Fully Automatic Random Case Tapermedia.laeisz-lueders.de/upload/documents/endoline/... · 2015. 3....

Transcript of Fully Automatic Random Case Tapermedia.laeisz-lueders.de/upload/documents/endoline/... · 2015. 3....

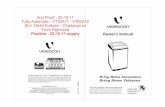

734Fully Automatic

Random Case Taper

This is the dominant machine of its type having originally been developed for the biscuits andsnack foods industries. It automatically adjusts to random sizes while sealing small and large,lightweight and heavy cases without the need for an operator. It is fully automatic and providessecure and accurate taping at speeds of up to 20 cases per minute. Fully automatic randomsealing machines are ideally suited to applications where there is insufficient room for a sealeron each packing line.

Features of the 734 include:High Speed System

Includes scanning devices to determinethe dimensions of the case beingpresented and automatically adjust headheights and guide widths to suit, thusenabling a throughput of 20 cases/minute.

Interchangeable TapeheadsThe standard 734 uses any machine tapeup to 50mm wide, 1000m long andfeatures instantly removable,interchangeable tapeheads, easilythreaded, with integral knife guards forrapid tape reload.

Four Column ConstructionOur unique four column design provides addedstability for the taping bridge to ensure the machineruns smoothly at all times with minimal interruptionand it provides the support necessary for the floatingbridge feature. This fully automatic machine is fittedwith two pairs of columns for additional support tothe folding section.

Ease of OperationOur digital message display unit allows forrapid set-up, entering of case data andmachine status. Simple mechanicaloperation and clear access allows for easycleaning and maintenance.

Robust ConstructionHigh quality components housed in a robust chassisensure minimal servicing and enable 24 houroperation. Designed for the rigours of typical end-of-line packaging environments.

Low Cost of OwnershipAll Endoline’s machines are designed for maximumefficiency and productivity thereby reducing the costof ownership to a minimum. This case sealer comesat a low capital cost and immediate savings can beseen through reduced labour costs and increasedpacking speeds.

734:Machine Leaflet Template 13/05/2010 10:04 Page 1

734Fully AutomaticRandom Case Taper

Options include:

• Low tape and no tape sensing

• Visual/audible alarm

• Discharge blocked sensing

• Infeed conveyor

• No scan reject conveyor

• Automatic tapehead retract

2830

STOPRESET START

LOWER

Bar Code Scanner

Optional Reject Conveyor

Optional Case Separation Station

Control Panel

Side Guides

Case Centralising

Folder Head

2850

Handing Of Control Panel & Reject ConveyorCan Change To Suit The Requirement

C

Taper Head

Endoline Machinery LimitedStratton Business Park, London RoadBiggleswade, BedfordshireSG18 8QBUnited Kingdom

Telephone: +44 (0) 1767 316422 Facsimile: +44 (0) 1767 318033 E-mail: [email protected] Website: www.endoline.co.uk © Endoline reserves the right to change specifications without prior notice.

Case Dimensions (mm)

Speed18-20 cases per minute

Electrical SupplyThree phase: 380-415V, 50Hz, 6amps per phase

PneumaticsSupply – 22litres per cycle at 5.5bar

Machine FinishMild steel, powder coated white(RAL9010) or stainless steel

Tape Size38mm, 50mm, 75mm

Length Width Height (high position)Minimum 200 200 140 (170)Maximum 600 420 540 (570)

734:Machine Leaflet Template 13/05/2010 10:04 Page 2

160 or 200 110 or 140 or 170(Closed)

460 or 500 510 or 540 or 570