Furnace Inspection Services...Since 1998, Intero has carried out inspections on furnaces and...

Transcript of Furnace Inspection Services...Since 1998, Intero has carried out inspections on furnaces and...

Maintaining the integrity of your installation with minimum downtime

Furnace Inspection Services

Regular cleaning and inspection of

your furnace increases its reliability

and continuity. Knowing the

remaining wall thickness of the

tubes can also lengthen the lifecycle

of the furnace tubes and prevent

unwanted shutdowns. Intero has

designed an intelligent, free-

swimming tool that is capable

of inspecting tubes and bends

of your furnace, with a minimum

impact on shutdown time.

Reliable and cost effective

Since 1998, Intero has carried out inspections on

furnaces and pipelines. In its continued effort to further

improve the applications of Intero’s patented Piglet®

ultrasonic internal inspection system, a new tool has

been developed and added to the Piglet® family.

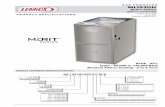

Furnace Piglet®

The Furnace Piglet® is utilized for the inspection of

furnace tubes, whether they are smooth, studded

or finned. The Intero designed Furnace Piglet® is an

intelligent free-swimming tool that is capable of

inspecting the tubes and bends of the furnace, with a

minimum impact on shutdown time.

Prior to a furnace inspection it is essential to clean

the furnace thoroughly to remove all the cokes in

order for the ultrasound to penetrate the pipe wall.

Our furnace cleaning department provides excellent,

proven cleaning results. When combined with Furnace

Piglet® inspection technology, it is possible to

guarantee the cleanliness of the furnace tubes. In

addition, during the cleaning, verification runs can be

used to demonstrate the cleanliness of the tubes in

order to optimize the results.

High quality cleaning and inspection contributes to

the integrity of the furnace, resulting in minimal

shutdown time. Regular cleaning and inspection

increases the reliability and continuity of your furnace

and knowing the remaining wall thickness of the

furnace tubes can also lengthen their lifecycle and

prevent unwanted shutdowns.

A-Scan dataThe storage of the raw A-scan data enables highly

accurate and reliable data analysis. The final report

is presented the day after the inspection when the

results of the cleaning, if needed, and minimum

wall thickness per tube are presented. The report

contains a brief overview in graphical and tabular

format linked to the furnace layout as well as detailed

C-scan graphics for each tube.

The Furnace Piglet® is typically configured with:

• Disk for sealing and centralization (4” to 8”)

• Piglet® UT-sensor body with fixed transducers

• Onboard data storage (A-scan)

• Flexible couplings for passing bends

Why you should use Intero Integrity Services’ Furnace

Piglet®:

• Inspection time has minimum impact on shutdown time

• Passing bend radii ≥ 1.5 D (smaller on request)

• Bi-directional, compact, lightweight, modular design

• In-house developed, tested and operated

• Reporting conforms to API579, ASME FSS-1/2007

(if required)

• Reporting and inspection executed by qualified NDT

specialist

• Storage of raw A-scan data to enable accurate and

reliable data analysis

• C-scan of full furnace in report

• Corrosion growth comparison capabilities

• Ability to modify the tool for specific situations

High quality cleaning and inspection in one solution

2

Launcher

Receiver

Decoking unit

Furnace inspection

3intero-integrity.com

4

C-scan results

Tabular

Data analysis / Final reporting

Launcher

Receiver

Decoking unit

Furnace inspection

Corrosion growth analysis A German refinery requested a Piglet® Furnace

inspection of coils in a hydrobon furnace which it

operated. Prior to the inspection, the coils were

cleaned by our furnace cleaning department. Both

the radiant and convection sections of the coils were

inspected, utilizing the Piglet® ultrasonic-based

intelligent pig technology. General wall thinning

caused by internal erosion/corrosion was detected

throughout. The material of the convection and radiant

coil sections were fabricated with X12CrMo9 and

12CrMo19, respectively. The nominal diameter of the

coil was 5” NPS. The furnace had been in service for a

long period of time and was identified as Schedule 40.

The furnace had been inspected in April 2008,

December 2011, July 2012 and January 2013 and during

these inspections the corrosion growth was monitored

to extend the lifetime of the furnace for a shutdown

in 2014. After the inspection, the customer decided to

cut out the worst tube. After it was removed, a third

party-certified manual UT inspection company verified

our finding and confirmed the minimum wall thickness.

Benefits• The inspection allows our clients to operate with

confidence until the next shutdown.

• A better understanding of the assets condition will

lead to improved operations.

• Operations can now see the effects of the process on

the performance of the heater coils and corrective

action can be implemented to prolong the life of the

coils or further understand the impact of extended

runs at higher loads.

• By knowing the condition of the coils and the heaters

operating parameters, the life of the furnace can be

calculated and a replacement strategy developed, thus

allowing greater plant reliability and occupancy.

5intero-integrity.com

6.6 mm / 0.925”

3.6 mm / 0.1411”

We know your space

Intero Integrity Services Headquarters

Steenoven 2-6

4196 HG Tricht

The Netherlands

+31 (0)345 228 600