Gear motors - CLR · 3.1 Worm wheel gear motors 10 3.2 Spur gear motors 10 3.3 Planetary gear...

Transcript of Gear motors - CLR · 3.1 Worm wheel gear motors 10 3.2 Spur gear motors 10 3.3 Planetary gear...

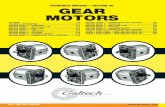

Gear motors:Choosing the best one

for each project

2Gear motors: Choosing the best one for each project

1. I have an idea and need a gear motor. Where do I begin? 3

1.1 What type of motion do I require? 3

1.2 What type of drive will be used? 4

1.3 Where will my actuation mechanism be located? 4

2. What should I consider when choosing a gear motor? 5

2.1 Technical requirements 5

2.2 Operational requirements

2.3 Environmental requirements 6

2.4 Space limitations 8

2.5 Issues related to industry regulations 8

3. Which model interests me the most? 9

3.1 Worm wheel gear motors 10

3.2 Spur gear motors 10

3.3 Planetary gear motors 10

3.4 Cycloidal or step gear motors 11

4. How to select the best supplier 12

4.1 Why select a one-stop supplier? 13

4.2 Large multinational corporation or specialized supplier 14

4.3 Which questions should the purchasing manager answer? 14

5. Why trust CLR? 15

Index

3Gear motors: Choosing the best one for each project

1. I have an idea and need an actuator. Where do I begin?

At this stage of development you start wondering how to solve the limitations linked to the design, which will enable the proper manufacturing and implementation of the project: supplier relationship, material selection, regulation analysis, etc. Being thorough and paying the utmost attention to all the details that will be a part of your project is paramount at this point. Always keep in mind that any modification on the product/process at engineering involves costs that are 10 times lower than if such a change were to be performed once production is underway.

After drafting a first design of the idea and involving your development team in the project, you come across the need to find an actuation mechanism to propel your invention so as to obtain the perfect motion and performance for the future machine. First and foremost, you should ask yourself and respond with certainty the following questions:

1.1 What type of motion do I require?

Usage of any gear motor stems from the simple need to automate or transfer a mo-tion, no matter what type it may be. Depending on the particularities of the motion to be performed, different types of gearbox models are to be used, along with their many accessories.

These actuating mechanisms may perform linear, rotary, reciprocating and oscillating motions, depending on their combination with certain components. For example:

• Linear: Use of gear racks or cams.

• Rotary: Motion-based mechanisms.

• Reciprocating: Based on electronic control systems.

• Oscillating: Actuators that control the required range of oscillating rotation through the use of an encoder or step motor.

4Gear motors: Choosing the best one for each project

1.2 What type of drive will be used?

Once we define which our motion needs are, we can delve deeper into how the trans-mission of power and energy necessary for actuation of the projected device will take place. In that sense, we would be referring to:

• Pneumatic drive: Energy is generated by air pressure.

• Hydraulic drive: These are actuators which generate motion through the flow of fluids.

• Electromagnetic drive: Mechanisms based on electromagnetism, whether through the use of a magnet or an electromagnet.

• Electric drive: Actuators which involve a motor. These may be brushed, brush-less, step, high-performance motors, or other types…

• Mechanical or electromechanical drive: These drives involve a motor that, while supported by a speed reducer gearbox, obtains an adequate output power and speed for small actuations. In other words, they reduce the power and RPMs of the motor in use.

1.3 Where will my actuation mechanism be located?

Now comes the time to ask where the gear motor is to be placed. Here, it is advis-able to place it at positions that are removed from heat or humidity sources in order to optimize their operation and diminish power loss.

In small-sized projects, we should opt for solutions based on electromechanical drives, since current gear motors allow for great reductions with small sizes and in a safe manner.

The location of the actuating mechanism will be more thoroughly studied and defined during the planning stage in order to avoid future surprises.

5Gear motors: Choosing the best one for each project

2. What should I consider when choosing a gear motor?

Even though we have already defined the basic needs of our idea, we start an in-depth analysis of the more technical aspects of our machine. In regards to ac-tuating solutions, this information is para-mount for the selection or design of the gear motor that will propel our idea. Let’s take a look at each of those aspects, one by one.

2.1 Technical requirements

They summarize the most basic data and are the first filter when choosing a gear mo-tor or designing a specific one depending on our needs. The gear motor that is to propel the mechanism should be capable of exceeding all of these values collected during the planning stage.

• Maximum torque output in kg-m or Nm: It is the force exerted over a driveshaft by a motor. Thus, the force value measures the rotating power of an object around a shaft and allows for the measurement of the ability of an engine to generate work. Therefore, if we know what the torque we need to move the load is, and which its optimal rotational speed is, we can calculate the required gear motor and motor power.

Along with this information, acceleration and stopping torques, acceleration torque output and average torque should be analysed.

• Speed or r.p.m: Here, the work of the speed reducer enables the input velocity to be regulated so that it provides a perfect output speed for operation.

• Power: Expressed in horsepower (HP) o KW: Power always substantially in-creases as the gear ratio is increased. We should consider this fact when choos-ing the power of the motor. The difficulty at this point is obtaining uniform transmission values.

6Gear motors: Choosing the best one for each project

• Gear ratio required. Studying the gear ratio is paramount, since it conditions the power output of the machine. Incorrect calculations over this ratio may cause ex-cess power and gear motor malfunction.

• Mechanical efficiency: Lastly, this value measures the amount of effective me-chanical work delivered by a machine per unit of time. In order to define the out-put magnitudes of a motor machine, the concept of loss should be considered: as a result of heat, friction, associated with the type of bearing in use, etc.

2.2 Operational requirements

These are aspects related to the daily operation of the gear motor. Defining these mat-ters will help us choose components that are more appropriate to improve precision and durability of the actuating mechanism. We could mention:

Type of motor machine:

Here we can find electric and hydraulic motors. In regards to electric motors, we could mention the following:

• Brushed motors: This is the most economical option. They offer a good torque-inertia ratio. They are common for operation under high-demand conditions. However, the brushes get worn fast and end up generating dust. Not to mention they are bad at dissipating heat.

• Brushless motors: Since they lack a mechanical commutator and brushes that may get worn out, DC brushless motors are low-maintenance and completely avoid the generation of sparks. Likewise, they cause lower shaft friction, which translates into less noise and an enhanced torque-weight ratio (power density). Therefore, these are much smaller motors than DC brushed motors.

• Step motors: They are associated with an electronic system which enables it to offer movement by specific degrees. In this manner, the motion they offer is much more precise.

7Gear motors: Choosing the best one for each project

Type of coupling between the motor machine, gearbox and output

A myriad of couplings or transmission devices can be mounted on the output shafts to transfer the motion to the client’s target machine.

• Fixed couplings: they are used when coupling shafts that require a very good or precise alignment. The most common are flange and split muff couplings.

• Moving couplings: they allow for a slight misalignment of the shafts. Here we can find a wide selection depending on our motion needs: jaw, perfect, multi-plex spring, internal gear, chain, etc. There are also couplings which are more specific, such as the friction torque limiter, or the drum brake, among others.

Lastly, coupling units are to be mounted very carefully on the shafts to avoid damaging the bearings. Additionally, they should be placed as close as possible to the housing so as to prevent possible torsion loads on the shafts.

Start-ups per hour and type of load

Most machines do not work at a constant speed or with a constant load. There are usual stops and start-ups. It is also common for the speed and working torque to vary. The transmitted torque may also increase when there are changes in the speed or load (uniform, continuous, or sudden). The traditional method to take all of these small vari-ations into account is through the application of service factors. These are multiplied by the working torque to establish the selection torque (or design torque). Thanks to this information we can select a much more precise motor for our project.

Gearbox part manufacturers publish tables where these operational specifications are precisely stated by type of motor, amount of start-ups per hour, variations in op-erational torque and total amount of hours that the device shall operate each day.

8Gear motors: Choosing the best one for each project

2.3 Environmental requirements

The environment where the machine operates may condition its daily performance and, as a result, its durability. For this reason, it is most important to consider these factors in order to select more resilient materials or apply external treatments to help counter these issues.

• Dust levels.

• Relative humidity.

• Ambient temperature.

• Atmosphere (well-ventilated location, free from corrosive gases).

2.4 Space limitations

The location and type of mounting should be well defined already at the design stage. All placement limitations should be considered in order to find the opti-mal location for the gear motor – the one that favours its proper operation. If space is limited, we can opt for planetary gear motors; their cylindrical shape allows for more flexibility, in addition to being the smallest.

In regards to installation and maintenance of the gear motor, manufacturer instruc-tions, as well as the operation manuals provided should be followed step by step. Any failure to comply may limit the service life of our gear motor.

1: Sectors such as vending demands small drive solutions.

9Gear motors: Choosing the best one for each project

2.5 Issues related to industry regulations

Each industry has strict regulations which may limit the choices of a machine’s components.

In the case of the automotive industry, brands have their own regulations for each part. Just to name one, VW 80000, which belongs to the Volkswagen group, applies to electrical components of vehi-cles under 35 tons.

When referring to the vending and HORECA industries, there are electrical safety regulations for contact with people, as well as specific health regulations in the case of food.

Moving on to the electromechanical industry, we can conclude there are no blanket regulations, even though in some cases, depending on the purpose, electromagnetic compatibility tests should be carried out. Even though commonly these types of regulations do not directly affect the gear mo-tor, they are worth mentioning to our trusted gear motor supplier so they can keep them in mind at all times.

10Gear motors: Choosing the best one for each project

3. Which model interests me the most?

Once we consider all of the aforementioned factors, we have enough information to make the gear motor selection or start with its custom design. There are many options on the market, and each one offers certain particularities which may be a better or worse fit for the requirements of our application. We will consider the fol-lowing options:

3.1 Worm wheel gear motors

The motor and gearbox shaft are positioned at a 90º an-gle. It has a toothed crown wheel that is in permanent contact with a spindle shaped as a worm screw. Each turn of the worm gear causes a tooth to move forward on the crown wheel, and thus the speed reduction.

Advantages: It is the simplest and cheapest model.

Disadvantages: Worse energy efficiency and less precision due to delays between cycles.

3.2 Spur gear motors

They use one or several pairs of gears to achieve the speed reduction. There is a significant variety of mod-els. These are the most widespread:

• Bevel: The shaft of the motor and the gearbox are at a 90° angle. Transmission using bevel gears.

• Parallel shaft: The shaft of the motor and the gear-box are at parallel planes. They allow for many output shafts,

• Coaxial: The shaft of the motor and the gearbox are aligned. They use spur gears. Their output shaft is always in line.

2: Example of worm wheel gear motor.

3: Example of spur gear motor.

11Gear motors: Choosing the best one for each project

Advantages: Constant transmission ratio, independently of the load; operation safety; increased duration; small size and high performance.

Disadvantages: High noise levels due to high friction. They are a little more expen-sive than worm wheel gear motors.

3.3 Planetary gear motors

They are characterised by the placement of up to three satellite gears which interlock with the central one (sun) offering a more uniform and precise reduction. Advantages: They are characterised by their low op-

erational noise level. Additionally, they offer better precision and efficiency, with a smaller size.

Disadvantages: Higher cost.

3.4 Cycloidal or step gear motors

They use a step motor. This motor converts the signal from an electrical impulse to a precise, specific angular displacement. Meanwhile, the speed reducer limits the speed and increases its torque.

Advantages: The most precise on the market. They are ideal for applications where reliability and motion precision are indispensable. They generate the least amount of noise and vibration.

Disadvantages: Need to use an encoder in order to place the motor at the start-up position before start-up, since the orientation of the shaft at start-up can never be known. They also stand out due to their higher price.

4: Example of planetary gear motor.

12Gear motors: Choosing the best one for each project

4. How to select the best supplier

Once all aspects related to movement, drive and location are defined, as well as the technical and operation aspects mentioned above, the search for suppliers begins. This phase requires a profound analysis and, in many cases, a re-engineering of the company’s supplier selection strategy.

There are no golden rules which guarantee selection of the best supplier of machinery or components. What we absolutely should consider is which supplier can be more versatile, knowledgeable, or which one would get more involved in the development of our engineering project. Here, we can opt for several models:

• Supplier - dealer: This supplier does not manufacture its own solutions. It acts as an intermediary between many manufacturing brands and your company. He will scour a large catalogue of products for a solution that can fit your project. It is the most limited option, since there are no standards for all applications.

• Base supplier model: This supplier can manufacture an actuator solution from a necessity and an engineering design that is already developed. In case you go to him with an idea in your head, he will not be able to draw it on a blueprint, since he does not have a design engineering department.

The opposite can also be true. It is possible for the supplier to be able to design an actuating mechanism, but to lack a production or manufacturing area, with the increased difficulties and delays this could result in.

• One-stop supplier: It is a supplier that is capable of providing a comprehensive solution to any need.

13Gear motors: Choosing the best one for each project

4.1 Why select a one-stop supplier?

Time savings

If design and production are carried out within the same environment, transport is minimised and communication is improved. If your team of engineers is to supervise manufacturing or perform constant adjustments over the initial designs of the project, your company will be losing valuable time in launching the product on the market.

Cost savings

If our supplier can control the entire development of the actuator and can provide us with all the necessary advice and components for us to manufacture the gear motor, we will work faster and with greater safety. This is the best way to avoid failures or delays that translate into mid-long term losses.

“It is estimated that the revenue from a new product is reduced by a 30% every 6 months its deployment on the

market is delayed”.

Greater involvement in the project

By knowing all aspects surrounding the development of any engineering project, the company is involved since the first call until the final delivery of the product. Further-more, this situation may improve the competitiveness of each project in our company. Starting from an idea, their greater expertise may provide very interesting insights when defining a design adapts as much as possible to the real world and the strate-gic goals of our new product.

Img 4: Specialized areas for a one-stop supplier:

Engineering Industrialisation Production

14Gear motors: Choosing the best one for each project

4.2 Large multinational corporation or specialized supplier

Choosing a large multinational corporation as a supplier has major risks you should not overlook. On one hand, its leading role on the market may limit our bargaining power. They will set margins, deadlines and conditions. Additionally, building supply relationships with these companies severely limits the possibility of switching sup-pliers due to associated costs. This situation may lead us to work with suppliers we no longer have a good relationship with, thereby limiting the know-how or fluidity of communication.

4.3 Which questions should the purchasing manager answer?

The project’s purchasing manager has a key role here. Even though he should con-sider the recommendations of the Product Manager, he has to develop a supplier evaluation system that leaves nothing to chance.

• Are they experienced in my industry?

• Do they have good logistics?

• How good is their customer service?

• Do they have standard solutions we can take advantage of under specific situations?

• Do they have an experienced engineering team?

• Do they work with other industries other than mine?

• Is it easy to contact them when I’m facing an issue?

• Can they provide solutions that fully adapt to our needs under every situation?

• Do they have the latest technology?

• Do they perform the necessary tests and studies? Are they capable of solving our quality requirements?

Improving the competitiveness of each new product is key to guaranteeing the suc-cess of each solution deployed on the market. Machinery and component suppliers play a major role in improving the performance of each new solution. It is recommend-able to be dynamic and work with several suppliers. In this way, we will confer new ideas and increased value to our organization.

15Gear motors: Choosing the best one for each project

5. Why trust CLR?

Compañía Levantina de Motorreductores is the ideal supplier to satisfy all actuator needs in your company’s projects. CLR is capable of developing an idea from the ground up to offer an efficient solution to every need. What can we offer?

01 Comprehensive solutions: Each project can be addressed comprehensively; in other words, addressing the design, production and industrialisation stages.

02 Machining: The company has cutting-edge machine tools, capable of design-ing and manufacturing all sorts of gearbox components fitting the particulari-ties of each machine.

03 Over 20 years of experience in several industries: automotive, vending, air conditioning, HORECA and security.

04 In-house, highly specialized team of engineers.

05 Turnkey solutions: CLR accompanies every project end to end, performing the most demanding quality tests on your machine.

06 Efficiency and adaptability. Fast, personalised response to every issue. CLR has hundreds of standard solutions that can perfectly be adapted for multiple purposes.

07 Our exceptional location results in great logistics. CLR is located in IBI (Ali-cante), right by major transport routes. In this way, fast distribution of all com-ponents can be offered.

“We understand your needs, turn them into ideas and manufacture your product”

At CLR we work to set your ideas in motion day by day. Contact us to find a cordial, experienced and professional supplier. No matter the type of motion you need, we will help you find it.

CONTACT US

www.clr.es | [email protected]