Gear couplings with more torque · Gear couplings with more torque The economic answer to very...

Transcript of Gear couplings with more torque · Gear couplings with more torque The economic answer to very...

siemens.com/couplings

FLENDER ZAPEX ZN

Gear couplings with more torqueThe economic answer to very rough conditions

2

Torsionally rigid coupling with maximum flexibility

Even in severe conditions our gear couplings perform. They satisfy

even highest expectations in terms of performance, reliability and

flexibility.

FLENDER ZAPEX ZN® – the coupling solution designed to meet all require-ments and show highest performance. It combines maximum torque and larg-est bores and it was especially designed for severe operating conditions

With the development of the FLENDER ZAPEX ZN highest application compe-tency were realized. The coupling designed according to demand and performance is the most economical solution for all industry sectors subject to severst operating conditions. It meets all requirements regarding the flexiblity of a coupling.

For years the Flender ZAPEX ZW and ZAPEX ZI gear couplings perform useful services in the steel industry and metal-lurgy, pumps, crushers, presses and mixers. They are very robust and transmit maximum forces despite its small size. The update of the ZI coupling provides even more customer benefits.

ZAPEX ZN replaces ZAPEX ZI The new FLENDER ZAPEX ZN will be introduced at the Hannover fair 2011. It entirely replaces our very reliable ZAPEX ZI. The new coupling was devel-oped for all applications of the ZAPEX ZI. It was conceived bringing various additional benefits to the customer.

More power and flexibility The ZAPEX ZN concept not only includes higher torque. Individuel hub cuts insure considerably higher more flexible cus-tomer orientation. This way the coupling is sooner available than the ZI having multi purpose hubs to be shortened.

Moreover the ZAPEX ZN has the addi-tional advantage of larger bores having the highest operating ratio as well as an excellent cost/performance ratio. Further possible savings can be realized by choosing a smaller size.

Fast availability of ZAPEX ZN The concept of the coupling satisfying the requirements along with structural improvements helps to streamline the value added chain of the production and to optimize supply processes.

Along with readily available hub variants very fast response and delivery times are possible.

The ZAPEX ZN is ideal for severest operating conditions such as in the

materials handling technology

3

The Siemens benefit Customers can be sure that all couplings are manufactured by Siemens in Ger-many. WE stand for highest quality and delivery reliybility but also for first class consulting and exceptional application know-how. Being the specialists in drive technology we have the product exper-tise that goes far beyond couplings. The asignment and its solution have a holistic effect, which lead to partnership and trust in Siemens.

The ZAPEX ZN is available in 12 sizes up to a torque of 162.500 Nm and a maximum bore of 288 mm ex stock.

Features:

• Double-jointed gear coupling compen-sates angular, radial and axial shaft misalignments

• Low restoring forces in case of shaft misalignments

• Small dimensions, can be used at high shock loads, with large safety reserves

• Suitable for both directions of rotation (reverse mode)

Your advantages:

• Considerably higher torque

• Larges bores are possible

• Solutions tailored to requirements

• Excellent price/performance ratio

• Very short delivery times

• Individual hubs

• Extremly robust designed

• Wide range of types

• Low restoring forces in case of high permissible shaft misalignment

Fields of application:

• Heavy machinery construction

• Metallurgical engineering

• Material handling technology

• Pumps

• Compressors

Coupling is subject to excessive stress: steel and metallurgy

Coupling suitable for potentially explosive environments.

Complies with Directive 94/9/EC for:

I 2 GD c 120 °C (T4)

II M2

1

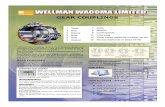

Technical Data

Dimensions in mmMass moment of inertia

Product code Weight

Size Rated Torque

Maximum speed

D1, D2 key-way DIN 6885

DA ND1/ ND2

NL1/ NL2

D4 S1 S2 S3 VA Q P J1/J2 m

TKN nKmax min. max.Nm min-1 kgm2 kg

83 1.020 8.500 0 50 117 67 43 83 3 12 21 55 52 31 0,003 2LC0330-0A -0AA0 3,2107 2.210 7.700 0 65 152 87 50 107 3 9 15 59 68 34 0,009 2LC0330-1A -0AA0 6,5130 4.020 6.900 0 82 178 108 62 129,5 3 17 31 79 85 42 0,02 2LC0330-2A -0AA0 9,8156 6.600 6.200 0 100 213 130 76 156 5 17 29 93 110 47 0,05 2LC0330-3A -0AA0 17,5181 11.000 5.800 0 116 240 153 90 181 5 19 33 109 130 58 0,09 2LC0330-4A -0AA0 25,5211 19.200 5.100 0 137 280 180 105 211 6 23 40 128 150 67 0,21 2LC0330-5A -0AA0 43250 30.680 4.500 0 164 318 214 120 249,5 6 24 42 144 175 72 0,39 2LC0330-6A -0AA0 60274 43.550 4.000 80 178 347 233 135 274 8 29 50 164 190 81 0,59 2LC0330-7A -0AA0 82307 61.750 3.750 90 198 390 260 150 307 8 32 56 182 220 91 1,1 2LC0330-8A -0AA0 115333 87.100 3.550 100 216 425,5 283 175 332,5 8 39 70 214 250 104 1.8 2LC0331-0A -0AA0 155364 117.000 3.400 120 242 457 312 190 364 8 46 84 236 265 126 2,3 2LC0331-1A -0AA0 180424 162.500 3.200 150 288 527 371 220 423,5 10 43 76 263 300 140 4,9 2LC0331-2A -0AA0 275Variant • A A

• B B• AB C

∅ D1:• Without finished bore - Without order codes 1• With finished bore - With order codes for diameter and tolerance 9

∅ D2:• Without finished bore - Without order codes 1• With finished bore - With order codes for diameter and tolerance 9

Q Diameter required for renewing the sealing rings P Length required for renewing the sealing rings, aligning the coupling parts and tightening the set screw. Mass moments of inertia apply to a coupling half with maximum bore diameter. Weights apply to the entire coupling with maximum bores.

Variant A

Variant AB

Variant B

Part1 1

Part 1

Part 1

Part 1

Part 2

Part 2

Part 2

Part 2

Further information on couplings: www.siemens.com/couplings

Contact in your area: www.siemens.com/automation/partner

You will find further information brochures and technical descriptions on our websites under the navigation point "support"

The information provided in this brochure contains merely general discriptions or characteristics of performance which in actual case of use do not always apply as described or which may change as a result of further development of the products. An obligation to provide the respective characteristics shall only exist if expressly agreed in the terms of the contract.

All product designations may be trademarks or product names of Siemens AG or supplier companies whoses use by third parties for their own purposes could violate the rights of the owners.

Siemens AG Industry Sector Mechanical Drives Alfred-Flender-Straße 77 46395 BOCHOLT GERMANY

Subject to change without prior notice 03/11 Order No.: E20001-A240-P900-X-7600 DISPO 27904 GD.MD.ST.XXXX.52.1.03 WS 03111.0 Printed in Germany © Siemens AG 2011

www.eriks.nl

AlkmaarSaffierstraat 31812 RM Alkmaar T (072) 514 17 17F (072) 514 16 25E [email protected]

AlmeloPlesmanweg 127602 PE AlmeloT (0546) 87 30 70 F (0546) 87 32 68 E [email protected]

AmsterdamDynamostraat 46-481014 BK Amsterdam-WestpoortT (020) 448 96 10 F (020) 613 77 65 E [email protected]

ArnhemPieter Calandweg 466827 BK Arnhem T (026) 362 92 44F (026) 361 00 63E [email protected]

Bergen op Zoom Van Konijnenburgweg 44 b4612 PL Bergen op Zoom T (0164) 27 55 44F (0164) 27 55 49E [email protected]

Delfzijl Deltaweg 309936 HK FarmsumT (0596) 63 38 20F (0596) 63 38 29E [email protected]

Den Haag / Marofra Neckar 2 2491 BD Den Haag T (070) 381 84 84F (070) 381 84 36E [email protected]

DoetinchemHavenstraat 557005 AG DoetinchemT (0314) 34 37 20F (0314) 34 37 41E [email protected]

EdeGalvanistraat 346716 AE EdeT (0318) 43 96 14F (0318) 64 01 04E [email protected]

EerbeekLoubergweg 196961 EJ EerbeekT (0313) 67 95 00F (0313) 65 47 68E [email protected]

EindhovenDe Witbogt 22 a5652 AG EindhovenT (040) 291 19 00F (040) 291 19 09E [email protected]

EmmenWillem Schoutenstraat 11 b7825 VV EmmenT (0591) 66 80 00F (0591) 66 80 06E [email protected]

HengeloHassinkweg 16 7556 BV HengeloT (074) 291 57 57F (074) 291 59 39E [email protected]

HoornDe Factorij 35 d1689 AK ZwaagT (0229) 21 28 82F (0229) 21 93 74E [email protected]

GoudaMarconistraat 1172809 PG GoudaT (0182) 33 11 60F (0182) 37 82 02E [email protected]

GroningenRouaanstraat 89723 CD GroningenT (050) 368 49 99F (050) 368 49 98E [email protected]

LeeuwardenJames Wattstraat 19 8912 AS LeeuwardenT (058) 215 05 87F (058) 215 85 16E [email protected]

MaastrichtAmerikalaan 286199 AE Maastricht-AirportT (043) 604 91 80F (043) 363 87 28E [email protected] RijnmondShannonweg 33, Haven 50793197 LG Rotterdam-BotlekT (010) 231 34 00F (010) 296 96 18E [email protected]

RoermondAda Byronweg 116045 GM RoermondT (0475) 37 22 70F (0475) 37 23 05E [email protected]

TilburgEllen Pankhurststraat 95032 MD TilburgT (013) 571 45 61F (013) 570 06 42E [email protected]

ZwolleAmpèrestraat 278013 PT ZwolleT (038) 467 29 20F (038) 467 29 29E [email protected]

ERIKS Servicecenters

DordrechtKeerweer 413316 KA DordrechtT (078) 652 21 21F (078) 652 21 29E [email protected]

GroningenRouaanstraat 89723 CD GroningenT (050) 368 49 49F (050) 314 62 57E [email protected]

LeeuwardenJames Wattstraat 198912 AS LeeuwardenT (058) 294 50 50F (058) 213 24 71E [email protected]

RoermondAlbert Einsteinweg 8 6045 GX RoermondT (0475) 37 22 33F (0475) 32 75 40E [email protected]

RotterdamSevillaweg 75 3047 AL RotterdamT (010) 245 50 00 F (010) 262 06 22E [email protected]

SchoonhovenBroeikweg 252871 RM SchoonhovenT (0182) 30 34 56F (0182) 38 69 20E [email protected]

ERIKS vestigingenAandrijftechniek