Gears Handout

-

Upload

api-3827852 -

Category

Documents

-

view

2.609 -

download

4

Transcript of Gears Handout

Chapter 4

Gears and gearing

Major topics in this chapterSimple gear trainsCompounded gear trainsEpicyclic gear trains

Objectives

• To be able to distinguish the different types of gears.

• To be able to determine the speed ratios of simple and compounded gear trains.

• To be able to determine the speed ratios of simple and compounded epicyclic gear trains.

4.0 Introduction

Gears are a machine element that is used totransmit rotary motion andtransfer power betweenmachinery shafts. As the shaft rotates, the gears (which pass through the centre of the shafts)also rotates. Gears of different sizes and arrangement can be used to increase/decrease the rateof rotation, change the direction of the axis of rotation, and convert rotary motion to linearmotion.

Some of the advantages (compared to pulleys and belt systems) and/or features of gears areas follow;

• Operates without slip,

• Has a large operating range (in both speeds and torques),

• Able to transmit motion between parallel, intersecting andskewed shafts,

• Have a potentially long life.

In this chapter, we begin by looking into the different typesof gears and their classifications.Next, we attempt to understand the meshing process of two gears and how the involute profilemeets the condition for correct gearing. Finally, we expandon our basic understanding of speedratios and analyse gears trains (both simple and epicyclic)and hence determine their relevantspeed ratio.

Gears can be classified according to the orientation of the shafts’ axes, i.e., parallel, inter-secting and skewed (neither parallel nor intersecting).

112

CHAPTER 4. GEARS AND GEARING 113

Parallel shafts

The meshing gears that are mounted on parallel shafts are known asspur gears. When two spurgears of different sizes mesh together, the larger gear is called a wheel while the smaller gearis called a pinion. For spur gears, the teeth lies in parallelto the shaft axes. Figure 6.1 shows apair of spur gear and a rack & pinion gear set. Note that the rack and pinion gear system is usedto convert rotary motion into linear motion. While the rack is still considered a gear, it is clearthat the axis of rotation of the rack would lie at infinity.

Figure 4.1 Picture of a pair of spur gear (shown on the left) and a rack & pinion (shown on the right)[http://www.mech.uwa.edu.au/DANotes/gears]

The contact made between the a pair of spur gear can either beinternal or external (See figure6.2). With the external arrangement, the pinion is located next to the spur gear. Hence therotation of the two shafts are opposite in direction. In contrast to the external arrangement, thepinion must lie inside the wheel to make internal contact. Asa result, the rotation of the twoshafts (in the internal arrangement) would be in the same direction.

Figure 4.2 Contact between the gears shown on the left isinternal while for those gears shown on theright, the contact isexternal. [http://www.engineering.com]

In addition to spur gear,helical gear is also classified under the ‘parallel shafts’ orientation.However, in contrast to spur gear, the teeth are not parallelto the shaft axes. Instead, they liealong helices about the axes. The difference in meshing of the helical gears over spur gearsis the former form a gradual contact across the teeth while for the latter, contact is over theentire teeth. This results is a smaller impact loading when helical gear is used. The benefits ofa helical gear over a spur gear are as follow; less noisy, can withstand a larger load, and have alonger life.

CHAPTER 4. GEARS AND GEARING 114

Figure 4.3 Picture of a pair of double helical gear [Courtesy ofhttp://www.mech.uwa.edu.au/DANotes/gears]

Intersecting shafts

Bevel gears are used when the axes of the two shafts intersects at a particlar angle. While theycan also be designed to work at other angles too, most bevel gears operate with the the shafts’axes at 90◦ apart. Bevel gears have teeth cut on a cone instead of a cylinder blank. An exampleof two bevel gears is shown in figure 6.4.

Figure 4.4 An example of a straight bevel gear pair. [Photo courtesy of Emerson Power TransmissionGroup]

Similar to spur gears, straight bevel gears too have a large impact loading because the entireteeth maintain contact at all times. A large impact loading results in noisy gears and a smallrange of torque. Hence, when it is necessary to transmit motion quietly through a right angle athigh velocities, spiral bevel gears can be used. Similar to helical gears, spiral bevel gears haveteeth cut in a helix form on the surface of a cone. As a result, spiral bevel gears are less noisyand have a longer life when compared to straight bevel gears.A practical application of spiral

CHAPTER 4. GEARS AND GEARING 115

bevel gears is the rear axle gearbox of motor vehicles. An example of a pair of spiral bevel gearis shown below in figure 6.5.

Figure 4.5 An example of a spiral bevel gear pair. [Photo courtesy of Emerson Power TransmissionGroup]

Skewed shafts

When the shafts are neither parallel nor intersecting, the shafts are said to be skewed. For suchsituations, the two types of gears are as follow;i. Spiral gears (rarely used as the range of torque is small),andii Worm and Wheel (most common).

Worm and wheel gear system is usually used when a large reduction in speed is required.Another interesting feature of the worm and wheel gear system is that while the worm caneasily turn the gear, the gear cannot turn the worm. This is because the angle on the worm is soshallow that when the gear tries to spin it, the friction between the gear and the worm holds theworm in place. This feature is called ‘self locking’ and is useful for machines such as conveyorsystems, whereby the self locking feature can act as a brake for the conveyor when the motor isnot turning.

Figure 4.6 Picture of a worm & wheel gear system [Photo courtesy of http://www.engineering.com]

CHAPTER 4. GEARS AND GEARING 116

4.1 Speed (or gear) ratio

Let us consider two circular disks (as shown in figure 6.1) that are rolling about each other. Ifone disk is rotated, friction will cause the other disk to rotate too. From insight, it is clear thatthe rotation of the disks is opposite in direction.

Figure 4.7 Two disks in rotation.

The velocity at the point of contact,v, is identical for both disks. The expression forv is asfollow;

v = ω1r1 = ω2r2,

∴ω1

ω2= −

r2

r1. (4.1)

Equation 6.1 states the speed ratio of the two disks as a function of the relative size of the twodisks. Note also that the above ratio has a negative sign to indicate that the direction of the twodisks is opposing one another.

In practice, smooth discs are rarely used to transmit power.This is because the discs tend toslip, and hence can’t be used to transmit large amount of torque. We can turn the circular disksinto gears by adding teeth into the disks.

Constant velocity gear ratio

In order for any gear system to maintain a constant velocity gear ratio, the tooth profile mustobey theFundamental Law of Gearing as stated below;

‘For a pair of gears to transmit a constant angular velocity ratio, theshape of their contacting profiles must be such that the common normalpasses through a fixed point on the line of centres’

The fundamental law of gearing can be shown schematically asfollow in Figure 4.8.

CHAPTER 4. GEARS AND GEARING 117

Figure 4.8 Schematic of two gears with the common normal line drawn.

Note that the fixed point on the line joining the centres of thetwo gears is known as thepitchpoint. As it is the point dividing the line joining the two centres of the gears, its position woulddetermine the gear (or speed) ratio of the gearing system. The dashed circular lines found inFigures 4.8 and 4.9 are known as the pitch circle. The pressure angle is defined as the anglebetween the common normal at the point of contact and the common tangent to the pitch circles.

Figure 4.9 Schematic of two gears with the common normal line drawn.

4.2 The involute

The two tooth profiles that meet the condition of correct gearing are thecycloidal andinvoluteprofiles. Theinvolute profile has advantages of1. being easy to manufacture, and2. does not require close tolerance between shaft locations.

Figure 4.10 shows how an involute profile is created. The pathAK generated as lineMNrolls about the circle (without slipping) is theinvolute. Alternatvely, it is also the path generatedas a ‘cord’ unwinds from the circumference of a circle.

The involute has the property that any point on the involute,the normal will always betangential to the base circle. Therefore, the involute meets the condition for correct gearing.

CHAPTER 4. GEARS AND GEARING 118

Figure 4.10 Diagram of an involute.

4.3 Gear ratios

When the position of the various gears are fixed in space, it issimple matter to calculate theoverall gear ratio. For this course, the gear ratio is definedas follow:

Gear ratio= Input speedOutput speed (4.2)

The gear ratio in terms of pitch circle diameter,D, is as follow;

ω1ω2

= −D2D1

(4.3)

If two gears are to mesh, the teeth must be of the same size on each gear. Therefore, thenumber of teeth then must be proportional to the circumference (and hence the diameter too).Three different methods are used to define tooth size. They are as follow;

• Module

Module= DiameterNumber of teeth

D1

N1=

D2

N2.

• Diametral Pitch

Diametral pitch= Number of teethDiameter

N1

D1=

N2

D2.

• Circular Pitch

Circular pitch= CircumferenceNumber of teeth

There are some simple relationships between these three ratios:

Module =1

Diametral pitch,

Circular pitch = π×Module,

Diametral picth =π

Circular pitch.

CHAPTER 4. GEARS AND GEARING 119

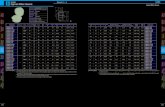

4.4 Simple gear trains

A gear train usually implies that the number of gears that aremeshing consists of two gears ormore. If every shaft has only one gear each, the gear train is called a simple gear train.

The diagram shown below is a simple gear train system. Find the speed ratio.

ω1

ω5= (

ω1

ω2)(

ω2

ω3)(

ω3

ω4)(

ω4

ω5)

= (−D2

D1)(−

D3

D2)(−

D4

D3)(−

D5

D4)

= (−N2

N1)(−

N3

N2)(−

N4

N3)(−

N5

N4) =

N5

N1

It is clear that the speed ratio depends on:1. Number of teeth in the first and last gears only, and2. Number of gears in the train ( affects the sign)

Another example of a simple gear train is shown in the diagrambelow;

Find the gear ratio.

ω1

ω5= (

ω1

ω2)(

ω2

ω3)(

ω3

ω4)(

ω4

ω5)

= (−N2

N1)(−

N3

N2)(−

N4

N3)(+

N5

N4) = −

N5

N1

CHAPTER 4. GEARS AND GEARING 120

4.5 Compound gear trains

In contrast to a simple gear train, there may be more that one gear per shaft in a compound geartrain. This implies that the multiple gears would also be rotating in the same direction, and havethe same magnitude too.

An example of a compound gear train

Note that gears 2 and 3 are compounded, i.e., rigidly connected together, and therefore theywould rotate at the same speed.To calculate the speed ratio,we first have to note the path ofmotion, i.e.,

1→2→3→4

Speed ratio =ω1

ω4,

=ω1

ω2

ω2

ω3

ω3

ω4

= (−N2

N1)(1)(−

N4

N3)

Unlike the simple gear train, a compound gear train involveseachof the gears in the speedratio.

4.6 Epicyclic gear trains

Epicyclic gear trains are characterised by the fact that thecentre line of some gears arenot fixedin space. These gears are calledplanet gears. The centre lines move in a circular path aboutthe central axis of the gear train.

Epicyclic gears have significant advantages over fixed-axesgear trains;

• The arrangement is compact, i.e., not bulky.• The gears are constantly in mesh.

CHAPTER 4. GEARS AND GEARING 121

• The load is shared between several gears.• Reverse is available without the need for an additional shaft.• Load can be applied gradually.• Several gear ratios can be obtained.

Side view of a simple epicyclic gear train (simplified)

Frontal view of a simple epicyclic gear train (simplified)

From the two diagrams above, it is clear that similar to the ring, the arm is also rotatingabout the central axis. Note that there are three shafts thatmay act as input or output for thegear train.

• Shaft attached to thesun gear,

• Shaft attached to thearm, and

• Shaft attachd to thering.

Since there are three shafts involved, it is necessary to define the motion of one of them inorder to calculate the ratio of the other two. For example, thering gear may be held stationary,and therefore, the ratio of the speed of the sun to the speed ofthe arm can be calculated.

First, we would have to find the relationship of the gears in terms of the number of teeth.Use geometry to establish the relations between the gears interms of size.

CHAPTER 4. GEARS AND GEARING 122

Note that the teeth must be of the same size in order for the gears to mesh, i.e., themoduleis identical for all the gears. Therefore, we can subtituting the module equations into the geo-metrical relationship and hence find an expression in terms of the number of teeth;

Now that we have found the relationship between the gears in terms of teeth number, whatabout the gear train relationship? It is clear that the normal relationships for gear ratios andteeth numbers do not apply. This is because the centre lines of the planets are not fixed in space.The former only apply when the centres are fixed in space.

Since it is thearm(or carrier) that is causing the centre of the planet to move in space, it isa good idea to write the angular velocities of the gearsrelative to the arm.

Then thearmwould appear to be stationary, while the angular velocitiesof the various gearswill change and become those that arerelative to the arm.

The angular velocity of the gears (relative to the ground) is shown schematically below;

The angular velocity of the gears (relative to the arm) is shown schematically below;

CHAPTER 4. GEARS AND GEARING 123

In the above diagram, thearmhas become‘stationary’.

If the arm now appears to be stationary, the angular velocities of the gears (writ-ten relative to the arm) would follow the normal relationship with respect to thenumber of teeth and the(relative) rotational speeds.

Thus,relative to the arm, (which now appears stationary) we write - (for example for externalteeth);

[

ω1

ω2

]

arm= −

(

N2

N1

)

Note: each of the rotational speeds is writtenrelative to the arm.

Let us apply the relative velocity method to a simple epicyclic gear trainAssuming that the sun is the input while the ring is the output, we would have to form thequotient of theangular speed of the sunto theangular speed of the ring. Both are measuredrelative to the arm.

Consider the pathsun→ planet→ ring. The gear ratio is as follow;[

ωsun

ωring

]

arm=

(

ωsun

ωring

)

arm

First consider the left hand side of the equation. The angular speed of the sun relative to the armis given as follow;

ωsun −ωarm,

and the angular speed of the ring relative to the arm is given as

ωring −ωarm

Therefore the left hand side of the equation becomes;

LHS =ωsun −ωarm

ωring −ωarm

CHAPTER 4. GEARS AND GEARING 124

Now let’s consider the right hand side of the equation. Sincethe arm appears to bestationary,the right hand side becomes as follow;

(

ωsun

ωring

)

arm

=ωS

ωP

ωP

ωR,

= (−NP

NS)(+

NR

NP)

Note that the planet and ring rotate in the same direction relative to the arm. The ring hasinternal teeth. Equating both sides of the equation produces

ωS−ωAωR−ωA

= −NRNS

(4.4)

All simple epicyclic gear trains can be solved using this equation. It is a normal equation for asimple gear train, except that the gear speeds are now written relative to the arm.

Example 1

The sun in a simple epicyclic gear train has 40 teeth, and the planet has 20 teeth. The ring gearis held stationary while the sun gear rotates at 100 rpm in theclockwise direction. Find thespeed of the arm.

Step 1 First find the number of teeth present in all the gears.

CHAPTER 4. GEARS AND GEARING 125

Step 2 Consider the path fromsun→ planet→ ring

Step 3 Having found the number of teeth and the equation for the gearratio, we can determineits value.

Therefore, the arm rotates in the same direction as the sun, but at 1/3 the speed of the sun.

Example 2

The sun in a simple epicyclic gear train has 40 teeth, and the planet has 20 teeth. The ring gearis held stationary while the sun gear rotates at 100 rpm in theclockwise direction. Find the

CHAPTER 4. GEARS AND GEARING 126

speed of the arm.

Step 1 From geometry, we can find the relation of the gears in terms oftheir diameters. We canthen find the number of teeth in the ring gear as all the gears have the same module (conditionfor gears to mesh).

Step 2 From example 1, we have found that the equation for the gear ratio, i.e., the ratio of theangular speed of the sun (relative to the arm) to the angular speed of the ring (againrelative tothe arm) is as follow;

ωS −ωA

ωR −ωA= −

NR

NS. (4.5)

Case 1. The sun gear is made stationary, i.e.,ωs = 0. Find the following the two gear ratios;ωR/ωA andωP/ωA.

Case 2. Instead of the sun gear, the ring gear is made stationary, i.e.,ωs = 0. FindωS/ωA.

CHAPTER 4. GEARS AND GEARING 127

4.7 Compound epicyclic gear train

We will consider a number of different compound epicyclic gear trains, to illustrate the methodof analysis. Note that the actual approach adopted will depend in each case on the detail of theconfiguration. Therefore, it is important to understand thebasic concepts which can be adaptedto suit a particular configuration.

Similar to the previous section on simple epicyclic geaer train, here we will examine therelationships that allow us to calculate the number of teethin the various gears, and carry outsome typical calculations of gear ratios.

Example 1A compound planet gear and two sun gears.

The planet gears are rigidly connected together with a shaft. The planets and shaft are free torotate in the housing connected to the arm.

Step 1. From geometry, find the relationship of the gears in terms ofdiameter. Note that thedistance between the centre line of the planet gears, and thecentre line of the sun gears is fixed.

Step 2. Since the gears have the same module, therefore, we can find the relationship of thegears in terms of the number of teeth.

Step 3. In determining the gear ratio, we may consider either path;(S1 → P1 → P2 → S2) or(S2 → P2 → P1 → S1)

CHAPTER 4. GEARS AND GEARING 128

If we consider path (S1 → P1 → P2 → S2), the gear ratio is as follow;

Example 2. Compounded planets with sun and ring.

Step 1. Use geometry to find the equation for the gears in terms of thepitch circle diameter.Again, recall that the vertical distance between the two centre lines is fixed.

CHAPTER 4. GEARS AND GEARING 129

Step 2. For teeth of the same module, we can write the expression forthe number of teeth byusing the the geometrical relationship.

Step 3. Let’s consider the pathS1 → P1 → P2 → R2.

The gear ratio (written relative to the arm) is as follow;

Example 3In the compound epicyclic gear train shown, all teeth have the same module. The driving gear,A, has 14 teeth, the ring gear, C, has 100 teeth, and ring gear,E, has 98 teeth. Gear C rotates at1 rpm anticlockwise while gear A rotates clockwise at 100 rpm. What is the speed of E?

CHAPTER 4. GEARS AND GEARING 130

First find the number of teeth in gear B.

Next, we can find the number of teeth in gear D.

We need to calculate theoutput speed (E), but since our calculations will require thearm speed,we have two unknowns and only one equation! Therefore, we must first calculate thearm speed.

Let’s consider path A→ B → C (relative to the arm)

We know that the sun gear A rotates 100rpm clockwise, and the ring gear C rotates at 1 rpmanticlockwise. The gear ratio is as follow;

CHAPTER 4. GEARS AND GEARING 131

Now that we have found the arm speed, we can next determine thespeed of the planet gear B.There are several possibilities! Perhaps path A→ B (relative to the arm)?

What if we have used path C→ B? Would we still get the same answer as the previous path ofA → B?

CHAPTER 4. GEARS AND GEARING 132

It is clear that the path doesn’t really matter at all! Are youconvinced?

To find the speed of the output, E, a possibility of the path is A→ B → D → E (as usual,relativeto the arm)

Let’s check our results by considering an alternative path,i.e., E→ D (relative to the arm).

CHAPTER 4. GEARS AND GEARING 133

In case you are not totally convinced yet, let’s check our results again by considering anotheralternative path, i.e., C→ B → D → E (relative to the arm)

Example 4

CHAPTER 4. GEARS AND GEARING 134

A compound epicyclic gear train consists of two compounded planets,P1 andP2, a sun gear,S,and two ring gears,R1 andR2. The common carrier (arm) for the planets is free to rotate onthe input shaft. All gears have the same module. Find the gearratio given that ring Gear 1 isstationary and the number of teeth are as follows:

Gear Teeth

S 10P2 35P1 34R1 79R2 80

As a first step, let’s check the number of teeth in the simple epicyclic train.

Next, we check the teeth number on the other side. Note that the shafts’ axes are in parallel,i.e., distance between the sun’s and the planets’ centre lines must be fixed.

CHAPTER 4. GEARS AND GEARING 135

Having checked that the number of teeth is right, we can proceed to derive the gear ratio. Ifwe had consideredonly the simple epicyclic gear train (S1P2R2), we would not be able to findthe required gear ratio (input/output). This is because we do not know the speed of the carrier(arm),C1 (which is free to rotate on the input shaft) yet.

Let’s consider the pathS → P2 → P1 → R1. As usual, the path must berelative to the carrier (orarm)

CHAPTER 4. GEARS AND GEARING 136

Now that we have found the arm speed (sort of), we can try to find the output speed. Let’sconsider the pathS → P2 → R2, all relative to the arm (as usual)

Assuming that the input speed is 552 rpm, the arm speed and theoutput speed are as follow;

How about the speed of the planets? Which path can we use? There are a couple of options forthe path, i.e.,S → P2 or R2 → P2 or R1 → P1. However, regardless of the path, each should give

CHAPTER 4. GEARS AND GEARING 137

the same result!

Let’s try R1 → P1 (relative to the arm)

Let’s try a different path,S → P2 to check our results.

CHAPTER 4. GEARS AND GEARING 138

Is it possible, for a given input, to rotate the ring gearR1 at some particular speed, so that theoutput,R2, is stationary? We will attempt to find out now. Lets set the input speed at say 1000rpm.

Since we know the rotational speeds ofS andR2, we can consider the pathS→P2→R2 (relativeto the arm) in order to find the arm speed.

Now that we have found the arm speed, we can consider the speedof the ring gearR1. Wewould use the path as follow;S → P2 → P1 → R1.

CHAPTER 4. GEARS AND GEARING 139

4.8 Summary on the analysis of gear trains

1. The number of teeth in the gears always has something to do with the geometry of the geartrain,2. The rotational speeds of the gears (in epicyclic gear trains) are always writtenrelative to thearm,3. Observe how the gear train works to get an idea on where to start the analysis,4. In particular, look to see where there is information given or required about rotational speeds,5. Decide on a path that makes sense, and will use the information about rotational speeds,6. The path does not necessarily have to start at the input andgo to the output.