Form-1 and Pre-Feasibility Report...24’ 50.0” E The site is about 2.8 km from SH-17 in NE...

Transcript of Form-1 and Pre-Feasibility Report...24’ 50.0” E The site is about 2.8 km from SH-17 in NE...

M/s Swastik Chloroffin LLP Proposed Chlorinated Paraffin Plasticizer Unit by M/s Swastik Chloroffin LLP at village Azimabad Pardi Nagda, District: Ujjain, State: Madhya Pradesh PRE FEASIBILITY REPORT

Page 1 of 23

Form-1 and Pre-Feasibility Report

For

Proposed Chlorinated Paraffin Plasticizer Unit by M/s

Swastik Chloroffin LLP At

Village Azimabad Pardi Nagda, District: Ujjain, State: Madhya Pradesh

PRE-FEASIBILITY REPORT

Table of Contents

Environment Consultant

Vardan Environet

(QCI and NABET/EIA/1619/RA 0037)

D-142, Sushant Lok-III, Sector 57

Gurgaon (Haryana)

Contact no.-9810355569

Mail ID: [email protected]

M/s Swastik Chloroffin LLP Proposed Chlorinated Paraffin Plasticizer Unit by M/s Swastik Chloroffin LLP at village Azimabad Pardi Nagda, District: Ujjain, State: Madhya Pradesh PRE FEASIBILITY REPORT

Page 2 of 23

S.no. Chapters

Page no

1 Executive Summary

3

2 Introduction of the Project / Background Information

4-5

3 Project Description

6-14

4 Site Analysis

15-17

5 Planning Brief

18-19

6 Proposed Infrastructure

20

7 Rehabilitation & Resettlement Plan

21

8 Project Schedule & Cost Estimates

22

9 Analysis of Proposal (Final Recommendation)

23

1. EXECUTIVE SUMMARY Project

M/s Swastik Chloroffin LLP Proposed Chlorinated Paraffin Plasticizer Unit by M/s Swastik Chloroffin LLP at village Azimabad Pardi Nagda, District: Ujjain, State: Madhya Pradesh PRE FEASIBILITY REPORT

Page 3 of 23

M/s Swastik Chloroffin LLP is Proposing Chlorinated Paraffin Plasticizer Unit withcapacity of production of Chlorinated paraffin plasticizer in Phase I &II is 18000 MTPA & Hydrochloric Acid (by product) is 36000 MTPA at Village Azimabad Pardi Nagda, District: Ujjain, State: Madhya Pradesh. Location The proposed project shall be located in a 0.73 Ha. (7300Square Meter) and is situated at Village Azimabad Pardi Nagda, Dist: Ujjain, State: Madhya Pradesh. The land is already under the possession of project proponent. The geographical location of the proposed plant lies from Latitude- 230 26’ 11.4” N and Longitude 750 24’ 50.0” E

Project Proponent Partners of M/s Swastik Chloroffin LLP are Mr. Ramesh Kumar and Mr. Jitesh Kumar

Process / Technology This H.N.P/N.P/L.N.P/L.P 2030 is brought in tankers and unloaded in storage tank and with pump, is sent to meltor and heated H.N.P/N.P is sent in to jacketed reactor through chlorine header and from header to vaporizer wherein pressure and flow rates are measured and sent to reactor.

CnHn+2Cl2=CnHnCl2+2HCl+Heat. 1 MT HNP + 3.5MT of Chlorine +3.6 H2O = 2.6 Mt CPW + 5.4 MT HCL + 0.14 MT waste. 0.14 MT of 3.5 MT of Cl2 is approx 1% of chlorine which is neutralized with sodium hypo and this sodium hypo have commercial value and sold in market.

Manpower Requirement It is estimated that total 18 persons will be required for the proposed project during operation phase I & II.

Water requirement Total water requirement for the proposed project will be 93 KLD (approx).

Power Requirement Maximum power requirement for the plant will be 190 KW. The power will be supplied from Madhya Pradesh Electricity board.

D.G. sets of capacity 280 KVA is also proposed as the backup power supply

Raw Material Requirement Raw Material requirement for production of Chlorinated Paraffin Plasticizer is Chlorine.

Capital Cost of the project The Total cost for the proposed project estimated to be Rs. 950 lacs.

---------------------

2. INTRODUCTION OF THE PROJECT / BACKGROUND INFORMATION

M/s Swastik Chloroffin LLP Proposed Chlorinated Paraffin Plasticizer Unit by M/s Swastik Chloroffin LLP at village Azimabad Pardi Nagda, District: Ujjain, State: Madhya Pradesh PRE FEASIBILITY REPORT

Page 4 of 23

(i) Identification of Project & Project Proponent Project

M/s Swastik chloroffin LLP is proposing Chlorinated Paraffin Plasticizerunit with the capacity of production of Chlorinated paraffin plasticizer in Phase I&II is 18000 MTPA& Hydrochloric Acid (by product) is 36000 MTPA.

Project Proponent

First partner Mr. Ramesh Kumar having business experience of more than 25 Years in CPW manufacturing and 2nd partner Mr. Jitesh Kumar.

(ii) Brief description of nature of project: M/s Swastik Chloroffin LLP is proposing to setup a manufacturing unit of Chlorinated

Paraffin Plasticizer with Total proposed capacity of plant is 18000 MTPA. It is proposed to install 4 reactors of each capacity of 8 MT per batch in first phase and 4 more reactors of same capacity in 2nd phase. After completion of second phase Annual production capacity will be 18000 MT. HCL byproduct 1st Phase 18000 MT & 2nd 18000 MT per annum, after completion of 2nd phase total Annual production of bye product HCL Will be 36000 MT.

(iii) Need for the Project and its importance to the country and or region. With increase in demand in the market partner has decided to install new plant at Nagda (M.P) adjacent to Grasim Industries Ltd. (a unit of Aditya Birla). Grasim Industries is manufacturer of Caustic Soda and produces Chlorine as byproduct and chlorine is used for Chlorination of Paraffin Oil to produce CPP (Chlorinated Paraffin Plasticizer). So it has been decided to setup plant at Nagda adjacent to Grasim Industries Boundry where Chlorine will be supplied through pipe line and sniff gas will be treated by Grasim. Agreement of chlorine supply and sniff gas treatment has already been finalized with Grasim Industries Ltd. Supply through pipeline will ensure transport cost saving and safety also (Agreement copy is attached as Annexure)

Supply – Demand Gap The project is envisaged to meet the demand supply gap in the domestic market, as the gap is created due to increase in growth of Chlorinated Paraffin Plasticizer.

(iv) Export possibility Export possibility for Chlorinated Paraffin Plasticizer is now growing in south asian countries & Middle East. So the export possibility is very high for the proposed product which ultimately helps our country to earn the foreign currency.

(v) Domestic/Export Market The group is having its own set up of marketing through Dealers/Distributors throughout the country. Since partners of unit have more than 25 years of experience a fleet of marketing staff and established dealer base is already available. We are trying our hand to explore and utilize export opportunities of CPP in global market. Since High class raw material and state of art technologies will be used there will be good demand in Local and international market.

M/s Swastik Chloroffin LLP Proposed Chlorinated Paraffin Plasticizer Unit by M/s Swastik Chloroffin LLP at village Azimabad Pardi Nagda, District: Ujjain, State: Madhya Pradesh PRE FEASIBILITY REPORT

Page 5 of 23

(vi) Employment Generation (Direct and indirect) It is estimated that total 18 persons will be required for the proposed project during

operation phase I & II. Direct employment is also likely to be generated with the proposed project which will be economically beneficial for the development.

-------------------

3. PROJECT DESCRIPTION

(i) Type of Project including interlinked and interdependent projects, if any

M/s Swastik Chloroffin LLP Proposed Chlorinated Paraffin Plasticizer Unit by M/s Swastik Chloroffin LLP at village Azimabad Pardi Nagda, District: Ujjain, State: Madhya Pradesh PRE FEASIBILITY REPORT

Page 6 of 23

The Project involves manufacturing of Chlorinated Paraffin Plasticizer.

There is no interlinked project or interdependent project.

(ii) Location (Map showing general location, specific location, and project boundary and project site layout) with coordinates The proposed project shall be located in 0.73Ha and is situated at Village Azimabad Pardi Nagda, District: Ujjain, State: Madhya Pradesh. The land is already under the possession of project proponent. The geographical location of the proposed plant lies from Latitude- 230 26’ 11.4” N to Longitude- 750 24’ 50.0” E The site is about 2.8 km from SH-17 in NE direction. The nearest settlement is Nagda town is at a distance of 3.5 km (approx) in North direction. The nearest major railway station is Nagda Jn. Railway stationis at a distance of 2.1 km (approx) in North direction. International Airport, Indore Airport is at a distance of 88 km (approx) in SE direction. Project site falls in survey of India Toposheet no. F43D6, F43D7, F43D10 & F43D11. Key Plan map of the Project site is presented in Figure 3.

M/s Swastik Chloroffin LLP Proposed Chlorinated Paraffin Plasticizer Unit by M/s Swastik Chloroffin LLP at village Azimabad Pardi Nagda, District: Ujjain, State: Madhya Pradesh PRE FEASIBILITY REPORT

Page 7 of 23

Figure 1: Location Map

M/s Swastik Chloroffin LLP Proposed Chlorinated Paraffin Plasticizer Unit by M/s Swastik Chloroffin LLP at village Azimabad Pardi Nagda, District: Ujjain, State: Madhya Pradesh PRE FEASIBILITY REPORT

Page 8 of 23

Figure 2: Location plan and road connectivity

M/s Swastik Chloroffin LLP Proposed Chlorinated Paraffin Plasticizer Unit by M/s Swastik Chloroffin LLP at village Azimabad Pardi Nagda, District: Ujjain, State: Madhya Pradesh PRE FEASIBILITY REPORT

Page 9 of 23

Figure 3: Key Plan showing 10 km radius study area

M/s Swastik Chloroffin LLP Proposed Chlorinated Paraffin Plasticizer Unit by M/s Swastik Chloroffin LLP at village Azimabad Pardi Nagda, District: Ujjain, State: Madhya Pradesh PRE FEASIBILITY REPORT

Page 10 of 23

Figure:4 Layout Plan of the Project

M/s Swastik Chloroffin LLP Proposed Chlorinated Paraffin Plasticizer Unit by M/s Swastik Chloroffin LLP at Village Azimabad Pardi Nagda, District: Ujjain, State: Madhya Pradesh PRE FEASIBILITY REPORT

Page 11 of 23

(iii) Details of alternate sites Considered and the basis of selecting the proposed site, particularly the environment consideration gone into should be highlighted. No alternate sites have been examined for the proposed project as the project shall be setup on the purchased land.

(iv) Size and Magnitude of Operation M/s Swastik Chloroffin LLP is proposing to setup a manufacturing unit of Chlorinated Paraffin Plasticizer with the capacity of production of 18000 MTPA and byproductHCLwith the capacity of 36000MTPA at Village Azimabad Pardi Nagda, District: Ujjain, State: Madhya Pradesh. The estimated project cost is about Rs. 950 Lakhs.

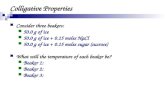

(v) Project description with process details: (a schematic diagram/flowchart layout, components of the project) Manufacturing Process: Heavy Normal Paraffin/Normal Paraffin/ Normal Paraffin/ L.R.2030 are saturated alkane of hydrocarbon chain C9-C18 and are commercially available from

M/s Reliance Industries Ltd. Patalganga Maharashtra M/s Tamilnadu Petro Products Ltd. Madras Imported we purchase the same from local market at market rate.

This H.N.P/N.P/L.N.P/L.P 2030 is brought in tankers and unloaded in storage tank and with pump, is sent to Meltor and heated H.N.P/N.P is sent in to jacketed reactor through chlorine header and from header to vaporizer wherein pressure and flow rates are measured and sent to reactor.

CnHn+2Cl2=CnHnCl2+2HCl+Heat.

1 MT HNP + 3.5MT of Chlorine +3.6 H2O = 2.6 Mt CPW + 5.4 MT HCl + 0.14 MT waste. 0.14 MT of 3.5 MT of Cl2 is approx 1% of chlorine which is neutralized with sodium hypo and this sodium hypo have commercial value and sold in market. HCl fumes goes to separator buffer S.N where vapor form of N.P/H.N.P is condensed and drained out for future use. HCl gas is passed on circulating water or dilutes HCl in graphite absorbers. HCl+H2O===== HCl + Heat. Graphite absorbers are cooled with water and hot water is sent to cooling tower and is rescued. Gases from absorber are sent to bubbling tank. The diluted acid of bubbling tank is used as fresh refill for circulating tank. HCl is stored in HCl storage tank for sale. Gases from bubbling tank are sent to waste gas storage system and from waste gas storage to sodium hypo chlorite plant or to lime neutralization system. The reaction on reactor is exothermic and temperature is controlled by circulating water from cooling tower the temperature of process from 60°C to 120°C am dos gradually increased by controlling chlorine feed rate. CRW thus processed of 1.4 is clear by compressed air initially in reactor

M/s Swastik Chloroffin LLP Proposed Chlorinated Paraffin Plasticizer Unit by M/s Swastik Chloroffin LLP at Village Azimabad Pardi Nagda, District: Ujjain, State: Madhya Pradesh PRE FEASIBILITY REPORT

Page 12 of 23

and subsequently in degasser. Epoxy plasticizer at rate of 8 Kg per Ton of CPW is added for Neutralization of remaining HCl fumes. CPW thus cleaned is packed in 250 Kg. PVC cans with weighing scale. Use of Epoxy Plasticizer depends on presence of untreated HCL Fumes.

Process Waste: As per present scheme, no process waste will be generated, if in case generated shall be stored and disposed off at Treatment Storage and Disposal Facility (TSDF) approved by Pollution Control Board at Village Azimabad Pardi Nagda, District: Ujjain, State: Madhya Pradesh.

Hazardous Waste: Used oil from machineries/D.G. Set will be carefully stored in HDPE drums in isolated covered facility. The used oil will be sold to vendors authorized by Central Pollution Control Board for the treatment of the same. Suitable care will be taken so that spills / leaks of used oil from storage could be avoided.

Air Emissions and Control: Present air pollution control system proposed will limit free chlorine is 3mg/nm3 (1PPM) in ambient air. These are as per pollution control board norms, factory act and Ministry of Environment Notification dated 29-10-1989.

CONTROL OF HCL FUMES AND CHLORINE GAS:- Plant will install 25 feet block condenser of graphite block and coolers of graphiteblockfor control of HCL fumes. HCL vapor gas from reactor is passed on separator and from separator to graphite bloc absorber. Conversion of HCL gas into HCL involved generation of heat & water is circulated for control of this heat from cooling tower. It is observed that absorption of gas in to liquid HCL is maximum below 55° C of temperature at absorbers is kept below 55°C.

HCL Vapor + H2O = HCL (Liquid) + Heat Two absorbers are employed in series so that entire HCL gases are converted into HCL

liquid. The outlet of absorber No. 2 is sent to bubbling tank where in cold water is kept ready and by bubbling and by bubbling further HCL gas is converted in dilute HCL Acid. The gases from reactor consist of HCL gases and approx 3% untreated chlorine. HCL gases are almost absorbed in graphite absorbers blocks 1 & 2 and balance if any, in bubbling tank. Chlorine is only slightly soluble in water when it reacts with pure water, a weak solution of hydrochloric and hydrochlorous acid is formed. Hydrochlorous acid further dissociates to HCL and nascent oxygen. Non reacted chlorine from each bubbling tank is sent in inverted dome covered floating vessel in pit where in chlorine is stored and sent for sodium hypo formation or neutralization.

M/s Swastik Chloroffin LLP Proposed Chlorinated Paraffin Plasticizer Unit by M/s Swastik Chloroffin LLP at Village Azimabad Pardi Nagda, District: Ujjain, State: Madhya Pradesh PRE FEASIBILITY REPORT

Page 13 of 23

Neutralization of waste chlorine gas with scrubber: -Excess waste gas is treated by two power full water scrubber free HCL fumes and free oil Particles are stored in FRP tank later on oil particles and HCL is separated and oil particles is sent to HNP storage tank and HCL is transferred to HCL storage tank.

Figure: 5 Process flow diagram for Formaldehyde

(vi) Raw material required along with estimated quantity, likely source, marketing area of final products, and mode of transport of raw material and Finished products. Raw Material requirement for production of Chlorinated Paraffin Plasticizer is Chlorine.

(vii) Resources optimization/recycling and reuse envisaged in the project, if any, should be briefly outlined. M/s Swastik Chloroffin LLP will optimize utilization ofresources including Land, Fuel, Water and Electricity.

(viii) Availability of Water its source, Energy/Power requirement and source

M/s Swastik Chloroffin LLP Proposed Chlorinated Paraffin Plasticizer Unit by M/s Swastik Chloroffin LLP at Village Azimabad Pardi Nagda, District: Ujjain, State: Madhya Pradesh PRE FEASIBILITY REPORT

Page 14 of 23

Water Requirement Total water requirement for the proposed project will be approx 93 KLD which will be sourced from own bore well for which the permission will be taken from CGWB.

Power Requirement Maximum power requirement for the plant will be 190 KW. The power will be supplied from Madhya Pradesh Electricity board. D.G. sets of capacity 280KVA is also proposed as the backup power supply

(ix) Quantity of waste to be generated (Liquid and solid) and scheme for their management. Process waste

As per present scheme, no process waste will be generated, if in case generated shall be stored and disposed off at Treatment Storage and Disposal Facility (TSDF) approved by Pollution Control Board at Village Azimabad Pardi Nagda, District: Ujjain, State: Madhya Pradesh.

---------------

4. SITE ANALYSIS (i) Connectivity

M/s Swastik Chloroffin LLP Proposed Chlorinated Paraffin Plasticizer Unit by M/s Swastik Chloroffin LLP at Village Azimabad Pardi Nagda, District: Ujjain, State: Madhya Pradesh PRE FEASIBILITY REPORT

Page 15 of 23

The proposed plant site is well connected with the rail and road connectivity. The site is about 2.8 km from SH-17. The nearest settlement is Nagda town is at a distance of 3.5 km (approx) in North direction. The nearest major railway station is Nagda Jn. Railway stationis at a distance of 2.1 km (approx) in North direction. Indore Airportis at a distance of 88 km (approx) in SE directionrespectively from the project site.

(ii) Land form, Land Use, Land Ownership Total area of the proposed project is 0.73Ha. The land is already under the possession on M/s Swastik Chloroffin LLP.

(iii) Topography ( along with map ) The site has been observed to be almost flat level in topography. Map showing study area of 10 km radius is given in Figure No. 6.

Figure:6 Google Image of the proposed project site

(iv) Existing Land use Pattern :

M/s Swastik Chloroffin LLP Proposed Chlorinated Paraffin Plasticizer Unit by M/s Swastik Chloroffin LLP at Village Azimabad Pardi Nagda, District: Ujjain, State: Madhya Pradesh PRE FEASIBILITY REPORT

Page 16 of 23

Total land area of the project is 0.73 Ha. Acquired land will be for Permanent change in land use, land cover or topography of the land use. CLU (Change of land use) for the project site was obtained from Revenue Department, Nagda, Dist.-Ujjain, M.P. No forest land is involved in the area identified for setting up of the proposed project for manufacturing of Chlorinated Paraffin Plasticizer by M/s Swastik Chloroffin LLP.

(v) Existing Infrastructure The proposed project is Greenfield project & the land is under the possession of project proponent. Road links:The proposed plant site is well connected with the road connectivity. The site is about 2.8 km from SH- 17 and well connected with internal roads from Nagda.

(vi) Soil: Black cotton soils with heavy to light texture are found in the whole area. Light textured silty ‘Kankar’ and admixtures of clay in the form of alluvium occur along the bank of major streams. The district faces considerable problem of soil erosion, which is aided and abetted by faulty forming practices and also by natural agents like wind and water.

(vii) Climatic Data from secondary sources: Climate: Ujjain has a humid subtropical climate, with mild, dry winters,a hot summer and a humid monsoon season. Summers start in late April and go on till mid-June, the average temperature being around 30 °C (86 °F), with the peak of summer in May, when the highs regularly exceed 40 °C (104 °F). The monsoon starts in late June and ends in late September. These months see about 40 inches (1020 mm) of precipitation, frequent thunderstorms and flooding. IMD normal annual rainfall of Ujjain city is 715 mm. The normal annual rainfall of Ujjain district is 914.5 mm. Ujjain district receive maximum rainfall during southwest monsoon period i.e. June to November. About 92.1% of annual rainfall is received during monsoon season. The surplus water for groundwater recharge is available only during the southwest monsoon period. The average temperature is around 25 °C (77 °F) and the humidity is quite high. Temperatures rise again up to late October when winter starts, which lasts up to early March. Daily mean normal temperature of Ujjain in May - 40.70 C and minimum - 26.40 C. The Annual Normal Rainfall in the area is 914.5 mm /yr Average temperature Summer: The temperature in summer may rise to a maximum of 42°C.Temperatures generally remain between 30°C to 40°C. Rainfall: The normal annual rainfall of Ujjain district is 914.5 mm. Ujjain district receive maximum rainfall during southwest monsoon period i.e. June to November. About 92.1% of annual rainfall is received during monsoon season.

(viii) Socio-Economic Environment:

M/s Swastik Chloroffin LLP Proposed Chlorinated Paraffin Plasticizer Unit by M/s Swastik Chloroffin LLP at Village Azimabad Pardi Nagda, District: Ujjain, State: Madhya Pradesh PRE FEASIBILITY REPORT

Page 17 of 23

Socio-economic status of the population is an indicator of development of the region. Any developmental project of any magnitude will have a bearing on the living condition and the economic bearing of the population in particular and the region as a whole. Similarly, the proposed project at Ujjain, State: Madhya Pradesh will have its share of socio-economic influence in the study area. The section delineates the overall appraisal of the socially relevant attributes. The data on socio-economic aspects in the study area has been carried out through the analysis of the secondary data available for the study area. As per 2011 Indian census record, Ujjain, State: Madhya Pradesh had a population of 19,86,864.

Population of Ujjain (2011 Census) Population Type

Male Population

Female Population

Total Population

Rural 6,16,353 5,91,298 12,07,651 Urban 3,99,939 3,79,277 7,79,213 Total 10,16,289 9,70,575 19,86,864

------------------

5. PLANNING BRIEF

M/s Swastik Chloroffin LLP Proposed Chlorinated Paraffin Plasticizer Unit by M/s Swastik Chloroffin LLP at Village Azimabad Pardi Nagda, District: Ujjain, State: Madhya Pradesh PRE FEASIBILITY REPORT

Page 18 of 23

(i) Planning concept As per EIA Notification dated 14.09.2006 and as amended from time to time, the project falls in Category ‘A’, at Serial No. 5(f) as project falls in outside the Industrial area.

(ii) Employment & Population projection It is estimated that total 18 persons are required toensure smooth working of the plant. Indirect employment will also be generated from the proposed project during construction and operation. The summary of direct employment estimate for the project is given in the table below:

Table 1.2: Manpower Requirement S.No. Description Manpower Phase I Phase II 1 Manager 2 2 Chemical Engineer 2 3 Clerk 1 1 4 Plant operators 3 3 5 Plant Helpers 3 3

11 7 Total 18

(iii) Land Use Planning Total land required of the proposed project shall be (78500 Sq. Foot) approx 0.73 Ha. which is in procession. 33% of the total plant area i.e. approx. 0.24 Ha shall be kept for greenbelt development.

(iv) Assessment of Infrastructure demand The following plants, machinery proposed for the project is given in the below table:

Table 1.4: PLANT & MACHINERY S No

Item Qty. Qty Supplier Phase 1 Phase 2

1 Reactor 4 4 Swiss Glasscoator Imported 2 Evaporator 1 1 Technofabor Open Market 3 Graphite Block 2 2 Graphicarb Engineers 4 H N P Storage

Tank 6 4 Self Made, Material from Open

Market 5 Electrical

Installation & Fitting

Open Market

6 HCL Storage Tank 6 4 Self Made, Material Open MKT. 7 Pipe Line ( MS &

FIBER) Open Market

M/s Swastik Chloroffin LLP Proposed Chlorinated Paraffin Plasticizer Unit by M/s Swastik Chloroffin LLP at Village Azimabad Pardi Nagda, District: Ujjain, State: Madhya Pradesh PRE FEASIBILITY REPORT

Page 19 of 23

8 Process Tank 4 4 Self Made 9 Compressor 2 2 Quotation from Open MKT 10 HCL Pump

&Motors 6 6 Quotation from Open MKT

11 Pollution Control Equipment &Fire Fighting Equipment

2 1 Quotation from Open MKT

12 Generator Set 300 HP With Fitting

1 Quotation from Open MKT

13 Cooling Tower 1 1 Open Market 14 Hoist 1 Open Market 15 Valves and Fitting Open Market 16 Pre Operative

(v) Amenities/Facilities Facilities like canteen, rest rooms and recreation facilities will be provided in the proposed project. No other additional facilities are proposed.

------------------

6. PROPOSED INFRASTRUCTURE

M/s Swastik Chloroffin LLP Proposed Chlorinated Paraffin Plasticizer Unit by M/s Swastik Chloroffin LLP at Village Azimabad Pardi Nagda, District: Ujjain, State: Madhya Pradesh PRE FEASIBILITY REPORT

Page 20 of 23

(i) Total Area: Total Plot area of M/s Swastik Chloroffin LLP is 7300 Square Meter (0.73 Ha.)

Residential Area: There is no residential area proposed within the proposed project site.

(ii) Green Belt : Total land area of the proposed project is (78500 Sq. Foot) 0.73 Ha. The greenbelt will also be developed at the site whose area is estimated as (25905 sq. foot) 0.24 Ha.

(iii) Social Infrastructure Schools, Colleges, Hospitals & Healthcare Centers, Shops & Bazaars and Community Centers etc. are all available in nearby Village Azimabad Pardi Nagda, District: Ujjain, State: Madhya Pradesh.

(iv) Connectivity The proposed plant site is well connected with the rail and road connectivity. The site is about 2.8 km from SH-17. The nearest settlement is Nagda town is at a distance of 3.5 km in North direction. The nearest major railway station is Nagda Jn. Railway station is at a distance of 2.1 km in North direction. Indore Airport is at a distance of 88 km in SE direction respectively from the project site.

(v) Water Requirement Water Requirement for the proposed project will be approx 93KLD. Ground water will be used at the project site through Tube well. Ground water permission will be obtained from the concerned Authority.

(vi) Drinking water management Domestic water requirement which include drinking water is envisaged as 3 KLD. The drinking water shall be sourced from bore well after taking the permission from CGWB.

(vii) Industrial Waste Management There will be no waste water discharge from the plant. Zero discharge shall be maintained after the proposed expansion.

(viii) Power requirement & Supply / Source Power requirement for the plant will be 190 KW. The power will be supplied from Madhya Pradesh Electricity board. D.G. sets of capacity 280 KVA is also proposed as the backup power supply

-------------------

7. REHABILITATION & RESETTLEMENT PLAN

M/s Swastik Chloroffin LLP Proposed Chlorinated Paraffin Plasticizer Unit by M/s Swastik Chloroffin LLP at Village Azimabad Pardi Nagda, District: Ujjain, State: Madhya Pradesh PRE FEASIBILITY REPORT

Page 21 of 23

Land required for the proposed project is in possession of M/s Swastik Chloroffin LLP and has no habitations in the project site. Hence no rehabilitationor resettlement plan is required.

M/s Swastik Chloroffin LLP Proposed Chlorinated Paraffin Plasticizer Unit by M/s Swastik Chloroffin LLP at Village Azimabad Pardi Nagda, District: Ujjain, State: Madhya Pradesh PRE FEASIBILITY REPORT

Page 22 of 23

8. PROJECT SCHEDULE & COST ESTIMATES

(i) Likely date of start of Construction and likely date of completion (Implementation schedule) : The construction of the project shall commence soon after receipt of Environment Clearance from SEIAA Madhya Pradesh and CTE from MPPCB. The project execution schedule shall be another 18 months after getting project clearance/ environment clearance.

(ii) Estimated Project Cost The capital cost of the project is worked out to be Rs 950 lacs working capital requirement and inclusive of cost of land as presented in the table below:

Table 1.5: Total Cost ITEM 1st phase 2nd Phase TOTAL PROJECT COST

Land Develop 20.00 10.00 30.00 Site Develop 50.00 10.00 60.00 Building 90.00 10.00 100.00 Plant Machinery and Electrical Installation 430.00 310.00 740.00 Other Assets 10.00 10.00 Pre Operative and Preliminary EXP 7.00 3.00 10.00

TOTAL 607.00 343.00 950.00

-------------------

M/s Swastik Chloroffin LLP Proposed Chlorinated Paraffin Plasticizer Unit by M/s Swastik Chloroffin LLP at Village Azimabad Pardi Nagda, District: Ujjain, State: Madhya Pradesh PRE FEASIBILITY REPORT

Page 23 of 23

9. ANALYSIS OF PROPOSAL (Final Recommendation)

CPW plasticizer is a secondary plasticizer used in fresh and reprocessed P. V. C. formulation for P.V.C. Cables, Footwear, Toys, and PVC Pipes, Flexible PVC Articles, PVC Flooring and number of other items like lubricant, gasket sheet, Paints and Impregnating textiles.

• Consumption of CPW on all India bases is approx. 35000 MT / Month out of which 15000 MT is used in Delhi itself and about 8000 MT is export

• CPW is secondary plasticizer and it is produced from H.N.P/L.N.P/N.P./LR 2030 and Chlorine Gas in exothermic reaction in lead glass line. Although earlier CPW used to be processed from wax but now, it is processed from H.N.P/L.N.P/N.P hence it can be called as C.H.N.P/ Chlorinated Paraffin Also.

• CPW should be 1.2gravity or 1.25 or 1.3 or 1.4 or 1.45gravity depending upon end uses and shall be crystal clear with thermal stability of 180°C for 20 Minutes 1.4 gravity represent approx. 62% of chlorine content.

So considering the above the M/s Swastik Chloroffin LLP is proposing to setup a manufacturing unit of Formaldehyde with the capacity of production of 18000 MTPA at a Village Azimabad Pardi Nagda, District: Ujjain, State: Madhya Pradesh.

-----------------