies Micro Cracking Matrix (resin) Concerns Uncured Resin

Blown Bag

Resin Rich Areas

Warped Laminate

X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X

X X X

X X X X X X X X X X

X X X X X

X X X

X X X X X X X X

X X

Course assessments

Testing & Homework • Conventional testing but

with problems that are specifically applicable to composite industry problems.

• Homework & research based on composite industry problems.

Ply orientations

IDENTIFY AND NAME THE COMPONENTS INDICATED BELOW (A THROUGH E)

60. ____________________ (A) 61. ____________________ (B)

62. ____________________ (C) 63. ____________________ (D) 64. ____________________ (E)

66. Preimpregnated cloth may be warmed to provide greater flexibility when laying up parts.

A. True B. False

65. The temperature hold period at 240 +/- 100F is intended to: A. Cure the laminate. B. Raise the viscosity of the resin so that it will no longer flow. C. Allow for break time D. None of the above

Test Panel or Test Cupon Vacuum Hose

Vacuum Probes Vacuum Gage T.C. Wire

CIRCLE THE CORRECT ANSWER: (example B )

Page 10

C

D

E

B

72. From (Figure 1) below identify item #4. #4. __________________________

73. From (Figure 1) below identify item # 1. #1. __________________________

Nylon bag

Tool Plate

74. From (Figure 1) below identify item # 3. #3. __________________________ Breather

75. From (Figure 1) below identify item # 7. #7. __________________________ TC wire

Page 12

(Figure 1)

(1) (2) Simulated Project Part (use cardboard) (3) (4) (5) Sealant Tape (6) Vacuum Probe (through the bag) (7)

4

2

1

5 6

3 7

Simulated Part flash-breaker tape

© Robert N. Young Rev. 1/21/06

All Rights Reserved

Team Projects

Projects • Develop drawing sets specific

to advanced composite parts and assemblies

• Develop a composite product through design and lay out its manufacturing sequences and then cost the product

• Graded via peer evaluations in presentation

References • ‘Manufacturing Processes for Advanced Composites’ by F. C. Campbell,

Elsevier • ‘Advanced composite stuctures: fabrication and damage repair’ Abaris

Training Resources Inc. • ‘Materials Science and Engineering an Introduction’ by William D. Callister,

Jr. 7th ed., Wiley • Cessna Training program Bend, OR • ‘Mechanics of Composite Materials’ by Autar K. Kaw 2nd Edition CRC Taylor

and Francis Group • ‘Materials Selection In Mechanical Design’ by Michael F. Ashby 3rd ed.,

Elsevier • CRC Practical Handbook of Materials Selection by James Shackelford,

William Alexander & Jun S. Park • Abaris Training-’Advanced Composite Structures: Fabrication and Repair’ • Cerritos College ‘Composite Lay-Up Manual’