Foundation Design for the Beatrice Offshore Wind Farm - Beatrice.pdf · Foundation Design for the...

Transcript of Foundation Design for the Beatrice Offshore Wind Farm - Beatrice.pdf · Foundation Design for the...

-

Foundation Design for the Beatrice Offshore Wind Farm

R. McLean – SUPERGEN Wind Hub General Assembly, 08th November 2018

Image: BOWL Image: BOWL

-

Contents

Foundation Design for the Beatrice Offshore Wind Farm - R. McLean – SUPERGEN Wind Hub General

Assembly, 08th November 2018

Introduction to Beatrice

Foundation Design Challenges

• Site characterisation

• Pile design

• Jacket design

• Fabrication approach

• Installation considerations

• Other challenges

Conclusions

-

Introduction

-

Overview

588MW offshore wind farm in the Moray Firth

Clean electricity for 450,000 homes

Overall project £2.6bn

Site:

Circa 13km offshore

132km2

Water depths 35-55m LAT

Scotland’s largest offshore wind farm!

Image: BOWL

Image: BOWL

Foundation Design for the Beatrice Offshore Wind Farm - R. McLean – SUPERGEN Wind Hub General

Assembly, 08th November 2018

-

Overview

Offshore structures

84no. 7MW wind turbine generators (WTGs)

2no. offshore transformer modules (OTMs)

Foundations = jackets on driven piles

86 jackets; 85,000 tonnes

344 piles; >14km total length; 44,000 tonnes

Deepest offshore wind fixed structures in the world

Image: BOWL

Image: Siemens UK

Foundation Design for the Beatrice Offshore Wind Farm - R. McLean – SUPERGEN Wind Hub General

Assembly, 08th November 2018

-

~55

~45

~11

0

154

Jacket

Piles

WTG

Gherkin, 180

Heron Tower, 230

Image: Wikimedia

Image: Hufton + Crow

Foundation Design for the Beatrice Offshore Wind Farm - R. McLean – SUPERGEN Wind Hub General

Assembly, 08th November 2018

-

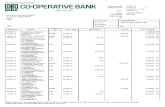

2011 2012 2013 2014 2015 2016

CONCEPT FEED DETAILED DESIGN

2019

INSTALLATION OPERATION

2017 2018Consent

Appli-cation

Qualified CfD Consent

CfDLease agree-ment

Financial CloseSG2 FID

Piling Start

Piling Com-plete

Jackets Start

Cables Start Turbines

Start

First gene-ration

Full Gene-ration

Feb 2009 -STW

Grant

SSE Offshore Wind Alliance

Framework of key suppliers designed to

address the key challenges of Round 3

offshore wind and drive efficiencies in SSE's

offshore wind programme.

Collaborative work through Concept and

FEED between Developer, WTG and OSP

Supplier, Installation contractor, Fabricator

and Designer.

BOWL

SHL

EPCI 91 inter-array cables

SIEM

EPCI 84 WTG foundations

Fabrication:

Jackets: Bladt, Smulders,

BiFab

Piles: EEW, SIF

Installation: SHL

Design: AtkinsT&I 2 OTM and foundations

STDL

EPC 2 OTM and foundations

Design: Atkins

EPCI export cables

SWP EPCI 84 WTG

AtkinsGI, soil

parameters for design

Foundation Design for the Beatrice Offshore Wind Farm - R. McLean – SUPERGEN Wind Hub General

Assembly, 08th November 2018

-

Foundation Design Challenges

-

Site Characterisation

-

Vast site

Foundation Design for the Beatrice Offshore Wind Farm - R. McLean – SUPERGEN Wind Hub General

Assembly, 08th November 2018

Image: Google

-

Available data - onshore

Foundation Design for the Beatrice Offshore Wind Farm - R. McLean – SUPERGEN Wind Hub General

Assembly, 08th November 2018

Image: BGS

-

Available data - offshore

Foundation Design for the Beatrice Offshore Wind Farm - R. McLean – SUPERGEN Wind Hub General

Assembly, 08th November 2018

Image: BGS

-

Phased investigation

Foundation Design for the Beatrice Offshore Wind Farm - R. McLean – SUPERGEN Wind Hub General

Assembly, 08th November 2018

CONCEPT FEED DETAILED DESIGN

20162014 2015201320122011

Desk study

Review GM

Geophys, 5 BH

Prelim GM Interim GI Update GM

CP

TS

am

plin

gLab tests

Routine Advanced

Completion GI Final GM

(BE-B5, -39.7)

(BE-C4, -38.1)

(BE-C5, -40.4)

(BE-C6, -41.4)

(BE-D3, -38.2)

(BE-D4, -39.4)

(BE-D5, -41.9)

(BE-E1, -38.9)

(BE-E2, -38.2)

(BE-E3, -38.6)

(BE-E4, -40.7)

(BE-E5, -40.4)

(BE-E6, -40.7)

(BE-F2, -40.2)

(BE-F3, -38.7)

(BE-F4, -40.4)

(BE-F5, -39.7)

(BE-F6, -41.6)

(BE-G3, -40.5)

(BE-G4, -38.6)

(BE-G5, -39.7)

(BE-G6, -40.2)

(BE-G7, -41.2)

(BE-H4, -41.1)

(BE-H5, -41.9)

(BE-H6, -40.0)

(BE-J5, -41.4)

(BE-J6, -41.5)

(BE-B6, -44.0)

(BE-B7, -46.4)

(BE-C7, -42.3)

(BE-C8, -43.3)

(BE-C9, -45.5)

(BE-D10, -45.3)

(BE-D6, -42.2)

(BE-D7, -44.0)

(BE-D8, -43.8)

(BE-D9, -44.4)

(BE-E7, -43.7)

(BE-E8, -46.0)

(BE-E9, -46.0)

(BE-F8, -45.7)

(BE-G8, -45.2)

(BE-H7, -42.5)

(BE-H8, -44.2)

(BE-J7, -42.7)

(BE-J8, -45.5)

(BE-K6, -44.6)

(BE-K7, -44.3)

(BE-L7, -44.5)

(BE-A5, -47.7)

(BE-E10, -46.6)

(BE-E11, -46.6)

(BE-F10, -48.2)

(BE-F11, -48.8)

(BE-F12, -48.6)

(BE-F9, -49.0)

(BE-G10, -49.4)

(BE-G9, -49.9)

(BE-H10, -49.6)

(BE-H9, -47.8)

(BE-J10, -49.5)

(BE-J9, -47.8)

(BE-K8, -47.6)

(BE-K9, -48.6)

(BE-L10, -49.6)

(BE-L8, -47.8)

(BE-L9, -49.4)

(BE-M9, -49.0)

(BE-M10, -49.9)

(BE-D11, -50.1)

(BE-E12, -52.9)

(BE-G11, -51.1)

(BE-G12, -50.5)

(BE-H11, -50.2)

(BE-H12, -51.8)

(BE-J11, -50.8)

(BE-J12, -52.2)

(BE-K10, -51.5)

(BE-K11, -52.0)

(BE-F13, -54.2)

(BE-G13, -53.4)

(BE-G14, -54.9)

(BE-H13, -53.4)

(BE-J13, -54.2)

(BE-K12, -53.1)

(BE-L11, -52.4)

(BE-F7, -42.5)

6448000

6449000

6450000

6451000

6452000

6453000

6454000

6455000

6456000

6457000

6458000

6459000

6460000

6461000

6462000

6463000

6464000

6465000

6466000

499000 500000 501000 502000 503000 504000 505000 506000 507000 508000 509000 510000 511000 512000 513000 514000

NO

RT

HIN

G

EASTING

Beatrice Farm Layout with Clusters & Water Depth

Cluster1

Cluster2

Cluster3

Cluster4

Cluster5

Spare

OTM Location

NOTES:

1. All Water depths are relative to (mLAT)2. Names and locations taken from LF000005-MAP-091

Locations in each Cluster:

Cluster 1 = 27 WTGs + 1 OTMCluster 2 = 21 WTGs + 1 OTMCluster 3 = 20 WTGsCluster 4 = 10 WTGsCluster 5 = 6 WTGs

Total = 84 WTGs + 2 OTMs

Spares = 2 locations not used

Date: 19/04/2016

Images: BOWL/ Fugro/ Atkins

-

Pile Design Process

-

Loading

Foundation Design for the Beatrice Offshore Wind Farm - R. McLean – SUPERGEN Wind Hub General

Assembly, 08th November 2018

Relatively small vertical load

Large horizontal loads from wind, waves and currents

High overturning moment at mudline

Resisted by piles in ‘push / pull’

Piles work in compression & tension

Cyclic

Wind

Wave & current

Largemoment

Small self weight

Push-pull(compression-tension in piles)

WTG

Jacket

Piles

-

Pile axial capacity

Need efficiency & reliability Which method?

Efficient & reliable pile

design

Optimised pile length

Reliable level of safety

Reliable axial

response

Reduced fatigue

damage

Reduced install. time

Reduced install. risk

Optimised CAPEX

Optimised safety

Reduced noise

0

5

10

15

20

25

30

35

40

0 2 4 6 8 10 12 14 16 18 20 22 24

Pil

e p

enet

raio

n (

m b

ml)

Pile Tensile Capacity (MN)

ICP-05

UWA-05

NGI-05

DNV / API

Load

6m difference between

ICP-05 and DNV / API

Foundation Design for the Beatrice Offshore Wind Farm - R. McLean – SUPERGEN Wind Hub General

Assembly, 08th November 2018

-

Jacket Design Process- Clustering approach

- Structural analyses

-

Foundation Design for the Beatrice Offshore Wind Farm - R. McLean – SUPERGEN Wind Hub General

Assembly, 08th November 2018

-

Design Process

AFC DesignUncoupled Analysis

Coupled Analysis

Bookending Site

Variances in-Cluster

Inclusive of all contributors

Foundation Design for the Beatrice Offshore Wind Farm - R. McLean – SUPERGEN Wind Hub General

Assembly, 08th November 2018

-

Design Process: Coupled Analysis

Pre-processing:

› ~1,000 wave loading simulations

SWP Analysis:

› Up to 20,000 combined wave + turbine simulations

Post-processing (Retrieval):

› ~300 critical ULS simulations

› 232 FLS simulations

› Code checking

Foundation Design for the Beatrice Offshore Wind Farm - R. McLean – SUPERGEN Wind Hub General

Assembly, 08th November 2018

-

Design Process: Uncoupled Analysis

ULS:

En

ve

lop

ing

Fa

cto

rs

Baseline:

As per CA

Deep Water:

5% WTG contingency

Water depth uncertainty

Shallow Water:

Short stickup

Stiff soil

5% WTG contingency

Water depth uncertainty

En

ve

lop

ing

Fa

cto

rs

Baseline:

As per CA

Deep Water:

5% WTG contingency

± Water depth uncertainty

Shallow Water:

Short stickup

Stiff soil

5% WTG contingency

± Water depth uncertainty

FLS:

Foundation Design for the Beatrice Offshore Wind Farm - R. McLean – SUPERGEN Wind Hub General

Assembly, 08th November 2018

-

Design Process: AFC Design

Primary Steel AFC

Weld Root Assessment

Uncoupled Analysis Factors

T&I & VIV Damage

TP & Joint FEM

Attachments [sympathetic

loading]

Joint Axial Stress

Factor for all FLS cases

Foundation Design for the Beatrice Offshore Wind Farm - R. McLean – SUPERGEN Wind Hub General

Assembly, 08th November 2018

-

Fabrication

-

Beatrice Foundation Fabricators

Image: Google

Foundation Design for the Beatrice Offshore Wind Farm - R. McLean – SUPERGEN Wind Hub General

Assembly, 08th November 2018

-

Design for Serial FabricationCommon TP & Upper Jacket

Cluster Specific Lower JacketImage: Smulders

Image: Smulders

Foundation Design for the Beatrice Offshore Wind Farm - R. McLean – SUPERGEN Wind Hub General

Assembly, 08th November 2018

-

Installation

-

Pile Installation risks

Foundation Design for the Beatrice Offshore Wind Farm - R. McLean – SUPERGEN Wind Hub General

Assembly, 08th November 2018

Boulders

Bedrock horizons

Strong and laterally traceable seismic

reflectors

Identified in intact Lower Cretaceous

Variable in lateral extent

Some have corresponding evidence in the

borehole data

Some relate to sandstone beds

Stratum II

Stratum IV

Stratum IV

Stratum IV

Stratum III

Stratum I Seabed

Major geological fault

Horizons within Stratum IV

Horizons within Stratum IV

~1km

-

Mitigation

Foundation Design for the Beatrice Offshore Wind Farm - R. McLean – SUPERGEN Wind Hub General

Assembly, 08th November 2018

Remediation = drive-drill-drive

Derive method to assess

Reduction of capacity from drilling

Shaft friction increase from ageing that can be relied upon

Capacity gain from concrete plug

Analyse impact of drilling at varying depths with and without concrete plug

Installation contractor has clear pre-defined scenarios to know instantly whether:

Pile must be abandoned,

Pile can be saved with a concrete plug

Pile does not require a concrete plug

-

Jacket Installation

Foundation Design for the Beatrice Offshore Wind Farm - R. McLean – SUPERGEN Wind Hub General

Assembly, 08th November 2018

• Transportation fatigue

• Upending vs vertical towing

• Installation vessel limits

• Early age cycling

• Safe access

• Walk to work systems

• Evacuation procedures

Image: Ian GreenwoodImage: SHL

-

Conclusions

-

Conclusions

› Multi-disciplinary approach required to manage risk and optimise

standardisation

› Good design should consider:

› Variable site conditions

› Fabrication approach

› Installation approach

› Project programme

› Through life user safety

› Innovation, collaboration and adaptability are key to future success of

industry.

Foundation Design for the Beatrice Offshore Wind Farm - R. McLean – SUPERGEN Wind Hub General

Assembly, 08th November 2018

-

Successes to date

› Design AFC and certification to

programme

› Pile installation completed

December 2017

› Jacket installation completed July

2018

› First power generation July 2018

› Fully operational in 2019

Image: BOWL

Foundation Design for the Beatrice Offshore Wind Farm - R. McLean – SUPERGEN Wind Hub General

Assembly, 08th November 2018

-

Foundation Design for the Beatrice Offshore Wind Farm - R. McLean – SUPERGEN Wind Hub General

Assembly, 08th November 2018

Thank you

All images © Atkins unless otherwise stated.