Fssc 22000 guidance manual april-2013

Click here to load reader

-

Upload

turbat-olzmunkh -

Category

Education

-

view

2.314 -

download

5

description

Transcript of Fssc 22000 guidance manual april-2013

© Foundation for Food Safety Certification 2013 Page 1 of 13

FOOD SAFETY SYSTEM

CERTIFICATION 22000

FSSC 22000

Certification scheme for food safety systems

in compliance with

ISO 22000: 2005 and technical specifications for

sector PRPs

Features

Foundation for Food Safety Certification

Gorinchem, The Netherlands: 2013

Version Control Version 3 Published on April 10, 2013

Reason for change All scheme documents updated from 2011 version

2, to include general updating of requirements and

edits made during benchmarking for GFSI GD 6

© Foundation for Food Safety Certification 2013 Page 2 of 13

FOOD SAFETY SYSTEM CERTIFICATION 22000

Certification scheme for food safety systems

in compliance with

ISO 22000:2005 and technical specifications for sector PRPs

This document contains a complete certification scheme for food safety systems which are in

compliance with the publicly available food safety management systems standard ISO 22000:

2005 ‘Requirements for any organisation in the food chain’ and technical specifications for

sector PRPs (published as e.g. PASxyz or ISO 22002-x documents)

As of February 2010 it is a Global Food Safety Initiative approved scheme. The scheme was

re-benchmarked and recognized by GFSI again in February 2013 against Guidance

Document version 6.

The Foundation for Food Safety Certification (here after the Foundation) retains the

ownership and the copyright and the license agreements for certification bodies.

Due to the dynamic content of this document the user of this document should always verify

if the correct version is held. Future revisions of this document will always be published

under the same name.

In all cases the English version of the FSSC 22000 certification scheme is leading.

Cornelie Glerum

Secretary Board of Stakeholders and Foundation for Food Safety Certification

Gorinchem, 2013

Copyright 2013, Foundation for Food Safety Certification, Board of Stakeholders

All rights reserved. No part of this publication may be reproduced and/or published in any

form, by means of printed matters, photocopy, microfilm, recording or any other method or

technology, without written approval by the Board of Stakeholders (here after the Board).

Foundation for Food Safety Certification

Board of Stakeholders

P.O. Box 693

4200 AR Gorinchem, The Netherlands

t: +31-183 645028

f: +31-183 621161

website: www.fssc22000.com

e mail: [email protected]

© Foundation for Food Safety Certification 2013 Page 3 of 13

CONTENT

CONTENT .................................................................................................. 33

INTRODUCTION ......................................................................................... 44

FEATURES OF THE SCHEME ......................................................................... 66

REQUIREMENTS AND REGULATIONS ............................................................ 99

Part I - Requirements for organizations that require certification............. 99

Part II - Requirements and regulations for certification bodies ................ 99

Part III - Requirements and regulations for providing accreditation .......... 99

Part IV - Regulations for the Board of Stakeholders ................................. 99

LIST OF DECISIONS BY THE BOARD OF STAKEHOLDERS ............................ 1010

REFERENCE DOCUMENTS ........................................................................ 1111

TERMS AND DEFINITIONS ....................................................................... 1212

© Foundation for Food Safety Certification 2013 Page 4 of 13

INTRODUCTION

Food safety is a global concern, not only because of the importance for public

health, but also because of its impact on international trade. Globalisation of food

production and procurement makes food chains longer and more complex and

increases the risk of food safety incidents. Effective and harmonized food safety

systems shall manage and ensure the safety and suitability of food in each link of

the supply chain. For this reason ISO developed the standard for food safety

management systems ISO 22000, which applies to all organizations in the food

chain and thus ensures integrity of the chain.

Parallel to this development there is an increasing need for harmonized certification

of the food safety systems in order to create justified confidence that all necessary

measures are taken to ensure food safety in previous links of the chain. In this

context ISO developed the technical specification ISO/TS 22003 that contains

requirements for bodies providing certification of the food safety management

systems.

These developments were triggered by the increasing need of organizations in the

food chain for a generally accepted food safety certificate that meets the

requirements of the customers in the chain and may incorporate the requirements

of the different certification schemes of the retail organizations.

As a follow up FoodDrinkEurope took the initiative to develop a technical

specification that specifies the requirements for good practices in food

manufacturing and that meets customer requirements. Implementation of these

good practices is an essential part of the food safety system and creates confidence

in trade. The British Standards Institution (BSI) issued these requirements as the

publicly available specification BSI-PAS 220

As a next step FoodDrinkEurope initiated the development of a certification scheme

for food safety systems of organizations in the food chain that incorporates the

standards ISO 22000, BSI-PAS 220 and guidance on the application of ISO 22000,

ISO/TS 22004. The aim of this scheme is to harmonize the certification

requirements and methods for food safety systems in the food chain and to ensure

the issue of trustworthy food safety certificates that are comparable as regards

content and scope.

The Foundation was commissioned by FoodDrinkEurope to develop this scheme and

retains the legal ownership and the license agreements for the certification bodies.

In this text this certification scheme is referred to as the scheme. The scheme meets

© Foundation for Food Safety Certification 2013 Page 5 of 13

the requirements of the guidance document of the Global Food Safety Initiative

(GFSI).

In addition to the developments described above stakeholder organizations from

other parts of the food supply chain have developed technical specifications

covering requirements for PRPs for other parts of the supply chain. These technical

specifications can be used in addition to ISO 22000 to provide further detail for

chapter 7.2 of ISO 22000.

FSSC 22000 provides a certification model that can be used in the whole food

supply chain. It can cover sectors where such a technical specification for sector

PRPs has been realized. FSSC 22000 follows the supply chain category description as

defined in ISO/TS 22003. As the development of new technical specifications for

sector PRPs is on going the actual scope of FSSC 22000 and the applicable technical

specifications for sector PRPs are described in Part I, chapter 2: Scope.

Note: PAS 220, referred to in this introduction, has been replaced by ISO TS 22002-

1: 2009. The PAS was withdrawn at the end of 2012. Requirements are consistent

across the old and new documents, so certifications using the PAS remain valid until

their scheduled recertification audit date, when they must be revised to quote the

ISO document.

© Foundation for Food Safety Certification 2013 Page 6 of 13

FEATURES OF THE SCHEME

Objective

This certification scheme outlines the requirements for certification bodies (CBs) to

develop, implement and operate a system for the assessment and certification of

food safety systems of organizations in the food chain and to guarantee its

impartiality and competence. The certificate indicates that the organizations food

safety system is in conformance with the requirements which are given in this

scheme and that the organization is able to maintain conformance with these

requirements. It is however not a guarantee of the organization continuous food

safety performance. The value added to an organization with a certified food safety

system lies in the efforts made by the organization to maintain that system and its

commitment to continuously improve its performance.

Scope

This scheme is intended for the audit and certification of food safety systems, which

ensure the safety of products during manufacturing of:

• perishable animal products (i.e. meat, poultry, eggs, dairy and fish products)

• perishable vegetal products (i.e. packaged fresh fruits and fresh juices,

preserved fruits, packaged fresh vegetables, preserved vegetables)

• products with long shelf life at ambient temperature (i.e. canned products,

biscuits, snacks, oil, drinking water, beverages, pasta, flour, sugar, salt)

• (bio)chemical manufacturing (food ingredients i.e. vitamins, additives and bio-

cultures) but excluding technical and technological aids

• food packaging manufacturing (i.e direct, indirect contact with the food)

Note: transport and storage on site and as part of the operation are included (e.g.

cheese ripening). It is applicable to all organizations in the food chain in these

categories, regardless of size and complexity, whether profit-making or not and

whether public or private.

Content and plan

The scheme consists of an introductory part and four separate parts in which

requirements and/or regulations for the actors in the process of certification have

been laid down. These actors are: the organization in the food chain, the

certification body (CB), the accreditation body (AB) and the Board of Stakeholders

(Board).

The introductory part contains a description of the scheme and information on the

background, definitions and reference documents.

© Foundation for Food Safety Certification 2013 Page 7 of 13

The three following main sections contain the normative documents for:

- the organization in the food chain (Part I),

- the CB (Part II) and

- the AB (Part III).

These normative documents are indicated in the scheme as ”Requirements”.

Guidance on the application of these requirements is included if deemed necessary.

Apart from this the main sections contain:

- guidance for the organization in the food chain to obtain and maintain a FSSC

22000 certificate (Part I),

- regulations of the Foundation concerning the conditions for the use of the

scheme and for providing certification and accreditation by the CB and AB (Parts

II and III)

Finally, Part IV contains the regulations for the Board which deals with the

requirements and regulations of this scheme.

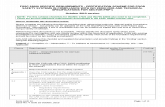

In figure 1 an outline of scheme is presented

Section 2 Regulations for

Board

Part IV

Normative documents Regulations

Part I

Section 3

Part II

Section 2 Section 3

Part III

Section 2 Section 3

Intr

od

uct

ory

Par

t

Organization in the food chain

Certification body

Accreditation body

Figure 1 - Plan of certification scheme FSSC 22000 NOTE: the figure does not show the guidance which is included in the normative documents

© Foundation for Food Safety Certification 2013 Page 8 of 13

Development

This certification scheme has been developed by project teams and steering

committees comprising of food safety experts of representative international

organizations in the food chain, experts of a number of international certification

bodies, a representative of the confederation of the food and drink industry of the

EU and sector experts. The scheme is approved by and will be maintained by the

Board of Stakeholders. Within the board the interests of all involved parties are

represented.

As of February 2010 it is a Global Food Safety Initiative approved scheme. The

scheme was re-benchmarked and recognized by GFSI again in February 2013

against Guidance Document version 6.

Board of Stakeholders

The Foundation aims to prepare a certification scheme, with a broad acceptance

adding particular value to the relationship between the certified organization in the

food chain and those around it (the government, customers). In order to achieve

this, the Board of the Foundation consists of representatives of trade and industry,

authorities and other parties concerned.

Maintenance and review

The Board has at least three meetings per year to maintain the certification scheme.

During every meeting major and/or minor changes are decided on. These decisions

will be directly published in a current list on the Foundation website. Revisions of all

relevant documents of the scheme are published annually on the Foundation

website and communicated with the licensed CBs and ABs. If the Board considers it

necessary that requirements or regulations should be amended or added on shorter

notice than one year, the Board can issue a directive that will be effective from a

given date. These directives will be communicated with the licensed CBs and ABs

and will be published on the Foundation website. The Board will have an overall

review of the certification scheme at intervals not exceeding three years and any

amendments arising from the review will be published by the Foundation and made

available to all stakeholders.

Operation

By entering into an agreement with the Foundation accredited CBs are authorized to

provide certification in accordance with this scheme. Accreditation shall be gained in

conformance with this scheme by an associated AB that complies with the regulation

for ABs (Part III). Licensed CBs are obliged to adhere strictly to this scheme.

© Foundation for Food Safety Certification 2013 Page 9 of 13

REQUIREMENTS AND REGULATIONS

The requirements and regulations are included in the following parts and are

attached to this document:

Part I - Requirements for organizations that require certification

Part II - Requirements and regulations for certification bodies

Part III - Requirements and regulations for providing accreditation

Part IV - Regulations for the Board of Stakeholders

© Foundation for Food Safety Certification 2013 Page 10 of 13

LIST OF DECISIONS BY THE BOARD OF STAKEHOLDERS

In the list all decisions of the Board of Stakeholders are included. The decisions

which affect the associated certification bodies as well as the certificate holders are

an integral part of the requirements for certification. After every meeting of the

Board an updated list is published on the website www.fssc22000.com.

© Foundation for Food Safety Certification 2013 Page 11 of 13

REFERENCE DOCUMENTS This scheme is based on the following documents and their future versions:

• GFSI Guidance Document, Sixth Edition, January 2011

• IAF Mandatory Document for duration of QMS and EMS audits; 2009 (Issue 1,

IAF MD 5: 2009) and all other relevant IAF Mandatory Documents

• ISO 9001: 2008, Quality management systems – Requirements

• ISO 19011: 2202, Guidelines for quality and/or environmental management

systems auditing

• ISO 22000: 2005, Food safety management systems – Requirements for any

organisation in the food chain

• ISO/TS 22002-1: 2009, Prerequisite programmes for food safety. Where

ISO/TS 22002-1 is stated, BSI-PAS 220 can be read

• ISO/TS 22003: 2007, Food safety management systems – Requirements for

bodies providing audit and certification of food safety management systems

• ISO/TS 22004: 2005, Food safety management systems – Guidance on the

application of ISO 22000: 2005

• ISO/IEC 17000: 2004, Conformity assessment – Vocabulary and general

principles

• ISO/IEC 17011: 2004, Conformity assessment – General requirements for

accreditation bodies accrediting conformity assessment bodies

• ISO/IEC 17021: 201106, Conformity assessment – Requirements for bodies

providing audit and certification of management systems

• BSI-PAS 96: 2008, Defending food and drink - Guidance for the

deterrence, detection and defeat of ideologically motivated and other forms

of malicious attack on food and drink and their supply arrangements

• BSI-PAS 223: 2011, Prerequisite programmes and design requirements for

food safety in the manufacture and provision of food packaging

© Foundation for Food Safety Certification 2013 Page 12 of 13

TERMS AND DEFINITIONS

For the purpose of this document the terms and definitions given in the standards

and technical specifications which are listed in the reference documents apply.

The following terms and definitions also apply:

• Audit: systematic, independent, documented process for obtaining records,

statements of fact or other relevant information and assessing them

objectively to determine the extent to which specified requirements are

fulfilled.

• Board of Stakeholders or Board: a group of representatives of key interests

within the scope of the certification scheme including experts on food safety.

• Certification system: rules of procedure and management for carrying out

conformity assessment leading to the issuance of a certification/registration

document and its subsequent maintenance.

• Certification scheme: a set of requirements for the process of certification to

certify conformance with a performance standard which is included or

referred to in the scheme. Apart from the performance standard, the scheme

may contain normative documents for the certification body and the

accreditation body which certifies the certification body.

• Food: any substance, whether processed, semi-processed or raw, which is

intended for human consumption, and includes drink, chewing gum and any

substance which has been used in the manufacture, preparation or treatment

of “food” but does not include cosmetics or tobacco or substances used only

as drugs

• Food manufacturing, also called food processing: The set of methods and

techniques used to make food. Food manufacturing typically takes harvested

crops or animal products and uses these to produce food for sale or delivery

to the consumer and ingredients for food manufacturing.

• Food processing: see definition of food manufacturing.

• Foundation: the Foundation for Food Safety Certification.

• General principles of food hygiene of the Codex Alimentarius: recommended

International code of practice - General principles of food hygiene, CAC/RCP

© Foundation for Food Safety Certification 2013 Page 13 of 13

1-1969, Rev. 4 (2003) of the Joint FAO/WHO Codex Alimentarius

Commission.

• Guidelines for drinking-water quality of the WHO: guidelines for drinking

water quality, Third edition, Volume 1, Recommendations, WHO, Geneva

2008.

• Major nonconformity: a nonconformity, as referred to in ISO/IEC 17021 clause

9.1.15b, that:

1) represents failure to fulfil one or more requirements of the management

system standard or

2) a situation that raises significant doubt about the clients system to achieve

its intended outputs.

• Minor nonconformity: other nonconformities as indicated in ISO/IEC 17021,

clause 9.1.15c.

• Normative document: normative documents are indicated in the scheme as

‘Requirements’.

• Organization in the food chain: the party that is responsible for ensuring that

products meet and, if applicable, continue to meet, the requirements on

which the certification is based.

• Periodically reviewed: periodically reviewed includes minimum annually.

• Standard: a document against which something can be measured, judged or

evaluated. "Document" is to be understood as any medium with information

recorded on or in it.

• Risk: the probability of causing an adverse health effect caused by the

likelihood of occurrence and by the possible severity of the adverse health

effect of a particular hazard in food when prepared and consumed according

to its intended use.

© Foundation for Food Safety Certification 2013 Page 1 of 14

FSSC 22000

Certification scheme for food safety systems

in compliance with

ISO 22000: 2005 and technical specifications for

sector PRPs

PART I

REQUIREMENTS FOR ORGANIZATIONS

THAT REQUIRE CERTIFICATION

Foundation for Food Safety Certification

Gorinchem, The Netherlands: 2013

Version Control Version 3 Published on April 10, 2013

Reason for change All scheme documents updated from 2011 version

2, to include general updating of requirements and

edits made during benchmarking for GFSI GD 6

Part I Requirements to obtain certification

© Foundation for Food Safety Certification 2013 Page 2 of 14

CONTENT

1. INTRODUCTION 3

2. SCOPE 5

3. REQUIREMENTS FOR THE FOOD SAFETY SYSTEM 6

3.1 Food safety management system ........................................................ 6

3.2 Prerequisite programmes .................................................................... 6

3.3 Additional requirements ..................................................................... 6

3.4 Guidance ............................................................................................ 6

Appendix I A: Additional requirements 9

Appendix I B: How to apply for certification 10

Part I Requirements to obtain certification

© Foundation for Food Safety Certification 2013 Page 3 of 14

1. INTRODUCTION

Purpose

This part of the scheme contains the requirements for organizations in the food

chain to gain certification. They shall be used by the organization to assess,

develop, implement and improve its food safety system and to apply for

certification. The requirements of the food safety system also serve as the normative

requirements for certification of the organization. They shall as such be used by the

certifying body to assess the continuous compliance of the food safety system that

is developed and implemented by the organization. Guidance is also given to the

CBs and the organizations on the application process for certification.

Food safety management and HACCP

For the greater part the requirements are based on the standard ISO 22000.

ISO 22000 was developed by the International Organization for Standardization (ISO)

and fulfils the need of:

• a worldwide food safety standard that is developed and owned by an

independent international organization;

• international harmonization of the requirements of food safety systems;

• integration of the technological (i.e. Good practices, HACCP, traceability) and

legal food safety requirements in the quality management system requirements

of standard ISO 9001;

• a food safety standard that is applicable to the whole supply chain and that

requires any organization in the chain to take into account the hazards of the

final product of the chain.

Based on this ISO 22000 is considered the most appropriate standard for the food

safety management system to be included in this scheme.

Good manufacturing practices

An important prerequisite for ensuring food safety is that organizations in the food

chain maintain the conditions for hygienic environment and production.

ISO 22000 requires in clause 7.2 that organizations shall select and implement

specific “Prerequisite programmes” (PRPs) for these basic hygiene conditions and

shall consider and utilize appropriate information when selecting the program (e.g.

the requirements as prescribed in the General principles of food hygiene of the

Codex Alimentarius, specific codes of practices of the Codex Alimentarius, food

safety legislation and possible customer requirements). It does not specify these

requirements as the standard is applicable to the whole food chain and the basic

Part I Requirements to obtain certification

© Foundation for Food Safety Certification 2013 Page 4 of 14

hygiene requirements may vary considerably between sectors. In order to create

explicitness on the requirements for PRPs and to allow for a benchmark of ISO

22000 certification schemes by customers (i.e. Global Food Safety Initiative of the

Consumer Goods Forum (GFSI)). Stakeholder organizations have developed detailed

technical specifications covering sector PRPs. These technical specifications can be

used in addition to ISO 22000 to provide further detail for chapter 7.2 of ISO 22000.

FSSC 22000 provides a certification scheme for sectors where such a technical

specification for sector PRPs has been realised as described in the scope (see also

chapter “Scope of the scheme”).

Additional requirements

To meet the needs of the key stakeholders and to ensure an adequate control of

food safety, specific requirements for the food safety system are included in this

scheme. These may be elaborations of the clauses in ISO 22000 and technical

specifications for sector PRPs or additional requirements and are included in the

section “Additional requirements” (Part I, Appendix IA). When it appears from the

three year review of the scheme by the Board or when the Board decides in one of its

three annual meetings that the requirements given in the standards need to be

amended or appended, these changes are also included in this section.

Part I Requirements to obtain certification

© Foundation for Food Safety Certification 2013 Page 5 of 14

2. SCOPE

The requirements in this document are set out for the assessment of food safety

systems (see also chapter “Features of the scheme”):

Category

codes

ISO/TS 22003

Categories Examples of

sectors

Applicable

PRP Technical

Specification

Additional

requirements

C perishable animal

products

i.e. meat, poultry,

eggs, dairy and fish

products

ISO/TS

22002-1

Appendix IA

D perishable vegetal

products

i.e. packed fresh

fruits and fresh

juices, preserved

fruits, packaged

fresh vegetables,

preserved

vegetables

ISO/TS

22002-1

Appendix IA

E products with a long shelf

life at ambient

temperature

i.e. canned

products, biscuits,

snacks, oil,

drinking water,

beverages, pasta,

flour, sugar, salt

ISO/TS

22002-1

Appendix IA

L (bio)chemical

manufacturing

food ingredients

i.e. vitamins,

additives, and bio-

cultures but

excluding technical

and technological

aids

ISO/TS

22002-1

Appendix IA

M food packaging material

manufacturing

i.e direct, indirect

contact with the

food

PAS 223 Appendix IA

The requirements are applicable to organizations in the food chain regardless of

size and complexity, whether profit-making or not and whether public or private.

Part I Requirements to obtain certification

© Foundation for Food Safety Certification 2013 Page 6 of 14

3. REQUIREMENTS FOR THE FOOD SAFETY SYSTEM

3.1 Food safety management system

The requirements for the development, implementation and maintenance of the

food safety management system are laid down in the standard ISO 22000: 2005

“Food Safety management systems - Requirements for any organization in the food

chain”.

3.2 Prerequisite programmes

When establishing, implementing and maintaining the Prerequisite programmes

(PRPs) in accordance with clause 7.2 of ISO 22000, the organization shall in addition

to ISO 22000 requirements consider and utilise the requirements of technical

specification for sector PRPs. Apart from these requirements, other appropriate

information shall be considered and utilised especially:

• regulatory requirements,

• recognized sector or product group codes of practices and guidelines,

• customer requirements.

The conditions of the PRPs shall be specified and documented, fully operational and

verified in order to facilitate the successful application and implementation of an

effective food safety management system. Exceptions where the requirements are

not applicable shall be motivated in writing.

3.3 Additional requirements

Additional requirements for the food safety system are laid down in Part 1,

Appendix IA.

3.4 Guidance

1. ISO/TS 22004

Guidance on the application of requirements of the food safety management system

is provided for in the Technical Specification ISO/TS 22004.

Reference: ISO 22000, various clauses

2. Definition food safety

In the requirements, food safety is defined as the concept that the food will not

harm the consumer when it is prepared and/or eaten according to its intended use.

Organizations in the chain are therefore required to take into account the food

safety hazards of their operation for the final product in the chain when establishing

prerequisite and HACCP programmes.

Reference: ISO 22000, clauses 3.1 and 3.3, note 4

Part I Requirements to obtain certification

© Foundation for Food Safety Certification 2013 Page 7 of 14

3. Chain approach

As is stated in chapter 2 of ISO/TS 22004, ISO 22000 promotes the adoption of a

food chain approach when developing, implementing and improving the

effectiveness and efficiency of a food safety management system. In this regard the

organization is required to consider the effects of the food chain prior and

subsequent to its operations when developing and implementing its food safety

management system. However, some food safety hazards which originate in the

food chain may not or cannot be controlled by the organization itself. In order to

ensure that these hazards are also controlled, the organization shall identify

organizations in the chain that may have an impact on the food safety of the

products of the organization (upstream), of which the food safety of the operations

may be affected by characteristics of the products of the organization (downstream).

The organization shall than establish, implement and maintain effective

arrangements for communication with these organizations, so that the relevant

hazards are known and can be controlled. In section 5.6 of ISO/TS 22004, the

requirements for external communication and arrangements with organizations in

the chain are elaborated. The requirement for communication on food safety

aspects and hazards in the chain is an essential criterion in the evaluation and

selection of suppliers and relevant partners.

Reference: ISO 22000, clauses 1.d and 4.1.a and b

4. Inventory of applicable regulations

It is pointed out that the organization in the food chain shall make an inventory of:

• the national, and if applicable foreign, regulatory and statutory requirements on

food safety which are applicable to the organization and which should be

implemented including the raw materials and services that are provided and

products that are manufactured and delivered,

• applicable codes of practice related to food safety, customer requirements

related to food safety, any other additional requirements on food safety

determined by the organization.

The food safety system of the organization shall ensure and demonstrate conformity

with these requirements

Reference: ISO 22000, clause 4.2.1, 5.6.1, 7.3.1 and 8.4.2

5. Application for certification

Guidance on the process of the application for certification is given in Appendix I, B.

Reference: ISO/TS 22003, clause 9.2.1(information to be provided by the applicant

organisation). ISO/IEC 17021, clause 5.1.2 (certification agreement), clause 8.6.1

(information to be provided by the CB), clause 8.6.1.d. (conditions to be included in

the agreement), clause 9.2.1 (information to be provided by the applicant

organisation,) clause 9.2.2.1 (review of application) and clause 9.5.1

Part I Requirements to obtain certification

© Foundation for Food Safety Certification 2013 Page 8 of 14

Note 1: the guidance in this section is a clarification of the requirements for the

food safety system and of the application of these requirements and is informative.

Note 2: if the guidance refers to a subject that is addressed in one or more of the

standards mentioned in the sections 3.1 and 3.2 of this part, the applicable

clause(s) of these standard(s) is/are indicated in the reference at the end of the

section with the guidance.

Part I Requirements to obtain certification

© Foundation for Food Safety Certification 2013 Page 9 of 14

Appendix I A

ADDITIONAL REQUIREMENTS

1. Specifications for services

The organization in the food chain shall ensure that all services (including utilities,

transport and maintenance) which are provided and may have an impact on food

safety:

• shall have specified requirements,

• shall be described in documents to the extent needed to conduct hazard

analysis,

• shall be managed in conformance with the requirements of technical

specification for sector PRPs.

Reference: ISO 22000, clauses 7.2.3.f and 7.3.3

2. Supervision of personnel in application of food safety principles

The organization in the food chain shall ensure the effective supervision of the

personnel in the correct application of the food safety principles and practices

commensurate with their activity.

Reference: ISO 22000, clause 6.2.2

3. Specific regulatory requirements

Organizations seeking certification shall assure that specifications for ingredients

and materials take account of any applicable regulatory requirements [e.g. control of

prohibited substances].

4. Announced, but unscheduled audits of certified organisations

The certification body will participate in a risk based programme of office audits and

announced, but unscheduled, audits of certified organisations. These audits shall be

carried out in accordance to the GFSI requirements.

5. Management of Inputs

The organization shall implement a system to assure that analysis of inputs critical

to the confirmation of product safety is undertaken. The analyses shall be

performed to standards equivalent to those described in ISO 17025.

Note: If an additional requirement refers to a subject that also is addressed in one or

more of the standards mentioned in the sections 3.1 and 3.2 of Part I, the applicable

clause(s) of these standard(s) is/are indicated in the reference at the end of the

section with the additional requirement.

Part I Requirements to obtain certification

© Foundation for Food Safety Certification 2013 Page 10 of 14

Appendix I B

HOW TO APPLY FOR CERTIFICATION

Introduction

According to this scheme, organizations are certified upon completion of a

satisfactory audit and a positive certification decision from a CB. The CB in turn shall

have been assessed and judged as competent by an accreditation body. The process

for accreditation of CBs and certification of organizations is outlined in Figure 1.

In order to receive a valid certificate, the organization shall select a CB which is

approved and licensed by the Foundation. The Foundation stipulates detailed

requirements that a CB shall meet in order to gain approval. As a minimum, the CB

shall be accredited in accordance with the requirements and regulations in Part II of

this scheme.

The certification process

Selection of certification body

It is essential that the organization is assessed against the current issue of the

scheme and that the scheme is available throughout the certification process. The

current issue of the scheme is available from www.fssc22000.com. The scheme

should be read and understood and a preliminary self assessment shall be

conducted by the organization against the requirements and guidance in the section

3 of Part I of this scheme. Any areas of nonconformities shall be addressed by the

organization. Once the self-assessment has been completed and nonconformities

addressed, the organization must select a CB. The Foundation cannot advise on the

selection of a specific CB, but the Foundation lists FSSC 22000 approved

certification bodies on www.fssc22000.com.

Certification agreement

A contract shall exist between the organization and the CB, detailing the agreed

scope of the audit including reference to the FSSC 22000 scheme requirements. This

contract shall be formulated by the CB. It is the responsibility of the organization to

ensure that adequate and accurate information is given to the CB to enable the CB to

select (an) auditor(s) with the required skills to undertake the audit (see Part II). The

CB shall require completion of an official application form, signed by a duly

authorized representative of the applicant.

Part I Requirements to obtain certification

© Foundation for Food Safety Certification 2013 Page 11 of 14

Audit program, duration and costs

For the initial audit, the organization shall agree a mutually convenient date or

dates, with due consideration given to the amount of work required to meet the

requirements of the scheme. The organization shall provide the CB with appropriate

information to allow them to review the application and to assess the duration and

the costs of the audit. There is a requirement on the organization to plan carefully

for the audit, to have appropriate documentation for the auditor to assess and to

have appropriate staff available at all times during the on-site audit. The initial

certification is carried out at the premises of the organization and is conducted in

two stages. In the first stage the documentation of the food safety system is

evaluated which includes among others the scope of the food safety system, the

food safety hazard analyses, the PRP programme, the managements structure, the

policy of the organization etc. An important objective of this audit is to assess the

preparedness of the organization for the audit. Any areas of concern that could be

classified as nonconformity shall be resolved before the stage 2 audit.

In the stage 2 audit the implementation and effectiveness of the food safety system

is evaluated.

Certification granted

The audit team of the CB shall analyse and review the findings of the stage 1 and

stage 2 audit and report on the assessment. Nonconformities are pointed out and,

where applicable, the effectiveness of the corrections and corrective action taken or

planned by the organization. On the basis of this audit report and any other relevant

information (e.g. comments of the organization on the audit report) the CB shall

make a certification decision (see flow diagram).

A certificate shall only be granted if all nonconformities are resolved. In case of

minor nonconformities the CB may grant certification if the organization has a plan

for correction and corrective action. The certificate shall be issued by the CB

typically within 30 calendar days after the CB has reviewed, accepted and verified

the effectiveness of the corrections and corrective actions and the plans of the

corrections and corrective actions for the revealed nonconformities. The users of the

certificates are advised to verify that the scope of the certificate is clearly stated and

this information is consistent with their own requirements. Whilst the certificate is

issued to the organization, it remains the property of the CB which controls its

ownership, use and display. The organization has the right to appeal the

certification decision made by the CB in accordance with the documented appeal

handling process of the CB.

Part I Requirements to obtain certification

© Foundation for Food Safety Certification 2013 Page 12 of 14

Changes, scope extension

Once certification has been granted, any changes that may affect the fulfilment of

the requirements for the certification shall immediately be communicated to the CB.

This may be changes in the products or manufacturing processes that may require

extension of the scope of the certification, in the management and ownership of the

organization, the location etc. The CB will then conduct a site visit to examine the

consequences and determine any audit activities necessary. The CB decides whether

or not extension may be granted. If extension is granted the current certificate will

be superseded by a new certificate using the same expiry dates as detailed in the

original certificate.

Surveillance

The certificate expires three years after the date of issuance. In the intermediate

period surveillance audits shall be conducted at least once a year. These audits shall

address all scheme requirements from ISO 22000, relevant PRP documents and FSSC

22000 plus including evaluation of internal audits and management review, review

of actions taken on nonconformities identified in the previous audit, treatment of

complaints, effectiveness of the management system, progress on continual

improvement, operational control, review of changes and use of marks and

references to certification. Surveillance audits shall be carried out and reported as

described in the scheme document “Guidance Notes on Surveillance Audits” which is

available on the website.

In case a nonconformity is identified by the audit team, the CB shall take a decision

continuation, suspension or withdrawal of the certificate depending on the

corrections and corrective actions of the organization (see flow diagram).

Recertification

Before the date of expiration of the certificate a recertification audit shall be

conducted. The purpose of this audit is to confirm the continued conformity and

effectiveness of the food safety system as a whole. The fulfilment of all

requirements is evaluated. The audit also includes a review of the system over the

whole period of certification, including previous surveillance audit reports. Identified

nonconformities are dealt with as described in the surveillance audits. The CB makes

a decision on renewing of the certification on the basis of the recertification audit,

the review of the system over the whole period and complaints received from users

of the certification.

Part I Requirements to obtain certification

© Foundation for Food Safety Certification 2013 Page 13 of 14

Communication with certification bodies

In the event that the organization becomes aware of legal proceedings with respect

to product safety or legality, or in the event of a product recall, the organization

shall immediately make the CB aware of the situation. The CB in turn shall take

appropriate steps to assess the situation and any implications for the certification,

and shall take any appropriate action.

Flow diagram

Obtain a copy of the scheme requirements from

www.FSSC22000.com

How to gain certification

Complete a Self Assessment to determine compliance with the requirements in section 3 of

Part 1 of the scheme documents

Initial Audit Stage 1 Evaluation of FSMS documentation, scope,

resources and preparedness for stage 2

Select an approved Certification Body. Approved certification bodies an be found on

www.FSSC22000.com

Closing meeting and confirmation of any non conformities

Initial audit corrections and corrective action

completed

No non conformities raised

Corrections and corrective action evidence assessed by

certification body by documented evidence or

Revisit. Successful close out documented

Certification decision made by certification body

Independent certification review completed

Ongoing surveillance audits ( see continued certification

flow chart)

Corrective action not completed or not

satisfactory

No certificate issued

Initial Audit Stage 2Evaluation of the implementation and

effectiveness of the FSMS

Part I Requirements to obtain certification

© Foundation for Food Safety Certification 2013 Page 14 of 14

Surveillance Audits

Following issue of the certification ongoing pre planned surveillance audits take a

minimum of once per year

Nonconformity raised

A Surveillance audit report is completed and details findings during the audit and

nonconformities are documented

No correction and corrective action

taken or not effective

Correction and corrective action plan submitted and verified . Full

verification of the corrective action completed at the next due visit

Decision taken on suspension or

withdrawal of the certificate

Correction and corrective action must be taken and verified by the

auditor either by a re visit or documented evidence

Minor nonconformity raised

No correction and no corrective action plan submitted

Re Certification every 3 years

Continuing Surveillance visits Correction and

correction action acceptable

Decision taken on suspension or

withdrawal of the certificate

No nonconformities raised

© Foundation for Food Safety Certification 2013 Page 1 of 35

FSSC 22000

Certification scheme for food safety systems

in compliance with

ISO 22000: 2005 and technical specifications for

sector PRPs

PART II

REQUIREMENTS AND REGULATIONS

FOR CERTIFICATION BODIES

Foundation for Food Safety Certification

Gorinchem, The Netherlands: 2013

Version Control Version 3 Published on April 10, 2013

Reason for change All scheme documents updated from 2011 version

2, to include general updating of requirements and

edits made during benchmarking for GFSI GD 6

© Foundation for Food Safety Certification 2013 Page 2 of 35

CONTENT

1. INTRODUCTION ....................................................................................... 3

2. REQUIREMENTS FOR CERTIFICATION ......................................................... 4

2.1 Requirements ..................................................................................... 4

2.2 Additional requirements ..................................................................... 4

2.3 Accreditation ...................................................................................... 4

2.4 Guidance ............................................................................................ 4

3. REGULATIONS FOR CERTIFICATION BODIES ............................................... 5

Appendix II A: Additional requirements ...................................................... 10

Appendix II B: Format of the audit report ................................................... 16

Appendix II C: Requirements for certification bodies defined by GFSI .......... 31

© Foundation for Food Safety Certification 2013 Page 3 of 35

1. INTRODUCTION

Purpose

This part of the scheme stipulates the requirements for certification bodies (CBs)

and their personnel and the way they shall perform assessments and certification. It

shall be used by the CB that wishes to grant certificates in conformance with this

scheme. It consists of:

• the requirements for the CB and the certification process and

• the regulations and rules for the assignment and authorization of the CB to

offer certification against the criteria of this scheme.

Standards and technical specifications

The normative requirements for the organization to gain certification are the food safety

management system requirements of ISO 22000, the detailed requirements of technical

specification for sector PRPs and a number of additional requirements as specified in

section 3 of Part I.

Food safety management systems should, like other quality management systems, be

certified by certification bodies that operate management system certification in a

competent, consistent and impartial manner in accordance with ISO/IEC 17021

requirements for bodies providing audit and certification of management systems. To

promote the harmonized certification of food safety management systems, ISO

developed the Technical Specification ISO/TS 22003. This TS elaborates on ISO/IEC

17021 and contains additional requirements to be applied by certification bodies to

make the food safety management system certification credible. Therefore, ISO/TS

22003 and ISO/IEC 17021 are considered to be the appropriate standards to apply for

certification in accordance with this scheme.

The requirements for assessment and certification according to ISO/TS 22003 also

includes the assessment of PRPs.

Additional requirements

To meet the needs of the key stakeholders and/or to ensure an adequate and

uniform assessment and certification of the food safety systems, specific

requirements for certification are included in this scheme. These may be

elaborations of the clauses in ISO/TS 22003 and ISO/IEC 17021 or additional

requirements and are included in the section “Additional requirements” (Part I,

Appendix IA). When it appears from the review of the scheme by the Board or when

the Board decides that the requirements need to be amended or appended, these

changes are also included in this section.

© Foundation for Food Safety Certification 2013 Page 4 of 35

2. REQUIREMENTS FOR CERTIFICATION

2.1 Requirements

Evaluation of conformance

The certification body shall take all steps required to evaluate conformance with the

standard and fully comply with other associated requirements of the certification

scheme.

Criteria for providing certification

The normative requirements for providing certification are specified in Part I, section

3.

2.2 Additional requirements

Additional requirements for the development and implementation of the

certification system are specified in Appendix IIA.

The GFSI requirements as indicated in Appendix IIC are explicitly to be met. Future

changes to this addendum will be valid. Most requirements in this addendum are in

line with ISO/IEC 17021 requirements; others are explicitly included in this scheme.

GFSI Requirements that are implicitly met by the scheme and ISO/IEC 17021,

however may require attention to guarantee full accordance, are specified in the

appendix.

2.3 Accreditation

The CB shall have an accreditation in the applicable Food Chain Category (ref. Part I,

chapter 2: scope) according to ISO/IEC 17021 and the additional requirements as

specified in the sections 2.1 and 2.2 and ISO/TS 22003.

The certification body shall ensure that accreditation is provided by an accreditation

body meeting the requirements specified in Part III.

The CB shall inform the Foundation about the accreditation status and directly

communicate suspensions or withdrawals of the relevant accreditations.

© Foundation for Food Safety Certification 2013 Page 5 of 35

3. REGULATIONS FOR CERTIFICATION BODIES

Application

When applying for association with the Foundation, the certification body (CB) must

specify the required category or categories and sector(s), related to its competence

and experience. The applicant CB will agree to meet all applicable requirements of

this scheme. The CB will be given written authorization enabling it to use the

scheme for certification.

Accreditation

A contract with the CB will only be signed up after it has been accredited. The CB

shall be accredited in accordance with the requirements of the scheme FSSC 22000.

CBs which have applied for accreditation or for extension of their scope of

accreditation to this scheme may certify within the applied scope for a maximum of

one year without being accredited, subject to a provisional contract with the

Foundation. The application for accreditation or for extension of their scope of

accreditation shall be demonstrated with a written confirmation of the accreditation

body (AB).

Application fee

An application fee has to be paid to the Foundation before this authorization will be

given.

Design of the certificate

The design of the certificate will be similar to the certificates that are issued by the

awarding CB. Notwithstanding this, the certificates shall include the following

information:

name and address of the organization (site) which food safety system is

certified;

period of validity; initial, reissue and valid until

relevant signatures and positions of signatories;

scope, expressed in terms of categories, sectors, production processes,

products and sites;

logo of the accreditation body;

date of the certification decision

© Foundation for Food Safety Certification 2013 Page 6 of 35

Furthermore, the certificate shall contain the following standard text:

The food safety management system of (name and place) has been assessed and

complies with the requirements of:

FOOD SAFETY SYSTEM CERTIFICATION 22000: 2010

Certification scheme for food safety systems

including

ISO 22000:2005, “name of applicable technical specification for sector PRPs”

and additional FSSC 22000 requirements

This certificate is applicable for (scope).

This certificate is provided on the base of the FSSC 22000 certification scheme,

version 3, published 10 April 2013. The certification system consists of a minimum

annual audit of the food safety management systems and a minimum annual

verification of the PRP elements and additional requirements as included in the

scheme and “name of applicable technical specification for sector PRPs”.

Certification logo

Organizations may not display the FSSC 22000 certification logo or mention

possession of a FSSC 22000 certificate on their products. The logo (copyright) is

allowed to be used on the issued certificates if the certification is conducted in

accordance with all requirements of this scheme.

Reference: Conditions for the use of the logo which can be found on the FSSC 22000

website.

Implementation of new requirements

In the event of the relevant documents in the FSSC 22000 scheme being changed,

the Board will give an appropriate period of grace for the organizations to adapt to

the implementation of the new requirements, unless the legal regulations stipulate a

different transition period.

Changes in the certification scheme

New information or changes with regards to the requirements in the FSSC 22000

scheme shall be communicated by the CBs to those parties involved, such as

certificate holders and auditors (auditors and experts), within a period of 2 months.

Appeals and complaints

The CB shall have arrangements for appeals and complaints. Clauses 9.7 and 9.8 of

ISO/IEC 17021 apply.

© Foundation for Food Safety Certification 2013 Page 7 of 35

Conflicts of interest

The certification body shall require all staff involved in the certification process to

sign a contract or agreement which clearly commits them to:

I. Complying with the rules of the organization, with particular reference to

confidentiality and independence from commercial or personal interests.

II. Declaring any issues in relation to personal conflicts of interests.

ISO/IEC 17021

The certification body shall clearly document and make known to its employees all

requirements in ISO/IEC 17021 related to personnel.

Full application of the FSSC 22000 certification scheme

The certification bodies are responsible for the full application of the certification

scheme and have to observe the regulations and directives issued by the Board.

Annual fee for certified organizations

Organizations certified against this scheme will be charged by the CB for an annual

fee to the Foundation. The CB will address this obligation in the certification

agreement with the organization. The Foundation will decide annually on the

amount of this fee. The CBs will be charged at least annually by the Foundation for

the total amount of fees of all certificates they have under contract per 31 December

of each year.

Duration of certification

The maximum validity of the certificate is three years. Reassessment has to take

place in time to ensure that recertification is granted before the expiry date of the

certificate (clause 9.4 of ISO/IEC 17021).

Register of certified organizations

The Foundation will keep a register with the names and certification information of

the certified organizations. This register will be made publicly available on the

website of the Foundation. The CBs will submit the following information to the

Foundation in a format as agreed in the contract between the Foundation and the

CB:

name and location of the certified organization

scope of the certification

date of the initial certification

expiry date of the certificate

© Foundation for Food Safety Certification 2013 Page 8 of 35

in case of suspension or withdrawal; the date of suspension or withdrawal

This information shall be submitted by the CB to the Foundation within 42 weeks

after the delivery of the certificate. The CB shall agree in the certification agreement

with the organization that this information will be submitted by the CB to the

Foundation and this information will be made public.

Auditor registration system

The scheme owner shall have in place an auditor registration system for every

scheme specific auditor employed by a certification body. The details of the

auditor’s qualifications, training, experience and scope of activity in relation to the

scheme’s product categorization shall be held and maintained within this register.

The scheme owner will register approved auditors and shall ensure that the

certification body has a system to update the auditors’ details, where appropriate.

The certification body shall register qualified auditors with the Foundation and

update the register at least once per year.

Distribution of audit reports

The certification body shall provide a written report for each audit. The audit team

may identify opportunities for improvement but shall not recommend specific

solutions. Ownership of the audit report shall be maintained by the certification

body. The content of audit reports is to be treated confidentially by the CB. At

discretion of the contracted client audit reports may be made available to authorized

parties, however the ownership of the audit report and determination of details

made available and authorization for access remain with the contracted client.

Exchange of information

At least once per year, the CBs are obliged to provide the Board with all relevant

information relating to the application and the functioning of the FSSC 22000

scheme. This information shall be made anonymous so that confidentiality with

respect to organizations is assured.

Harmonization process

The CB is obliged to participate in consultations on the interpretation of the scheme.

Once every year there will be a harmonization meeting. In principle a coordinating

officer represents the CB during this meeting. Cases will be brought in for

discussion. Each CB shall discuss the cases and the results in their own CB with their

auditors. A regulation can be set up for the harmonization process.

© Foundation for Food Safety Certification 2013 Page 9 of 35

Implementation of regulations

The CBs are required to ensure that the regulations which are decided by the Board are

included in their existing system documentation within a period of two months.

Certification bodies are required to control these documents according to their own

document control procedures.

Noncompliance with FSSC Scheme Requirements

In cases where a CB fails to comply with the requirements set out in the scheme

documents, detailed information will be gathered for review by the Board of

Stakeholders. The review will normally take place at the next scheduled BoS meeting. If

the nonconformance is of a serious nature, the secretary may request a special meeting

to deal with matter. The BoS will determine appropriate measures to be taken to deal

with the nonconformity.

The Board of Stakeholders approved these regulations in April 2013.

© Foundation for Food Safety Certification 2013 Page 10 of 35

Appendix II A1

Additional requirements

Note: if an additional requirement refers to a subject that is also addressed in one or

more of the standards mentioned in section 2.1 of Part II, the applicable clause(s) of

these standard(s) is/are indicated in the reference at the end of the section with the

additional requirement.

1. Work experience of auditors

Concerning the requirements on work experience of the auditors in ISO/TS 22003,

clause 7.2.42.4, the following is added:

• The five years full time work experience in a food chain related industry, shall be

in the food related industry in the areas of processing, technology, raw materials

and /or products;

• The two years of full time work in quality assurance or food safety functions shall

be in the food related industry;

• The allowance to reduce the required five years of total work experience by one

year if the auditor has completed appropriate post secondary education, is not

applicable;

• The competence of auditors shall be reestablished every 3 years.

Reference: ISO/TS 22003 clause 7.2.4.4 and ISO 19011 clause 7.3.2

2. Auditor training

Training program

A training program for each auditor will incorporate:

• an assessment of knowledge and skills for each field and sub field and

assignment of fields of evaluation;

• an assessment of knowledge of food safety, HACCP, PRP’s and to have access

to, and be able to apply relevant laws, regulations and codes;

• a period of supervised training to cover the assessment of food safety

management systems, PRPs and HACCP, specific audit techniques and

specific category knowledge;

• for extension of auditor scope for new categories the requirements of ISO/TS

22003, clause 7.2.4.5 apply;

• a documented sign off of the satisfactory completion of the training program

by the appointed supervisor;

• a plan for continued training to keep the auditors up to date with the best

practices and relevant regulatory and statutory developments in the sector(s)

where they perform audits. In order to maintain category and scheme

knowledge, auditors shall be required to carry out a minimum of 5 on-site

© Foundation for Food Safety Certification 2013 Page 11 of 35

GFSI Recognized audits at different organizations each year;

• instructions for the auditor to maintain written records of all relevant training

undertaken.

Reference: ISO/TS 22003, clause 7.2.4.5 and ISO/IEC 17021, clause 7.2.8

Food safety training

The training in HACCP principles, hazard assessment and hazard analysis shall have a

duration of at least 2 days/16 h. The food safety management training shall also include

specific elements of the sector(s) in which the auditor conduct audits like raw materials,

processes, products, risks and legislation and prevailing code(s) of hygiene.

Reference: ISO/TS 22003, clause 7.2.4.2

Audit training

The training prescribed in section 7.2.4.3 of ISO/TS 22003 shall also cover:

• audit techniques for food safety systems as described in Part I of this scheme;

• the content of this scheme including the standards and technical specification to

which is referred.

The training in audit techniques shall have a duration of at least 1 week/40h.

Reference: ISO/TS 22003, clauses 7.2.6 and 7.2.4.3

3. Audit experience

For qualification the requirements of ISO/TS 22003 apply.

In addition to ISO/TS 22003 auditors need to have knowledge of the delivery

requirements of FSSC and knowledge of the content of the technical specification for

sector PRPs. The certification body shall define how to ensure that this requirement is

met.

The total supervised training against this scheme shall include a successful

completion of supervised training in practical assessment of this standard through

10 audits or 15 audit days at a number of different organizations.

Previous experience in ISO 22000 and/or GFSI recognized audits is considered to

be applicable for meeting the practical assessment training requirements.

Reference: ISO/TS 22003, clause 7.2.4.5

4. Defining the scope of the certification

When defining the scope, the CB shall indicate for each location the name of the food

chain category and the specific sector as specified in Annex A of ISO/TS 22003 and

clause 2 of Part 1.

Reference: ISO/TS 22003, clause 9.1.1 and FSSC 22000 guidance document on

certification scopes.

© Foundation for Food Safety Certification 2013 Page 12 of 35

5. Duration of audit and audit reporting

In addition to the onsite audit time and preparation and reporting time as stipulated in

ISO/TS 22003, clause 9.1.4. and Annex B, the CB shall depending of the size of the

organization add half to one day for the audit and reporting of the establishment and

implementation of the PRPs as stipulated in section 6 of this appendix. This additional

time is as well required for an initial, surveillance and renewal audit. Details of the

duration of the audit shall be incorporated In the audit report.

Reference: ISO/TS 22003, clauses 9.1.2 and 9.1.4 and Annex B

6. Requirements for audit of PRPs

The CB shall assess whether the organization has established and implemented and

maintains the necessary PRPs according to the requirements of section 3.2 of Part I.

Of all requirements it shall be assessed to what extent the requirements are

fulfilled. The specific requirements for which the necessary PRP is not established or

is not effective in controlling the introduction of food safety hazards (as specified in

clause 7.2.1 of ISO 22000) shall be identified. In order to verify if the PRPs are met a

plant tour shall be part of the audit.

Reference: ISO/TS 22003 clauses 9.2.3.1.1 and 9.2.3.1.2, 9.2.3.1.4, 9.2.3.1.5 and

9.2.3.2

7. Requirements for the audit reports

General

Additional to the items for the audit and certification reports as stipulated in ISO/TS

22003, clauses 9.1.7 and ISO/IEC17021, clauses 8.2.3, 9.2.3.1.2, the audit and

certification report shall identify the following:

• Name and description of the company to which the organization belongs

(name, legal entity and address of headquarters);

• Date of previous audit and name of CB conducting the previous audit

• Details of existing certificates;

• Overview of relevant changes to documentation, requirements, processes and

products since the last audit;

• Registered complaints on Food Safety and reports to concerning government;

• List of key personnel present at the audit;

• Evidence that the client representative has seen the report and has accepted

any NCs raised and provided an appropriate response;.Names and signatures

of the audit team members;

• Names, function and signatures of the representatives of the auditee;

• Description of the assessment of the identification by the organization of the

food safety hazards to be controlled and the selection of the appropriate

(combinations of) control measures for relevant hazards in the operational

© Foundation for Food Safety Certification 2013 Page 13 of 35

PRPs or in the HACCP plan;

• The audit of the PRP requirements (specified in Part I, section 3.2) shall be

reported separately according to the requirements in section 8 “Audit report

of PRPs” in this Annex and attached to the audit report;

• Results and the conclusions of the audit per clause of the normative standard

or technical specification (specified in Part I, section 3.1) and per additional

requirement (specified in Part I, section 3.3);

• Overview of nonconformities and minor nonconformities together with the

corresponding clause number of the normative standard or technical

specification (specified in Part I, section 3.1 and 3.2) or the number of the

additional requirement (specified in Part I, section 3.3);

• Expiry date of the certificate.

The Board may decide on more specific requirements for reporting.

In the result section of the report conformance of compliance or noncompliance

shall be indicated. In case of nonconformance details shall be provided. Non

applicable clauses shall be motivated. In the summary section positive evidence of

confirming compliance shall be provided.

Reference: ISO/TS 22003, clauses 8, 9.1.7 and 9.2.3.1.4 and ISO/IEC 17021, clauses

8.2.3, 9.2.3.1.2 and 9.2.5.1

Audit report format

The audit report shall cover all elements described in the format as indicated in Part

II, appendix IIB (ISO 22000, PRPs and additional requirements) in order to confirm

that all requirements are assessed and reported.

8. Criteria for nonconformities and certification decision

The CB is required to establish and maintain criteria as a reference against which a

nonconformity and minor nonconformity is determined, in accordance with the

definitions in this scheme.

Food organizations can only qualify for granting certification on the basis of this

scheme if:

- the CB has not revealed any outstanding nonconformities and

- the CB has reviewed and accepted the planned corrections and corrective actions

for minor nonconformities.

Reference: ISO/IEC17021, clause 9.1.9, 9.1.15 and 9.2.5.2 and ISO 19011, clause

6.2.2.

© Foundation for Food Safety Certification 2013 Page 14 of 35

9. Requirements for initial certification

Stage 1 includes all requirements of 9.2 of ISO/TS 22003 and shall be performed at

the client premises in order to evaluate the preparedness of the organization for

stage 2. During the initial certification audit (stage 1 and 2) all requirements of this

scheme shall be evaluated. This includes ISO 22000, the applicable technical

specification for sector PRPs and additional FSSC requirements (clause 3.3 of Part I).

Stage 2 includes a comprehensive site tour and shall cover a representative number

of product lines, categories and sectors covered by the scope. The site tour shall

include the review of implementation of all CCP’s and Operational PRP’s and shall

include a representative sampling of the PRP’s. The tour shall include all areas that

might influence food safety. Where comparable activities / processes take place it is

allowed to sample.

Reference: ISO/TS 22003, clause 9.1.2

10. Requirements of the surveillance audits

During the surveillance activities and surveillance audit all scheme requirements

from ISO 22000, relevant PRP documents and FSSC 22000 the effectiveness of the

food safety management system and the compliance with the requirements of ISO

22000, technical specification for sector PRPs and the additional requirements of

this scheme (section 3.3 of Part 1) will be reviewed. Surveillance audits shall be

carried out and reported as described in the scheme document “Guidance Notes on

Surveillance Audits” which is available on the website. This shall include an

examination of the food safety management system documentation on the

registration of changes and of the internal communication of changes in the

production process, the (origin of) raw materials, the products and product

characteristics or in the context in which the food safety system is operating (e.g.

changes in legislation, codes of practices, customer requirements) in the period

after the previous audit. If any changes are identified by this examination or

otherwise, the surveillance audit shall include a full assessment and reporting of the

assessment of:

• the documentation requirements, specifically clauses 4.2.1. and 7.3.1 of ISO

22000 and clause 1 of Section 3.3 (Appendix I A) of Part I of this scheme;

• the establishment and implementation of the PRPs;

• the hazard analysis and the operational PRPs and CCPs.

During surveillance audits it is allowed to sample activities and a number of product

lines, categories and sectors covered by the scope. The sampling shall result in a

representative review of the scheme implementation.

Reference: ISO/IEC 17021, clauses 9.3.

© Foundation for Food Safety Certification 2013 Page 15 of 35

11. Notification of factors affecting the certification

The CB shall have arrangements in place with certified organizations for the timely

notification in the event that the organization becomes aware of legal proceedings

with respect to product safety or legality, or in the event of a product recall. The

organization shall immediately, at least within 3 working days, make the CB aware

of the situation. The CB in turn shall take appropriate steps to assess the situation

and any implications for the certification, and shall take any appropriate action. The

CB shall have procedures in place to ensure the integrity of certification following

such notification.

12. Requirements for additional audits

The CB shall undertake additional surveillance audits in the event that there is evidence

or suspicion of nonconformity within the certified organization.

13. Requirements for recertification

All requirements given in ISO/IEC 17021 clause 9.4 apply. The recertification shall

include a full assessment and reporting of all requirements (see Part II, chapter 9).

14. Risk based office audits

The CB will participate in a risk based programme of office audits and announced,

but unscheduled, audits of certified organisations. These audits shall be carried out

in accordance to the GFSI requirements.

© Foundation for Food Safety Certification 2013 Page 16 of 35

Appendix II A2

Additional requirements Packaging

1. Auditor competence

A primary qualification, a degree or higher certificate in packaging technology and a

relevant certificate recognised by the scheme owner in food technology, food

hygiene or related science subject OR a primary qualification in food technology,

food safety/ hygiene or related science subject and a certificate in packaging

technology that is recognised by the scheme owner. Experience is required in the

specific sectors of packaging manufacture:

- plastics

- paper and board

- metal

- glass.

Food auditor with a packaging certificate

A primary qualification in food technology, food safety/ hygiene or related science

subject and a certificate in packaging technology that is recognised by the scheme

owner. The training organization needs to demonstrate to the Foundation that the

training (live or on-line) is delivered by a WPO recognized training organization

(including post-training examination) which include the following minimum

requirements which have to be verified by the CBs:

a. Basics of Packaging Principles & Concepts