Glass International March 2016

description

Transcript of Glass International March 2016

CHINESE OVERVIEW

REFRACTORIES

SHANDONG HUAPENG - CHAIRMAN INTERVIEW

WWWGLASS-INTERNATIONALCOM

I N T E R N A T I O N A L

March 2016mdashVol39 No3

A GLOBAL REVIEW OF GLASSMAKING

Glass International M

arch 2016

Thin Glass

Tableware

Container Glass

Float Glass

Fibre Glass

Our fresh breeze for all types of glass production

GI Cover-marchindd 1 3916 259 PM

To make glass better

put us in the mix

copy 2016 Air Products and Chemicals Inc US +1 800 654 4567 Europe +44 (0) 800 389 0202 Asia +886 2 2521 4161 South America +55 11 3856 1651

tell me more wwwairproductscombetterglass

Our in-house melting experts can help you improve

combustion to increase glass production reduce fuel

consumption improve glass quality and reduce emissions

Including NOX SOX CO2 and particulate matter every day

From the very first oxygen enrichment applications

to our latest Cleanfirereg burners wersquove delivered safe

low-emission oxy-fuel solutions for over 50 years And

right now in addition to providing reliable gas supply our

team is optimizing production for hundreds of furnaces

all over the world

Call 800-654-4567 (code 344) to put the skills and

experience of our global team to work for you When

you want improved melting add one key ingredient Us

Contents

Glass International March 2016

ww

wg

lass

-int

erna

tion

alc

om

1

March 2016 Vol39 No3

2 Editorrsquos Comment

5 International news

13 Company overview Shandong Huapeng A Chinese group with global plans

17 Chinese overview Chinarsquos container industry set to rise to higher peaks 20 Company profile FERVER Federation proves that glass recycling is not a waste of time

Supplier profile Zippe24 A family affair

27 Lubricants Swabbing Robot lubricant success

28 History British Glass30 Small is beautiful

Case study Verallia Bad Wurzach32 Verallia installs synchronous reluctance technology

Refractories37 Recycling refractories40 Analysis of glass defect compositions from AZS refractory

Inspection44 Improving the quality of hollow glass through inspection

Plant technology46 A production monitoring solution

Front cover image wwwemede

Plus find us on Linked-In and Twitter

wwwglass-internationalcom

Glass_Int 32

20

24

13

CHINESE OVERVIEW

REFRACTORIES

SHANDONG HUAPENG - CHAIRMAN INTERVIEW

WWWGLASS-INTERNATIONALCOM

I N T E R N A T I O N A L

March 2016mdashVol39 No3

A GLOBAL REVIEW OF GLASSMAKING

Glass International M

arch 2016

Thin Glass

Tableware

Container Glass

Float Glass

Fibre Glass

Our fresh breeze for all types of glass production

Contents FEBindd 1 31616 941 AM

Editorrsquos comment

Glass International March 2016

ww

wg

lass

-int

erna

tion

alc

om

2

Itrsquos been an interesting month for me mostly spent in a car or train travelling to several meetings with prominent

suppliers and leading fi gures of the glass manufacturing industry

These people are at the forefront of our business and represent a variety of sub sectors They travel a lot speak to plenty of people and generally have their fi nger on the pulse of the industry

Among our varied chats ndash which are always a pleasure ndash one concern alone stood out the lack of young people enter-ing the industry

The glass industry is not an attractive one to youngsters Glass plants are hot noisy and dirty places Other industries with minimalistic air-conditioned offi c-es and a glamorous end product such as the automotive industry in the UK are regarded as cooler and cutting edge

One correspondent told me that the last innovation in the glass industry was 30 years ago with the introduction of the NNPD process Where will the new ideas come from if young talent is snapped up by other industries

It is not all hopeless Projects such as British Glassrsquo Glass Academy have raised the profi le of glass in schools and encour-aged apprentices to pursue a career in the industry Other national associations should follow its lead

Glass is still regarded as a desirable industry in developing nations such as

China India and the Philippines Young less weathered faces were prominent at events such as Glasspex in India the AFGM event in the Philippines and Glass-man in Mexico

The exchange of knowledge and new ideas is as important as ever If young peo-ple are opting to forge careers elsewhere glass must make use of the talent it has if it is to retain its leading position

The forthcoming Glassman Middle East conference is one such event where suppliers and manufacturers will present the latest trends and innovations

The Middle East with its fl ourishing youthful population is an ideal market in terms of attracting young people to glass It should follow the lead of the regionrsquos aluminium industry which has plenty of fresh-faced graduates working in it

Given the recent boom in activity in the MENA region including the lifting of trade sanctions in Iran the free to attend conference has attracted attention from manufacturers keen to visit the hollow glass industryrsquos most prominent suppli-ers The event will welcome the Director of Iranrsquos Noritazeh and the Operations Director of Frigoglassrsquos glass manufactur-ing division as keynote speakers

Greg MorrisEditorgregmorrisquartzltdcom

Greg Morris

Where have all the young people gone

wwwglass-internationalcom

Quartz Glass Portfolio

Editor Greg MorrisTel +44 (0)1737 855132Email gregmorrisquartzltdcom

Assistant Editor Sally LoveTel +44 (0)1737 855154Email sallylovequartzltdcom

Designer Annie BakerTel +44 (0)1737 855130Email anniebakerquartzltdcom

Sales Director Ken ClarkTel +44 (0)1737 855117Email kenclarkquartzltdcom

Sales Manager Jeremy FordreyTel +44 (0)1737 855133Email jeremyfordreyquartzltdcom

Production Executive Martin LawrenceManaging Director Steve Diprose

Chief Executive Offi cer Paul Michael

Subscriptions Elizabeth BarfordTel +44 (0)1737 855028 Fax +44 (0)1737 855034Email subscriptionsquartzltdcom

Published by Quartz Business Media LtdQuartz House 20 Clarendon Road Redhill Surrey RH1 1QX UKTel +44 (0)1737 855000 Fax +44 (0)1737 855034 Email glassquartzltdcomWebsite wwwglass-internationalcom

Glass International (ISSN 0143-7838) (USPS No 020-753) is published 10 times per year by Quartz Business Media Ltd and distributed in the US by DSW 75 Aberdeen Road Emigsville PA 17318-0437 Periodicals postage paid at Emigsville PA POSTMASTER send address changes to Glass International co PO Box 437 Emigsville PA 17318-0437

Offi cial publication of Abividro - the Brazilian Technical Association of Automatic Glass

Industries

Member of British Glass Manufacturersrsquo Confederation

China National Association for Glass Industry

United National Council of the glass industry (Steklosouz)

Glass International annual subscription rates including Glass International DirectoryFor one year UK pound164 all other countries pound231For two years UK pound295 all other countries pound416Airmail prices on request Single copies pound45

Glass International Directory 2015 editionUK pound206 all other countries pound217

Printed in UK byPensord Tram Road Pontlanfraith BlackwoodGwent NP12 2YA UK

copy Quartz Business Media Ltd 2015ISSN 0143-7838

Monthly journal for the industry worldwide

Directory 2015Annual international reference source

Glassman specialist exhibitions rotate between America Asia and Europe

wwwglass-internationalcom

China National Association for Glass Industry

Comment marchindd 1 31116 1235 PM

wwwbucheremhartglasscom

No compromisesengineered precisely to match your business case

We can supply the precise solution for your production needs Our machine range spans traditional pneumatic to sophisticated servo operation and the flexibility built into every machine ensures a perfect fit for your current needs with adaptability for the future Wersquore committed to your success with leading performance outstanding customer support and continuing advances to the glassmaking process

Bucher Emhart Glass The future of glassmaking technology delivered today

Bucher Emhart GlassMachine Portfolio

NIS machine

IS machine AIS machine

BIS machine

BEG_Portfolio-Glass_Intlindd 1 9315 305 PM

ENSURE THAT YOUR INVESTMENT PAYS OFFThat is why our furnaces and conditioning

systems are designed to reduce your total

cost of ownership

Reliability and ef ciency built by design

wwwsorgde

International News

Glass International March 2016

5

Technology suppliers sign up for Middle East hollow glass event

NEWS IN BRIEF

Vitro sales boosted 22Growth in its container and flat glass businesses helped Vitro grow sales by 22

The Mexican company reported that the growth in the construction and automotive sectors as well as strong export and domestic sales had boosted business in the final quarter of 2015

Consolidated net sales increased 222 to US$229 million in the quarter it reported in its quarter four 2015 financials

Vitro CEO Mr Adrian Sada Cueva said ldquoThe strong dynamics of the construction market driven by shortages in Mexico and the economic recovery in the US coupled with the acquisition of new customers and increased exports of glass for the automotive sector and strong sales volumes in the pharmaceutical industry were the main factors that boosted sales this quarterrdquo

Frigoglass terminates GZI sale Frigoglass has terminated its agreement to sell its glass business in Dubai and Nigeria to GZ Industries (GZI)

The agreement was signed with GZI in May 2015 but a condition of the terms was not met GZI did not secure the necessary level of debt financing for the acquisition as a result of a change in regulations that restricts the ability to leverage Beta Glass and the adverse economic conditions in Nigeria

Amended offers were made by GZI but these were declined by Frigoglassrsquo Board of Directors

PPG sells PGW stakePPG is to sell 40 of its stake in Pittsburgh Glass Works (PGW)

The sale is in connection with LKQ Corporationrsquos plan to buy PGW which is expected to be completed by the end of the second quarter this year

PPG has held a minority interest in PGW since 2008 when it completed the sale of its automotive glass and services business to PGW

Several of the hollow glass in-dustryrsquos leading technology suppliers have confirmed their presence at the Glassman Mid-dle East event

German company Penneka-mp and UK group Electroglass have each taken a booth at the exhibition

They will be joined by French inspection group Tia-ma and Anderman Ceramics who will both present papers at the parallel conference

Pennekamp manufactures equipment for thermal pro-cesses (lehrs) as well as other

product areas within the glass industry

Electroglass has been in-volved in electric glass melt-ing technology since 1976 Its core activities are the develop-ment design engineering and supply of electric glass melting and conditioning systems and related equipment

Tiama is a provider of in-spection solutions for the hollow glass industry and will provide an update about its vi-sion product range

Anderman Ceramicsrsquo Gary Hateley will present a paper

titled Supplying refractory in-sulation for furnace linings

Glassman Middle East is a free to attend exhibition and conference dedicated to the hollowcontainertablewarespeciality glass sectors

It takes place on May 10 and 11 in Abu Dhabi UAE and vis-itors will include glass man-ufacturers from the region associations and technology suppliers

For more information visit wwwglassmaneventscommid-east

Iranian manufacturer Noritazeh confirmed as keynote speakerIranian tableware manufac-turer Noritazeh has been con-firmed as a keynote speaker at the Glassman Middle East hol-low glass conference

Noritazehrsquos Director Saeed

Kalafchi will give a 20-min-ute overview of the Iranian glass industry and provide an update on Noritazeh and its recent developments

Other speakers at the hol-

low glass conference include glass container manufacturer Frigoglass inspection compa-ny Tiama Pneumofore IRF Europa and French refracto-ries group Sefpro

Interglass and Pennekamp form LATAM partnership

Mexican group Interglass has formed a partnership with German lehrs company Pen-nekamp

The new partnership will see Interglass introduce and push Pennekamprsquos range of prod-ucts and equipment through-out the entire LATAM region

Jose Luis Velez Interglass Managing Director said ldquoWersquore very optimistic about

the success that this collabora-tion will bring to both compa-nies as Pennekamprsquos top tech-nology perfectly complements our solutions portfolio

ldquoWe are sure that this new partnership will be very pros-perous and that it will main-tain us on the right track to lead the LATAM market on be-half of all the companies that we represent and work withrdquo

March newsindd 1 31116 210 PM

International News

Glass International March 2016

ww

wg

lass

-int

erna

tion

alc

om

6

NEWS IN BRIEF

Borosilicate glassrsquo 125th anniversaryExactly 125 years ago Otto Schott the founder of the technology group Schott discovered borosilicate glass and created the basis for high-tech applications in the 21st century

The glass is used in a variety of applications from streaming of sports events to high-tech material research These modern applications would not be possible without the borosilicate glass to protect cameras or for use in neutron conductors

Thai Glass forms partnership with XparThai Glass Industries (TGI) has joined forces with Xpar Vision in a stragetic partnership to provide hot end sensor technology to the global container glass industry

The partnership is the crown on the co-operation which started two years ago between TGI which is the container glass manufacturing subsidiary of Berli Jucker in Thailand and Xpar Vision based in The Netherlands

The collaboration began with an extensive trial of the Xpar Vision InfraRed Dual (IR-D) camera The trial was executed at the TGI production facility at Saraburi With the IR-D camera system all bottles are inspected in real time to detect critical defects

Libbey reports 35 drop in sales in 2015US tableware manufacturer Libbey reported a full year sales drop of 35 in 2015 compared to the prior year

In its full year financials for 2015 it said net sales decreased in the EMEA and Latin American region but increased in the US and Canada

It said sales performance in the US and Canada last year was led by a 75 increase in sales within the segmentrsquos foodservice channel

For 2016 Libbey forecast a sales growth of 1 from $8223 million to $830 million

Ground clearing begins at Ethiopian bottling plantAtlasrsquo 100 owned subsid-iary East Africa Packaging Holdings (lsquoEAPHrsquo) is building a glass bottle manufacturing facility 45km north of Ethio-piarsquos capital Addis Ababa

The plant will have the ca-pacity to produce 105 million 330ml bottles a year

Named the lsquoChancho Pro-jectrsquo Atlas has commenced ground clearing at the site and held a ceremony to com-memorate the event (pictured with Atlasrsquo CEO Carl Esprey pictured second from left)

Commissioning of the fa-cility has been scheduled for 2018 with full production tar-geted for early 2019

Levelling of the 55 acre site has begun and the topsoil has been stripped

The Chancho Project site is located in an established in-dustrial area that is serviced by excellent road infrastruc-ture as well as power

Preliminary assessments of potential sources and studies of local mining operations carried out confirm appropri-ate grades of silica sand and

limestone are available in de-posits 30km away from the site

An initial pre-feasibility study was completed at the Chancho Project and re-turned positive results

A full feasibility study is now being conducted in tandem with local and internation-al engineering consultants which is close to completion

The total capital expend-iture is estimated at US$42 million to be funded on a staged basis by a mixture of debt from local development banks other debt providers

industrial partners and equityFor the last five years due to

increased consumer demand and a young demographic Ethiopia has been attracting investment from internation-al beverage companies with more than $500 million in-vested to date

Beer production has been growing at a CAGR of 143 over the last 14 years with an additional 47 capacity cur-rently under construction

The demand for glass bottles is largely unmet by domestic production and is at present mainly satisfied by imports

Record year for UK electric melting specialistUK-based electric melting spe-cialist Electroglass has report-ed a ten-year record in its 2015 results

ldquoDespite uncertainty and slow-down in a number of world markets we have had an excellent yearrdquo said Managing Director Richard Stormont

ldquoAll-electric furnace and forehearths projects for fluo-ride opal tableware glass in south Asia in particular have been significant contributors

to this along with borosili-cate electric forehearths work in the USA gas-to-electric soda-lime forehearth conver-sions in South Korea electric boosting projects in Indonesia and elsewhere and contin-uing development and sales of our Precision Control Bub-bling Systems

ldquoAlso holding up well are sales of hardware notably the Molycool and Vertical Splash-guard ranges of electrode

holders and our dry-type fore-hearth electrodesrdquo he added

ldquoThe rest of 2016 sees the commissioning of several re-cently supplied systems and work is expected to start on a number of significant new projects for the companyrdquo

Electroglass will be exhib-iting at the upcoming Glass-man Middle East show in Abu Dhabi on the 10th and 11th May

March newsindd 2 31116 210 PM

+ ENGINEERING OMCO has an experienced engineering and design team ready to handle any project+ MATERIAL OMCO has two foundries ensuring a flexible supply of quality castings

+ TECHNOLOGY OMCO uses tailored technology to weld and machine moulds plungers and neck rings

+ FLEXIBILITY OMCO uses efficient manufacturing processes enabling quick turnarounds for urgent jobs

+ CAPACITY OMCO has six production plants with enough capacity to meet all your needs

= QUALITY PROMPTLY DELIVERED AT A COMPETITIVE PRICE

MOULDSHOPS OMCO BELGIUM I OMCO AUSTRIA I OMCO UK I OMCO CROATIA I OMCO ISTANBUL I OMCO ROMANIA FOUNDRIES OMCO BELGIUM I OMCO SLOVENIA

OMCOLEADING MOULD MAKERTO THE GLASS WORLD

International News

Glass International March 2016

Orora to invest $42MOrora has committed to spending $42 million on additional glass bottle forming lines at its South Australia glass plant to in-crease capacity

The increase in output will be approximately 60 million bottles per annum

To maintain production rates commissioning will be progressive and is ex-pected to commence in the

second half of 2016 with completion expected in the first half of 2017

Approximately 35 of the cash flow will be in-vested in FY16 with the balance in FY17

The company is also as-sessing a potential invest-ment of a further $10-$15 million in an automated warehouse

Ororarsquos glass business

is experiencing increased demand within the wine segment driven by the re-patriation of wine that is currently bottled offshore

ldquoThe glass business is al-ready in an oversold posi-tion and this investment will further enhance Oro-rarsquos ability to service the increased demand from customersrdquo said Nigel Gar-rard Ororarsquos CEO

Vetropack orders SIL systemSwiss group Vetropack closed a deal with Vertechrsquo early this year to install SIL2016 in the companyrsquos recently acquired Italian plant Trezzano sul Naviglio

Vetropack bought the northern Italian plant from Bormioli Rocco in June 2015 in order to strengthen its position in the European market

Trezzano sul Naviglio currently produces around 140000 tons of glass packaging every year for the food and beverage in-dustry and used Vertechrsquo solutions for production line monitoring and qual-ity control on some of its lines

Vetropackrsquos decision to extend SIL to the remain-

ing production lines and the mould department is part of the companyrsquos corporate strategy to gain significant market share as well as expand its current product portfolio and cus-tomer base

SIL2016 is scheduled for installation in Trezzano sul Naviglio before the end of the first quarter

Siam Glassrsquos vacuum system

Italian company Pneumo-fore has installed a vacuum system at Siam Glassrsquos Ro-jana plant in Thailand

The vacuum system used in glass forming has helped reduce the weight of bottles from 145 grams to 140 grams and means Siam Glass can produce 21600 more bottles each day

Siam Glass runs three plants in Thailand making

energy drink bottles of var-ying size

The challenge for Pneu-mofore was to reduce the container thickness and decrease the rejection rate of 150ml bottles by the use of vacuum Only one of the three IS lines was modified and configured as a lsquotest benchrsquo for vacuum

The results convinced the management to ex-tend the use of vacuum on

to Lines 1 and 3 and it will also become standard at its other two plants

Three UV50 rotary vane vacuum pumps are con-stantly in operation at the Rojana plant

They ensure the exact vacuum level required on the moulding machines by means of variable speed drives and deliver a higher performance with minor power consumption

Production performance per IS line

37 TPD saveddayIS 7200 more bottlesdayISTotal of

21600 more bottles produced in the plantday

BEFOREWeight (g) 145 140 -335

097130

520945

515932

Speed (bottlemin)Efficiency ()

AFTER DEVIATION

March newsindd 3 31116 210 PM

Making potentials visible

E20001-F120-T112-X-7600_Ad_Glass_A4indd 1E20001-F120-T112-X-7600_Ad_Glass_A4indd 1 200415 1016200415 1016

International News

Glass International March 2016

ww

wg

lass

-int

erna

tion

alc

om

10

NEWS IN BRIEF

Glassman sign-upsMega Enterprises is the latest company to secure a stand at the forthcoming hollow glass show Glassman Middle East

The company has taken a 54m2 booth at the free to attend hollow glass exhibition and conference

The company represents a number of leading European container glass suppliers including Tiama Antonini Revimac Ruitai and Messerssi

They will be joined by German group LWN Lufttechnik which has taken a 9m2 stand at the exhibition

Furnace life website PaneraTech has released a dedicated website for Smart-Melter a technical solution for furnace life optimisation

SmartMelter provides asset management for glass melting furnaces

The website allows glass manufacturers to learn more about the technology and outlines service and licensing options The website is wwwsmartmeltercom

Interglass gas crisis Gazprom Kyrgyzstan has threatened to turn off the gas supply to flat glass manufac-turer Interglass

The gas company said it would disconnect Interglass due to unpaid debts amounting to 1117400000 of Kyrgyzstan soms ($15 million)

According to Gazprom Kyrgyzstan it has not stopped trying to settle the matter out of court and has tried to initiate meetings with Interglass

It has to date not turned off the gas supply due to the social importance of the plant

PneumoforeIn the last issue of Glass International magazine in an interview with GIMAV Director Laura Biason Pneumoforersquos location was labelled incorrectly in a map of Italy

The company is based in the north west of the country rather than the north east

Be first with the news VISIT wwwglass-internationalcom for daily news updates

All full stories can be found on our website wwwglass-internationalcomnewsr 1 Iranrsquos Nafis Glass commissions glass plantr 2 Borosilicate glass celebrates 125th anniversaryr 3 Ground clearing begins at Ethiopian bottling plantr 4 Interview with Shandong Huapeng General Manager Mr Zhang De Huar 5 Wine and spirits help boost O-I volumes by 3 in 2015r 6 Ardagh Glass launches updated educational programmer 7 Quantum and Interglass form partnershipr 8 Impianti Novopac latest company to sign up for hollow glass exhibitionr 9 Frigoglass terminates sale to GZ Industriesr 10 Glass school in China

Top 10 stories in the newsOur most popular news items as determined by our website traffic

Heye welcomes Stoumllzle expertsHeye International welcomed senior production experts from the Stoumllzle group to Obernkirchen Germany re-cently to discuss their develop-ment priorities

Stoumllzle is an important cus-tomer for hot and cold end equipment and Heyersquos techni-cal team were on hand to dis-cover the customerrsquos priorities

Ten senior members of Stoumll-zlersquos multinational production team attended the meeting in Obernkirchen where Gerd Muumlller Cold End Manager presented the grouprsquos latest developments including the creation of a centre of excel-lence for cosmetic flacons at the Masnieres plant in France

As well as discussing best

practice solutions for the glass container production process the workshop addressed future inspection priorities

This included a debate about which cold end inspection functions could be moved to the hot end the elements re-quired in the lsquoidealrsquo inspection machine and the potential for automatic job changes

Bastuumlrk Glass selects SorgGerman company Sorg said it was honoured to have been selected as the furnace sup-plier by Bastuumlrk Glass for its greenfield project in Turkey

Bastuumlrk is a new player to the glass industry and is build-ing a site in Malatya in the Eastern Province of Turkey

The new factory will go into operation at the beginning of 2017 and produce 300 tons per day of glass containers

Sorg said it lsquowanted to thank Y amp H Foreign Trade Limited for its assistance in securing the order and Bastuumlrk Glass for placing its trust in usrsquo

The Bastuumlrk delegation at the Sorg site in Lohr am Main Germany

March newsindd 4 31116 210 PM

Even thehardestpuzzles have asolution

Tomorrows Technology Today

Electro-heat solution for glassFIC

The Worlds Number One in Furnace Technology

wwwfic-ukcom +44 (0) 1736 366 962

n Innovative all-electric furnace designn Electric boost for extra tonnagen Versatile bubbler systemsn Supplementary electric heating for

gas-fired forehearthsn Mathematical modellingn Proven technical innovations

FIC (UK) Limited Long Rock Industrial Estate Penzance Cornwall TR20 8HX United Kingdom

FIC - Cube ad 2016 20216 1200 Page 1

G L A S S Q U A L I T YFives is a leading provider of glass technologies for the most demanding applications ultra-thin automotive pharmaceutical fiber solar crystal and speciality glass We contractually guarantee the productivity and environmental performance of your plant for secured profitability of your investmentWith over 60 years of experience in the glass industry Fives designs engineers manufactures installs tests and commissions glass equipment in a wide range of glass processes and applications all over the worldTrust Fives professionals to enhance your plantrsquos performance and competitiveness and to optimize your investmentglassfivesgroupcom wwwfivesgroupcom

FIVES PRIUMreg TECHNOLOGY THE ULTIMATE ADDED VALUE TO YOUR INVESTMENT

Fives Verre 210x297indd 1 250216 1008

Glass International March 2016

ww

wg

lass

-int

erna

tion

alc

om

13

A Chinese group with global plans

Mr Zhang De Hua is the Chairman and General Manager of container and tableware manufacturer Shandong Huapeng Glass The company has its headquarters and two factories in Shandong one factory in Liaoning one in Shansi one in Anhui and one in Zhejiang

Continuedgtgt

Shandong Huapeng Glass consists of Huapeng Glass (Heze) Liaoning Huapeng Guangyuan Glass Anqing Huapeng Changjiang Glass and

Shanxi Huanpeng Shuita GlassIt specialises in RampD production and sales of all

kinds of medium and top grade glassware and glass bottles

Its main bottle and glass production lines and ancillary on-line automatic inspection machines are advanced equipment that has been imported from the USA Italy Germany France and Belgium and are of the highest international advanced level The company also has a Provincial Enterprise Technology Centre and a Provincial Glassware Engineering Technology Research Centre with RampD ability

A total of 37 types of its glassware products have won the design patent certifi cation issued by the Sate Intellectual Property Offi ce and the product quality has reached the domestic leading level and an international advanced level It is the main supplier to Metro Wal Mart Carrefour Trust-mart and many other well-known international supermarkets

Could you briefl y present the current Chinese glass packaging marketMr Zhang De Hua The Chinese glass industry faces strong consolidation the new environmental regulations have made it diffi cult for small glass factories to survive The market leaders will certainly shape tomorrowrsquos glass industry

Could you please introduce your com-pany Shandong Huapeng Glass and your strategy at this timeShandong Huapeng is one of Chinarsquos leaders in glass packaging and the largest manufacturer of crystal-like tableware We have taken advantage of todayrsquos industry evolution and our company has opened new factories all over China At this stage we already have more than seven glass factories Our company strategy is to bring higher quality products to the domestic market as well as carrying on our strong development of international sales For this reason Huapeng chose to use international standard imported equipment and we voluntary selected international standard inspection equipment as well

In 2015 Huapeng upgraded one complete new production line with Tiamarsquos latest inspection machines MCAL4 (sidewall amp dimensional) MULTI4 (fi nish amp base) and MX4 (carousel technology) equipped with ATLAS systems (non-contact check detection) Before May 2016 Huapeng will install an additional 12 machines MCAL4 MULTI4 and MX4 with ATLAS

What benefi ts has the Tiama equip-ment brought to Shandong Huapeng We have achieved a lot of quality inspection improvement for example we have drastically reduced the quantity of cracks Our global product standard and our overall product quality have both surged We are using the most advanced

Mr Zhang De Hua is

chairman and General

Manager of Chinese

container and tableware

manufacturer Shandong

Huapeng Glass

Chinese

overview

A Chinese group with global plans

Mr Zhang De Hua is

chairman and General

Manager of Chinese

container and tableware

manufacturer Shandong

Huapeng Glass

Company overview Shandong Huapeng

A Chinese group with global intentions

Company profile shandong 2 pagesindd 1 31116 215 PM

Company overview Shandong Huapeng

Glass International March 2016

ww

wg

lass

-int

erna

tion

alc

om

14

technology for detection which is the ATLAS system and it ensures a repeatability of the detection that we could not reach in the past We are also monitoring and inspecting the glass thickness in our glassware as a general results we have no broken ware delivered to customers We have received appraisal from our most demanding North American foreign customers

How important is automation and au-tomated equipment to your company Automation is very important for our company as it is directly linked with quality Our customers are very demanding for quality and automated equipment has helped us to achieve our productivity targets while improving our quality

What is the Shandong Huapeng main range of products Shandong Huapeng has positioned itself as one of the leaders for the production of wide-mouth jar packaging as well as all kind of bottles shapes for wine liquors and olive oils

ldquoThe Tiama

inspection

equipment has

helped us achieve

the highest quality

standards required

by our customers

and ensures our

product safetyrdquo

We manufacture for Chinarsquos market but also a large share of our production is for export market in the APEC regions These containers require a high quality level of inspection The Tiama inspection equipment has helped us achieve the highest quality standards required by our customers and ensures our product safety

Finally can you briefly tell me about Huapengrsquos tableware capacity Yes that is right Huapeng Glass is a leader for the production of crystal wine glass and lead-free wine glass We provide our products to famous five stars hotels in China as well as export them worldwide our main markets are South Korea Japan the United States Canada and Russia r

Shandong Huapeng Glass Shandong Chinahttpenhuapengglasscom

Tiama Vourles near Lyon Francewwwtiamacom

An overview of its head-

quarters in Shandong

The company has installed

the latest inspection equip-

ment from French company

Tiama

Chinese

overview

Company profile shandong 2 pagesindd 2 31116 216 PM

MULTIPOINTWALL THICKNESS

wwwheye-internationalcom

Covers all critical areas of a container

Flexible combination with single point sensor

Superior chromatic confocal method

Independent of measuring range and angle

Suitable for round and non-round containers

MULTIPOINT THICKNESS SENSOR MTS1005STAND-ALONE OR INTEGRATED IN HEYE SMARTLINE

WE ARE GLASS PEOPLE

RZ_HEY_AZ_MTS10_A4_Kanchindd 1RZ_HEY_AZ_MTS10_A4_Kanchindd 1 030216 1152030216 1152

Glass containers are one of the most important packaging materials in the food beverage medical and cosmetic industry with a huge variety of shapes sizes and colors

Single or multi furnace batch plantsHigh quality container glass requires a precise batch composition and accurate cullet addition One or several furnaces with different glass types can be served from one batch plant without contamination ndash Just perfect

From raw material delivery to batch chargingWe manage all your raw materials including cullet and provide sophisticated batch charging technology Com-pletely sealed doghouses less dust less emissions less energy losses and now also modular for full redundancy

As the leading supplier of batch plants cullet handling equipment and batch charging technology EME has developed and successfully delivered specifi c solutions for the container glass industry

Enjoy these benefi ts ndash go with EME

Glass is our PassionEME Maschinenfabrik Clasen GmbH middot E-Mail contactemede middot wwwemede

Thin Glass

Tableware

Fibre Glass

Float Glass

We have solutions for all types of glass production

Container Glass

Country profi le China

Glass International March 2016

ww

wg

lass

-int

erna

tion

alc

om

17

Chinarsquos container industry set to rise to higher peaks

Ahead of the much-anticipated China Glass show in Shanghai Seema Gahlut provides an overview of the Chinese container glass industry which in recent years has grown at an astonishing rate

Continuedgtgt

ldquoBy 2022

China is

expected to

become the

largest global

consumer of

food packaging

surpassing the

USrdquo

Producing around 26 million tons per year the Chinese container glass industry has more than 900 large medium and small

container glass producers and grew at a CAGR of more than 12 from 2000-2014 Production fi gures for 2015 are not yet available but it is anticipated that growth fi gures remained close to 10 on a year-to-year basis

The industry has achieved this gigantic growth on the back of brisk urbanisation a rise in disposable incomes for a vast section of the population and increased spending on food and beverages An increased focus on healthcare has also been an important spur for the development of the industry

The top 10 provinces contributed 85 to the countryrsquos overall container glass production in 2014 with most production based in the coastal provinces including Shandong Zhejiang Guangdong Jiangsu and Fujian The concentration of industry in these provinces is due to cheaper transportation costs for sea freight compared to land transportation More manufacturing plants have set-up up along the coastal provinces to ship goods overseas which in turn has also reduced freight prices

Demand drivers Alcoholic and non- alcoholic beverages food and the pharmaceutical industry (in that order) are the largest demand drivers for container glass

Due to the complex nature of the Chinese container glass manufacturing industry it is diffi cult to evaluate the performance of each sub-segment on a numbers basis This is due to the batch production nature of many of the mid and small scale producers which often operate on a lsquoby demandrsquo basis

Alcoholic beverages hold the largest share

of container glass consumption despite the industryrsquos hold on beer packaging slipping for several reasons Higher transport costs and a declining rate of returnable glass bottles are leading to higher costs when using glass bottles in the beer industry The profi t margins of glass-bottled beers are low compared to beer in cans and as a result a numbers of brewers have turned to metal packaging Consumers have also accepted canned packaging particularly in retail consumption due to the convenience of carrying

After beverages the food industry is the largest consumer of container glass and is likely to be the key driver of the sector in future years The population has shifted to larger urban centres which means large supermarkets selling packaged food items have replaced the traditional rural vendor or market stall selling raw minimally packaged items

By 2022 China is expected to become the largest global consumer of food packaging surpassing the US This is due to increased urbanisation higher personal incomes and an escalating interest in packaged foods PET packaging currently accounts for a large share of food packaging in China but with an increased purchasing power glass is expected to corner a share in the industry

The performance of the container industry in Chinese pharma and cosmetics sub-segments has been particularly satisfactory with the largest gains in the industry coming from these two sectors in recent years

OvercapacityThe establishment of a record number of new container glass producers and a huge capacity addition in the past few years has resulted in extensive overcapacity

Chinarsquos container industry set to rise to higher peaks

Chinese overviewindd 1 31116 1251 PM

Country profile China

Glass International March 2016

ww

wg

lass

-int

erna

tion

alc

om

18Continuedgtgt

Lower than expected demand growth in recent years and the replacement of glass in some sub-segments by alternative forms of packaging have led to an overcapacity The overcapacity is more prominent in the mid and low end sub-segments of the industry

Schott Xin Kang GlassSchott is a German manufacturer of speciality glass products and is investing heavily in Chinarsquos container glass industry The company broke ground on the construction of a new pharmaceutical packaging plant in Jinyun County Zhejiang province in July 2015 The company already owns two production facilities in China including an integrated production facility in Suzhou and one in Jinyun that was developed as a joint venture with Xinkang

Schottrsquos expansion plan also includes the modernisation and expansion of its existing facilities in Suzhou It will invest $33 million in China in the next three years to increase its overall production capacity in the region by 50 The new pharmaceutical packaging facility is being constructed at Schott Xinkangrsquos site in Jinyun It will produce glass containers for injectable drugs including vials and ampoules and is scheduled for commissioning in 2017

Shandong Pharmaceutical Glass Shandong Pharmaceutical Glass is a publicly held company engaged in the production and distribution of pharmaceutical glass bottles The company was established in 1970 and has its registered office in Zibo China

Shandong Pharmaceutical is one of Chinarsquos largest pharmaceutical packaging manufacturers It produces pharmaceutical glass such as moulded injectable vials glass tubing ampoules and tubular vial for injection It also produces container glass for cosmetics and the food amp beverage industries

The companyrsquos products are sold and distributed to domestic markets and to more than 1000 medical companies all over China It also has a presence in USA Europe India South Africa

Australia the Middle East Thailand Vietnam Pakistan and Syria

Shandong Huapeng Glass Shandong Huapeng Glass is one of the largest and most reputable container glass producers in the country It comprises subsidiaries Huapeng Glass (Heze) Liaoning Huapeng Guangyuan Glass Anqing Huapeng Changjiang Glass and Shanxi Huapeng Shuita Glass It has an installed capacity of more than 240000 TPA of container glass and more than 40000 TPA of tableware glass

Yantai Changyu Glass CompanyA subsidiary of the largest wine producer in China Changyu Wine Yantai Changyu Glass Company produces almost 90 of the bottles needed for its parent companyrsquos wine packaging

Yantai Changyu Glass also meets the packaging glass demand of other major wine producers in the country

Yantai Changyu has an installed capacity of more than 600000 tons of container glass a year It has seven furnaces and 20 production lines in operation at two sites in Shandong province The company is capable of producing products from 100ml to 6000ml with the blow-blow and press-blow technique

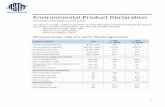

S No Company Location Production Capacity Product Segments

1 Yantai NBC Glass Packaging Shandong 140000 TPA Food amp Beverage

2 Shandong Pharmaceutical Glass Company Shandong 500000 TPA Pharmaceutical Glass

3 Linuo Glass Jinan 140000 TPA Pharmaceutical Glass

4 Yantai Changyu Glass Company Yantai Shandong Province 500000 TPA Alcoholic Beverages

5 Rockwood amp Hines Glass Factory Jiaxing 120000 TPA Alcholic Beverages amp Cosmetics

6 Kohler Glass Company Jiangsu 80000 TPA Food amp Beverage Industry

7 OMPI Pharmaceutical Packaging Company Jiangsu 180000 TPA Pharmaceutical Glass

8 Shandong Yuncheng Ruisheng Glass Co Ltd Yuncheng Shandong 160 000 TPA Beverage Industry

9 Xuzhou Dahua Glass Company Jiangsu 180000 TPA Cosmetics and Pharmaceuticals

10 Yammamura Glass Qinhuangdao Company Limited Jiangsu 200000 TPA Beverage Industry

11 Beijing Gerresheimer Glass Company Jiangsu 300000 TPA Pharmaceutical Glass

12 Shandong Heishan Glass Group Shandong 100000 TPA Beverage Industry

13 Zibo Baoxiang Glass Company Shandong 120000 TPA Beverage Industry

14 Shendong Shenhua Glass Joint Company Shandong 160000 TPA Food and Beverage Industries

15 Dalian Shengdao Glass Dalian 120000 TPA Food amp Beverage Industries

Table 1 Major Chinese container glass producers

ldquo[Schott]

will invest $33

million in

China in the

next three years

to increase its

overall

production

capacity in

the region by

50rdquo

Chinese overviewindd 2 31116 1251 PM

Country profile China

Glass International March 2016

ww

wg

lass

-int

erna

tion

alc

om

19

ldquo[O-I] has

scaled down

its operations

considerably in

the country due

to the issue of

profitabilityrdquo

Xuzhou Rui Tai Glass CompanyLocated in the Mao economic development zones in the city of Xuzhou Jiangsu province Xuzhou Rui Tai Glass Company is among the top ten container glass producers in the country

Claiming to have lsquobest of its classrsquo equipment from some of the most reputable suppliers Rui Tai operates six furnaces and 42 production lines to produce 500000 tons of container glass per annum for beverage and food industries

Kohler Glass Bottle CompanyKohler produces 250 million glass bottles per year for the food and beverage industry and is located in Mapo town in Jiangsu province The company produces container glass in flint half flint green and amber colours

It can design and produce customised glass bottles according to customerrsquos requirements The company also carries out deep processing such as sand blasting silk screen printing glazed and transparent paints on glass bottles

Shenzhen Tongchan Group Shenzhen Tongchan Group was founded in 2000 and has emerged as an important player in the countryrsquos container glass production The company owns Shenzhen Beauty Star Zhaoqing Tongchan Glass Technology Sichuan Tongchan Huajing Glass and Shenzhen Huajing Glass Bottle and has an installed capacity to produce 800000 tons of glass through its subsidiaries

Its main businesses are high-end cosmetics and it supplies some of the top brewers in the country Its major cosmetic packaging customers are PampG Shiseido Unilever Avon LrsquoOreal and Arrow

Its main beverage customers are Carlsberg Heineken Tsingtao Pearl River Haitian and other beer brewers

Owens-Illinois Owens-Illinois (O-I) which had strengthened its position in the industry via the acquisition of two domestic companies in 2010 has scaled down its operations considerably in the country due to the issue of profitability

According to an earlier press statement of

outgoing CEO Al Stroucken ldquoIn China there are more than 1000 bottle makers and many sell at prices that didnrsquot make economic sense to usrdquo

He added ldquoWe found it was difficult to compete profitablyhellipwith so many small playersrdquo conceding that the effort to produce on a large scale for domestic customers rather than multinationals with higher quality standards was ldquoa mistakerdquo

In one of his last investor meetings Mr Stroucken repeated the importance of the Chinese market He said ldquoI would say long term the trends in China still remain fairly positive But of course we are operating from a much more restricted basis than we have had in the past We have really focused on very few facilities that serve predominantly multinational or international customers because that is where we can get a satisfactory price levelrdquo

Slower growth Chinese container glass production has reached an unprecedented level of production although judging from recent trends in the Chinese and global economy there are tough times ahead

According to data reported by Chinarsquos National Bureau of Statistics (NBS) industrial production in the country rose 59 year-on-year in December 2015 slowing from a 62 increase the previous month The manufacturing sector expanded the most by 7 followed by mining (+14) In contrast electricity heat gas and water production and supply declined by 08 From January to December 2015 industrial output rose 61 On a month-on-month basis industrial output grew 041 Industrial production in China averaged 1272 from 1990 until 2015 reaching an all time high of 294 in August of 1994 and a record low of -211 in January 1990

The industrial output of the flat glass industry dropped by 86 year-on-year according to the NBS The slowdown in the flat glass industry is a result of central governmentrsquos strong commitment to slashing excess capacity and discouraging zombie factories ndash those unable to pay their debt and survive without outside support ndash which face greater challenges to survive this year

Container glass demand will drop in future due to Chinarsquos economic slowdown

Container producers have already made production cuts as demand from end users has dwindled Production levels in the segment have not dropped as sharply as those in the flat segment where the temporary suspension in a large number of construction projects has led to a substantial fall in flat glass demand But flat or low growth in the container sector cannot be ruled out r

China Glass takes place this year in Shanghai between April 11 and 14th

wwwchinaglass-expocom

Chinese overviewindd 3 31116 1251 PM

Company profi le FERVER

Glass International March 2016

ww

wg

lass

-int

erna

tion

alc

om

20

Federation proves that glass recycling is not a waste

Continuedgtgt

Glass recycling collection rates in Europe have improved dramatically in the past 10 years In autumn last year the latest fi gures

showed more than 25 billion glass containers were recycled in the EU which is about 73 of all the bottles made in Europe

Terms such as recycling sustainability and lsquobeing greenrsquo have entered the public consciousness and most of us are aware of the benefi ts of recycling whether it be glass paper or food

It is no coincidence that the rise in recycling has coincided with the formation of the European Federation of Glass Recyclers (FERVER) federation which was developed at the end of 2004 to represent the glass recycling companies of the continent

Promisingly the amount of glass recycled in Europe looks set to rise even further companies in countries where glass recycling is still a relatively new phenomenon have applied to join Ferver

Greg Morris travelled to the Federation of Glass Recyclersrsquo (FERVER) headquarters in Brussels to meet its General Secretary Baudouin Ska Mr Ska discussed the recent Circular Economy package put forward by the European Commission as well as the dramatic rise in glass recycling rates across Europe

Once they are members they will receive the benefi t of its expertise and be given information on how to develop their business It has 40 member companies represented in 18 countries 15 in the EU and three from outside the EU

Some 1900 staff from 66 recycling plants are represented by the federation with requests to join from companies in countries such as Turkey Poland Croatia Romania and even Canada

BackgroundFERVER represents European glass recyclers The majority of its members are from packaging glass but there is a substantial number of fl at glass recyclers who are represented

Like any traditional federation it helps its members develop business protects and informs them and promotes their activities at an EC and

Ferverrsquos member companies have invested heavily in machinery in order to supply glass

manufacturers high quality cullet

Company profile FERVERindd 1 31116 220 PM

Company profi le FERVER

Glass International March 2016

ww

wg

lass

-int

erna

tion

alc

om

21Continuedgtgt

national level When new legislation is discussed at a European level FERVER negotiates with the authorities to make it as acceptable as possible for its members The new rules are then explained to members to ensure they understand and comply with the legislation at EU level as well as at national level

A current piece of legislation is the Circular Economy package which is of huge importance to glass recyclers The package proposed by the European Commission sets glass recycling rates at 75 across Europe by the end of 2025 and 85 by the end of 2030 The legislation broadly welcomed by groups such as FERVER and container glass manufacturers association FEVE has revised glass recycling targets in Europe

FERVERrsquos General Secretary Baudouin Ska said they had to see if the targets were both ambitious enough and realistic enough

ldquoThere is currently a huge difference in recycling rates in the established countries such as France and the Benelux compared to places such as eastern Europe where they are a long way from reaching even existing targets

ldquoIt will take time for these countries It took a long time for them to realise the value of waste and it takes time education and fi nancial effort to organise a specifi c collection system to reach a valuable product for recyclingrdquo

In countries where recycling rates are low fi nancial measures from government such as landfi ll taxes will help boost recycling rates

Mr Ska has been in his current role for six years and said ldquoEastern European countries are very active but the problem they have is it is diffi cult to

get the source of the glass in their countries They can perfectly recycle any glass that they collect but the problem is the inputrdquo

He warns of European legislation becoming too strict causing the glass manufacturing industry to move to less regulated parts of the world

ldquoItrsquos a fact that due to more stringent legislation we have seen the movement of glass factories from Europe to other parts of the world

Transport is not a cost at the moment so it is easy to import glass worldwide to Europe but it is not suitable to send untreated collected glass all over the world In the Circular Economy where sustainability and proximity are key terms it makes no sense to recycle material to send to other parts of the worldrdquo

Glass recycling rates vary greatly across Europe from 97 in Sweden and 88 in Germany to 38 in the Slovak Republic and 32 in Hungary Work has begun to improve rates in those countries and one of the benefi ts of being a FERVER member is that different countries swap best practice ideas

The EU Commission in its Circular Economy package proposes to change the defi nition of recycling At present recycling is considered as the moment of collection but the Circular Economy package has changed the defi nition and refers to the fi nal recycling process which means that the stream is re-integrated into the production chain Mr Ska admits there is a lot of work to do in eastern European countries but states that the majority of FERVER members are safe in terms of the Circular Economy package

ldquoMore than 90 of our membersrsquo production is sold as end of waste so we have already reached the end of waste status so what we are selling is no longer waste but a product That means recycledrdquo

Black glassThe improvement in glass recycling rates in Europe has been obtained by close collaboration between glass recyclers and glass producers Each glass manufacturer wants to reduce its energy consumption and CO2 emissions so therefore asks for high quality input material

For recyclers it has required investment in more sophisticated sorting machines to sort out the non-glass such as ceramic stone and porcelain (CSP) and lead content in both crystal glass and in television screens One recent problem for recyclers has been the rise of trendy colourful glass bottles which are designed to stand out on the shelf against competitor drinks Some bottles such as black glass are so dark they are considered stones by optical sorting machines and are rejected

Mr Ska said ldquoThese bottles are recyclable if they go directly in a glassmakersrsquo oven but when it comes into the chain via collection in municipalities it is rejected by optical sorting machines or the recyclers

ldquoThere is a trend for bottles that stand out on the

Mr Ska

FERVERrsquos Secretary

General

Company profile FERVERindd 2 31116 220 PM

Company profi le FERVER

Glass International March 2016

ww

wg

lass

-int

erna

tion

alc

om

22

shelf but this marketing is bad for recycling The best product for us is a cylindrical bottle without a label and any colour but then you have an anonymous productrdquo

Glassmakers have been encouraged to be more aware of their packaging The recyclability has to be tested before launching a new product

For example a re-sealable cap with wire and ceramic can cause inclusions Metalised labels can also cause inclusions in a new bottle But glass cork rubber stoppers crown cork and well-designed aluminium caps are fi ne and sleeved labels are ideal for glass recycling Other challenges for recyclers are the design of bottles Glass bottles with a convex uneven or embossed shape make it diffi cult to check for failures on newly produced bottles RFID tags in labels can also cause inclusions

Opportunities Mr Ska is positive about the future of glass and of glass recycling He

believes the general concept of sustainability favours the glass sector compared to other types of packaging

ldquoSome foods that were previously not packaged in glass have been brought back into glass because of the sustainability of the packaging and thanks to the unique tasteless property of glass

ldquoThe new Circular Economy has clear targets and clear calculation methods so

the wrong reportage to Eurostats will no longer be a possibility It is certainly an

opportunity to promote recycling at a European level

ldquoWe are in contact with recyclers and authorities outside of Europe

that view Europe as an example of good recycling Glass is one of the best examples of recycling so we are an lsquoexample of the examplersquo We hope to promote outside of Europe the real recycling of glassrdquo

FERVER Brussels Belgium wwwfervereu

Latest fi gures show

more than 25 billion glass

container bottles a year were

recycled in Europe

Some of FERVERrsquos mem-

ber companies

Some bottles such as

black glass are so dark they

are considered stones by

optical sorting machines and

rejected

Company profile FERVERindd 3 31116 220 PM

SOLUTIONS FOR THE GLASS INDUSTRYFurnacesForehearthsRobotics

OUR HIGH PERFORMANCE OXY-FUEL FURNACE COMBUSTION SYSTEMSLOWEST NOX EMISSIONSHIGHER PRODUCT QUALITYENERGY SAVINGS2015 installations 410 tonsday - container glass - England270 tonsday - container glass - Estonia 18 tonsday - borosilicate glass - Ukraine220 tonsday - container glass - Italy 24 tonsday - borosilcate glass - Iran - refurbishing

GLASS SERVICE srl - ITALY tel+3905714442 wwwglassserviceit

Supplier profi le Zippew

ww

gla

ss-i

nter

nati

onal

com

24

As part of our series of profi les on German suppliers in the run up to glasstec 2016 Sally Love met with Dr Holger Zippe at the companyrsquos headquarters in Wertheim As well as being CEO of the family-run Zippe Industrieanlagen he is also President of the VDMA and head of the organising committee for glasstec and so was able to share his thoughts on the industryrsquos biggest event

Can you give us a brief history of ZippePut in a nutshell the Zippe company was founded in 1920 by my grandfather Alfred Zippe Senior and his wife Maria on their wedding day At that time they worked for the Bohemian glass industry but after 1945 all this was gone and they left their home in Bohemia and went to Germany They made their way through Eastern Germany and fi nally settled in Wertheim We are happy they settled here because the location is fantastic for us ndash we are only 45 minutes from the airport which is a major asset because we can easily travel all around the world

In 1960 my father Alfred Zippe Jr built the fi rst automatic batch plant in Germany for a container glass company making bottles in Nienburg In 1964 we built our fi rst batch plant overseas and since then it has become a success story We work worldwide for glass factories and glass groups whenever they need a batch plant modifi cation or even a new batch plant We do not get all the orders but I feel we often get the big important orders We have a staff of 200 people all highly professional and with a lot of experience however we are still a young team with an average age of 36

Does being a family-run company affect Zippersquos core valuesCertainly yes We have many positive effects from being a family company One is with all our employees we work very closely together with a long-term perspective We have

A family affair

staff of 200 people all highly professional and with a lot of experience however we are still a young team with an

z Dr Holger Zippe CEO of Zippe with his son Dr Philipp Zippe

Managing Partner and COO of the company

Glass International March 2016

Zippe company profileindd 1 31116 926 AM

Supplier profile Zippe

Glass International March 2016

ww

wg

lass

-int

erna

tion

alc

om

25

many people who have been been with us for 30 years all their working career and so they have a lot of experience We work together like a big family they know my ancestors we know fathers and sons of theirs and thatrsquos a very nice community

The core values are also affected in that we look more for the long-term perspective and not for short-term profit The negative is that maybe we look too little for short-term profit We perhaps take orders that we should rejecthellip ldquoNo not for this time not for this amount of moneyrdquohellip But the positive side outweighs this and when the family works well together with all our employees and our managers it is a very positive situation

How many plantsoffices do you have around the world We have 200 employees here in Wertheim and 45 highly qualified technicians in our second production plant in East Germany where we mostly produce conveying equipment We also have representatives in 55 countries all around the world so all the major markets are covered Thatrsquos very helpful because they know the situation with the customers and can approach them on a level that is much more suitable for them in their respective countries with their respective traditions Then we have a couple of firmly established companies such as in Italy China England or Poland which help to execute contracts on a larger scale when you have to include local services

Where is the majority of Zippersquos busi-ness done in the world at the momentIt is always changing It changes from year to year At the moment the biggest orders we have are from Europe Latin America and North america these are the biggest jobs that we execute But that can change in a year easily South East Asia always remains an important market for us

Thatrsquos good for Europe ndash often you hear about the market slowing downYes there is still investment in Europe Europe is more of a mature market thatrsquos true so there is not as much growth But still companies are changing locations are changing situations are changing The glass industry is where the market is where the energy is where the raw materials are and so locations even change within Europe from time to time Some factories are closing because they are old and not working efficiently anymore some new ones are being built quite often close to the customer where you have little transport ndash so there is always something going on New types of glass industry are also being developed such as fibreglass and pharmaceutical glass which were maybe not produced on the same scale 20 years ago

Where in the world do you see the most opportunity for future business Asia is still an important market and the Americas and Europe continue to be important In the medium term the clear answer is Africa this will be a market of the future Several countries are coming up very rapidly on the African continent

There is a very simple rule in business that I have experienced over the decades wherever there is stability there is investment Itrsquos very simple Where there is no stability there is no investment You can follow that pattern all over the world Luckily in spite of all the difficulties that are happening in the world and the Middle East and a few countries in North Africa there are still countries in the world with a lot of stability and thus there will be investment Not to forget Iran - there will be a lot of demand for new techniques in this country after years of isolation We are ready to serve this new market

How important is the German market to Zippe The German market is important to us as we usually have a very constant rate of 15-20 of our turnover coming from customers in Germany That means we have an export rate of 80-85 of business outside of Germany Germany has a very dynamic glass industry with many glass factories and is a strong home market which is certainly an advantage for us There wonrsquot be new glass factories built every year not even every three years but there is still always some investment going on

Continuedgtgt

z Zippersquos headquarters in

Wertheim Germany

Zippe company profileindd 2 31116 926 AM

Supplier profi le Zippe

Glass International March 2016

ww

wg

lass

-int

erna

tion

alc

om

26

Are you currently developing any new technologies or investing in any RampD efforts that you can tell us about I canrsquot tell you all the details but batch and cullet pre-heating will continue to be advanced and will be made more user-friendly Last year we successfully incorporated and started up at Nampak the fi rst cullet pre-heater that was built overseas and not in Europe and this gives us hope and confi dence for similar cases

Our latest generation of batch chargers the Vibrotube is having a lot of success and so we will continue to develop this system in the future It combines all the advantages of previous chargers without the disadvantages which is to say the screws The screw charger is always a disadvantage because it has a screw which needs to be replaced from time to time and the Vibrotube doesnrsquot have that That is another example of sound development

Also user-friendly and more advanced control systems with more management information capabilities ndash this is another area that we are strongly focused on

In your view what are the most press-ing challenges and opportunities fac-ing the glass industry at the moment Itrsquos always the same glass has a certain weight and glass breaks These are the two disadvantages the comparatively heavy weight and the ability to break Everything else speaks for glass ndash there is no other disadvantage It is probably not more expensive than other packaging materials it does not react with any of its contents which is a fantastic ability especially in food packaging and its transparency is great

Energy consumption is also a big factor so cullet-handling systems need to be more advanced in the future These are the biggest challenges

You are President of the VDMA which of course supports glasstec What is it about the show that makes it so impor-tant to the glass industry

First of all it is by far the largest glass show in the world It has a variety of exhibitors and the glass industry itself showcases its products there especially in terms of fl at glass It also has a broad range of technology suppliers to the glass industry which is equally important All the key technology suppliers are at glasstec with large booths that show real machinery ndash at least partly We cannot build a batch house at glasstec it would be larger than one of the halls

Ultimately itrsquos a great place to come together and itrsquos conveniently located It is fi rmly established in peoplersquos minds ndash people are in the habit of going there every two years at around the same time There are other events organised around it such as conferences but the main thing is that you have all the big exhibitors there Every glass person should be there for two days every two years Thatrsquos how we see it

What does your role as President of the VDMA entail in general Do your duties increase in a glasstec year I have been President of the VDMA for six years now and the role entitles you to be the head of the organising committee on the board of glasstec During a glasstec year there is a lot more work than in normal years because you have to prepare meetings and make decisions such as how the opening events will look Of course Messe Dusseldorf prepares all of this very professionally but they also need the advice and the assistance of the board Itrsquos a great role and Irsquom happy to fulfi l it Itrsquos very demanding and very challenging but you always grow with your challenge

Zippe Wertheim Germanywwwzippede

ldquoNot to forget

Iran - there will

be a lot of

demand for new

techniques in

this country

after years of

isolationrdquo

A Zippe batch plant

at SGD in France which

began operation at the end

of 2015

z Zippersquos Vibrotube batch charger

Zippe company profileindd 3 31116 926 AM

Lubrication

Glass International March 2016

Swabbing Robot lubricant success

The hollow glass market has to catch up on new technologies to achieve a higher effi ciency and reach customersrsquo expectations A lot of innovation has already taken place

but there is still a lot to do In this context a huge contrast exists highly automated IS machines are usually still operated with manual swabbing to lubricate the moulds

Belgian company Socabelec known in the glass industry for turnkey automated production lines developed an automatic spray system for Heye International The spray system effi ciently replaces the manual operation of swabbing the blank moulds

However it only succeeded in meeting the required results with the development of a specially designed lubricant by the Belgian company VDV Lubricants the Glassline SwabMatic 180

Based on their respective know-how in the glass industry the two companies have demonstrated that the machine and appropriate lubricant can generate substantial results zero rejects from swabbing no need for section stops a 75 saving on lubrication consumption and improved operator safety

Recent on-site testing on a Heye IS machine ndash NNPB processlight bottles has proven these results and the glass plant was happy to see a higher production output within the specifi cations

ChallengesBeside the automation approach it was challenging for VDV LubricantsndashGlassline to develop the appropriate lubricant The combination of know-how present in the Glassline product range for manual swabbing and the technical team of the company have contributed to a successful conclusion to the project

Lubricating the blank mould is a specifi c process and requires the following criteria a good friction coeffi cient between glass and mould stable in time and something non-polluting and safe for the operator An additional requirement for automatic swabbing was to have a formulation able to be effi ciently sprayed on the blank mould surface Glassline SwabMatic is formulated with a combination of oils solids and additives

VDV Lubricants and Glassline will now in partnership with Socabelec further update the Glassline SwabMatic accordingly to other types of process such as blowblow pressblow and others

Director VDV LubricantsGlasslineSales amp Technical Manager VDV LubricantsGlasslineBaasrode Belgium francoisbreyevdv-lubcomwwwglasslinebe wwwsocabeleccom

Dirk Jongers and Francois Breye discuss how a lubricant has helped replace the manual operation of the swabbing of blank moulds during the glassmaking process

Contact us vidromecanicavidromecanicacom wwwvidromecanicacom

bull Belt and spindles tempering lines bull Decorating lehrs bull Chemical tempering ovens bull Roller annealing lehrs bull Mold pre-heating kilns bull Stackers + cross conveyors

bull Scraper conveyors bull Cullet crushers bull Thermal shock test systems

COLD-END COATING

HOT-END COATING

ANNEALING LEHRS

Belt Cleaning Brush

2015 anuncio HALF PAGE ARCA TSF HOT bleed off 3mm CMYK v4indd 1 24042015 161042

VDVindd 1 3916 245 PM

History

Glass International March 2016

ww

wg

lass

-int

erna

tion

alc

om

28

Last year the ovenware product Pyrex celebrated its centenary and Coca Colarsquos iconic bottle was first patented

in 1915 The same year Wes Turner began a mission to revolutionise the UK Glass Industry which led to the formation of the Society of Glass Technology (SGT)

Wes Turner was born in 1881 in Wednesbury West Midlands to William and Blanche Turner the second of seven and their first son His father a man of strong Christian principles was at various times a railway porter signalman ironworker postman and insurance agent Against the odds including polio at three Turner excelled receiving accolades at school and progressed to higher education in Birmingham a Chemistry BSc in 1898 a Masters degree and the Erhardt research prize

In 1904 he was appointed assistant lecturer in Physical Chemistry at the University of Sheffield Characteristically his first observation was the lack of order in its chemical stores His organisational skills quickly remedied this He was keen to apply his knowledge to industrial processes and began lecturing to local metallurgists even offering evening classes He wrote on science and industry in the local press (1909) and became President of the Sheffield Society of Applied Metallurgy (1914)

World War 1 began in July 1914 Following Turnerrsquos suggestion to his vice-chancellor the University commissioned a scientific advisory committee in September 1914 to help manufacturers adapt Inevitably he was appointed secretary WW1 also proved a wake-up call to the UK glass industry which had become moribund relying on secret recipes passed down the generations and unable even to measure furnace temperature The sudden lack of imports from the continent required them to extend their product range particularly in laboratory ware and optical components source raw materials domestically

and adapt their technologies Firms in Rotherham Mexborough and Barnsley were quick to seek help and Turner was quick to respond In May 1915 a report on lsquoThe Glass Industry in Yorkshirersquo proposed that a centre for research and teaching on glass manufacture be created In June the proposal became a reality led by Turner The Department of Glass Manufacture soon became the Department of Glass Technology the first in the world

Unusually it was administered by a lsquoGlass Research Delegacyrsquo with members from both the university and industry not by the University Council

The freedom this gave Turner meant he was not always popular with his academic colleagues but lsquothen orthodoxy would have been a serious handicap to a man of Turnerrsquos foresight and drive for innovationrsquo (Douglas) He particularly appreciated the lack of a direct telephone line to the Vice Chancellor

Turner soon strengthened his links to industry by creating lsquothe SGTrsquo which first met formally in November 1916 Wisely the SGT selected its first president from industry Frank Wood of Wood Brothers Barnsley with Turner as secretary Its aim was to strengthen collaboration not only between academia and industry but also between its industrial partners Turner perceived that these inward looking firms shared many problems best solved by working collaboratively

The SGT offered a forum for frank discussion of common issues From 1917 it was enhanced by adding a library an information database and publishing transactions of meetings and research proceedings in its Journal of the Society of Glass Technology Early issues remain an amazingly rich source of knowledge both the physical chemistry of making glass and its properties The SGT still maintains this philosophy and is this year celebrating its centenary with an international conference and several colloquia (wwwsgtorg)

After the war Turner with almost missionary zeal began contacting international glass experts In the 1920s he was negotiating with Prof Gehlhoff of the DGG in Germany and others in the USA France Belgium Italy and Spain Reciprocal conferences and factory visits became almost commonplace and in 1933 led to the foundation of the International Commission on Glass (ICG) still active and represented in 33 countries (wwwicglassorg)

During these visits Turner acquired a substantial Glass Art collection often pieces created uniquely for him or experimental samples by eminent artists In 1943 he donated it to the university where it forms the Turner Museum of Glass He also received many awards (eg OBE FRS DSc) and yet more from overseas Even after retiring (1945) he remained active until his death in 1963

By 1955 the university was pursuing fundamental research alongside industrial trouble shooting and this entailed different funding streams To solve the associated administrative issues the British Glass Industries Research Association (BGIRA) now Glass Technology Services (GTS) was created and housed in a new building next door In 2003 they moved to Chapeltown Sheffield The SGT now shares the same home Professor Turnerrsquos legacy is enormous and retains an ability to adapt in a changing world Herersquos to the SGTrsquos bicentenary r

BibliographyR W Douglas Biographical Memoirs of Fellows of the Royal Society Vol 10 (Nov 1964) pp 325-355F J Gooding amp E Meigh Glass and WES Turner Published by the SGT 1951

Curator of the Turner Museum of Glass Sheffield University UKwwwturnermuseumgroupshefacukjmparkersheffieldacuk

The SGT 100 not out

Prof John ParkerTurner Museum of Glass and ICG

Historyindd 1 31116 253 PM

British Glass

Glass International March 2016

ww

wg

lass

-int

erna

tion

alc

om

30

AllGlass Scotland produces more than 15000 tonnes of glass beads annually for a host of applications