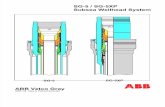

FMC Conventional Wellhead Chart

description

Transcript of FMC Conventional Wellhead Chart

C-21 C-22 C-24 C-29

TC-2C TC-60 TC-60-WD

Conventional Wellhead Configuration Chart

BO-2 BO-10 A-3-EC A-5-EC A-4-D

Tubing Head Adapters

Tubing Hangers

Tubing Heads

Secondary Seals(optional)

Secondary Seals(optional)

Casing Hangers

Casing Heads

Bottom Prep Options

Base Plate Option

Casing Spools

Couplings

BO-2 BO-10

TC-1A

TC-ET

TC-1A-EMS TC-1A-EN TC-1A-ENS-DHCV TC-1A-ENS TC-1W

TCM-ET

Reducer BushingSlick FS

TC-60-ET TC-WD-ET

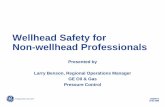

Product Specification Levels

No

No No No No

No No No

1 1 22 3

Yes Yes

Yes

Yes Yes

Yes

Yes

1

Yes Yes

NoNace?

High H2S?

Recommended PSL

Selection Chart for PSL — 5,000 psi

No

No No No No

No No No

2 2 3 3 3

Yes Yes

Yes

Yes Yes

Yes

YesYesYes

NoNace?

High H2S?

Gas Well?

Recommended PSL

Selection Chart for PSL — 10,000 psi

No

No No No No

No No No

3 3 3G 3G 3G 3G

3G

Yes Yes

Yes

Yes Yes

Yes

YesYesYes

NoNace?

High H2S?

Recommended PSL

Selection Chart for PSL — 15,000 psi

Reducer BushingS/OD - FS/ID

PI-Seal

C-21 C-22

C-22-EG C-29 C-29-ET

C-122 C-121S C-24 C-29 C-129 C-229

SBMS-II FX-RCMS

Reducer BushingSlick FS

Reducer BushingS/OD - FS/ID

PI-Seal SBMS-II FX-RCMS

C-29-ETC-22-EG C-29

Casing Hangers

API Reference ChartsMaterial

Class ApplicationBody, Bonnet, End,

& OutletPressure Controlling Parts,Stems, & Mandrel Hangers

AA

BB

CC

DD

EE

FF

HH

General Service

General Service

General Service

Sour Service

Sour Service

Sour Service

Sour Service

Carbon/Alloy Steel

Carbon/Alloy Steel

Stainless Steel

Carbon/Alloy Steel

Carbon/Alloy Steel

Stainless Steel

CRA’s

Carbon/Alloy Steel

Stainless Steel

Stainless Steel

Carbon/Alloy Steel

Stainless Steel

Stainless Steel

CRA’s

PR1

Hangers

Valves

PR2 PR2 (Annex F)

API 6A Testing Requirements

1 cycle fromminimum tomaximumrated load

3 cycles fromminimum tomaximumrated load

3 cycles from minimum tomaximum rated load; 3

temperature cycles on the sealsfrom top to bottom at high, low,

and ambient temperatures

200 open-close cycles at fulldifferential WP, including 160

cycles at ambient, 20 at themaximum temperature and 20 at the minimum temperature.

200 open-closecycles at

fulldifferential

WP

3 open-closecycles at

fulldifferential

WP

KLPRSTUVXY

-75º to 180º-50º to 180º-20º to 180º-40º to 120º

0 to 150º0 to 180º0 to 250º

35º to 250º0 to 350º0 to 650º

Temperature Class Temp (F)

Gas Well?

Gas Well?

Slip-on-Weld SliplocThreaded

B-1

TC-EC

B-2/P A-4A-4-M