GDI Seminar

description

Transcript of GDI Seminar

Seminar On Gasoline Direct Injection

BIJESH P8th SEM MECHANICAL

Contents:

• Introduction• Transition of fuel supply• Major Objectives of the GDI engine• The difference between new GDI and current MPI • Basic technical features of GDI Engine• Operation• Major characteristics of the GDI engine• Achievements in GDI• Disadvantage• Conclusion

INTRODUCTION In internal combustion engines, gasoline direct injection is a

variant of fuel injection employed in modern two- and four- stroke petrol engines. The petrol/gasoline is highly pressurised, and injected via a common rail fuel line directly into the combustion chamber of each cylinder, as opposed to conventional multi-point fuel injection that happens in the intake tract, or cylinder port.

Transition of fuel supply

Major Objectives of the GDI engine

Ultra-low fuel consumption that betters that of even diesel engines

Superior power to conventional MPI engines

WHY NOT CARBURETTOR?

Carburetor has following disadvantages

•Vapour lock•Perfect air/fuel mixture cannot be obtained•Lack of throttle response•Low volumetric efficiency •Mechanical device•Compromises on emission

Why The GDI ?

• Lower Fuel Consumption and More Output•Improved Volumetric Efficiency•Very efficient intake and relatively high compression ratio deliver both high performance and response•Lower octane requirement •More precise air-fuel ratio control•More rapid starting•Reduced CO2 emissions•Improved transient response.

Advantages of GDI Engines are:

In two-stroke engines

The benefits of direct injection are even more pronounced in two-stroke engines, because it eliminates much of the pollution they cause. In conventional two-strokes, the exhaust and intake ports are both open at the same time, at the bottom of the piston stroke. A large portion of the fuel/air mixture entering the cylinder from the crankcase through the intake ports goes directly out, unburned, through the exhaust port. With direct injection, only air comes from the crankcase, and fuel is not injected until the piston rises and all ports are closed

The difference between new GDI and current MPI

•In MPI or Multi-Point Injection, the fuel is injected to each intake port•In MPI engines there are limits to fuel supply response and the combustion control because the fuel mixes with air before entering the cylinder. •In GDI, gasoline is directly injected into the cylinder as in a diesel engine•The injection timings are precisely controlled to match load conditions.

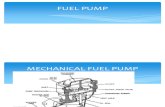

Basic technical features of GDI Engine The Upright Straight Intake Port.

The Curved-top Piston.

The High Pressure Fuel Pump.

The High Pressure Swirl Injector.

Operation• Fuel is delivered to the fuel rail by the high-pressure

pump• A closed control loop comprising the fuel pressure

sensor, pressure control valve and electronic control unit controls the pressure of the hydraulic system individually for all operating points.

• The Electronic control unit coordinates the different torque parameters according to the position of the accelerator pedal and undertakes the necessary control actions in the engine.

Engine Diagram

Major characteristics of the GDI engine

1. Ultra-lean Combustion Mode Under most normal driving conditions, up to

speeds of 120km/h, the GDI engine operates in ultra-lean combustion mode for less fuel consumption. In this mode, fuel injection occurs at the latter stage of the compression stroke and ignition occurs at an ultra-lean air-fuel ratio of 30 to 40

2. Superior Output Mode When the GDI engine is operating with higher loads or at higher speeds, fuel injection takes place during the intake stroke. This optimizes combustion by ensuring a homogeneous, cooler air-fuel mixture that minimized the possibility of engine knocking.

3. In-cylinder Airflow

The GDI engine has upright straight intake ports rather than horizontal intake ports used in conventional engines. The upright straight intake ports efficiently direct the airflow down at the curved-top piston, which redirects the airflow into a strong reverse tumble for optimal fuel injection

4. Fuel Spray Newly developed high-pressure swirl injectors provide the ideal spray pattern to match each engine operational modes. And at the same time by applying highly swirling motion to the entire fuel spray, they enable sufficient fuel atomization that is mandatory for the GDI even with a relatively low fuel pressure of 50kg/cm2

5. Optimized Configuration of the Combustion ChamberThe curved-top piston controls the shape of the air-fuel mixture as well as the airflow inside the combustion chamber, and has an important role in maintaining a compact air fuel mixture. The mixture, which is injected late in the compression stroke, is carried toward the spark plug before it can disperse.

Realization of lower fuel consumption

•Fuel Consumption during IdlingThe GDI engine maintains stable combustion even at low idle speeds. Moreover, it offers greater flexibility in setting the idle speed.Compared to conventional engines, its fuel consumption during idling is 40% less.

• Fuel Consumption during Cruising Drive

At 40km/h, for example, the GDI engine uses 35% less fuel than a comparably sized conventional engine

Realization of Superior Output

Compared to conventional engines, the GDI engine provides better volumetric efficiency. The upright straight intake ports enable smoother air intake. And the vaporization of fuel, which occurs in the cylinder at a late stage of the compression stroke, cools the air for better volumetric efficiency.

•Improved Volumetric Efficiency

•Increased Compression Ratio

The cooling of air inside the cylinder by the vaporization of fuel minimizes engine knocking. This allows a high compression ratio of 12, and thus improve combustion efficiency.

Achievements• Engine performance Compared to conventional MPI engines of a comparable size, the GDI

engine provides approximately 10% greater output and torque at all speeds.

• Vehicle Acceleration

In high-output mode, the GDI engine provides outstanding acceleration.The following chart compares the performance of the GDI engine with a conventional MPI engine

Disadvantage

Complexity and Cost :

Direct injection systems are more expensive to build because their components must be more rugged -- they handle fuel at significantly higher pressures than indirect injection systems and the injectors themselves must be able to withstand the heat and pressure of combustion inside the cylinder.

ConclusionGasoline direct injection (GDI) engine technology has received considerable attention over the last few years as a way to significantly improve fuel efficiency without making a major shift away from conventional internal combustion technology. In many respects, GDI technology represents a further step in the natural evolution of gasoline engine fueling systems.

References

1. Internal Combustion Engines By: Anand V Domkundwar.2. Internal Combustion Engines By: Mathur & Sharma. 3. www.howstuffworks.com4. www.mitsubishi-np.in5. www.autoworld.com6. Wikipedia.org

![GDI@KYqDfl] jYlagfBma]](https://static.fdocuments.in/doc/165x107/6175ca615a834c1ddf600613/gdikyqdfl-jylagfbma.jpg)

![Unique Properties of Gasoline Direct Injection (GDI ... AVL Seminar [Khalek et al. SAE 2010-01-2117] Objectives Examine GDI PM properties at various enigne conditions, which are unanalyzable](https://static.fdocuments.in/doc/165x107/5aa24c7f7f8b9ac67a8ce56a/unique-properties-of-gasoline-direct-injection-gdi-avl-seminar-khalek-et-al.jpg)