FoundationTreatmentAssessmentandPostconstruction ...Apr 09, 2020 · rolling 10,TLLS 0.4m,λ...

Transcript of FoundationTreatmentAssessmentandPostconstruction ...Apr 09, 2020 · rolling 10,TLLS 0.4m,λ...

Research ArticleFoundation Treatment Assessment and PostconstructionSettlement Prediction of a Loess High Fill Embankment ACase Study

Caihui Zhu 123 Xiaosong Zhou 4 and Songhe Wang 123

1State Key Laboratory of Eco-hydraulics in Northwest Arid Region Xirsquoan University of Technology Xirsquoan China2Institute of Geotechnical Engineering Xirsquoan University of Technology Xirsquoan 710048 Shaanxi China3Shaanxi Provincial Key Laboratory of Loess Mechanics Xirsquoan University of Technology Xirsquoan China4China Jikan Research Institute of Engineering Investigastions and Design Co Ltd Xirsquoan China

Correspondence should be addressed to Caihui Zhu anderth123163com and Songhe Wang wangsonghexauteducn

Received 9 April 2020 Revised 21 October 2020 Accepted 24 October 2020 Published 12 November 2020

Academic Editor Sara Amoroso

Copyright copy 2020 Caihui Zhu et al is is an open access article distributed under the Creative Commons Attribution Licensewhich permits unrestricted use distribution and reproduction in any medium provided the original work is properly cited

e design of high fill embankments (HFEs) on the loess plateau requires proper foundation treatment methods and reasonableprediction of postconstruction settlement (PCS) In situ tests were carried out on a test section of the collapsible loess foundationof a high fill airport to assess the reinforcement effects of common treatment methods Based on in situ monitored data thespatial-temporal variations of the PCS of the HFE were investigated with a simple empirical formula proposed for PCS predictione PCS increases linearly with the fill thickness and the PCS rate varies exponentially with the fill rate Two engineeringrecommendations were made to reduce differential PCS and water damage for the test site e first is to combine the rein-forcement methods to reduce PCS of the HFE ie dynamic compaction for loess foundation with lower water content and gravelpiles with stabilizers for that with higher water content e second is to employ the dynamic compaction (DC) percussivecompaction (PC) and vibration compaction (VC) to strengthen the fill to reach an average compaction degree above 093 and awater content close to the optimal

1 Introduction

Northwest China is a mountainous area with a growingdemand for deep excavation and high fill projects such asdams airports subgrades and urban space constructionespecially in the collapsible loess area [1] Collapsible loess isa special soil with a loose structure and high porosity andthe shear strength of unsaturated loess is high and thecompressibility is low When it is soaked by water and isunder a certain pressure the soil structure will be destroyedquickly resulting in large additional subsidence and a rapiddecrease in strength [2] ese high fill projects bring newopportunities and challenges to the field of geotechnicalengineering research Fill technology of high embankmentsfoundation treatment methods and postconstruction set-tlement (PCS) control are widely concerned issues e

prototype tests in situ monitoring numerical methodslaboratory tests model tests fuzzy theory and analyticalsolutions have been used to study the PCS and controltechnology in high fill embankment (HFE) projects [3ndash11])In situ tests and monitoring are of great significance forquickly obtaining construction control standards and thespatial-temporal deformation of such projects e foun-dation soil and the high fill body are the two geologicalentities that constitute HFE projects they need to bereinforced to achieve the design function

In order to reduce the PCS of embankments the stiffnessof the high fill and foundation soil should be enhanced andthe bearing capacity of the soil should be increasedere aremany techniques that are used to improve the stiffness andbearing capacity of the saturated clayey soil [12ndash21] esetechniques include soil removal and replacement

HindawiShock and VibrationVolume 2020 Article ID 8864690 22 pageshttpsdoiorg10115520208864690

precompression or preloading improvement and stabili-zation Rowe and Liu et al [16] studied the reinforcementeffects of a full-scale geosynthetic-reinforced pile-supportedembankment by using a fully coupled three-dimensionalfinite element method which indicates the applicability ofthe proposed method in reducing the settlement at thesubsoil surface Reference [19] found that the pile spacingwith the geosynthetic-reinforced method is the most sen-sitive factor influencing the maximum settlement of thesubsoil In recent decades geotextile reinforcement and tire-reinforced methods have been verified to improve thestrength of the soil of embankments [14 17]e deepmixedcolumns with cement-fly ash-gravel piles (CFGs) are alsocommonly used for ground improvement to treat the set-tlement of embankments [5 13 20 22 23]

e above methods are mostly used in soft soil foun-dations some of which are available for foundation treat-ment in deep collapsible loess foundation in HFE projectsWang et al [24] performed a centrifugal model test with ageogrid-reinforced pile-raft-supported method consideredin high-speed railways embankments on collapsible loessand the proper value of the pile spacing was suggested Meiet al [15] reported that the dynamic compaction (DC)method can effectively improve the bearing capacity andeliminate the collapsibility of the loess foundation Li et al[12] proposed the explosive compaction technology for loessembankment settlement control Zhu and Han et al [21]suggested that the compaction technology pile platestructure effective drainagemeasures and soil improvementwith admixtures can be systematically adopted for col-lapsible loess foundations to reduce the engineering prob-lems For controlling the PCS of the HFE projects in loessregions Hu et al [3] suggested that the water content shouldbe controlled within a range of 12ndash14 Wang [24]proposed that the following methods could be used to de-crease the PCS of fill embankments using lightweight fillmaterials enhancing the compaction degree of the fillmaterials and increasing the pile length in the foundationsoil For predicting the PCS of fill embankment the em-pirical method numerical method and in situ monitoringare widely used [4 5 11 25] In previous studies researchersproposed empirical formulas to estimate the crest PCS of theHFE [26ndash30]e empirical formulas were shown in Table 1ey can be generally represented as

S a +bH

c

Ed

eminus mtn( )

(1)

where S is the crest PCS of the fill body (m) H is the fillheight of the embankment (m) t is the duration time of PCS(years) E is the deformation modulus of the fill material(MPa) and a b c d m and n are the empirical coefficients

Equation (1) indicates that the PCS has nonlinear re-lationships with the fill height the compression character-istics of the fill body and the duration time Howeverequation (1) does not consider the thickness and com-pression characteristics of the foundation soil and it is usedfor self-weight settlement prediction of embankment fillesettlement of foundation soil is not included in it

e sources of PCS or its major components are cur-rently not sufficiently clear from previous studies Moreoverthe effects of foundation treatment and fill process are notreasonably considered in PCS predictions In this study atest section of a high fill airport was taken as the study object(the purpose of fill construction is to reach an adequate levelfor an airfield andor other structures related to airportconstruction) In situ tests of PCS were carried out to studythe reinforcement effects of different treatment methods forthe HFE e proportions of the PCS of the foundation soiland the fill body in the total were explored e relationshipbetween the PCS and the fill height fill rate and the averagecompaction degree was analyzed with an empirical formulaof PCS considering different factors proposed and verifiedFinally combined with a case history of engineeringproblems caused by uneven PCS the construction controlstandards for loess HFE were proposed

2 Engineering Background of HFE

21 Project Description of Lvliang Airport Lvliang Airport islocated over the loess ridge in the city of Lvliang Shanxiprovince as shown in Figure 1(a) e test section of theHFE was constructed over the thick loess foundation in adeep ravine e geographical location and project profile ofthe high fill airport are shown in Figure 1(b) For guiding thedesign and construction of HFE in the loess region the PCSof the test section which is filled in the deep ravine [31] wasstudied in this study

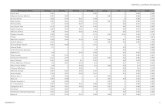

22 Geotechnical Properties of the Foundation Soil Based onthe borehole sampling and laboratory tests [31] the stratumconsists of five main types of soils ieQ4 loess (32ndash258m)Q3 loess (31ndash215m) Q2 loess (29ndash146m) silty clay(306ndash481m) and sandy shale (ge122m)e soil used to fillthe foundation is mainly composed ofQ3 loesse profile ofthe stratum is shown in Figure 2(a) According to thestandard for soil test method (GBT 50123-2019) soilsamples taken from Zone-1 Zone-2 and Zone-3 were usedto obtain the physical and mechanical parameters throughlaboratory tests including physical index test (water contentw dry density ρd saturation degree Sr the liquid limit wLand the plastic limit wP) modified proctor test (the maxi-mum dry density ρdmax and the optimal water content wop)oedometer test (the coefficient of compressibility av and thecompression modulus Es) collapsibility coefficient test (thegravity collapsibility coefficient δzs and the collapsibilitycoefficient δs under different vertical stress σ) and directshear test (the cohesion c and the angle of internal frictionφ) e variations of the above parameters along the sam-pling depth are shown in Figures 2(b)ndash2(j) e statisticalmean values of the above parameters of soil samples arelisted in Table 2 Note that av and Es are the coefficients ofcompressibility and compression modulus of undisturbedloess samples when the stress range is between 100 and200 kPa respectively

From Figure 2 and Table 2 the water content growsfrom 8 to 25 with depth and the dry density increases

2 Shock and Vibration

from 12 to 18 gcm3 e results indicate that the naturalwater content of Q3 loess (w1697) is higher than theoptimal water content (wop133) is will have sig-nificant consequences on the design since the soil needsto be dried prior to use as a fill material e mean value ofgravity collapsibility coefficient of undisturbed loess isδzs 0008 which is lower than the critical value sug-gested by the standard for soil test method (GBT 50123-2019) ie [δs] 0015 is indicates that the collaps-ibility of the undisturbed loess can be neglected for thesake of simplicity in engineering design However whenthe stress level σ0>200 kPa δs ge 002> [δs] 0015 thecollapsibility of foundation loess should be wellconsidered

3 Assessment of Foundation TreatmentMethods for the Test Section

31 Pile Reinforcement and DC Methods for Foundation SoilIn this study the DC method and vibrating sinking gravelpile (VSGP) or plain soil compaction pile (PSCP) areadopted to enhance the strength and bearing capacity ofthe deep loess foundation e test regions are dividedinto 10 sections as shown in Figure 3 with sections A BC D E and F reinforced by DC sections G and H byVSGP and sections K and L by PSCP

e dynamic compactor of W200A-50t (Hangzhou HeavyMachinery Co Ltd) and QUY35A-35t (FuWaHeavy IndustryMachinery Co Ltd) was employed to reinforce the foundatione dynamic compact effort (DCE) of the single-point DC is2000 3000 and 6000kNmiddotm while the DCE of the overlappingDC is 800 and 1000kN middotm respectivelyese single-point DCsare squarely arranged e tamping distance (TD) is 35ndash55mand the number of tamping times is 10ndash12 e stoppingstandard is defined as the last settlement after tamping less than3 cm e number of tamping times of the overlapping DC is3ndash6 and the length of overlapping is TD4 e stoppingstandard is defined as the last settlement after tamping less than5 cm e design of the DC reinforcement test is illustrated inFigure 4 and Table 3

32 Combined Compaction Methods for HFE e HFE isintended to be constructed by the following four methods

(1) Vibration compaction method (VC) the 50 t vi-bration compactor is used with the walking speedle3 kmh and the times of rolling 4 6 8 and 10ethickness of the loose laying soil (TLLS) is controlledto be 04m 05m and 06m respectively

(2) Percussive compaction method (PC) the triangularcompactor (25T3-25 kJ) is adopted here with thewalking speed ge10 kmh and the times of roll-ing 10 15 20 and 25 e TLLS is controlled to be07m 08m and 09m respectively

(3) VC+PC method in the first step the VC method isused to reach a fill thickness of 15m (times ofrolling 10 TLLS 04m λ 093) Here λ denotesthe compaction degree of the fill e PC method isadopted in the second step with the times of roll-ing 10 15 20 and 25

(4) VC+DC method first the thickness of the fillreaches 60m using the VC method (times of roll-ing 10 TLLS 04m λ 093) Next the single-point DC (tamping times 8ndash10) with the DCE of2000ndash3000 kNmiddotm and an overlapping DC (tampingtimes 3ndash5) with the DCE of 1000 kNmiddotm areemployed to further reinforce the fill embankment

33 Evaluation of Reinforcement Effect of the Foundationbefore and after DC In order to comprehensively evaluatethe reinforcement effects of the foundation before and afterDC the oedometer tests direct shear tests and plate loadtests of the undisturbed loess (before DC) and the com-pacted loess (after DC) are carried out e plate load testresults are shown in Table 4 e mechanical parameters ofthe undisturbed soil (before DC) and compacted soil (afterDC) at different depths are shown in Table 5

From Tables 4 and 5 during the DC stage with the DCEof 2000 3000 and 6000 kNmiddotm the optimal tamping times are11 11 and 10 respectively while the effective reinforcementdepths of the fill are 50m 60m and 90m In the range of

Table 1 PCS estimation formulas of fill embankment from case studies

References Relationship between crest PCS and fill height of the embankment

[29]

Germany and Japan S H23000 where S (m) is the crest PCS of fill body H (m) is the height of fill embankmentLawton formula S 0001H15 where S (m) is the crest PCS of fill body

Gu Weici formula St kHneminus mt

Empirical coefficient k m nConcrete-faced rockfill dam 0004331 1746 12045Earth dam with inclined core 00098 14755 10148

Core wall dam 0016 10932 0876Russia formula St minus0453(1 minus e008H)e0693t1157 where t (days) is the duration of PCS St (mm) is the crest PCS of fill

body

[30] Longbao Airport in Guiyang and Dali Airport in YunnanS H2E23

radic where E(MPa) is the deformation modulus of

high fill where S (mm) is the crest PCS of fill body[26] S 4493 + (0672H2E) where S (mm) is the elastic modulus of high fill[27] S 00014H095 (λge 085) S 07-10H where S (m) is the crest PCS of fill body

[28] Longdongbao Airport S 0492H13823 where S (mm) is the crest PCS of fill bodyDali Airport S 116H minus 1098 where S (mm) is the crest PCS of fill body

Shock and Vibration 3

the reinforcement depth the bearing capacity of the com-pacted soil after DC is P 300ndash400 kPa Besides the com-pression modulus of the compacted soil after DC is 16-38times that of the undisturbed soil e cohesion is 29ndash55times that of the undisturbed soil while the internal frictionangle exhibits little change rough the load plate test the

deformation modulus of the foundation after DC is280ndash350MPa with an average value of about 306MPaAfter DC the collapsibility coefficient of the loess decreaseswhile the compression modulus and shear strength increaseHowever the effective reinforcement depth is limited etotal reinforcement effect of the foundation with the DC

ShanxiProvince

110deg 111deg

N

EW

S

112deg 113deg 114deg 115deg

110deg 111deg 112deg 113deg

0 70 140 280 kilometers

114deg 115deg

40deg

39deg

38deg

37deg

36deg

35deg

40deg

41deg

39deg

38deg

37deg

36deg

35deg

34deg

(a)

Airstrip

700m

300m

2600m

45m

Test region

Test section of the highfill in the loess gully

40~60deg80deg

100m

High fill

Excavation

Bed rock

N

E

(b)

Figure 1 Overview of Lvliang Airport (a) Geographical location of Lvliang Airport (b) Profile of the high fill of Lvliang Airport (after [31])

4 Shock and Vibration

Zone-3

Zone-1

Zone-2

1 layerplain fill

layerLishi loess

1 layersilty clay

2 layersilty clay

layerMalan loess

32~258m

31~215m

Q4 loess

Q3 loess

Q2 loess29~146m

306~481m

1

2 layerloess-like soil

2

3

4

4

layersandy shale ge122m

1

5

(a)

0020406080

100120140160180200

50 100 150 200 250

w ()

Sam

plin

g de

pth

h (m

)

(b)

0020406080

100120140160180200

12 14 16 18

Sam

plin

g de

pth h

(m)

ρd (gcm3)

(c)

0020406080

100120140160180200

04 06 08 10 12

e

Sam

plin

g de

pth

h (m

)

(d)

00

20

40

60

80

100

120

140

160

180

200

200 250 300 350

w1 ()

Sam

plin

g de

pth

h (m

)

(e)

00

20

40

60

80

100

120

140

160

180

200

120 140 160 180 200

wp ()

Sam

plin

g de

pth

h (m

)

(f )

Figure 2 Continued

Shock and Vibration 5

method is affected by not only the DCE but also thethickness and soil property Moreover the bearing capacitiesof the foundations treated by the VSGP and PSCP methodsare 400 kPa and 340 kPa respectively e deformationmoduli of the soil after VSGP and PSCP reinforcement are23 and 20 times those of the undisturbed soil respectivelyIt shows that the treatment of the foundation by the VSGP orPSCP method can also reinforce the original loess foun-dation However the borehole can easily collapse during thepiling process when the water content of the foundation istoo high erefore the above methods are well suited for

treating the loess foundation with low water content Hencesoil improvement methods using admixtures like stonecement lime fly ash or mixed columns should be used inthis case eg the CFG piles

34 Reinforcement Effect on the Fill Body In order to de-termine the reinforcement effect on the fill body after dif-ferent reinforcement methods the compaction degree testsshallow plate load tests oedometer tests and direct sheartests are carried out e plate load test results of

00

20

40

60

80

100

120

140

160

180

200

00 200 400 600 800 1000

Sr ()

Sam

plin

g de

pth

h (m

)

(g)

0020406080

100120140160180200

000 001 002 003 004 005

Sam

plin

g de

pth h

(m)

δzs

(h)

R2 = 08624

0005

0010

0015

0020

0025

0030

0035

0040

0 500 1000 1500

δ s

Gravitycollapsibility

coefficient -δsz

σ (kPa)

δs = 2E ndash 05σ + 00123

(i)

Sam

plin

g de

pth

h (m

)

0020406080

100120140160180200

00 100 200 300 400

Es (MPa)

(j)

Figure 2 Profile of the stratum of the test section and physical-mechanical parameters of soil samples (a) Profile of the stratum of the testsection of the airport (b) Water content (c) Dry density (d) Void ratio (e) Liquid limit (f ) Plastic limit (g) Saturation degree (h) Gravitycollapsibility coefficient (i) Collapsibility coefficient (j) Compression modulus

Table 2 Mean values of physical and mechanical parameters of soil samples

Layer w () ρd (gcm3) ρdmax (gcm3) wop () e wL () wP () av (MPaminus1) Es (MPa) c (kPa) φ (deg)

①1 2366 160 mdash mdash 0696 2520 1589 0396 465 193 205①2 1565 144 mdash mdash 0882 2472 1575 0249 748 494 266② 1697 156 188 133 0741 2487 1608 0228 823 366 236③ 2136 165 193 122 0647 2929 1749 0231 757 702 235④1 2200 164 mdash mdash 0663 2991 1753 0238 720 1149 213④2 2153 167 mdash mdash 0628 3013 1766 0229 721 1266 228

6 Shock and Vibration

VSGP andPSCP test

Airportstation

Airstrip

VSGP andPSCP test

DC test

Aircrafttraffic link

Boundary of filland excavation

DC-3000kNmiddotm testVC + DC test

DC-2000kNmiddotm testVC + DC test

DC-6000kNmiddotm testVC + DC test

ABCD

EF

GH

KL

Figure 3 Reinforcement methods for the deep loess foundation

35~50mn times (35~50m)Andash

Andash

n times

(35

~50

m)

(CE

200

0~60

00kN

middotm)

35~

50m

(a)

35~50m

60m

n times (35~50m)

(2000~6000kNmiddotm)

Start positionof DC

(b)

TD = 35~55m

TD2 TD2

TD4+++

+++

+++

TD4

TD4

TD4

TD2

TD2

TD =

35

~55

m

(c)

Figure 4 Design scheme for DCs (a) Plane layout of DCs (b) A-A section (c) Overlapping design of overlapping DCs

Shock and Vibration 7

VC+2000 kNmiddotm-DC and VC+ 3000 kNmiddotm-DC are shown inTable 4 e compaction degree of soil after reinforcementand three characteristic mechanical parameters (ie com-pression modulus cohesion and internal friction angle) areshown in Figures 5ndash7

When the VC method is used for reinforcing the fillembankment the smaller the thickness of the loose layingsoil (TLLS) and the greater the number of tamping times(TT) of compaction the more obvious the compaction

effect e average compaction degree λle 090 when theTLLS 04ndash06m and the TT is 4ndash6 while λge 093 when theTT of the VC is 8ndash10 It is recommended that the TLLS is04m and the TT for the VC method is 10 When the PCmethod is used for reinforcing the fill embankment and theTLLS 07ndash08m the average compaction degree λ 090093 095 and 098 when TT10 15 20 and 25 respec-tively When the VC+PC method is used the first step is tocompact 4 layers (the thickness of each layer is 04m) of

Table 3 Foundation soil treatment methods

Sections Areas (m2) Treatment methods Abbreviations or symbols

DC

A 20mtimes 20m Single-point DC-2000 kN middotm (TT10ndash12) TD 35m TD4-overlappingDC-800 kNmiddotm (TT 3-5) DC-dynamic compaction

B 20mtimes 20m Single-point DC-2000 kNmiddotm (TT10ndash12) TD 40m TD4-overlapping DC-800 kNmiddotm (TT 3-5)

VSGP-vibrating sinkinggravel pile

C 20mtimes 20m Single-point DC-3000 kNmiddotm (TT10ndash12) TD 40m TD4-overlapping DC-1000 kNmiddotm(TT 3-5)

PSCP-plain soil compactionpile

D 20mtimes 20m Single-point DC-3000 kNmiddotm (TT10ndash12) TD 45m TD4-overlapping DC-1000 kNmiddotm (TT 3-5) TD-tamping distance

E 20mtimes 20m Single-point DC-6000 kNmiddotm (TT10ndash12) TD 45m TD4-overlapping DC-1000 kNmiddotm(TT 4-6) TT-tamping times

F 20mtimes 20m Single-point DC-6000 kNmiddotm (TT10ndash12) TD 50m TD4-overlapping DC-1000 kNmiddotm (TT 4-6)

VSGP G 20mtimes 15m d 05m l 15m L 10ndash18m (average value 15m) d-pile diameterH 20mtimes 15m d 05m l 20m L 10ndash18m (average value 15m) l-pile spacing L-pile spacing

PSCP K 20mtimes 15m d 05m l 15m L 10ndash18m (average value 15m)L 20mtimes 15m d 05m l 20m L 10ndash18m (average value 15m)

Table 4 Plate load test results of loess before and after DC with different reinforcement methods

Types of loess I0 μ d0 (m) c (kNm3) P (kPa) s (mm) E0 (MPa)

Undisturbed loessQ2 0785 038 06 200 360ndash450 58ndash77 235

Q3(Zone-1) 0785 035 08 185 875 118ndash132 39Q3 (Zone-3) 0785 035 08 188 120ndash135 107ndash115 65

Compacted loess

DC (2000 kNmiddotm) 0886 035 10 210 310ndash420 632ndash996 300DC (3000 kNmiddotm) 0886 035 10 210 320ndash450 897ndash100 350DC (6000 kNmiddotm) 0886 035 10 210 360ndash420 678ndash836 390

VC+DC (2000 kNmiddotm) 0886 035 10 210 350ndash360 969ndash100 280VC+DC (3000 kNmiddotm) 0886 035 10 210 360ndash400 945ndash100 288

VSGP 0785 035 05 230 336ndash500 92ndash100 132PSCP 0785 027 05 210 240ndash410 100ndash150 160

Note I0 is the shape factor of the rigid bearing plate μ is Poissonrsquos ratio of soil d0 is the diameter or edge length of the rigid bearing plate c is the unit weight ofsoil s is the settlement of the rigid bearing plate P is the bearing capacity value E0 is the deformation modulus

Table 5 Laboratory test results of mechanical parameters of the soil before and after DC

Depth(m)Es (MPa) c (kPa) φ (deg) δs

Before DC After DC Before DC After DC Before DC After DC Before DC After DC1 54 206 180 mdash 191 mdash 0093 00162 49 158 245 mdash 185 mdash 0080 00153 57 170 265 769 250 271 0078 00154 55 182 330 mdash 198 mdash 0073 00145 72 143 220 563 231 279 0057 00136 71 114 210 1150 236 136 0055 00137 71 124 313 mdash 207 mdash 0054 00128 79 152 330 mdash 208 mdash 0050 00109 61 182 230 1170 227 223 0025 000910 78 177 365 mdash 206 mdash 0020 0008

8 Shock and Vibration

loose soil to reach 15m Secondly the PC method is used tofurther reinforce the fill When the TT of the PC method is15 20 and 25 the corresponding compaction degree is 095096 and 098 respectively When the VC+DC method isused the VCmethod is first utilized An average compactiondegree that exceeds 0945 is achieved when TT10 Whenthe thickness of the fill reaches 60m the DC method withthe DCE of 2000 or 3000 kNmiddotm can be used to further re-inforce the fill and the compaction degree can increase to098 and 0996 respectively e bearing capacity of the fillembankment can reach 350 kPa

At the optimal water content the deformation modulusof the fill foundation is about E0 285MPa after rein-forcement by the VC+DCmethod which is 44 times that ofthe foundation soil At higher water contents the com-pression modulus (Es) and the shear strength index (c φ) ofthe Q2 and Q3 loess quickly decrease e compressionmodulus Es increases linearly with the axial stress σ thehigher the compaction the larger the Es c and φ When thecompaction degree is enhanced by 3 the compressionmodulus increases by 15 while the cohesion and internalfriction angle increase by 21 and 4 respectively Whenthe water content increases by 20 the cohesion and in-ternal friction angle decrease by 14 and 5 respectivelyWith the increase of the compaction degree and the watercontent of the soil is close to the optimal value the

compressive properties and strength characteristics of thesoil can be significantly improved which is of great sig-nificance for the PCS and the stability of the HFE

35 Adopted Reinforcement Methods of the HFE

351 DC Methods of the Foundation Soil Based on thecollapsibility level and the thickness of the loess thefoundation is divided into six zones which are Zone D1(4ndash6m alluvial soil) Zone D2-1 (4ndash6m alluvial soil) ZoneD2-2 (the bottom of the slope) Zone D3 (less than 7m loesswith slight collapsibility 0016le δsle 0029) Zone D4 (7-10m loess with medium collapsibility 0031le δsle 0065)and Zone D5 (gt10m loess with strong collapsibility0071le δsle 0093) as shown in Figure 8

e foundation soil is firstly tamped with the single-point DC method followed by the overlapping DC methodFor Zones D1 D2-1 D3 and D2-2 the single-point DC(DCE 3000 kN middotm TD 35ndash40m TT10ndash12) andoverlapping DC (DCE 1000 kNmiddotm overlapping dis-tance 10m TT 3ndash4) are utilized in the foundation soiltreatment For Zone D4 the single-point DC(DCE 6000 kNmiddotm TD 50m TT10ndash12) and over-lapping DC (DCE 1000 kNmiddotm overlapping dis-tance 125m TT 4-5) are utilized For Zone D5 the

075

080

085

090

095

100

4 5 6 7 8 9 10

Com

pact

ion

degr

ee λ

Time of VC

TLLS = 04m

TLLS = 05m

TLLS = 06m

(a)

088

090

092

094

096

098

100

10 15 20 25

Com

pact

ion

degr

ee λ

Time of PC

PCmethod

PC + VCmethod

TLLS = 07m

TLLS = 08m

TLLS = 09m

TLLS = 15m

(b)

0945

098

0996

094

095

096

097

098

099

100

0 1000 2000 3000 4000

Com

pact

ion

degr

ee λ

DCE (kNmiddotm)

VCmethod

VC + DCmethod

(c)

Figure 5 Compaction degree with different reinforcement methods (a) VC method (b) VC or VC+PC method (c) VC or VC+DCmethod

Shock and Vibration 9

single-point DC (DCE 10000 kNmiddotm TD 55mTT10ndash12) and overlapping DC (DCE 1500 kNmiddotmoverlapping distance 1375m TT 4ndash6) are utilized

352 Combined Reinforcement Methods of the Fill Bodye high fill in the test section is compacted with loose Q3Q2 loess which is divided into three domains ie the fillslope zone the ordinary zone and the airstrip zoneCombined reinforcement methods including the VC PCand DC methods are used e compaction methods of highfill are shown in Figure 9 and Table 6 For the airstrip zonethe 20m thick of loess is compacted with VC+PC andVC+DC methods e loose layer of soils with the VCmethod is 035ndash050m while 10ndash15m for the PC methode compaction degree is designed between 096 and 098e single-point DC (DCE 3000 kN middotm) is used to rein-force the fill body when the fill thickness reaches 6m e

compaction degrees in other regions are controlled between090 and 093

4 PCS Prediction of the HFE

41 In Situ Monitoring System of PCS e maximum fillheight of the test section in Lvliang Airport is 800m andthe digital electronic level and deep-layer settlement gaugesare used for monitoring the PCS of the fill body and thefoundation soil e deep-layer settlement gauges (CX-1CX-2 CX-3 and CX-4) are installed in the high fill sloperegion as shown in Figure 9e surface monitoring pointsof the HFE during the intermission period and the post-construction period are shown in Figures 10(a) and 10(b)During the construction stage the in situ monitoring dataare recorded every day During the postconstruction stagethe measured data are registered once every 10 days forthree months followed by once every 30 days after thate

00

50

100

150

200

250

300

350

01-02 02-03 03-04 04-06 06-08 08-10

E s (M

Pa)

Vertical stress level σ (MPa)

Optimal water content wop = 133Saturated water content ws = 215

λ = 090 w = 133

λ = 096 w = 133

λ = 090 w = 215

λ = 096 w = 215

λ = 093 w = 133

λ = 098 w = 133

λ = 093 w = 215

λ = 098 w = 215

(a)

200

300

400

500

600

700

800

c (kP

a)

Cohesion at wop

80 120 160 200 240

Water content w

λ = 090

λ = 093

λ = 096

λ = 098

Undisturbed soil

(b)

190

210

230

250

270

290

310

φ (deg

)

80 120 160 200 240

Water content w

λ = 090

λ = 093

λ = 096

λ = 098

Undisturbed soil

φ at wop

(c)

Figure 6 Mechanical parameters of compacted Q3 loess (a) Compression modulus of soil samples at various stress levels (b)e cohesionof soil samples at various compaction degrees and water contents (c) Internal friction angle of soil samples at various compaction degreesand water contents

10 Shock and Vibration

benchmarks from BM-1 to BM-7 are installed in the stableloess ridge and proofread one time every three months asshown in Figure 10(c) e monitoring duration for theintermission stage consists of 113 days in winter and 342days in the postconstruction stage

42 Components of PCS of the HFE In order to analyze thelong-term PCS for assessing the engineering stability it isnecessary to divide the total PCS into two parts ie the fillbody and the foundation According to the in situmonitoring data of the deep-layered settlement gaugesthe PCS of the foundation is So e layer settlements arerecorded by the magnet ring as S1 S2 Sn-1 Sn wherethe term Si is a representative settlement value relative to

the foundation and i is the number of the settlementmagnet ring

e total crest PCS of the surface leveling points is St(Figure 11) e relationship between the compression PCSof the fill body (Sf ) and that of the foundation (S0) can bewritten as

Sf Sn minus Snminus1( 1113857 + Snminus1 minus Snminus2( 1113857 + middot middot middot + S3 minus S2( 1113857

+ S2 minus S1( 1113857 + S1 minus So( 1113857 Sn minus So(2)

When the settlement plate is installed near the surface ofthe high fill Sn is approximately equal to St and the crestPCS of the HFE (St) can be written as

St Sf + So (3)

60

110

160

210

260

310

360

410

460

01-02 02-03 03-04 04-06 06-08 08-10

E s (M

Pa)

Vertical stress level σ (MPa)

λ = 090 w = 122

λ = 098 w = 122

λ = 096 w = 162

λ = 093 w = 199

λ = 093 w = 122

λ = 090 w = 162

λ = 098 w = 162

λ = 096 w = 199

λ = 096 w = 122

λ = 093 w = 162

λ = 090 w = 199

λ = 098 w = 199

Optimal water content wop = 122

Plastic limit water content wp = 162

Saturated water content ws = 199

(a)

200

300

400

500

600

700

800

80 120 160 200 240

c (kP

a)

Water content w

Cohesion at wop

λ = 090

λ = 093

λ = 096

λ = 098

Undisturbed soil

(b)

190

210

230

250

270

290

310

80 120 160 200 240

φ (deg

)

Water content w

λ = 090

λ = 093

λ = 096

λ = 098

Undisturbed soil

φ at wop

(c)

Figure 7Mechanical parameters of compactedQ2 loess (a) Compression modulus at various compaction degrees and water contents(b) Cohesion at various compaction degrees and water contents (c) Internal friction angle at various compaction degrees and watercontents

Shock and Vibration 11

For analyzing the PCS components of the HFE themeasured crest total PCS of the high fill (St) the compressionPCS of high fill body (Sf ) and that of the foundation soil (So)of platform No 2 (10770m) No 5 (11070m) No 6(11170m) and top of the high fill (11585m) are shown inFigure 12

Figure 12 shows the measured crest PCS with time atfour elevations including No 2 No 5 and No 6 platformsat different fill elevations (FEs) and the top of the HFE CX-1 CX-2 CX-3 and CX-4 represent the PCS values of thefoundation soil (So) as shown in Figure 12 e monitoringpoints of p2-2 p5-3 p6-4 and p3 represent the total PCS ofthe surface of the high fill (St) e layout of the monitoringpoints is shown in Figures 9 and 10 From the abovemonitoring results it can be concluded that during theconstruction stage the crest settlement of different plat-forms increases rapidly with the high fill elevation how-ever during the postconstruction stage the crest PCS ofHFE increases slowly and tends to be stable after one yeare crest PCS of the HFE consists of the compression of thefill body and that of the foundation induced by the fill loade former part (Sf ) accounts for 20 to 40 of the totalPCS while it is 60 to 80 of the total PCS (S0) for thelatter It can be concluded that 75 of the total PCS isinduced by the deformation of the thick loess foundationunder the high fill load e settlement of the high fill bodyitself almost is completed during the construction stageOnly 25 of the total PCS occurs during the post-construction stage ere is a large differential PCS on thesurface of the HFE which implies that the distribution ofthe original soil layers and fill thickness are uneven in theloess ravine Besides the compaction degree and watercontent of the fill materials are not homogeneous

43 Influence of Fill Height on the PCS Based on themonitoring data the crest total PCS of the high fill (St) thecompression PCS of high fill body (Sf ) and that of thefoundation (So) are analyzed e relationships between theSt Sf So and the thickness of the fill (H) are shown inFigure 13 Among them St1 So1 and Sf1 are the monitoringresults at the elevation of 11585m during the completionperiod (T 342 days) St2 So2 and Sf2 are the monitoringresults at the elevation of 11436m during the intermissionperiod (T113 days) in winter

From Figure 13 the PCS of the high fill surface (St) highfill body (Sf ) and foundation soil (So) varies approximatelylinearly with the fill thickness H as can be seen from thefitted relationships in Figures 13(a)ndash13(c) For a 10 in-crement in the fill thickness the total PCS increases by 26with three-quarters from the foundation and one-quarterfrom the fill body e crest PCS of the high fill isSt (011ndash088)H with an average St 028H e PCSof the fill body is Sf (003ndash022)H with an averageSf 010H e average value of the PCS ratio of the fillbody is Sf 038H and the average value of the crest PCSratio of the high fill is St 127H e measured PCS ofloess HFE in this case is smaller than the average value of thereported cases [26ndash30] is indicates that the controltechnology of the PCS in this case is better than previousprojects

44 Influence of Fill Rate on thePCSRate e average fill rateand the fill elevation with respect to the construction du-ration are shown in Figure 14e average fill rate of the highfill varies from 02md to 14md

Suppose that the fill thickness is H (m) the total fillduration isD (days) and the monitoring duration of the PCSis T (days) During the completion period the overall in situmonitoring duration is T 217ndash342 d and the monitoringduration of the intermission period in winter is T113 de average fill rate of the HFE below the monitoring pointis defined as

v H

D (4)

e average crest PCS rate Stprime (mmd) of the HFE the

average PCS rate of the foundation soil Soprime (mmd) and the

average PCS rate of the fill body due to self-weight com-pression Sf

prime (mmd) are respectively defined as follows

Stprime

St

T

Soprime

So

T

Sfprime

Sf

T

(5)

Previous engineering experiences show that the insta-bility of the high fill slope due to excessive PCS frequentlyoccurs during the construction period when the fill rate istoo high e highest fill rate is 1-2md in a loess high fill

Fill boundary

Slope bottom of high fill embankment

DCE 3000kNmiddotm

DCE 6000kNmiddotm

DCE 10000kNmiddotm

Graphic symbol

Edge of gully

Test section boundary

D2-1

D1 D2-2

D3D5

D4

D2-2

Airstrip

D2-2

Figure 8 Foundation soil treatment with DC method

12 Shock and Vibration

project [31] In order to comprehensively analyze the in-fluence of the fill rate on the average PCS rate of high fill thein situ monitoring results at the elevations of 11436m and11585m in addition to the 4th 5th and 6th platforms of thefill slope are discussed e relationships between the av-erage PCS rates (St

prime Soprime and Sf

prime) and the average fill rate (v)

are shown in Figures 15 and 16Figure 15 shows that the exponential relationship be-

tween Stprime Soprime Sfprime and v during the postconstruction stage

which can be written as

Stprime 00009e

15935v

Soprime 00009e

15367v

Sfprime 00003e

15825v

⎧⎪⎪⎪⎨

⎪⎪⎪⎩

(6)

Figure 16 shows that during the construction stagewhen the average elevation of the fill reaches 10970m (4thplatform) 11070m (5th platform) and 11170m (6th plat-form) an exponential relationship can be obtained betweenthe PCS rate St

prime of the platform surface and the upper Earthfill rate v

Stprime 03e

30v (7)

Comparing Figures 15 and 16 the fill rate has a greatinfluence on the PCS rate e total PCS rate varies

exponentially with the fill rate For each 1 increment of thefill rate the PCS rate increases by 7When the fill rate is toohigh it may cause an excessive PCS and the instability of thehigh fill slope

45 Influence of Compaction Degree on the PCS e in situcompaction degrees of the high fill in different domains andelevations are detected and compared with design valuese SfH is defined as the vertical compression ratio of thehigh fill body and the average compaction degree λ is usedto depict the integrated compaction degree of the fill body asfollows

λ 1113936

ni1 Hiλi

1113936ni1 Hi

(8)

where λi is the compaction degree of the fill body at differentelevations and Hi is the depth of the fill body with a certaincompaction degree λi

Based on the monitoring results at the elevations of11436m and 11585m the monitoring domain is dividedinto three parts according to the average compaction degreee relationship between SfH and H in the three parts withdifferent average compaction degrees is shown inFigures 17(a) and 17(b) During the intermission period theregression curves of the compression ratio of the high fill

Top of airstrip

Top of original foundation

200

mH

Compaction degree λ = 090Ordinary region

107

5

1075

Airstrip regionCompaction degree λ = 096

Compaction degree λ = 090Ordinary region

Compaction degreeλ = 093

Fill slope region10770m (CX-1)

11070m (CX-2)

11170m (CX-3)

11580m (CX-4)

Deep settlement gage

X (m)

Y (m)

00~04m λ = 09804~40m λ = 09640~90m λ ge 093

Figure 9 Compaction degree design of fill material in the test section

Table 6 Compaction methods and compaction degree standards of test fill

Location Below airstrip(m) Compaction method ickness of loose laying Compaction degree

Airstrip regionY 0-1 VC+PC VC-4times 035m PC-10m 098Y 1ndash20 VC+PC VC-5times 040m PC-15m 096

Y 20-H-20 VC+DC VC-20times 040m DC-60m

Fill slope region Y 0ndash20VC (H represents the height of fill body in

Figure 8)

04m 090Y 20-H-20 04m 093

Ordinaryregion

Y 0-1 3times 045m 090Y 1-H 05m

Shock and Vibration 13

Original foundation

Fill embankment

Top of high fillembankment

Bedrock

Elevation 11436m

Bench mark

Deep settlement gage

Measuring point

(a)

Original foundation

Fill embankment

Bench mark

Deep settlement gage

Measuring point

Top of high fill embankment

Bedrock

Elevation 11585m

(b)

Bench mark

Deep settlement gage

Measuring point

BM-2

BM-1

BM-3

BM-4

BM-5

BM-6

BM-7

N01-platform

N02-platform

N03-platformN04- platform

N05-platform

N06-platformN07-platform

N08-platform

N09-platform

CX-1

CX-2

CX-3

CX-41 2 3 4 5

678910

11 12 13 14 15

1617181920

21 22 23 24 25

5-1 5-2 5-35-4 5-5

4-1 4-2 4-3 4-4 4-5

2-1 2-2 2-3

6-1 6-2 6-3 6-4 6-5 6-6 6-7 6-8

Junction betweenfill and excavation

Top of high fill

Loess gully region

(c)

Figure 10 In situ monitoring pointsrsquo layout of the test section of Lvliang Airport (a) Monitoring points during the intermission period(Elevation 11436m) (b) Monitoring points during the completion period (Elevation 11585m) (c) Measuring points layout from the topview of the 3D model

14 Shock and Vibration

body with fill height under different average compactiondegrees can be written as

Sf

H 18545H

minus0880(λ 093)

Sf

H 78243H

minus0808(λ 096)

Sf

H 05177H

minus0141(λ 098)

⎧⎪⎪⎪⎪⎪⎪⎪⎪⎪⎪⎨

⎪⎪⎪⎪⎪⎪⎪⎪⎪⎪⎩

(9)

During the completion period the regression curves ofthe compression ratio of the high fill body with fill heightunder different average compaction degrees are as follows

Sf

H minus00042H + 12242 (λ 090)

Sf

H minus00044H + 11129 (λ 093)

Sf

H minus00015H + 07980 (λ 096)

⎧⎪⎪⎪⎪⎪⎪⎪⎪⎪⎪⎨

⎪⎪⎪⎪⎪⎪⎪⎪⎪⎪⎩

(10)

From Figure 17 during the intermission and completionperiods the relationships between SfH and H is quite dif-ferente former can be expressed as a power function andthe latter can be described as a linear equation Besides thevalue of the term SfH in the intermission stage is higher thanthat in the completion stage because the PCS rate is unstablee term SfH gradually decreases to a stable value as the fill

thickness increases within the same compaction degreedomainis indicates that the fill materials tend to undergoa hardening process under high-pressure conditions eSfH value gradually decreases as the compaction degree ofthe fill increases in different compaction degree domainsWhen the average compaction degree increases by 1 thevalue of SfH decreases by 12 It is effective in reducing thePCS of the high fill and the foundation when their integratedcompaction degree increases during the construction stage

46 PCS Prediction Methods In addition to providing sta-bility standards for the HFE and to guide the starting timefor the infrastructure construction on the top of the HFE itis necessary to statistically analyze the PCS Many mathe-matical methods are proposed to predict the PCS based on alarge collection of measured data Some of the commonlyused predictive methods are Pearl and Gompertz Model[9 10] hyperbolic model [32] exponential method andpolynomial method [6] Asaoka and Weibull model [4]empirical method [7] and closed-form equation [8] Basedon the monitoring data the hyperbolic logarithmic ex-ponential Gompertz and Peal curves have also been used topredict the relationship between the PCS and the duratione measured crest PCS of the HFE is set as regressionanalysis e PCS and the PCS rate over the monitoringduration of the critical monitoring points are shown inFigures 18(a) and 18(b) e prediction results and pre-diction error of the crest PCS of the high fill with differentmodels are shown in Figures 18(c) and 18(d) e regressivemodels and parameters are listed in Table 7

However except for the monitoring duration (D) thefactors that influence the PCS are not considered in theabove regressive models Hence the models cannot reflectthe fill height fill rate and the average compaction degree ofthe high fill According to the previous monitoring resultsthe crest PCS of the high fill is closely related to the fillthickness (H) average fill rate (υ) average compactiondegree (λ) and duration time (D) us based on equations(4)ndash(10) the empirical formula of the crest PCS of the highfill can be expressed as

S 01305e(1525v)

+2D

435 + 0705Dminus 651λ + 6641113874 1113875H

(11)

A comparison between the monitored PCS and thepredicted PCS with equation (11) is shown in Figure 18(e)e prediction error is less than 2 which well satisfies therequirements of major geotechnical engineering designse final crest PCS of the high fill as calculated by theempirical equation is shown in Figure 18(f ) Taking themonitoring point 3 as an example the predicted andmeasured PCS values are shown in Table 7 From the curvesof PCS and PCS rate over time the maximum PCS ratedecreases from 523mmd at the beginning to 023mmdafter 170 days with the average PCS rate for all the mon-itoring points reduced to 009mmd However the crest PCS

Settlement gauge Leveling point

Fill body

Settlement plateFoundation soil

St

Sn

Si

S2

S1

So

Settlementplate Sindash1

Figure 11 Layout of surface and deep-layered settlement moni-toring points

Shock and Vibration 15

rate of the HFE suddenly increases in July and Septemberdue to the occurrence of heavy rainfall which results in thewetting deformation of the surface soil e environmentvariations including heavy rainfall infiltration and risinggroundwater levels also influence the PCS erefore wa-terproofing and drainage measures must be considered inthe loess HFE

e crest PCS of the HFE increases and tends to stabilizeover time e relationship between the PCS and the time canbe well described by the exponential and the GompertzmodelsHowever the proposed empirical formula (ie equation (11)including the factors that influence the PCS) can more ac-curately predict the crest PCS of the high fill FromFigure 18(f)the predicted final maximal PCS and differential PCS of theaircraft traffic link area and the high fill slope region during sixyears are 270ndash450mm and 021ndash031 respectively How-ever the deformation control standard of the differential PCS isless than 015 which indicates that the maximal crest dif-ferential PCS of the high fill exceeds the allowable value

5 Standard for PCS Control of the HFE

For controlling the crest PCS and the differential PCS of theHFE according to MHT 5027-2013 the allowable values of

the PCSwithin 20 years should not exceed the values listed inTable 8

Table 8 shows that the crest PCS and the differential PCSof the building areas on the HFE should be limited within200mm and 015 respectively However the measuredmaximal PCS differential PCS during one year and the finalpredicted crest PCS (see Figure 18(f )) exceed the allowablevalues When the differential PCS exceeds the limits and therainfall infiltrates into the surface soil at the same time thecracks and doline between the boundary of the fill and theexcavation are generated as shown in Figure 19 eseresults indicate that the crest PCS and the differential PCS ofthe HFE do not meet the design requirements

During the construction process the water contentcompaction degree and fill rate of the compacted soil aredetected Based on the heavy compaction test of the fill theoptimal water contents of Q3 and Q2 loess are 1327 and1223 respectively while the maximum dry densities are188 and 193 gcm3 respectively e results are shown inFigure 20

Taking the design area of λ 090 as an example themeasured compaction degree varies from 087 to 092 withan average value of 089 which is lower than the designvalue e measured water content varies from 108 to

0 50 100 150 200 250 300 350 400 450

109001100011100112001130011400115001160011700

ndash900ndash800ndash700-600ndash500ndash400ndash300ndash200ndash100

00

Monitoring duration (days)

Filli

ng el

evat

ion

(m)

PCS

(mm

)

So

Sf

St

FE

(a)

So

Sf

St

FE

0 50 100 150 200 250 300 350 400 450

1115011200112501130011350114001145011500115501160011650

ndash2500

ndash2000

ndash1500

ndash1000

ndash500

00

Monitoring duration (days)

Filli

ng el

evat

ion

(m)

PCS

(mm

)

(b)

So

Sf

St

FE

0 50 100 150 200 250 300 350 400 450

11200112501130011350114001145011500115501160011650

ndash4500ndash4000ndash3500ndash3000ndash2500ndash2000ndash1500ndash1000

ndash50000

Monitoring duration (days)

Filli

ng el

evat

ion

(m)

PCS

(mm

)

(c)

ndash350

ndash300

ndash250

ndash200

ndash150

ndash100

ndash50

000 500 1000 1500 2000 2500 3000 3500 4000

PCS

(mm

)

Monitoring duration (days)

So

St

Sf

(d)

Figure 12 PCS versus monitoring date curves of surface and foundation (a) No 2 platform (10770m) (b) No 5 platform (11070m) (c)No 6 platform (11170m) (d) Top of the high fill (11585m)

16 Shock and Vibration

203 and the average value is 156 which is higher thanthe design value of 130 ese results indicate that theactual compaction index of the HFE does not meet thedesign requirements

From the above-measured data of the crest PCS and theconstruction parameters of the HFE the following con-clusions can be drawn

(1) e actual compaction degree is 1 lower than thedesign value and the actual water content is 20 onaverage higher than the design value ese may

cause the measured crest PCS and the differentialPCS to exceed their allowable values

(2) During the construction period the maximal fillrate of HFE is 14md and the average fill rate is045md which exceeds the allowable rate of 04md e intermission time of each treatment with theDCmethod is less than 2 days (which is less than therecommended standard of 7 days) erefore thefill cannot be sufficiently compressed under self-weight

St1 = 29322H + 17256R2 = 0937

St2 = 16029H + 33181R2 = 0839500

500

1000

1500

2000

2500

3000

0 20 40 60 80

S t (m

m)

Fill thickness H (m)

Fill completion period

Fill intermission period

(a)

So1 = 21992H + 12942R2 = 0937

So2 = 11861H + 24554R2 = 08395

00

500

1000

1500

2000

0 20 40 60 80 100

S o (m

m)

Fill thickness H (m)

Fill completion period

Fill intermission period

(b)

Sf1 = 07331H + 43141R2 = 0937

Sf2 = 04167H + 08627R2 = 0839500

100200300400500600700

0 20 40 60 80 100

S f (m

m)

Fill thickness H (m)

Fill completion period

Fill intermission period

(c)

Figure 13 Relationship between St So Sf and H (a) Curves of St-H (b) Curves of So-H (c) Curves of Sf-H

1080

1100

1120

1140

1160

1180

0002040608101214

2009626 20091024 2010221 2010621

Fill

elev

atio

n (m

)

Aver

age

fill r

ate

(md

)

Fill date (yymmdd)

Average fill rate

Height of fill

Figure 14 Fill process of the HFE

Shock and Vibration 17

Stprime = 03e3v

00

20

40

60

80

100

120

00 02 04 06 08 10 12 14

S tprime (m

md

)

Fill rate v (md)

Measured data

Regression curve

Figure 16 Relationship between PCS rate and fill rate of the platform at the fill slope

Stprime = 00009e15935υ

Soprime = 00009e15367υ

Sfprime = 00003e15825υ

000

020

040

060

080

100

120

024 029 034 039 044

Sprime (m

md

)

Fill rate v (md)

Top of high fill

Original foundation

Fill body

Figure 15 Relationship between PCS rate and fill rate of the high fill surface

SfH = 18545Hndash088

R2 = 09557

SfH = 78243Hndash0808

R2 = 09304

SfH = 05177Hndash0141

R2 = 09712

00

05

10

15

20

25

30

35

0 10 20 30 40 50 60 70

S fH

(mm

m)

Fill thickness H (m)

λ = 093

λ = 096

λ = 098

(a)

SfH = ndash00042H + 12242R2 = 07888

SfH = ndash00044H + 11129R2 = 09958SfH = ndash00015H + 0798

R2 = 099

06

07

08

09

10

11

12

13

0 10 20 30 40 50 60 70 80

S fH

(mm

m)

Fill thickness H (m)

λ = 090

λ = 093

λ = 096

(b)

Figure 17 Relationship between SfH andH under different average compaction degrees (a) During the intermission period (11436m) (b)During the completion period (11585m)

18 Shock and Vibration

(3) e monitoring results show that the PCS of thefoundation accounts for most of the total settlementis probably results from the fact that the

collapsibility of the deep loess layer is not eliminatedin that the effective reinforcement depth of the DC isless than 5ndash9m and the VSGP and PSCP exhibit poor

ndash3000

ndash2500

ndash2000

ndash1500

ndash1000

ndash500

000 50 100 150 200 250 300 350

PCS

S t (m

m)

Monitoring duration D (days)

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

(a)

00

10

20

30

40

50

60

0 50 100 150 200 250 300 350

PCS

rate

v (m

md

)

Monitoring duration D (days)

00102030405060

1052 10810 101118 11226 1166

PCS

rate

v (m

md

)

Monitoring date (yymmdd)

Rainfallinfiltration

13

28

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

(b)

00500

1000150020002500300035004000

0 500 1000 1500 2000 2500

PCS

(mm

)

Monitoring duration D (days)

Measuement data

Exponential curve

Hyperbolic curve

Gompertz curve

Peal curve

(c)

ndash40

ndash30

ndash20

ndash10

0

10

20

30

0 50 100 150 200

Pre

dict

ion

erro

r (

)

Monitoring duration D (days)

Exponential curve

Hyperbolic curve

Gompertz curve

Peal curve

(d)

00

500

1000

1500

2000

2500

3000

00 500 1000 1500 2000 2500 3000

Pred

icte

d da

ta o

f PCS

(mm

)

Measured data of PCS (mm)

S = 01305e(1525v) + ((2D(435 + 0705D))ndash 651λ + 664) H)

Measured data of PCS

(e)

High fillslope region

Aircrafttraffic link

Airportstation

PCS

(mm

)

X (m)Y (m

)

ndash430ndash390ndash350ndash270

ndash270

ndash230ndash170

ndash70

ndash70

ndash130

ndash270ndash230ndash170ndash130

ndash70ndash30

Differential PCS002~305permil

Differential PCS043~109permil

Differential PCS102~211permil

Control standard ofDifferential PCS 15permil

ndash130

ndash170

ndash230

0

ndash200

ndash4005750

57005650

56005550

5500 37003750

38003850

3900

(f )

Figure 18 Crest PCS and differential PCS curves of the HFE (a) PCS over monitoring duration (b) PCS rate over monitoring duration (c)Prediction of PCS (d) Prediction error (e) Comparison between prediction results and measured data (f ) Prediction PCS with theempirical method

Shock and Vibration 19

Table 7 Regressive models of PCS and its parameters

Mathematical model Mathematical expressionRegression parameter

Predicted (mm) Measured (mm)a b c

Exponential curve S a minus be(minusc D) 3530 29716 000667 3226

3224Hyperbolic curve S D(a + b D) 02368 000248 mdash 3152Gompertz curve S e(c+alowastbD) minus1528 0989 5793 3168Peal curve S c(1 + aeminusb D) 2931 00152 3184 3133Presented by authors S f(υ λ H D) mdash mdash mdash 3277Note In Table 7 the monitoring point 3 is taken as an example to compare the predicted and measured data (H 80m D 342 d λ 089 v 041md)

Table 8 Allowable values of crest PCS and differential PCS of HFE in loess ravine

No AreasS (mm) Differential PCS ()

Standard (20a) Measurement (1a) Standard (20a) Measurement (1a)

① Important or special building area aircrafttraffic link airport station 100 132ndash242 010 109ndash211

② General building area high fill slope region 200 323 015 002ndash305③ Traffic area 300 mdash 020 mdash④ Green area and other nonbuilding areas 500 mdash mdash mdash

(a) (b) (c)

Figure 19 Cracks and doline between the boundary of the fill and the excavation (a) Cracks between the fill and the foundation soil(b) Cracks in the fill (c) Doline in the fill

100

120

140

160

180

200

220

0 20 40 60 80

wat

er co

nten

t w (

)

Sample number

λ = 090

λ = 093

λ = 095

λ = 098

Optimal water content

(a)

0102030405060

086 088 090 092 094 096 098 100

Det

ectin

g po

ints

num

ber

Compaction degree λ

Measurement (λ = 093)

Measurement (λ = 098)

Measurement (λ = 090)

Measurement (λ = 095)

Design value

(b)

Figure 20 Measured value and design value of compaction degree and water content (a) Measured water content (b) Measuredcompaction degree

20 Shock and Vibration

performance because of the high-water content inthe foundation soil It indicates that the stabilizersand admixtures should be mixed into compactionpiles to reduce the water content and enhance thecompression modulus of the foundation soilerefore the commonly used CFG piles in soft soilfoundations may be well suited

6 Conclusions

Based on a high fill airport over deep collapsible loess layersthe foundation treatment methods of the test section areassessed using field and laboratory tests e PCS predictionmethods are discussed based on the in situ monitoringresults e standards for controlling the PCS of the HFEconstructed on the deep collapsible loess layer are proposede main conclusions are as follows

(1) e average bearing capacities of the foundationreinforced by the DC VSGP PSCP and VC+DCmethods are 350 kPa 400 kPa 340 kPa and 370 kParespectively while the elastic moduli after rein-forcement are 26 23 20 and 44 times those of theundisturbed soil respectively e effective treat-ment depth of the foundation by the DCmethod canreach 5ndash9m While the VSGP method has a deepertreatment depth it is prone to collapse duringdrilling e PSCP method is more feasible inreinforcing the deep collapsible loess foundation

(2) e PCS of the foundation accounts for approxi-mately 75 of the total PCS and about 028 of thefill height while the PCS of the fill body itself ac-counts for a lower proportion e crest PCS of theHFE increases linearly with the fill thickness ePCS rate increases exponentially with the fill rateWhen the average fill rate increases by 1 the PCSrate increases by 7 on average However when thefill rate is too high it may cause excessive PCS and anegative effect on the stability of the high fill slope inthe loess ravine

(3) e average compaction degree of the fill body ex-hibits great influence on the PCS When the averagecompaction degree increases by 1 the SfH de-creases by 12erefore the PCS of the HFE can beeffectively reduced by increasing the integratedcompaction degree during the construction stage

(4) For reducing the differential PCS the VSGP methodwith the addition of limecement or CFG piles offersa suitable reinforcement treatment for deep col-lapsible loess and the reinforcement depth should bemore than 10m e VC+DC method is a favorableway to treat the fill body e average compactiondegree should be more than 093 and the watercontent should be controlled between 11 and 15

Data Availability

e monitoring data used to support the findings of thisstudy are available from the corresponding author uponrequest

Conflicts of Interest

e authors declare that they have no conflicts of interest

Acknowledgments

e authors would like to extend their gratitude to theNational Natural Science Foundation of China (Nos51678484 and 51778528) and the Research Fund of the StateKey Laboratory of Eco-hydraulics in Northwest Arid Re-gion Xirsquoan University of Technology (2019KJCXTD-12)which funded this research as well as the graduate studentsfor their hard work in carrying out the testing

References

[1] China Airport Construction Group CorporationMHT 5027-2013 Code for Geotechnical Engineering Design of AirportChina Civil Aviation Press Beijing China 2013

[2] Z D Liu Loess Mechanics and Engineering Shaanxi Scienceand Technology Press Xirsquoan China 1997

[3] Y Hu Y W Ju W Z Wang and X M Zheng ldquoStudy onsettlement after construction for the high loess-filled em-bankmentrdquo Applied Mechanics and Materials vol 744ndash746pp 613ndash616 2015

[4] M Inagaki M Nakano T Noda M Tashiro and A AsaokaldquoProposal of a simple method for assessing the susceptibilityof naturally deposited clay grounds to large long-term set-tlement due to embankment loadingrdquo Soils and Foundationsvol 50 no 1 pp 109ndash122 2010

[5] R Ishikura N Yasufuku and M J Brown ldquoAn estimationmethod for predicting final consolidation settlement ofground improved by floating soil cement columnsrdquo Soils andFoundations vol 56 no 2 pp 213ndash227 2016

[6] L Jia J Guo and K Yao ldquoIn situ monitoring of the long-termsettlement of high-fill subgraderdquo Advances in Civil Engi-neering vol 2018 Article ID 1347547 9 pages 2018

[7] M Kermani J-M Konrad and M Smith ldquoAn empiricalmethod for predicting post-construction settlement of con-crete face rockfill damsrdquo Canadian Geotechnical Journalvol 54 no 6 pp 755ndash767 2017

[8] M Kermani J M Konrad and M Smith ldquoIn situ short-termand long-term rockfill compressibility as a function of voidratio and strength of parent rockrdquo Journal of Geotechnical andGeoenvironmental Engineering vol 144 no 4 Article ID04018009 2018

[9] X Kong ldquoResearch and application on the prediction methodof Pearl Model of high-filling subgrade Settlementrdquo Inter-national Congress and Exhibition ldquoSustainable Civil Infra-structures Innovative Infrastructure Geotechnologyrdquo SpringerCham Switzerland pp 356ndash362 2017a

[10] X Kong ldquoResearch on the prediction method of GompertzModel for high subgrade settlementrdquo International Congressand Exhibition Sustainable Civil Infrastructures Innovative

Shock and Vibration 21

Infrastructure Geotechnology Springer Cham Switzerlandpp 363ndash369 2017b

[11] M Mirjalili S Kimoto F Oka and T Hattori ldquoLong-termconsolidation analysis of a large-scale embankment con-struction on soft clay deposits using an elasto-viscoplasticmodelrdquo Soils and Foundations vol 52 no 1 pp 18ndash37 2012

[12] H Li J Tao L Wei and Y Liu ldquoExplosive compactiontechnology for loess embankment settlement control nu-merical simulation and field implementationrdquo Acta Geo-technica vol 15 no 4 pp 975ndash997 2019

[13] H B Li X L Zheng Y P Sheng and S Ke ldquoDifferentialsettlements of embankment treated by cement fly-ash gravelpile and sheet pile in freeway extension constructionsrdquo In-ternational Journal of Geomechanics vol 17 no 11 Article ID04017092 2017

[14] L Li H Xiao P Ferreira and X Cui ldquoStudy of a small scaletyre-reinforced embankmentrdquo Geotextiles and Geo-membranes vol 44 no 2 pp 201ndash208 2016

[15] Y Mei C M Hu and X Y Wang ldquoExperimental research ondeep collapsible loess foundation treatment by dynamiccompaction under super high fillrdquo Applied Mechanics andMaterials vol 256ndash259 pp 129ndash138 2012

[16] R K Rowe and K-W Liu ldquoree-dimensional finite elementmodelling of a full-scale geosynthetic-reinforced pile-sup-ported embankmentrdquo Canadian Geotechnical Journal vol 52no 12 pp 2041ndash2054 2015

[17] EM D Silva J L Justo P Durand E Justo andM Vazquez-Boza ldquoe effect of geotextile reinforcement and pre-fabricated vertical drains on the stability and settlement ofembankmentsrdquo Geotextiles and Geomembranes vol 45 no 5pp 447ndash461 2017

[18] C Wang B Wang P Guo and S Zhou ldquoExperimentalanalysis on settlement controlling of geogrid-reinforced pile-raft-supported embankments in high-speed railwayrdquo ActaGeotechnica vol 10 no 2 pp 231ndash242 2015

[19] K Wang Y Zhuang H Liu and H Xiao ldquoMultilayered low-strength geogrid-reinforced piled embankmentrdquoGeotechnicalResearch vol 5 no 4 pp 231ndash246 2018

[20] C Zhang G Jiang X Liu and Z Wang ldquoDeformationperformance of cement-fly ash-gravel pile-supported em-bankments over silty clay of medium compressibility a casestudyrdquo Arabian Journal of Geosciences vol 8 no 7pp 4495ndash4507 2015

[21] G Zhu and Y Han ldquoTreatment of collapsible loess foun-dationrdquo IOP Conference Series Earth and EnvironmentalScience IOP Publishing vol 218 no 1 Article ID 012006Bristol UK 2019

[22] M Esmaeili and H Khajehei ldquoMechanical behavior of em-bankments overlying on loose subgrade stabilized by deepmixed columnsrdquo Journal of Rock Mechanics and GeotechnicalEngineering vol 8 no 5 pp 651ndash659 2016

[23] H Zhang J K Chen S W Hu and Y Z Xiao ldquoDeformationcharacteristics and control techniques at the shiziping earthcore rockfill damrdquo Journal of Geotechnical amp Geo-environmental Engineering vol 142 no 2 Article ID04015069 2016

[24] Y Wang ldquoAnalysis of control measures for settlement ofdifferences on the problems of highway subgrade wideningrdquoOpen Journal of Civil Engineering vol 5 no 2 pp 149ndash1532015

[25] M Tashiro T Noda M Inagaki M Nakano and A AsaokaldquoPrediction of settlement in natural deposited clay groundwith risk of large residual settlement due to embankment

loadingrdquo Soils and Foundations vol 51 no 1 pp 133ndash1492011

[26] G He Q Li F Hong et al ldquoAnalysis of post-constructionsettlement of Transformation substation high fill foundationin mountainous areasrdquo Journal of Architecture and CivilEngineering vol 24 no 4 pp 45ndash49 2007

[27] Li Peng Study on Settlement of High Embankment andComposite Foundation Properties Changan University XirsquoanChina 2005

[28] H Liu P Li and Z Zhang ldquoPrediction of the post-con-struction settlement of the high embankment of Jiuz-haimdashhuanglong airportrdquo Chinese Journal of GeotechnicalEngineering vol 27 no 1 pp 90ndash93 2005

[29] Q C Wang Speed Railway Civil Engineering SouthwestJiaotong University Press Chengdu China 2000

[30] C Xie Study on the Behavior and Deformation of the GroundCompacted with Crushed Stone of High Fill Block in theOutgoing Airport Chengdu Univerisity of TechnologyChengdu China 2001

[31] C Zhu and N Li ldquoRanking of influence factors and controltechnologies for the post-construction settlement of loesshigh-filling embankmentsrdquo Computers and Geotechnicsvol 118 Article ID 103320 2020

[32] Q Q Zhang S C Li F Y Liang M Yang and Q ZhangldquoSimplified method for settlement prediction of single pileand pile group using a hyperbolic modelrdquo InternationalJournal of Civil Engineering vol 12 pp 179ndash192 2014

22 Shock and Vibration

precompression or preloading improvement and stabili-zation Rowe and Liu et al [16] studied the reinforcementeffects of a full-scale geosynthetic-reinforced pile-supportedembankment by using a fully coupled three-dimensionalfinite element method which indicates the applicability ofthe proposed method in reducing the settlement at thesubsoil surface Reference [19] found that the pile spacingwith the geosynthetic-reinforced method is the most sen-sitive factor influencing the maximum settlement of thesubsoil In recent decades geotextile reinforcement and tire-reinforced methods have been verified to improve thestrength of the soil of embankments [14 17]e deepmixedcolumns with cement-fly ash-gravel piles (CFGs) are alsocommonly used for ground improvement to treat the set-tlement of embankments [5 13 20 22 23]

e above methods are mostly used in soft soil foun-dations some of which are available for foundation treat-ment in deep collapsible loess foundation in HFE projectsWang et al [24] performed a centrifugal model test with ageogrid-reinforced pile-raft-supported method consideredin high-speed railways embankments on collapsible loessand the proper value of the pile spacing was suggested Meiet al [15] reported that the dynamic compaction (DC)method can effectively improve the bearing capacity andeliminate the collapsibility of the loess foundation Li et al[12] proposed the explosive compaction technology for loessembankment settlement control Zhu and Han et al [21]suggested that the compaction technology pile platestructure effective drainagemeasures and soil improvementwith admixtures can be systematically adopted for col-lapsible loess foundations to reduce the engineering prob-lems For controlling the PCS of the HFE projects in loessregions Hu et al [3] suggested that the water content shouldbe controlled within a range of 12ndash14 Wang [24]proposed that the following methods could be used to de-crease the PCS of fill embankments using lightweight fillmaterials enhancing the compaction degree of the fillmaterials and increasing the pile length in the foundationsoil For predicting the PCS of fill embankment the em-pirical method numerical method and in situ monitoringare widely used [4 5 11 25] In previous studies researchersproposed empirical formulas to estimate the crest PCS of theHFE [26ndash30]e empirical formulas were shown in Table 1ey can be generally represented as

S a +bH

c

Ed

eminus mtn( )

(1)

where S is the crest PCS of the fill body (m) H is the fillheight of the embankment (m) t is the duration time of PCS(years) E is the deformation modulus of the fill material(MPa) and a b c d m and n are the empirical coefficients

Equation (1) indicates that the PCS has nonlinear re-lationships with the fill height the compression character-istics of the fill body and the duration time Howeverequation (1) does not consider the thickness and com-pression characteristics of the foundation soil and it is usedfor self-weight settlement prediction of embankment fillesettlement of foundation soil is not included in it

e sources of PCS or its major components are cur-rently not sufficiently clear from previous studies Moreoverthe effects of foundation treatment and fill process are notreasonably considered in PCS predictions In this study atest section of a high fill airport was taken as the study object(the purpose of fill construction is to reach an adequate levelfor an airfield andor other structures related to airportconstruction) In situ tests of PCS were carried out to studythe reinforcement effects of different treatment methods forthe HFE e proportions of the PCS of the foundation soiland the fill body in the total were explored e relationshipbetween the PCS and the fill height fill rate and the averagecompaction degree was analyzed with an empirical formulaof PCS considering different factors proposed and verifiedFinally combined with a case history of engineeringproblems caused by uneven PCS the construction controlstandards for loess HFE were proposed

2 Engineering Background of HFE

21 Project Description of Lvliang Airport Lvliang Airport islocated over the loess ridge in the city of Lvliang Shanxiprovince as shown in Figure 1(a) e test section of theHFE was constructed over the thick loess foundation in adeep ravine e geographical location and project profile ofthe high fill airport are shown in Figure 1(b) For guiding thedesign and construction of HFE in the loess region the PCSof the test section which is filled in the deep ravine [31] wasstudied in this study

22 Geotechnical Properties of the Foundation Soil Based onthe borehole sampling and laboratory tests [31] the stratumconsists of five main types of soils ieQ4 loess (32ndash258m)Q3 loess (31ndash215m) Q2 loess (29ndash146m) silty clay(306ndash481m) and sandy shale (ge122m)e soil used to fillthe foundation is mainly composed ofQ3 loesse profile ofthe stratum is shown in Figure 2(a) According to thestandard for soil test method (GBT 50123-2019) soilsamples taken from Zone-1 Zone-2 and Zone-3 were usedto obtain the physical and mechanical parameters throughlaboratory tests including physical index test (water contentw dry density ρd saturation degree Sr the liquid limit wLand the plastic limit wP) modified proctor test (the maxi-mum dry density ρdmax and the optimal water content wop)oedometer test (the coefficient of compressibility av and thecompression modulus Es) collapsibility coefficient test (thegravity collapsibility coefficient δzs and the collapsibilitycoefficient δs under different vertical stress σ) and directshear test (the cohesion c and the angle of internal frictionφ) e variations of the above parameters along the sam-pling depth are shown in Figures 2(b)ndash2(j) e statisticalmean values of the above parameters of soil samples arelisted in Table 2 Note that av and Es are the coefficients ofcompressibility and compression modulus of undisturbedloess samples when the stress range is between 100 and200 kPa respectively

From Figure 2 and Table 2 the water content growsfrom 8 to 25 with depth and the dry density increases

2 Shock and Vibration

from 12 to 18 gcm3 e results indicate that the naturalwater content of Q3 loess (w1697) is higher than theoptimal water content (wop133) is will have sig-nificant consequences on the design since the soil needsto be dried prior to use as a fill material e mean value ofgravity collapsibility coefficient of undisturbed loess isδzs 0008 which is lower than the critical value sug-gested by the standard for soil test method (GBT 50123-2019) ie [δs] 0015 is indicates that the collaps-ibility of the undisturbed loess can be neglected for thesake of simplicity in engineering design However whenthe stress level σ0>200 kPa δs ge 002> [δs] 0015 thecollapsibility of foundation loess should be wellconsidered

3 Assessment of Foundation TreatmentMethods for the Test Section

31 Pile Reinforcement and DC Methods for Foundation SoilIn this study the DC method and vibrating sinking gravelpile (VSGP) or plain soil compaction pile (PSCP) areadopted to enhance the strength and bearing capacity ofthe deep loess foundation e test regions are dividedinto 10 sections as shown in Figure 3 with sections A BC D E and F reinforced by DC sections G and H byVSGP and sections K and L by PSCP