Futera XLF IOM

-

Upload

sunil-pawar -

Category

Documents

-

view

217 -

download

1

Transcript of Futera XLF IOM

-

7/21/2019 Futera XLF IOM

1/4405/14 Copyright 2014 Mestek, Inc

XLF-I0M-682-0317

Boiler ManualInstallation and Operation

Instructions

Also read and follow:

HeatNet Control Manual

Tis manual is inended only or use by a qualied heaing insaller/echnician. ead and ollow his manual, all supplemens and relaedinsrucional inormaion provided wih he boiler. Insall, sar and service he boiler only in he sequence and mehods given in heseinsrucions. Failure o do so can resul in severe personal injury, deah or subsanial propery damage.

Do not use the boiler during construction.Consrucion dus and pariculae, paricularly drywall dus, will cause conaminaion ohe burner, resuling in possible severe personal injury, deah or subsanial propery damage. Te boiler can only be operaed wih a dus-ree air supply. Follow he insrucion manual procedures o duc air o he boiler air inake. I he boiler has been conaminaed by operaionwih conaminaed air, ollow he insrucion manual guidelines o clean, repair or replace he boiler i necessar y.

Affi x hese insrucions near o he boiler. Insruc he building owner o reain he insrucions or uure use by a qualied service echnician,and o ollow all guidelines in he Users Inormaion Manual.

Finned Copper TubeGas Boilers (MB) &Water Heaters (MW)

-

7/21/2019 Futera XLF IOM

2/44

inned copper tube gas boilers & water heaters Boiler Manual

2

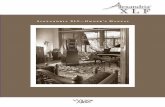

XLF PRIMARYCOMPONENTS

1. Electrical enclosure (rear)

2. Blower and motor

3. Air inlet connection

4. Flue outlet connection

5. Gas entrance

6. Boiler water return

7. Boiler water supply

8. Gas valve

9. Power entrance box

10. DP switch blocked air

inlet

11. DP switch blocked ue

12. DP switch blower prov-

ing

13. DP switch pilot air prov-

ing

14. Ignitor

15. Pilot gas valve and pilot gaspressure regulator

16. Flow switch

17. Low water cutoff

18. Pressure/temperature

gauge

19. Relief valve

20. High gas pressure switch

21. Low gas pressure switch

1

6

7

8

2

9

4

5

17

18

19

21

20

10

11

12

13

14

15

16

3

XLFRear view

Air chamber cover removed

RBIFuteraXLF-Series boilers Overview

See the Futura XLF Control manual

for electrical component locations.

-

7/21/2019 Futera XLF IOM

3/44

inned copper tube gas boilers & water heaters Boiler Manual

3

BEFORE YOU START

his manual covers he applicaion, insallaion, operaion andmainenance o a Fuera XLF Series nned copper heaing boiler/

waer heaer/pool heaer (Canada Only).

o obain he sae, dependable, eicien operaion and long lieor which his heaing boiler/waer heaer was designed, heseinsrucions mus be read, undersood and ollowed.

Te Fuera XLF Series nned copper heaing boiler/waer heaershave been design ceried by CSA or use wih naural and propanegas under he laes revision o ANSI Z21.10.3/CSA 4.3, Gas WaeHeaers, ANSI-Z21.13/CSA 4.9, Gas-Fired Low Pressure Seamand Ho Waer Boilers ANSI-Z21.56/CSA 4.7 Gas Fired PooHeaers (Canada Only) and CAN 1-3.1, Indusrial and CommerciaGas Fired Packaged Boilers. Each uni has been consruced andhydrosaically esed or a maximum working pressure o 160 psi1103 kPain accordance wih Secion IV o he ASME Boiler andPressure Vessel Code.

All aspecs o he boiler/waer heaer insal laion mus conormo he requiremens o he auhoriy having jurisdicion, or, in heabsence o such requiremens, o he Naional Fuel Gas Code, ANSZ223.1/NFPA 54-laes revision. Where required by he auhoriyhaving jurisdicion, he insallaion mus conorm o he Sandard orConrols and Saey Devices or Auomaically Fired Boilers, ANSI/

ASME CSD-1.

In Canada, he insallaion mus be in accordance wih herequiremens o CSA B149.1 or .2, Insallaion Code or Gas Burning

Appliances and Equipmen.

I insalled in he Commonwealh o Massachuses, you MUSFOLLOW he addiional insrucions conained in BIs insrucion

shee, MACODE-3, locaed in he back o his manual.he owner should mainain a record o all service workperormed wih he dae and a descripion o he work doneInclude he name o he service organizaion or uure reerence.

Direc all quesions o your BI disribuor or conac heBI Cusomer Service Deparmen a:

U. S. 260 Norh Elm Sree Weseld, MA 01085

Canada 7555 ranmere Drive Mississauga ON L5S 1L4

Always include he model and serial numbers rom he raing plaeo he boiler/waer heaer in quesion.

Before You Start . . . . . . . . . . . . . . . . . . . . . . . 3

Ratings & Capacities . . . . . . . . . . . . . . . . . . . . 4

Boiler/Water Heater Locat ion . . . . . . . . . . . . . . . . 4

Combust ion Air & Ventilation . . . . . . . . . . . . . . . . 4

General Venting Guidelines . . . . . . . . . . . . . . . . . 6

Existing Common Vent Systems . . . . . . . . . . . . . . 6

Vent System Options . . . . . . . . . . . . . . . . . . . . 6

Option1: Direct Vent Positive Pressure Category IVHorizontal Or Vertical . . . . . . . . . . . . . . . . . . . . 7

Option 2: Vertical Venting Positive Pressure, Category IVFigure 5 Or Figure 6 . . . . . . . . . . . . . . . . . . . . . 11

Option 3: Side Wall Venting Positive Pressure Category IV

Figure 7 . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Option 4: Vertical Chimney Venting Negative Pressure Category II (Multiple Boilers With Common Venting)

Figure 8 . . . . . . . . . . . . . . . . . . . . . . . . . . . 13Category II Chimney Inspect ion & Sizing . . . . . . . . . . 13

Category II Vent Connections . . . . . . . . . . . . . . . . 13

Outdoor Venting . . . . . . . . . . . . . . . . . . . . . . . 14

General Piping Requirements . . . . . . . . . . . . . . . . 16

Heating System Piping . . . . . . . . . . . . . . . . . . . 16

Domestic Water Supply Piping . . . . . . . . . . . . . . . 21

Temperature Rise Control . . . . . . . . . . . . . . . . . . 21

Gas Supply Piping . . . . . . . . . . . . . . . . . . . . . . 24

Electr ical Wiring . . . . . . . . . . . . . . . . . . . . . . . 25

General Operation . . . . . . . . . . . . . . . . . . . . . . 26Propane Gas . . . . . . . . . . . . . . . . . . . . . . . . . 26

Wiring & Control Set-up . . . . . . . . . . . . . . . . . . . 26

Controls & Interlocks . . . . . . . . . . . . . . . . . . . . 26

Sequence Of Operation . . . . . . . . . . . . . . . . . . . 27

Operating Instruct ions . . . . . . . . . . . . . . . . . . .28

To Turn Off Gas To Appliance . . . . . . . . . . . . . . . . 30

Checking & Adjustments . . . . . . . . . . . . . . . . . . 30

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . 32

Repair Parts . . . . . . . . . . . . . . . . . . . . . . . . . 35

Start-up Report . . . . . . . . . . . . . . . . . . . . . . .40

-

7/21/2019 Futera XLF IOM

4/44

inned copper tube gas boilers & water heaters Boiler Manual

4

RATINGS & CAPACITIES

Beore underaking he insallaion o he Fuera XLF Series boiler/waer heaer check he raing plae o ensure ha he uni has beensized properly or he job. Te AHI speciy he equivalen amoun

o direc cas iron radiaion ha he uni can supply under normalcondiions. Also ensure ha he uni has been se up or he ype ogas available a he insallaion sie. Oher imporan consideraionsare he availabiliy o an adequae elecrical supply, resh air orcombusion and a suiable chimney or ven sysem.

BOILER/WATER HEATER LOCATION

1. his boiler/waer heaer is suiable or indoor and oudoorinsallaions. Locae he boiler/waer heaer in an areaha provides good access o he uni. Servicing mayrequire he removal o jacke panels. Allow he minimumclearances beween adjacen consrucion and he boiler/waerheaer as lised in able 1.

Service clearances are no mandaory, bu arerecommended o ensure ease o ser vice should i berequired.

Table 1 Required Clearances

From

Clearance tocombustible surfaces

Serviceclearances

Inches mm Inches mm

Top 6 153 30 762

Back 6 153 24 610

Left side 6 153 12 306

Right side 6 153 12 306Front 6 153 30 762

2. An opimum sie will be level, cenral o he piping sysem, closeo a chimney or ouside wall and have adequae resh air orcombusion. Ensure ha he boiler/waer heaer is level romron o back and rom side o side. Use meal shims o level heboiler/waer heaer. Elecrical and elecronic componens musalso be proeced rom exposure o waer during operaion andmainenance. DO NO insall his boiler/waer heaer in alocaion ha would subjec any o he gas igniion componenso direc conac wih waer or excessive moisure duringoperaion or servicing.

3. Ensure ha he oor is srucurally sound and will suppor heweigh o he boiler/waer heaer.

he Fuera XLF may be insalled direcly oncombusible ooring, bu never on carpeing.

4. Locae he boiler/waer heaer in an area ha will preven waerdamage o adjacen consrucion should a leak occur or duringrouine mainenance. I such a locaion doesn exis, asuiable drain pan has adequaely drained mus be insalledunder he uni.

5. DO NO place his boiler/waer heaer in a locaion hawould resric he inroducion o combusion air ino he unior subjec i o a negaive pressure, see GENERL VENINGGUIDELINES.

6. NEVE place his boiler/waer heaer in a locaionha would subjec i o emperaures a or near reezing,see he FEEZE POECION secion.

Never sore combusible maerials, gasoline or anyproduc conaining ammable vapors or liquids in he

vicini y o he boiler/waer heaer. Failure o complywih his warni ng can resul in an explosion or irecausing exensive propery damage, severe personalinjury or deah!

COMBUSTION AIR & VENTILATION

his boiler/waer heaer mus be supplied wihcombusion air in accordance wih Secion 5.3, Airor Combusion & Venilaion, o he laes revisiono he Naional Fuel Gas Code, ANSI Z223.1/NFPA54 and all applicable local building codes. Canadianinsallaions mus comply wih CAN/ CGA B149.1

or .2 Insallaion Code or Gas Burning Appliancesand Equipmen, or applicable provisions o helocal building codes. Failure o provide adequaecombusion air or his boiler/ waer heaer can resulin excessive levels o carbon monoxide which can resulin severe personal injury or deah!

o operae properly and saely his boiler/waer heaer requires aconinuous supply o air or combusion. NEVE sore objecs onor around he boiler/waer heaer!

Combusion air conaminaed wih luorocarbonsor oher halogenaed compounds such as cleaningsolvens and rerigerans will resul in he ormaion

o acids in he combusion chamber. Tese acids willcause premaure ailure o he boiler/waer heaervoiding he warrany!

I he boiler/waer heaer is operaed while he buildingis under consrucion i MUS be proeced rom

wood, concree, shee rock and oher ypes o dus.Failure o properly proec he uni rom consruciondus will damage he uni voiding he warrany!

Buildings will require he insallaion o a resh air duc or ohermeans o providing make-up air i he inake air opionisn used. Any building uilizing oher gas burning appliances, areplace, wood sove or any ype o exhaus an mus be checked oradequae combusion air when all o hese devices are in operaion

a one ime.Sizing o an ouside air duc mus be done o mee he requiremenso all such devices.

Never operae he Fuera XLF in an environmensubjeced o a negaive pressure unless i is Direc

Vened. Failure o comply wih his warning can resulin excessive levels o carbon monoxide causing severepersonal injury or deah!

-

7/21/2019 Futera XLF IOM

5/44

inned copper tube gas boilers & water heaters Boiler Manual

5

All air from inside the building

I he Fuera XLF is o be locaed in a conned space, he minimumclearances lised in able 1, mus be mainained beween i andany combusible consrucion. When insalled in a coninedspace wihou he inake air opion (as in Figure 5 hroughFigure 8) wo permanen openings communicaing wih anaddiional room(s) are required. Te combined volume o hesespaces mus have suicien volume o mee he crieria or anunconned space. Te oal air requiremens o all gas uilizaionequipmen, ireplaces, wood soves or any ype o exhaus anmus be considered when making his deerminaion. Eachopening mus have a minimum ree area o 1 in2/1000 Btu/hr,2200 mm2/kWbased on he oal inpu raing o ALL gas uilizaionequipmen in he conned area. Each opening mus be no less han100 in2, 64,516 mm2in size. Te upper opening mus be wihin12 in, 305 mmo, bu no less han 3 in, 76 mmrom, he op ohe enclosure. Te botom opening mus be wihin 12 in, 305 mmo, bu no less han 3 in, 76 mmrom, he botom o he enclosure.

All air from outside the building

When insalled in a conned space w ihou ui lizing he inake airopion wo permanen openings communicaing direcly wih, or

by ducs o, he oudoors or spaces ha reely communicae wihhe oudoors mus be presen. Te upper opening mus be wihin12 in, 305 mmo, bu no less han 3 in, 76 mmrom, he op ohe enclosure. Te botom opening mus be wihin 12 in, 305 mmo, bu no less han 3 in, 76 mmrom, he botom o he enclosure.

Where direcly communicaing wih he oudoors or communicaingwih he oudoors hrough verical ducs, each opening shall have aminimum ree area o 1 in2/4000 Btu/hr, 550 mm2/kWo heoal inpu raing o all o he equipmen in he enclosure.

Where communicaing wih he oudoors hrough horizonal ducs,each opening shall have a minimum ree area o 1 in2/2000 Btu/hr, 1100 mm2/kWo he oal inpu raing o all o he equipmenin he enclosure.

When ducs are used, hey mus have he same cross-secional areaas he ree area o he opening o which hey connec.

When calculaing he ree area necessary o mee he make-up airrequiremens o he enclosure, consideraion mus be given o heblockage effecs o louvers, grills and screens. Screens mus have aminimum mesh size o 1/4 in, 6.4 mm. I he ree area hrough alouver or gril l is no known, ducs should be sized per able 2.

Canadian insallaions mus comply wih CSA B149.1 when air

supply is provided by naural air ow rom he oudoors or nauraldraf, parial an-assised, an-assised, or power draf-assised burners,here shall be a permanen air supply opening(s) having a cross-secional area o no less han 1 in2per 7,000 Btuh, 310 mm2perkWup o and including 1 million Buh, plus 1 in2per 14,000 Btuh,155 mm2per kWin excess o 1 million Buh.

Table 2 Make-up Air Louver Sizing

InputMBH

Required cross-sectional area

Wire screen in(6.4 mm)

Metal louvers75% free area

Wooden louvers25% free area

in2 cm2 in2 cm2 in2 cm2

2500 625 4031 833 5382 2500 16127

3000 750 4838 1000 6452 3000 19354

3500 875 5645 1167 7522 3500 22581

4000 1000 6452 1334 8592 4000 25808

Intake air option General guidelines

Tis conguraion provides combusion air direcly o he boilerwaer heaers air inake adaper using a dedicaed pipe when usinghe direc ven opion. Combusion air can be drawn in horizonallyhrough he same ouside wall which erminaes he exhaus gases o

verically hrough he roo, see Figure 1 hrough Figure 4. Common inake air sysems may be used provided he

common duc is sized properly. An inake combusionair damper should be insalled i he common venopion is used in he inake air pipe o each heaerImproper insallaion can resul in excessive levels ocarbon monoxide which can cause severe personalinjury or deah!

Table 3 Intake Air Pipe Sizing

InputMBH

Vertical Horizontal

in mm in mm

2500/3000 10 254 8 203

3500/4000 12 305 10 254

All joins in meal inake air sysems mus be secured using corrosionresisan aseners and sealed using a suiable Silicone caulk. I PVCor CPVC is used, he joins mus be cleaned wih a suiable solvenand conneced using a solven based PVC cemen.

Te combusion air sysem MUS be suppored by hebuilding srucure no he boiler/waer heaer.

A combusion air damper inerlocked wih he unishould be insalled in he inake air pipe when he

inlraion o subreezing air could occur, oherwisehe uni could reeze up voiding he warrany!

Intake air option Vertical guidelines

Te maximum equivalen lengh or he verical inake air pipe is100 f, 30.5 m. Each 90oelbow and he inake air erminal are equao 10 linear f, 3.0 mo pipe, see able 3.

An approved, nonresricive inake air erminal mus be used. Teinake air erminal mus erminae as shown in Figure 3. hepeneraion poin in he roo mus be properly ashed and sealed.

-

7/21/2019 Futera XLF IOM

6/44

inned copper tube gas boilers & water heaters Boiler Manual

6

Intake air option Horizontal guidelines

Te maximum equivalen lengh or he horizonal inake air pipe is100 f, 30.5 m. Each 90oelbow and he inake air erminal are equalo 10 linear f, 3.0 mo pipe. I horizonal runs exceed 5 f, 1.5 mhey mus be suppored a 3 f, 0.9 minervals wih overhead hangers.Te ceried inake air erminal rom BI mus be used, see Figure 1,Figure 2 and Figure 4.

GENERAL VENTING GUIDELINES

Te ven insallaion mus be in accordance wih Par7, Vening o Equipmen, o he Naional Fuel GasCode, ANSI Z223.1/NFPA 54laes revision orapplicable provisions o he local building codes.Canadian insallaions mus comply wih CAN/CGAB149.1 or .2 Insallaion Code. Improper vening canresul in excessive levels o carbon monoxide which canresul in severe personal injury or deah!

All ven sysems mus be ul ly suppored by he building srucureand no by he boiler/waer heaer. Appropriae himbles and re-sops mus be used where required.

Common ven sysems mus be properly engineeredand sized o provide a negaive dra o 0.02 in,0.5 mm o 0.1 in, 2.5 mm WC a he lue oule.Common posiive pressure ven sysems are no o beused. Improper insallaion can resul in excessive levelso carbon monoxide which can cause severe personalinjury or deah!

Common-ven sysems It is required that the

boiler nearest the vertical chimney be red rstwhen the horizontal distance exceeds 50% of thevertical distance. Refer to the HeatNet manual onhow to select the lead boiler. Consul he acory iany quesions. Improper insallaion can resul inexcessive levels o carbon monoxide which can causesevere personal injury or deah!

EXISTING COMMON VENT SYSTEMS

I an exising boiler/waer heaer is removed rom an exisingcommon vening sysem, he common vening sysem may hen

be oo large or he proper vening o he remaining appliances

conneced o i. A he ime o removal o an exising boiler/waerheaer, he ollowing seps shall be ollowed wih each applianceremaining conneced o he common vening sysem placed inoperaion, while he oher appliances remaining conneced o hecommon vening sysem are no in operaion.

1. Seal any unused openings in he common vening sysem.2. Visually inspec he vening sysem or proper size and horizonal

pich and deermine here is no blockage or resricion, leakage,corrosion and oher deciencies which could cause an unsaecondiion.

3. Insoar as is pracical, close all building doors and windows andall doors beween he space in which he appliances remainingconneced o he common vening sysem are locaed and oher

spaces o he building. urn on clohes dryers and any applianceno conneced o he common vening sysem. urn on anyexhaus ans, such as range hoods and bahroom exhaus, so hey

will operae a max imum spee d. Do no operae a summe rexhaus an or a boiler insallaion. Close replace dampers.

4. Place in operaion he appliance being inspeced. Follow helighing insrucions. Adjus hermosa so appliance will operaeconinuously.

5. es or spillage a he draf hood relie opening afer 5 minueso main burner operaion. Use he ame o a mach or candle, orsmoke rom a cigarete, cigar or pipe.

6. Aer i has been deermined ha each appliance remainingconneced o he common vening sysem properly vens whenesed as oulined above, reurn doors, windows, exhaus ans,replace dampers and any oher gas-burning appliance o heirprevious condiion o use.

7. Any improper operaion o he common vening sysem shouldbe correced so he insallaion conorms wih he Naional Fuel

Gas Code, ANSI Z223.1/NFPA 54. When resizing any poriono he common vening sysem, he common vening sysemshould be resized o approach he minimum size as deerminedusing he appropriae ables in Appendix F in he Naional FuelGas Code, ANSI Z223.1/ NFPA 54 and or CAN/CGA B149Insallaion Codes.

VENT SYSTEM OPTIONS

he lue producs in he ven sysem may be cooled below heirdew poin and orm condensae in he ue. Te maerials used or aCaegory IV ven mus be resisan o any corrosive damage rom uegas condensae. Te ue rom a Caegory IV ven sysem mus have

a condensae drain wih provisions o properly collec and disposeo any condensae ha may occur in he vening sysem.

Te maximum equivalen lengh or he ue oule vensysem or Category IVcondiions is 100 f, 30.5 m.Use able 4 or he equivalen lenghs per ting. able4 - Caegory IV Equivalen Lengh per Fiting charis mean as a guideline or preliminary sizing. I venlengh approaches 75% o maximum lengh lised, anengineered ven sysem calculaion mus be perormed,consul acory.

The Futera XLF may be vented the following ways:

1. OPTION 1 Direct Vent, Positive PressureCategory IV (individual venting only)Combusion air is piped rom he oudoors o he blower inle.

Ven sysem is ceried o UL 1738 or insallaions in he UniedSaes, ULC S636 or insallaions in Canada.

2. OPTION 2 Vertical Vent, Positive PressureCategory IV (individual venting only)Combusion air is obained rom he space in which he uni isinsalled. Ven sysem is ceried o UL 1738 or insallaionsin he Unied Saes, ULC S636 or insallaions in Canada.Combusion air is obained rom he oudoors or he space in

which he uni is insalled.

-

7/21/2019 Futera XLF IOM

7/44

inned copper tube gas boilers & water heaters Boiler Manual

7

3. OPTION 3 Side Wall Vent, Positive PressureCategory IV (individual venting only)Combusion air is obained rom he space in which he uni isinsalled. Ven sysem is ceried o UL 1738 or insallaionsin he Unied Saes, ULC S636 or insallaions in Canada.

Combusion air is obained rom he space in which he uni isinsalled.

o ensure proper boiler operaion, boilers ha arevened side wall and use room air mus no be red aless han 33% inpu.

4. OPTION 4 Vertical Vent, Negative PressureCategory II (common venting)equires negaive pressure in ven (naural draf). equires ameal chimney sysem approved or Caegory II vening. Tismehod is required i common vening muliple XLF boilers.

All vening and combusion air maerial supplied byinsaller. All vening maerials mus be approved or he

applicaion. Consul he ven manuacurers produclieraure.

Table 4 Category IV Equivalent Length Per Fitting

Model/Outlet

Diameter*K

Equivalent Feet

of Straight Pipe

2500

8"

3000

8"

3500

10

4000

10"

Standard Tee 1.25 35 ft 35 ft 40 ft 40 ft

Boot Tee 0.65 15 ft 15 ft 20 ft 20 ft

Cap - Low Res (UL) 0.5 15 ft 15 ft 15 ft 15 ft

45 w/Bird Screen 0.4 10 ft 10 ft 15 ft 15 ft

Elbow - 90 0.38 10 ft 10 ft 15 ft 15 ft

Elbow - 45 0.15 5 ft 5 ft 7 ft 7 ft

*Equivalent lengths based on K - factors and (5X) pipe

diameters straight length between ttings.

Mus consul acory when vening single or mulipleuni(s) over 100 equivalen ee. Mechanical sysemmay be required.

OPTION 1: DIRECT VENT

POSITIVE PRESSURE CATEGORY IV

HORIZONTAL OR VERTICAL

In his coniguraion he boiler/waer heaer blower is usedo push he ue producs o he oudoors while drawing combusionair rom he oudoors. Te Inake Air Opion insrucions under he

Combusion air & venilaion secion mus be ollowed! Te vensysem mus be sized per able 4.

Horizontal direct vent systems Figures 1 & 2

he ven maerials used in horizonal ven sysems musbe ceried o UL 1738 or insallaions in he Unied Saes, ULCS636 or insallaions in Canada. Te ceried ven erminal romBI mus also be used.

I any par o a single wall meal ven sysem passes hrough an

unheaed space, i mus be insulaed wih insulaion raed or 400o

F204oC. Srucural peneraions mus be made using approved resops. For bes resuls, horizonal ven sysems should be as shor andsraigh as possible.

Te ven sysem mus be boh gas igh and waer-igh. All seams andjoins in meal pipes mus be joined and sealed in accordance wihhe ven sysem manuacurers insrucions.

When hor izon al ven runs exce ed 5 t, 1.5 m hey mus besuppored a 3 f, 0.9 minervals wih overhead hangers. Te vensysem mus be piched down, oward he ven erminal, 1/4 inf, 20 mm/m. I any par o a single wall meal ven sysem passeshrough an unheaed space i mus be insulaed wih insulaion raedor 400oF, 204oC.

Horizonal ven sysems shall erminae a leas 4 f, 1.2 mbelow, 4 f1.2 mhorizonally rom or 1 f, 0.30 mabove any door, window orgraviy air inle ino any building.

I mus no erminae less han 4 f, 1.2 mhorizonally rom, and inno case above or below, unless a 4 f, 1.2 mhorizonal disance ismainained, rom elecric meers, gas meers, regulaors and relieequipmen; and no less han 7 t, 2.1 mabove adjacen public

walkway.

Canadian insallaions require a minimum o 6 t18.3 m clearance rom elecric meers, gas meersregulaors and relie equipmen or compliance wihCAN B149.1.

Te botom o he ven erminal(s) shall be locaed a leas 5 f, 1.5 mabove he air inake erminal(s) unless here is a minimum 5 f, 1.5 mhorizonal separaion beween hem.

Avoid erminal locaions likely o be affeced by winds, snowdrifspeople and pes. Proec building maerials and vegeaion romdegradaion caused by he ue gases.

-

7/21/2019 Futera XLF IOM

8/44

inned copper tube gas boilers & water heaters Boiler Manual

8

Vertical direct vent systems Figure 3

I any par o a single wall meal ven sysem passes hrough anunheaed space, i mus be insulaed wih insulaion raed or 400oF,204oC. Srucural peneraions mus be made using approved re-sops.

An approved, nonresricive ven erminal mus be used. Te op o averical ven sysem mus exend a leas 5.5 f, 1.7 mabove he roosurace and maximum snow line ha i passes hrough, 4 f, 1.2 mabove he inake air erminal, see Figure 3.

In addiion he ven sysem mus conorm o he dimensions shownin Figure 3. he peneraion poin in he roo mus be properlyashed and sealed.

he ven sysem mus be gas igh. All seams and joins in mealpipes mus be joined and sealed in accordance wih he ven sysemmanuacurers insrucions.

Combination direct vent systems Figure 4

Te boiler/waer heaer can be vened verically wih he inake airpiped horizonally hrough an ouside wall. Follow he insrucionsin he Inake Air Opion Horizonal Guidelines. Also ollow hegeneral insrucions in he Combusion Air & Venilaion and

General Vening Guidelines secions.

Figure 1 VENT OPTION 1: DIRECT VENT Horizontal air intake and venting for a single direct vent system

10 3.1

When running horizonal combusionair and vening or single or muliple unis,exhaus and combusion air erminals mus

be insalled on he same plane (ouside wall)in order o preven pressure dierences dueo prevailing winds. In cold climaes, double-

wall or insulaed inle pipe is recommended opreven condensaion.

-

7/21/2019 Futera XLF IOM

9/44

inned copper tube gas boilers & water heaters Boiler Manual

9

Figure 2 VENT OPTION 1: DIRECT VENT Horizontal air intake and venting for multiple direct vent systems

Figure 3 VENT OPTION 1: DIRECT VENT Combination direct vent system

-

7/21/2019 Futera XLF IOM

10/44

inned copper tube gas boilers & water heaters Boiler Manual

10

Locate exhaust terminaldownwindrom air inakeo reduce poenial or uegas recirculaion. Failureo comply could resul insevere personal injury ordeah.

Figure 4 VENT OPTION 1: DIRECT VENT Vertical air intake and venting for direct vent system

-

7/21/2019 Futera XLF IOM

11/44

inned copper tube gas boilers & water heaters Boiler Manual

11

Figure 5 VENT OPTION 2: VERTICAL CHIMNEY VENTINGVertical venting with a metal chimney system

See Table 4 for minimum pipe diameters.

Figure 6 VENT OPTION 2: VERTICAL CHIMNEY VENTING

Vertical venting using a lined masonry chimneySee Table 4 for minimum pipe diameters.

Recommended(12"(0.3 m)minimumrequired)

OPTION 2: VERTICAL VENTING

POSITIVE PRESSURE, CATEGORY IVFIGURE 5 OR FIGURE 6

Masonry chimneys, when used, mus be lined wih ameal liner ceried or Caegory IV vening.

A h orou gh in sp ec i on o h e masonr y ch im ne y mu s beperormed o ensure ha he chimney is clean, properly consruced,lined and sized. Exerior masonry chimneys should no be usedunless properly lined o preven condensaion and draf problems.able 4 liss he equivalen breeching and ue sizes required or heboiler/waer heaer.

-

7/21/2019 Futera XLF IOM

12/44

inned copper tube gas boilers & water heaters Boiler Manual

12

Figure 7 VENT OPTION 3: SIDE WALL VENT Side wall venting

Recommended(12"(0.3 m)

minimum required)

OPTION 3: SIDE WALL VENTING

POSITIVE PRESSURE CATEGORY IVFIGURE 7

In his coniguraion he boiler/waer heaer blower is usedo push he lue producs horizonally o he oudoors, seeFigure 7. he air or combusion is aken rom he spacein which he uni is insalled. Te applicable insrucions under he

Combusion Air & Venilaion secion mus be ollowed! Te venguidelines under he Horizonal Direc Ven Sysems secion musalso be ollowed.

o ensure proper boiler operaion, boilers ha arevened side wall and use room air mus no be red aless han 33% inpu.

-

7/21/2019 Futera XLF IOM

13/44

inned copper tube gas boilers & water heaters Boiler Manual

13

OPTION 4: VERTICAL CHIMNEY VENTING

NEGATIVE PRESSURE CATEGORY IIMULTIPLE BOILERS WITH COMMON VENTING

FIGURE 8Caegory II vening is required or muliple XLF boilersconneced o a common ven. Common ven sysemscanno be pressurized.

Te Fuera XLF is lised as a Caegory II appliance when venedverically ino a lised meal chimney sysem. See Figure 8 (mulipleboilers). Te chimney mus provide a negaive pressure no greaerhan 0.10 in, 2.5 mmWC a he boiler/waer heaer ue collar wihhe uni running.

When using a lised meal chimney sysem he chimneysysem manuacurers insrucions mus be ollowed.

Te ven piping mus be large enough o saely ven hecombined oupu o all o he appliances conneced ohe sysem.

I an appliance using any ype o a mechanical drafsysem operaing under posiive pressure is connecedo a chimney ue, never connec any oher applianceso his ue. Doing so can resul in excessive levels ocarbon monoxide which can cause severe personalinjury or deah!

CATEGORY II CHIMNEY

INSPECTION & SIZING

Masonry chimneys, when used, mus be lined wih ameal liner ceried or Caegory IV vening.

A h orough in spec i on o h e mas on ry chim ne y mu s beperormed o ensure ha he chimney is clean, properly consrucedlined and sized. Exerior masonry chimneys should no be usedunless properly lined o preven draf problems.

able 5 liss he minimum riser sizes required or he XLF boiler/waer heaer.

Table 5 Riser diameters to common vent for Category II venting

Input MBH in mm

2500/3000 12 305

3500/4000 14 356Noe: Tese sizes are based on a 20 f, 6.1mchimney heigh.

CATEGORY II VENT CONNECTIONS

Locae he boiler/waer heaer as close o he chimney aspossible. Use he shores, sraighes ven connecor possible orhe insallaion. I horizonal runs exceed 5 f, 1.5 mhey mus besuppored a 3 f, 0.9 m inervals wih overhead hangers.

Te boiler ven connecors should be sloped up oward he breechinga a minimum rae o in per t, 21 mmper m. On masonry

chimneys he connecor mus erminae ush wih he inside o hechimney liner (as shown in Figure 6).

Always provide a minimum clearance o 6 in, 152 mmbeweensingle wall ven pipe and any combusible maerials.

Failure o mainain minimum clearances beween venconnecors and any combusible maerial can resulin a ire causing exensive propery damage, severepersonal injury or deah!

Exi cones are avorable when used o increasehe velociy o he ue gas exiing he sack and,may also help, in cold climaes, o reduce icebuild-up. Exi cone erminaions mus be

supplied by ohers, insalled per manuacurersinsrucions, and mee local and ederal code.generic exit cone

-

7/21/2019 Futera XLF IOM

14/44

inned copper tube gas boilers & water heaters Boiler Manual

14

OUTDOOR VENTING

When insalled oudoors he Fuera III mus be ted wih he ac-ory supplied oudoor hood, air inake adaper wih ler and exhauserminal, see Figure 7A. Muliple unis mus be spaced per Figure 7B.

Te boiler/heaer mus be a leas 2 f, .62 mrom any door, windowor graviy air inle ino any building and a leas 3 f, 1 mrom anyoverhang unless local codes dicae differenly.

Avoid locaions where wind deecion off o adjacen walls, buildingsor shrubbery migh cause a downdra. he uni(s) shouild belocaed a leas 3 f, 1 mrom srucures. Oudoor insallaions areno recommended in areas where he danger o snow blockage exiss.

Do no place he boiler/waer heaer in a locaion hawould subjec i o runoff rom adjacen buildings ordamage may occur voiding he warrany!

Te boiler and sysem mus be lled wih an ehyleneglycol/waer anireeze mixure no o exceed 50%

glycol by volume. All waer piping exposed o lowemperaures mus be insulaed.

Figure 7A Outdoor Venting

Figure 7B Multiple Outdoor Units

RIOM-60 REV. A

2 FT

(0.62 M)

3 FT

(1 M)

-

7/21/2019 Futera XLF IOM

15/44

inned copper tube gas boilers & water heaters Boiler Manual

15

Figure 8 OPTION 4: VERTICAL CHIMNEY VENTING Vertical venting multiple-boiler installationsSee Table 5 for minimum riser diameter (dimension F)

Legend for Figure 8

I is recommended ha he boiler neares heverical chimney mus always be red rs when hehorizonal exceeds 50% o he verical. eer o he

HeaNe manual on how o selec he lead boiler. A negaive pressure o 0.02 to 0.10 inwc is required

in each boiler's riser when all boilers are operaing aull inpu.

Provide clearance rom he boiler o no less han6 ino combusible suraces or 24 inor service.

1. A barometric damper must be installed on the riser of each boiler,24 inabove the vent elbow. [Exception: If the vent system isdesigned using accepted engineering practices, and the designcalculations prove there is no need for barometric dampers,the barometric dampers may be omitted.] When required byapplicable codes, install a thermal spill switch on each barometricdamper.

2. Install a thermal spill switch on each barometric damper (whenrequired by applicable codes).

3. Connect each boiler riser to the common ven t with a Yconnection or Boot T.

4. Install an approved vent cap at the vent termination.

5. DIMENSIONS:B breeching lengthC chimney heightD breeching diameterF riser diameter (no smaller than the dimension given in

Table 5)

6. Size the chimney and breeching per local codes and vent pipemanufacturer's recommendations, using generally acceptedengineering practices.

Consult factory for vertical heights beyond 100 ft.

-

7/21/2019 Futera XLF IOM

16/44

inned copper tube gas boilers & water heaters Boiler Manual

16

GENERAL PIPING REQUIREMENTS

Improper piping o his boiler/waer heaer will voidhe manuacurers warrany and can cause boiler

ailure resuling in ooding and exensive properydamage! Excessive waer hardness causing scaling inhe copper hea exchanger ubes is NO coveredunder he manuacurers warrany. See able 8.Excessive piting and erosion o he inernal surace ohe copper hea exchanger ubes is NO coveredunder he manuacurers warrany i he resul o high

waer ow raes. See able 7. eurn waeremperaures below 140oF, 60oCwill resul in heaexchanger damage rom excessive condensaion

voiding he manuacurers warrany, see Primary/Secondary Piping. See Figure 9.

Shu off valves and unions should be insalled a he

inle and oule connecions o he boiler/ho waerheaer o provide or isolaion o he uni shouldservicing be necessary.

Freeze protection

Insallaions in areas where he danger o reezing exiss are norecommended unless proper reeze proecion is provided. heollowing precauions MUS be observed:

1. A coninuous low o waer hrough he uni MUS bemainained! he pump responsible or low hrough heboiler/waer heaer mus run coninuously!

2. An ehylene glycol/waer mixure suiable or he minimum

emperaure ha he uni will be exposed o mus be used. Tepump mus be capable o producing a minimum o 15% moreow and overcoming a 20% increase in head loss.Domesic waersysems mus be isolaed rom he waer heaer by he use o ahea exchanger or oher approved mehod.

3. I he uni mus be shu off or any reason he elecric, gas andwaer suppli es MUS be shu o and he uni and is pumpcompleely drained.

Improper oudoor insallaion o his uni can causeboiler ailure voiding he manuacurers warrany!

Relief valve

Pipe he discharge o he pressure relie valve as shown in Figure 9.

Never insall any ype o valve beween he boiler/waer heaer and he relie valve or an explosion causingexensive propery damage, severe personal injury ordeah may occur!

Flow Switch

Te ow swich supplied wih he boiler/waer heaer mus be wiredo he erminal srip in he conrol panel o preven he boiler romring unless heres adequae waer ow hrough he uni. Te owswich mus be insalled in he supply piping adjacen o he boileroule connecion.

Failure o properly insall he ow swich may resulin damage o he boiler/waer heaer hea exchanger

voiding he warrany!

HEATING SYSTEM PIPING

General piping requirements

All heaing sysem piping mus be insalled by a qualied echnicianin accordance wih he laes revision o he ANSI/ASME Boiler andPressure Vessel Code, Secion IV, and ANSI/ASME CSD-1, Sandardor Conrols and Saey Devices or Auomaically Fired Boilers. Allapplicable local codes and ordinances mus also be ollowed. Aminimum clearance o 1 in, 25 mmmus be mainained beweenheaing sysem pipes and all combusible consrucion. Allheaing sysem piping mus be suppored by suiable hangers no he

boiler. Te hermal expansion o he sysem mus be considered whensupporing he sysem. A minimum sysem pressure o 12 psig,82.7 kPamus be mainained.

Heating boiler piping connections

Te supply and reurn connecions should be sized o sui he sysem,per able 6.

Table 6 Supply & Return Pipe Sizing

InputMBH

Supplysize

Returnsize

2500/3000 4" FLANGE 4" FLANGE

3500/4000 4" FLANGE 4" FLANGE

Pump requirements

This low mass boiler requires a continuous minimum

water ow for proper operation. Te boiler pump mus besized o overcome he head loss o he boiler and he near-boilerpiping in order o achieve he required emperaure rise. able 7provides he hea exchanger pressure drop and emperaure risegures. Te emperaure rise across he boiler mus never exceed35oF, 19.4oC. Te adjusable pump delay urns he pump on eachime he burner res and runs he pump or 20 o 600 seconds aferhe call or hea is saised.

-

7/21/2019 Futera XLF IOM

17/44

inned copper tube gas boilers & water heaters Boiler Manual

17

Figure 9 Futera XLF Piping

A emperaure rise ouside o he range lised in able 7will resul in damage o he hea exchanger, voiding hewarrany! Te maximum allowable emperaure risehrough he boiler is 35oF, 19.4oC.

Te maximum allowable ow rae hrough a FueraXLF boiler is 260 GPM, 16.4 L/swhen equippedwih copper ubes. A cupronickel hea exchanger allowor 315 GPM, 19.9 L/s.

-

7/21/2019 Futera XLF IOM

18/44

inned copper tube gas boilers & water heaters Boiler Manual

18

Table 7 Temperature Rise Table

ModelNumber

T = 20oF T = 11.1oC

Flow Rate Pres. Drop Flow Rate Pres. Drop

GPM Ft L/s kPa

2500 217.5 10.05 13.7 29.6

3000 261.0 15.20 16.5 44.8

3500 304.5* 20.26 19.2* 59.7

4000 NA NA NA NA

ModelNumber

T = 25oF T = 13.9oC

Flow Rate Pres. Drop Flow Rate Pres. Drop

GPM Ft L/s kPa

2500 174.0 6.45 11.0 19.0

3000 208.8 9.73 13.2 28.7

3500 243.6 13.40 15.4 39.5

4000 278.4 * 17.30 17.6* 51.0

ModelNumber

T = 30oF T = 16.7oC

Flow Rate Pres. Drop Flow Rate Pres. Drop

GPM Ft L/s kPa

2500 145.0 3.71 9.1 10.9

3000 174.0 6.75 11.0 19.9

3500 203.0 9.56 12.8 28.2

4000 232.0 12.00 14.6 35.4

ModelNumber

T = 35oF T = 19.4oC

Flow Rate Pres. Drop Flow Rate Pres. Drop

GPM Ft L/s kPa

2500 124.3 2.79 7.8 8.2

3000 149.1 4.65 9.4 13.7

3500 174.0 7.19 10.9 21.2

4000 198.9 10.48 12.5 30.9

* This ow rate exceeds the recommended maximum for a boiler with

a standard copper heat exchanger. Use a greater temperature rise or

consult manufacturer. Consider a cupro-nickel heat exchanger, because

its maximum ow rate is 315 GPM.

Low water cutoff

I a boiler is insalled above any radiaion elemens i mus be ted

wih a low waer cuoff device.eer o he wiring diagram supplied wih he boiler/waer heaer orproper wiring connecions.

Expansion tank and air separator

An expansi on ank or oher means o conrol hermal expansionmus be insalled in he heaing sysem. An expansion ank mus beinsalled close o he boiler on he sucion side o he pump. An airscoop and auomaic air ven mus also be insalled o eliminae airrapped in he sysem.

Primary/secondary piping

Boilers conneced o heaing sysems using zone valves, zone pumps,or sysems ha have excessive ow raes or reurn waer emperauresless han 140oF, 60oCmus be isolaed rom hese sysems o proeche boiler.

Variable water ows

Figure 10, shows a ypical primary/secondary piping sysem. Adedicaed pump is used o mainain a consan waer lowhrough he boiler. Tis boiler pump is sized o overcome he headloss o he boiler and near-boiler piping sysem while supplying heow rae required o mainain he desired emperaure rise across heboile r hea exchanger. he sysem pump is sized o provide herequired ow o he heaing sysem. Te boiler piping connecionso he heaing sysem piping mus be a maximum 6 pipe diameers

beween ceners o ensure zero pressure drop in he primary sysem.

Low return water temperatures

o preven he problems associaed wih condensaion o heproducs o combusion due o low reurn waer emperaures aprimary/secondary piping sysem wih a bypass and bypass valvemus be insalled, see Figure 11. Te bypass sysem mus be sizedhe same as he secondary piping. Te primary and secondarypumps should be sized o provide he required ow hrough eachsysem. Te boiler piping connecions o he heaing sysem pipingmus be a maximum 6 pipe diameers beween ceners o ensurezero pressure drop in he primary sysem.

Multiple boiler systems

Sysems using muliple boilers can also be insalled using a primary/secondary maniold sysem, Figure 13.

Piping for use with cooling units

Te boiler, when used in connecion wih a rerigeraion sysem, musbe insalled so he chilled medium is piped in parallel wih he boiler.Appropriae valves mus be used o preven he chilled waer romenering he boiler.

When a boiler is conneced o a heaing coil ha may be exposedo rerigeraed air rom an air handling device, he piping sysemmus be equipped w ih ow-conrol valves or some oher auomaic

means o prevening graviy circulaion o he boiler waer during hecooling cycle.

-

7/21/2019 Futera XLF IOM

19/44

inned copper tube gas boilers & water heaters Boiler Manual

19

Figure 10 Typical Primary/Secondary Piping System (See Notes)

Figure 11 Low Temperature Piping with Thermostatic Valve(See Notes and Adjustment Procedure)

NOTES:

1. For pump selection consult factory.

2. Boiler pump sized to boiler and thermostatic3-way valve design ow requirements.

3. Boiler circuit piping must be sized large enough

to handle maximum ow through unit.4. All boilers furnished with factory mounted

outlet water temperature gauge.

5. Boiler pump purging required. Use terminals

supplied.

6. Valve is pre-calibrated for 140oFreturn temperature7. For HeatNet operation a sensor is required and

installed at a minimum of 12 from primary loop tee.supplied.

Notice: These drawings show suggested piping

conguration and valving.

Check with the local codes and ordinances for specic

requirements.

NOTES:

1. Boiler circuit piping must be sized

large enough to handle maximum

ow through unit.

2. Boiler pump sized to boiler design

ow requirements.3. All boilers furnished with factory

mounted outlet water temperature

gauge.

4. Boiler pump purging required.

Use terminals supplied.

5. For HeatNet operation, a sensor is

required and installed at a minimumof 12 from primary loop tee.

Notice: These drawings show suggestedpiping conguration and valving.

Check with the local codes and ordinances

for specic requirements.

hese drawings showsuggesed piping con-guraion and valving.Check wih local codesand ordinances or spe-cic requiremens.

H-1 Rev 5

H-18 Rev 4

-

7/21/2019 Futera XLF IOM

20/44

inned copper tube gas boilers & water heaters Boiler Manual

20

NOTES:

1. Boiler circuit piping must be sized large enough to handle maximum ow through unit.

2. Boiler pump sized to boiler design ow requirements.

3. All boilers furnished with factory mounted outlet water temperature gauge.

4. Boiler pump purging required. Use terminals supplied.

5. Secondary loop pipe diameter must be sized large enough to handle maximum ow through all units.

6. For HeatNet operation, a sensor is required and installed at a minimum of 12 from primary loop tee.

Notice: Theses drawings show suggested piping conguration and valving.

Check with local codes and ordinances for specic requirements.

Figure 13 Multiple Boiler Piping (See notes)

hese drawings showsuggesed piping con-guraion and valving.

Check wih local codesand ordinances or spe-cic requiremens.

H-15 Rev 6

-

7/21/2019 Futera XLF IOM

21/44

inned copper tube gas boilers & water heaters Boiler Manual

21

TEMPERATURE RISE CONTROL

Waer reurned o he waer heaer inle musno be less han 140oF, 60oC or excessivecondensaion o he producs o combusion

will damage he waer heaer, voiding he warrany.Te mehod oulined below can be employed opreven his condiion rom occurring.

A balancing valv e should be insalle d on heoule side o he waer heaer or purposeso adjusing he low rae hrough he heaexchanger. hermomeers are insalledon boh he inle and oule o he waer heaeror deermining he emperaure rise hrough heuni.

he proper velociy hrough he waer heaermus be mainained in accordance wih able 9,or eicien operaion and long lie. I heemperaure rise hrough he waer heaer islower han recommended he waer velociy isoo high. Premaure erosion o he hea exchanger

will occur. Conversely, i he emperaure rise ishigher han recommended in able 9, he owrae is oo low. Scaling and sofening o he heaexchanger will occur.

Termosaic Mixing Valve Waer Above 140oF,60oCWaer can be sored a emperaures above140oF, 60oCprovided ha a hermosaicallyconrolled mixing valve is used o emper heho waer o an accepable emperaure beoreis supplied or domesic use.

Te mixing valve MUS be se o preven a scaldinjury rom occurring, see he cauion againsscalding.

Sorage o waer or domesic use above 140oF,60oC will provide an increased quaniy oempered waer and help preven he growh o

waer born baceria.

DOMESTIC WATER SUPPLY PIPING

Proper conrols mus be used o preven waer suppliedor domesic use rom exceeding 130oF, 54oCor a scaldinjury wil l occur! When higher waer emperaures are

required or appliances such as a dishwasher, a mixingvalve or some oher empering means mus be insalled.Households wih small children may require waeremperaures less han 120oF, 49oC. Local codes musbe complied wih!

General piping requirements

Ensure ha he waer heaer is equipped wih bronze headers. Pipingand componens conneced o he waer heaer mus be suiable oruse wih poable waer. Te waer heaer mus no be conneced oany heaing sysem piping or componens previously used wih a non-poable waer heaing appliance. No oxic chemicals, such as hoseused or boiler reamen, are o be inroduced ino he poable waerused or space heaing. I a ho waer sorage ank is used in he sysemi mus be equipped wih a emperaure and pressure relie valve hacomplies wih ANSI Z21.22 or CAN-4.4 and CAN-4.6.

Te sorage ank mus be locaed as close o he waerheaer as possible o preven excessive head loss which

will reduce ow.

Water chemistry

Te required emperaure rise across he waer heaer is based onwaer having a hardness beween 8 and 18 grains per gallon wih

a level o dissolved solids no exceeding 350 ppm. Waer having ahardness less han 8 grains can cause excessive corrosion o he heaexchanger. Waer ha has a hardness greaer han 18 grains per gallonand/or a level o dissolved solids exceeding 350 ppm will require arecalculaion o he pump size and emperaure rise.

A cupronickel hea exchanger may also be required. Te manuacurershould be consuled when hese waer condiions are encounered.See able 8.

Te maximum allowable ow rae hrough a Fuera XLFwaer heaer is 260 GPM, 16.4 Lwhen equipped wihcopper ubes. Te cupronickel hea exchanger allows or315 GPM, 19.9 L/s. See able 9.

BI waer heaers are designed o run scale ree. Due o he exremevariables o waer condiions world wide i is necessary o considerpH values and waer hardness in relaionship o scaling. I is crucialo consider hese wo variables when making hea exchanger andpump selecions. I local waer condiions are exreme, ollow heguidelines in he Hea Exchanger Selecion able (able 8) and hePumping Perormance able (able 9). Scale ree operaion can beachieved by using waer wih a hardness beween 8 and 18 and bymainaining he pH beween 5 and 9. Follow he condiions lisedunder NOMAL in he able. In some areas o he counry addiionalprecauions mus be observed due o unusual characerisics o helocal waer supply. Call he neares BI represenaive or deails.

-

7/21/2019 Futera XLF IOM

22/44

inned copper tube gas boilers & water heaters Boiler Manual

22

Table 8 Futera XLF Heat Exchanger Selection

Table 9 Futera XLF Pumping Performance Requirements

Maximum (Hard - 18+ Grains)

Calculated

GPM PD (FT) PD (kPa) T (F)

2500 315 18.86 55.6 14

3000 315 19.75 58.2 17

3500 315 20.65 60.8 19

4000 315 21.54 63.5 22

Recommended (Normal - 8-18 Grains)

Calculated

GPM PD (FT) PD (kPa) T (F)

2500 210 9.34 27.5 21

3000 210 9.76 28.8 25

3500 210 10.18 30.0 29

4000 210 10.61 31.3 33

o properly size he pump a grain hardnessand pH es mus be aken a he insallaionsie beore he order is placed. Proper pumpsizing will improve heaer perormance andhelp ensure heaer longevi y.

Expansion Tank

An expansion ank or oher means o conrolhermal expansion mus be insalled in he

waer heaing sysem i back ow preveniondevices are insalled.

Pump Requirements

his low-mass waer heaer requires aconinuous minimum waer low orproper operaion. he low waer low

swich provided or his uni will shudown he waer heaer i ow alls below herequired minimum level. able 9 provideshe hea exchanger pressure drop char andemperaure rise able. Te emperaure riseacross he waer heaer mus never exceed35oF, 19.4oC.

Cold Water Supply

he cold waer supply mus be piped ohe waer heaers oule piping beweenhe waer heaer and he ho waer sorageank. Tis will preven unempered waer

rom enering he waer heaer. See heemperaure ise Conrol secion.

wo ypical waer heaing sysems areshown in Figures 14 and 15.

-

7/21/2019 Futera XLF IOM

23/44

inned copper tube gas boilers & water heaters Boiler Manual

23

Figure 14 Typical Water Heating Piping (MW Models Only) (See Notes)

NOTES:

1. Optional cold water make up and recirculation line location.2. When using intermittent pump and pump delay, locate remote HeatNet sensor with well in lower 1/3 of tank. Install sensor with heat sensing

compound. For multiple tanks, self balancing reverse-return systems, a single HeatNet sensor is applied.

3. Thermal expansion tank may be required, check local codes.

4. When using optional factory mounted pump, max pipe length 30 fttotal, 6-90 elbows, full pipe size.5. CAUTION: MEASURE WATER HARDNESS AND pH AT JOB SITE.

6. The pH and water hardness must be measured before selecting heat exchanger and pump. Consult the Heat Exchanger Graph and

Pumping Performance Table before making selection.

7. Common piping must be sized for maximum combined heater ow.

8. Hot water tanks should be equipped with a combination temperature & pressure relief valve.

9. MA Code requires an 1/8 inhole in check valve to compensate for thermal expansion.

Notice: These drawings show suggested piping conguration and valving. Check with local codes and ordinances for specic requirements.

Figure 15 Multiple Water Heating Piping (MW Models Only)(See Notes)

Tese drawings show sug-gesed piping conguraionand valving. Check wihlocal codes and ordinancesor specic requiremens.

D-4 Rev 8

D-1 Rev 8

-

7/21/2019 Futera XLF IOM

24/44

inned copper tube gas boilers & water heaters Boiler Manual

24

Table 10 Gas pipe capacities (natural gas)

Maximum pipe capacity in ft3/hr, based on 0.60 specic gravity natural gas at a pressure of 0.5 psig or less and a 0.3" WC pressure drop,

for iron pipe with nominal size below, and for total equivalent length (in feet):

Pipe

size

10 20 30 40 50 60 70 80 90 100 125 150 175 200 250

2" 3,050 2,100 1,650 1,450 1,270 1,150 1,060 990 928 870 777 710 648 602 534

2" 4,800 3,300 2,700 2,300 2,000 1,850 1,690 1,600 1,480 1,400 1,240 1,130 1,030 960 851

3" 8,500 5,900 4,700 4,100 3,600 3,250 3,000 2,800 2,610 2,500 2,190 2,000 1,820 1,700 1,500

4" 17,500 12,000 9,700 8,300 7,400 6,800 6,110 5,800 5,330 5,100 4,460 4,100 3,720 3,460 3,070

5" 31,700 21,800 17,500 15,000 13,300 12,000 11,100 10,300 9,650 9,110 8,090 7,320 6,730 6,260 5,550

6" 51,300 35,300 28,300 24,200 21,500 19,500 17,900 16,700 15,600 14,800 13,100 11,900 10,900 10,100 8,990

Note: For propane piping Multiply the gas volume capacities above by 0.62 for propane ow capacities in ft3/hr. Multiply the propane

ow capacity by 2500 Btu/ft3to determine the propane Btu/hr capacity for a given pipe size and length.

GAS SUPPLY PIPING

Check he boiler/waer heaer raing plae o makesure ha he boiler/waer heaer is or he ype o gasha will be used. I i isn, do no connec he boiler/

waer heaer o he gas supply. Gas supply piping musbe in accordance wih he Naional Fuel Code, ANSIZ223.1-laes revision or applicable provisions o helocal building codes. Canadian insallaions muscomply wih CAN/CGA B149.1 or B149.2 InsallaionCode. Failure o comply wih his warning can resul inexensive propery damage, severe personal injury ordeah!

Te Fuera XLF comes rom he acory ready o be piped o he gassupply. I or any reason he boiler/waer heaer is no or he ypeo gas available a he insallaion sie, call your BI represenaive oresolve he problem.

Wih all unis operaing he gas supply pressure (nauralgas) a he saey shuoff valve inle mus be:

Minimum 3.5 in, 88.9 mm, WC Maximum 14 in, 356 mm, WC

Gas pressure no o exceed a maximum o a (1.0 in WC)drop when ring rom minimum inpu o ull load ohe gas supply line and all he appliances running.

ables 10 and 11 should be used o ensure ha he gas supply pipingis sized properly. I more han one appliance is supplied by he samesupply pipe, he piping mus be sized based on he maximum possibledemand. Do no neglec he pressure drop due o pipe tings.able 10 should be used in conjuncion wih able 11 o ensure hahe gas supply piping has he capaciy o mee he demand.

Figure 16 depics he proper way o connec he boiler/ waerheaer o he gas supply piping. Te manual shu-off valve MUS beinsalled in he supply piping. I should be insalled 5 f, 1.5 mabovehe oor where required by local codes. Provide a sedimen rap ahe botom o he verical secion o he gas supply pipe upsream ohe gas conrols.

Figure 16 Gas Supply Piping

-

7/21/2019 Futera XLF IOM

25/44

inned copper tube gas boilers & water heaters Boiler Manual

25

Table 11 Equivalent length (feet) for typical ttings

Pipe

size

Fitting or valve

90oelbow

Tee(branch ow)

Gatevalve

Gascock

2" 5.2 10.3 1.2 3.0

2" 6.2 12.3 1.4 3.5

3" 7.7 15.3 1.8 4.5

4" 10.1 20.2 2.4 6.0

5" 12.6 25.2 2.9 7.3

6" 15.2 30.4 3.5 13.4

Equivalent lengths above are for threaded ttings. Multiply values above by

0.75 for anged ttings.

A ground join union should be insal led beween he boiler gasconrols and he supply piping. Each o hese iems are needed oensure long lie and ease o servicing. Always use a pipe sealan hais suiable or use wih LP gas.

Always use a wrench on he gas valve body whenmaking gas connecions o i. Never over-ighen hepiping enering he gas valve body or gas valve ailuremay resul!

When applicable, provisions or ven, bleed and gas relie lines musbe made in accordance wih he laes revision o ANSI Z223.1/NFPA 54. Te main Dungs gas valve supplied wih boiler/waerheaer does no require exernal vening.

Sae lighing and oher perormance crieria were me wih hegas maniold and conrol assembly provided on he boiler. All gasconnecions MUS be leak esed beore puting he boiler inooperaion.

Never use an open ame o es or gas leaks. Always usean approved leak deecion mehod. Failure o comply

wih his warning can cause exensive propery damage,severe personal injury or deah!

Whenever he gas supply piping is pressure esed he boiler/waerheaer gas conrols mus be proeced. I he es pressure is equalo, or less han 1/2 psig, 3.5 kPaisolae he boiler/waer heaer byclosing is manual shu off valve, see Figure 16. I he es pressure is

greaer han, or equal o 1/2 psig, 3.5 kPa, disconnec he boiler/waer heaer and is individual shu-off valve.

ELECTRICAL WIRING

Electrical power connections

Label all wires prior o disconnecion when servicing

conrols. Wiring errors can cause improper anddangerous operaion! Veriy proper operaion afer servicing.

Failure o comply could resul in severe personal injurydeah or subsanial propery damage.

Te elecrical connecions o his boiler/waer heaermus be made in accordance wih all applicable localcodes and he laes revision o he Naional ElecricaCode, ANSI/NFPA-70. Insallaion should alsoconorm wih CSA C22.1 Canadian Elecrical CodePar I i insalled in Canada.

Insall a separae 240 vol circui breaker or he boiler/waer heaer, see

able 12. A properly raed shu-off swich should be locaed a he boiler/waer heaer. Te boiler/waer heaer mus be grounded in accordancewih he auhoriy having jurisdicion, or i none, he laes revision o heNaional Elecrical Code, ANSI/NFPA-70.

Table 12 Futera XLF Electrical Requirements

Futera XLFModel

RequiredCircuit Breaker

(amps)FLA *

2500-4000 25 17

* Use separate circuit breaker that is properly sized for pumpand pump contactor.

Line volage eld wiring o any conrols or oher devices musconorm o he emperaure limiaion o ype EW or equivalena 189oF, 105oC. Use appropriae wiring maerials or unis insalledoudoors. Te wire size mus be compaible wih he oal amp drawo he circui.

eer o he wiring diagram supplied wih he boiler/waer heaer oproper wiring connecions and wire size.

-

7/21/2019 Futera XLF IOM

26/44

inned copper tube gas boilers & water heaters Boiler Manual

26

PROPANE GAS

Propane gas may no always be deeced by smell. Propane gas is heavier han air and can collec in low areas.

Propane gas can ignie or explode i an igniion source is presen and resul in deah, serious injury and propery damage!

GENERAL OPERATION

Beore proceeding read and ully undersand heinsrucions conained in his manual. Do no atempo operae his boiler/waer heaer i i has no been

insalled in accordance wih he guidelines se orh inhis manual. Failure o comply wih his warning canresul in exensive propery damage, severe personalinjury or deah!

Should overheaing occur or he gas supply ail o shu off, urn offhe manual gas conrol valve o he appliance. Do no inerrup waerow hrough he boiler/waer heaer.

Hydronic heating boilers

Open he make-up waer valve and slowly ll he boiler and all o heradiaion wih waer. Ensure ha all bleed and drain valves are closed.

Adjus he make-up waer pressure regulaor so a minimum 12 psig,82.7 kPasysem pressure is mainained a he highes poin in hesysem piping. I a make-up waer pump is used adjus i o mainaina minimum 12 psig, 82.7 kPasysem pressure.

Open he sysem bleed and drain valves, one a a ime, o purge heair rapped in he heaing sysem piping.

Wih he boiler off, run he sysem pump or a leas 30 minues andbleed he sysem piping using he bleed valves. I srainers are usedin he sysem piping, he make- up waer valve should be closed andhe srainers checked and cleaned.

Te sysem expansion ank should be checked o ensure ha hecorrec waer level in he ank is mainained. Te ank should be lesshan hal ull o waer wih he sysem ull and adjused o he correcoperaing pressure.

Sar he boiler as described in he Operaing Insrucions secion.un he boiler or a leas an hour. he sysem pump(s) and allradiaion unis mus be operaed during his ime. Ensure ha hemake-up waer valve is open.

Shu he boiler off and open he bleed valves o purge he air rappedin he heaing sysem piping. Close he make-up waer valve andcheck and clean he srainers and make-up waer pressure reducing

valve.

Open he make-up waer valve and adjus he sysem pressure inecessary. Te sysem should be checked and bled afer hree dayso operaion.

WIRING & CONTROL SETUP

Follow he insrucions in he Fuera XLF Conrolinsallaion and operaion insrucion manual

shipped wih he boiler o wire he boiler and seup he HeaNe conrol. Te conrol mus be seup beore atemping o re he boiler.

See Figure 17 or locaion o elecrical componens.

In addiion o he inormaion in he Fuera XLF Conrol IOM, seehe ollowing inormaion on conrols and inerlocks.

CONTROLS & INTERLOCKS

Low Water Cutoff

I he boiler is o be insalled above radiaion or i required by ohercodes or regulaions, insall a low waer cuoff in appropriae piping.

Wire he swich o he Inerlock conacs as illusraed on FieldWiring schemaic. Ensure ha he low waer cuoff device(s) willuncion properly.

Operating Control

Te operaing conrol should be se o he lowes seting ha willsaisy he consumers needs.

Seting he hermosa or operaion conrol oo high

can resul in scalding resuling in severe personalinjury!

High Limits (Aquastats)

Te high limis are locaed in he op conrol area o he boiler/waerheaer. emoe capillary bulbs run o wells on he oule side o hesupply header. he high limi can be rese by depressing he red

buton.

Te waer heaer high limi should be se o a minimum o 20oF,11oChigher han he operaing conrol. eer o he HO WAESUPPLY secion or he proper supply waer emperaure.

Flow Switch

A ow swich is provided in he waer oule piping o preven heboiler/waer heaer rom ring wihou adequae waer ow hroughhe hea exchanger.

-

7/21/2019 Futera XLF IOM

27/44

inned copper tube gas boilers & water heaters Boiler Manual

27

Figure 17 HeatNet Control Panel SEQUENCE OF OPERATION

NO DEMAND

Standby1. Te boiler is idle wih no inerlocks in he aul condiion.

DEMAND

Pre-Purge

1. Te blower operaes a purge PM. Te waer ow inerlock musmake wihin 15 seconds afer he demand signal is iniiaed.

2. Te Honeywell 7800 sars a 10 second purge delay once he aiprove swich conacs close.

Pilot Run - % Input

1. he blower operaes a minimum igniion seing. See hecalibraion secion in he HeaNe Conrol-IOM o ener hecalibraion menus.

2. Te igniion ransormer is energized. Te pilo solenoid valveopens or he 10 second pilo igniion rial.

Main Run % Input

1. Te main gas valve opens.2. Te igniion ransormer is de-energized.3. Te pilo solenoid valve closes.4. Te blower says a he minimum inpu seting or 3 seconds

hen operaes a demand % inpu. See he calibraion secion in

he HeaNe Conrol IOM o ener he calibraion menus.

NO DEMAND

Post-Purge

1. Te main gas valve closes.2. Te blower operaes a purge PM or 10 seconds.3. Te boiler is idle wih no inerlocks in he aul condiion.

HEAT NETCONTROLBOARD

MANUAL RESETHI-LIMIT

LOCAL REMOTESWITCH

TRANSFORMER TEST RUNSWITCH

FLAMESAFEGUARDMODULE

PROTOCESSORMODULE(OPTIONAL)

VFD CONTROL

AUTOMATIC RESETHI-LIMIT

250 VA

TRANSFORMER

(on models 3500 and larger)

HIGH VOLTAGE

IGNITION STATUSWINDOW

UP BUTTOM

DOWN BUTTOM

POWER SWITCH

SELECT BUTTOM

BACKBUTTOM

DISPLAYWINDOW

C:\DISTRIBUTEDPRODUCTSDIVISION\B- VAULT - RBI\RBI HOT WATERHEATERS\DOCUMENTS\IMAGEFILES\futeraxlf_logo.bmp

-

7/21/2019 Futera XLF IOM

28/44

inned copper tube gas boilers & water heaters Boiler Manual

28

he ollowing sar-up procedure assumes ha allwaer piping, gas piping and elecrical connecionsare correc as saed in his manual and he insallaionmees all Sae, Local, and Ciy codes.

See he Fuera XLF Conrol IOM or roubleshooinginormaion and conrol operaion.

OPERATING INSTRUCTIONS

Operating instructions

1. I, a any ime, he boiler will no operae properly, ollow heinsrucions O UN OFF GAS O APPLIANCE, and call

your service echnician or gas supplier.2. urn off all elecrical power o he boiler.3. Close main gas shu-off valve (eld supplied), Figure 16.

4. Purge he gas piping up o he boilers manual gas valve (locaedahead o he main gas valve). When he bleeding is complee,check all gas joins up o he gas valve or leaks.

5. Wai ve (5) minues o clear ou any gas.6. Make sure all limis, pressures swiches and saey device conacs

are closed.7. Open he main gas shu-off valve.8. Disable any exernal call or hea, such as rom a building

managemen sysem or remoe operaing conroller.9. oggle he remoe/local swich (in conrol cabine see

Figure 18) o REMOTE.10. urn on elecrical power o he boiler.

11. urn he power swich on he ron o he boiler conrol cabineo ON.

12. Te HeaNe display will ligh up when he power is on. I allinerlocks are properly closed, he display will say STANDBY. Ino, reer o he XLF HeaNe Conrol IOM or roubleshooing.

13. Slide he HeaNe conrols low re swich (on HeaNe conrolboard) o he LOW FIREposiion.

14. Te boiler will begin he sar-up sequence.15. Allow he boiler o pre-purge and ener he pilo igniion cycle.16. I pilo lighs (indicaed by a good ame signal 5.0 V DC)

proceed o sep 18. (See Honeywell 7800 lieraure or use o ameer o check ame signal i keypad readou is no available.)

17. I pilo is unsable (indicaed by a low or erraic lame signalcausing pilo ame ailure), oggle he low re swich o DISABLE,hen back o ENABLEo sar anoher cycle (rese he Honeywellconrol i necessary). epea or one or wo more imes o ensurehe pilo line is purged o all air. I pilo is sill unsable, he pilogas pressure may need o be increased. See sep 18.

18. Pilo pressure adjusmen:a. Swich he Honeywell conrol o TESTposiion wihin he

rs 10 seconds o he pilo igniion sequence.

b. Connec one side o a manomeer or pressure gauge o hemanomeer pressure por (barbed) on he pressure es maniold(locaed inside conrol panel). See Figure 18. Leave he oherside o he manomeer open o he room.

Figure 18 Manometer connections to the test manifold (incontrol cabinet)

c. Measure pilo gas pressure by pressing and holding heservice valve marked PILOT GAS.

d. Se pilo gas pressure o 3.0 inwc ( 0.5 in) by adjusing hepilo gas pressure regulaor, inside he air box. Access romhe boiler op cover. See Figure 19.

Figure 19 Access to air trim adjustment and pilot regulator

e. Check pilo air pressure using serv ice valve marked PILOTAIR.

. Pilo air pressure should be 0.60 inwc ( 0.10 in).

Combusion readings mus be in he range speciedin he ollowing insrucions. Adjus he boiler asnecessary o ensure proper combusion.

-

7/21/2019 Futera XLF IOM

29/44

inned copper tube gas boilers & water heaters Boiler Manual

29

Verify low re operation

1. Connec a manomeer or Magnehelic gauge wih he pressureside o he maniold pressure por. See Figure 18, or locaions.

2. Se Honeywell 7800 conrol o UN posiion. Te boiler willoperae a low re because he low re swich is in he low reposiion.

3. Measure he ue gas CO2wih he boiler running a low re. Se

low re CO2o 8.0% 8.5% by adjusmen on he Dungs valve

using a 3mm Allen wrench.a. urn he wrench in small incremens (10 a a ime).

b. Allow ime afer each adjusmen or he boiler o reach seadysae.

4. Afer seting he CO2, measure he pressure signal, Ps.

a. Press he Ps (signal)buon and read he pressure. hepressure a low re should be as shown in Figure 18.

b. I he pressure is ouside his range, ollow insrucions in heXLF Conrol IOM o calibrae he ring rae. Increase rae ihe pressure signal is low, or decrease rae i he signal is high.

c. eurn o sep 1 o adjus low re CO2afer changing low re

ring rae.

I using a U-ube manomeer urned sideways or lowpressure readings, you MUS urn he manomeeruprigh beore atemping o measure pressures a oherhan low re. Pressure signal will reach up o 9 inches

when he boiler is a high re, and can cause uid o bepulled ou o he manomeer ino he boiler. Shouldhis occur, immediaely shu down he boiler andconac he acory or procedure. Preerably, use aMagnehelic gauge insead o a U-ube manomeer omeasure he pressure o avoid his poenial hazard.

Table 13 Pressure signal (Ps) (Nat Gas)

Firingrate

%

XLF-2500 XLF-3000 XLF-3500 XLF-4000

SignalInches wc

SignalInches wc

SignalInches wc

SignalInches wc

100% -9.50 -11.00 -6.0 -8.5

20% (-0.50) .1 (-0.50) .1 (-0.50) .1 (-0.50) .1

To determine signal in mm wc, multiply signal pressure by 25.4.

For LP Gas: All unis are esed a acory. LP Combusion Values arelocaed on Combusion Daa label.

o ensure proper boiler operaion, boilers ha useroom air and vened side wall mus no be red a lesshan 33% inpu.

5. Observe he burner ame afer seting low re. Make sure heame is sable, bu no oo igh on he burner (causing inraredoperaion).

DO NOT LEAVE THE BURNER IN AN INFRARED STATE.A ew random speckles o red are accepable, bu largeconcenraions o spos or large areas o red are no.I large amouns o red concenraions are observed,

veriy combusion readings.

Leave he manomeer conneced o he es manioldI will be needed or high re operaion esing.

Verify high re operation

1. Jumper he AA erminals on he HeaNe board and allow he

boiler o rise o maximum (100%) inpu.2. Allow he boiler o reach seady sae combusion a high re.3. Veriy high re blower speed as ollows:

a. Wih he manomeer (or gauge) conneced o he es manioldpress he Ps (signal)buton and read he pressure.

b. Te pressure a low re should be as shown in Figure 18.c. I he pressure is NO correc, ollow sep 4.

4. I he high re signal pressure is no correc:a. emove he jumper on A-A. Te boiler will reurn o low re

b. Follow he insrucions in he XLF Conrol IOM o calibraehe high re ring rae. (Slide he HeaNe conrol calibrae

swich oCAL

. Follow he Conrol IOM procedure onavigae o he HeaNe conrol calibraion screen.)

Te maximum ring rae value in he HeaNe conrois acory se a 90%. A his seting, a sea level, and

wih ypical ven lengh, he boiler will be at rateDO NO increase he HeaNe conrols maximumrae seting above 90% unless needed or high aliudeinsallaions.

c. I Ps is oo high, reduce he HeaNe conrols maximumring rae seting by 2%. Ten slide he calibraion swich oNORMALand exi he HeaNe conrols calibraion screenseplace he jumper on A-A and allow he boiler o reurn ohigh re. eurn o sep 2 o repea he process. I necessary

repea his sequence, reducing he ring rae by 2% each imed. I Psis oo low, increase he ring rae seting by 2%. Ten

slide he calibraion swich o NORMALand exi he HeaNeconrols calibraion screens. eplace he jumper on A-A andallow he boiler o reurn o high re. eurn o sep 2 o repeahe process. I necessary, repea his sequence, increasing hering rae by 2% each ime.

e. Check he pressure signal again. I he signal is now correcreconnec he jumper on AA and proceed o sep 5.

. I he pressure signal is sill no correc, veriy ha he air rimadjusmen (see Figure 19) is in he hal-open (acoryseting) posiion. I i is a acory seting , you will need oconac echnical suppor a he acory o roubleshoo he

pressure signal issue.5. I he pressure signal is correc, measure he lue gas CO

2. I

should be beween 9% and 9.5%.a. I CO

2is correc, proceed o sep 6.

b. I CO2is no wihin his range, adjus he air rim adjusmen

slighly (see Figure 19) on op o mixing box o achieve a COo 9% - 9.5%.

c. I adjusing he air rim adjusmen does no correc heproblem, conac echnical suppor a he acory oroubleshoo he problem.

-

7/21/2019 Futera XLF IOM

30/44

inned copper tube gas boilers & water heaters Boiler Manual

30

6. I CO2and pressure signal are correc, allow he boiler o reach

seady sae and veriy supply gas pressure and check inpu raesas explained in he Gas Supply Piping secion.

7. emove jumper on AA and allow boiler o setle ino minimuminpu. Observe he combusion readings o ensure he boiler is

operaing correcly.8. When nished, disable he low re hold swich and replace es

pors o normal sae. emove he manomeer connecions andclose he conrol panel door.

9. Te Fuera XLF boiler allows or many modes o operaion andconrol mehods. eerence he XLF HeaNe Conrol IOM.

TO TURN OFF GAS TO APPLIANCE

1. Se he operaing conrol o is lowes seting.2. urn off all elecric power o he boiler i service is o be

perormed.3. Close he manual main and pilo gas shu-off valves.

CHECKING & ADJUSTMENTS

Proper polariy o he igniion ransormer wiring isimpor. Improper wiring o he igniion ransormercan resul in an explosion causing exensive properydamage, severe personal injury or deah!

Spark gap

Wih he main and pi lo gas manual valves in he closed posiionenergize he uni. Look hrough he sigh glass in he pilo ubeo observe he rial or igniion. Make sure ha he spark is srongand coninuous. I no, check and adjus he spark gap as shown inFigure 20.

Figure 20 Spark Gap

-

7/21/2019 Futera XLF IOM

31/44

inned copper tube gas boilers & water heaters Boiler Manual

31

Pilot adjustment

1. Te pilo pressure has been acory se a 3 inWC, and shouldnneed adjusmen.a. Wih he boiler powered, generae a call or hea.

b. When he prepurge is complee he igniion/pilo rial wi llbegin.2. o adjus he pilo he ollowing seps mus be aken:

a. Pu he Honeywell M7800 es swich in he es posiion.Te conrol will hold in he igniion/pilo sequence, allowingyou o check he pressure.

b. Connec one side o a manomeer or pressure gauge o hemanomeer pressure por (barbed) on he pressure esmaniold (locaed inside conrol panel). See gure 18. Leavehe oher side o he manomeer open o he room.

c. Measure pilo gas pressure by pressing and holding heservice valve marked PILOT GAS.

d. Se pilo gas pressure o 3.0 inwc ( 0.5 in) by adjusing hepilo gas pressure regulaor, inside he air box. Access romhe boiler op cover. See Figure 19.

e. Check pilo air pressure using service valve marked PILOTAIR.

. Pilo air pressure should be 0.60 inwc ( 0.10 in).

Never orce he regulaor adjusmen screw beyond hesop limis or damage o he regulaor will occur!

Required gas pressure

Provide gas supply pressure a inle o boiler gas rain as ollows:

Gas supply pressure (Nat/LP)Inches

water columnmm

water column

Minimum (in WC) 3.5 88.9

Maximum (in WC) 14 356

1. Measure pressure when he boiler is ring a ull rae. Low gaspressure could indicae undersized gas line or insuffi cien gassupply.

2. Saic and operaing gas pressure required a he gas valve inle islised in he able above.

I he gas pressure is above he limi in he able belowa lock-up syle gas pressure regulaor suiable ordead-end service, (such as an Equimeer or Fisher)mus be insalled o preven increase (creep) o gaspressure when he unis are no operaing. Gas supply

pressure, as indicaed in he able below, mus bemainained o he inle o he boiler gas rain no oexceed a maximum (1.0 in WC) drop when ring romminimum inpu o ull load o he gas supply line andall he appliances running.

Tis pressure regulaor (supplied by ohers) may beinsalled a he service enrance o each uni or a maserregulaor sized o handle muliple unis may be uilizedConsul local gas uiliy or regulaor manuacurer orrecommendaions o mee specic job sie requiremens

Input rate Natural gas

Gas appliances are raed based on sea level operaion wihno adjusmen required a elevaions up o 2000 t, 610 m

A elev ai ons above 2000 t, 610 m inpu raings shouldbe reduced by 4% or each 1000 f, 305 m.

Check the input rate as follows:

1. urn off all oher gas appliances ha use he same gas meer ashe boiler/waer heaer.

2. Call your gas supplier and ask or he heaing value o he gas.3. Sar he boiler/waer heaer and le i run or 15 minues.4. Using he gas meer and a sopwach, clock he ime ha i ake

o burn 10 f3, 0.28 m3o gas and divide his ime by 10.

5. Inser he heaing value and he ime, in seconds, ino he ormulabelow.6. Inpu = (heaing value, Bu/hr)(3600)/(ime, seconds)7. I he compued rae deviaes by more han 5% rom he raed

inpu value o he uni, consul acory.

Never increase he inpu o he boiler/waer heaeabove ha or which i is raed. Doing so can causepremaure ailure o he boiler!

-

7/21/2019 Futera XLF IOM

32/44

inned copper tube gas boilers & water heaters Boiler Manual

32

MAINTENANCE

Disconnec elecrical power and close he manual gasshu off valve beore perorming mainenance or severepersonal injury may resul!