Flex System Article

-

Upload

tomjordan12321 -

Category

Documents

-

view

213 -

download

0

description

Transcript of Flex System Article

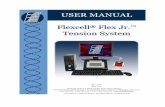

The Mecon The Mecon The Mecon The Mecon The Mecon FlexSystemFlexSystemFlexSystemFlexSystemFlexSystem FlexSystem FlexSystem FlexSystem FlexSystem FlexSystem by: Russ Deneau

econ Industries Ltd.

presents their “TheMecon Flex System” a modular,built to order, manufacturing systemdesigned to allow for quick and costeffective changes in production set-ups. The flexibility of the controlsystem allows it to command avariety of tools and can be config-ured in many ways, limited only bythe imagination.

A typical system incorporatesmultiple punching/notching stations, afeed to position system and a shear.

Components can include, but

are not limited to; coil car, uncoiler,straightener, punch tools, notchtools, servo roll feeder, shear,stamping press, brake press, panelbender and gag tooling. Punch/Notch units can be mounted onslides to allow them to be positionedover strip and in pairs to allow forpunching on either side of centerline.Punch positions can be adjustedmanually or be motorized and beequipped with readouts to indicateoffset from machine centerline. Gagtools are set/reset as the material ispositioned to be ready for the nextpressing. The servo driven feederaccurately positions the material toaccommodate all tool positions.

The controller has a simple to

use interface with manual andautomatic programming modes.Programs can be keyed directly intothe controller or downloaded from acomputer. An Excel based pro-

SampleConfigurations

One 25 ton hydraulic press with 8gag toolsFour 25ton single station hydraulicpunchesServo roll feedHydraulic shearCapacity 10 gauge x 24”Speed: 30 to 80 fpm*

5 roll straightener2 hydraulic 10 ton punchesair press with punch toolingservo roll feedhydraulic shearCapacity: 16 gauge x 48”Sped 30 to 80 fpm*

* thru-put speed is dependant

upon input limits, on part length, andfeature positions.

Photo 1

MMMMMMMMMM gramming tool simplifies the devel-opment of complex programs. Thecontrol program uses sequencesof lengths and tooling commandsto maximize the flexibility of thetooling, and is designedto operate up to 16 tools and16 presses.

“The Mecon Flex System”

is compatible with mechanical,pneumatic, or hydraulic actu-ated tooling and can be used in3 operating modes (standalonemachine, station within system,press feeder). Designed for shortand medium sized runs it allows forquick set-up changes and eliminatesthe need to purchase expensivespecial purpose dies.

The latest addition to the

line-up of quality-manufacturedproducts by Mecon can beconfigured to meet manyproduction requirements.

- Pre-punch systems in roll forming- Brackets- Cut to length systems- Punch notch and cut to length for duct work, stove pipe etc.- Batching- In press gagging Systems to date have been built

for 10 ga x 48” wide.

Consider This Machine For:

Photo 2