Finite element analysis and experimental investigations

description

Transcript of Finite element analysis and experimental investigations

International Journal of Mechanical Engineering and Technology (IJMET), ISSN 0976 –

6340(Print), ISSN 0976 – 6359(Online) Volume 3, Issue 3, Sep- Dec (2012) © IAEME

493

FINITE ELEMENT ANALYSIS AND EXPERIMENTAL

INVESTIGATIONS ON SMALL SIZE WIND TURBINE BLADES

T.Vishnuvardhan, Associate Professor, Intell Engineering College,

Anantapur.A.P

Dr.B.Durga Prasad, Associate Professor, JNT University,

Anantapur.A.P

ABSTRACT

The demand for Small / Micro Wind Turbines is increasing worldwide and the basic

advantage of using small size wind turbines is the production of power at low wind speeds.

The electricity produced by wind power is cost effective when compared with remaining

green energy sources. Small wind turbine systems can be easily installed near the site where

the power is required thus the investment on power transmission lines can be reduced. The

paper presents the development of small wind turbine blade models in two different profiles

R21 and R22. NACA 63-415 airfoil is used for the development of blades. The blades are

developed and fabricated for one kW wind turbine generator system. Finite element analysis

was conducted by varying the composition of materials used for blade fabrication.

Experimental investigations through load deflection test and cyclic load bench test conducted

on six blade varieties. The results show the degradation of material properties as the

experiment is getting progressed. Finally a better performing blade was identified from the

result obtained from FEA, load deflection test and cyclic load bench test.

Key Words: Small Wind Turbine – Blade Profiles – Load Deflection Test - Cyclic Load

Bench Test.

1. INTRODUCTION

Most small / micro size wind turbines are developed to produce power at the locations

where the availability of wind at low speeds. Most of the small wind turbines use permanent

INTERNATIONAL JOURNAL OF MECHANICAL ENGINEERING

AND TECHNOLOGY (IJMET) ISSN 0976 – 6340 (Print) ISSN 0976 – 6359 (Online) Volume 3, Issue 3, September - December (2012), pp. 493-503 © IAEME: www.iaeme.com/ijmet.asp Journal Impact Factor (2012): 3.8071 (Calculated by GISI) www.jifactor.com

IJMET

© I A E M E

International Journal of Mechanical Engineering and Technology (IJMET), ISSN 0976 –

6340(Print), ISSN 0976 – 6359(Online) Volume 3, Issue 3, Sep- Dec (2012) © IAEME

494

magnet alternators which are simplest and robust generator configurations. As the wind

turbine size decreases the rotor speed increases and the power extraction will be more based

on the wind velocity parameter. The blades on the rotor experience a high number of flexing

cycles which impacts their life. The aerodynamics, material properties are the key factors in

identifying a better performing blade model. The following sections deal with profile

development, FEA and experimental investigations on small size wind turbine blades with

different profiles.

2. BLADE PROFILE DEVELOPMENT

The present paper focuses on the development of small wind turbine blades

developed from R21 and R22 profiles using a specified design methodology for small size

horizontal axis wind turbine systems. NACA 63-415 airfoil is used to develop the wind

turbine blades in R21 and R22 profiles. The investigations are carried out by varying the

material compositions used for blade development. The following are the materials used for

fabrication of wind turbine blades. i) Glass fiber reinforced with polyester resin ii) Glass

fiber reinforced with polyester resin sandwiched with UV hard foam and iii) Glass fiber

reinforced with Epoxy resin sandwiched with UV hard foam. UV hard foam is used as a

central beam, which increases the stiffness properties of the blade [1]. NACA 63-415 airfoil

shape used for the development of blade profiles is shown in the Figure 1. The

corresponding station and ordinate values for both upper and lower surfaces are shown in

Table 1.

Table 1 Stations Values along with Ordinates NACA 63-415

Upper Surface Values Lower Surface Values

Station Ordinate Station Ordinate

0 0 0 0

0.3 1.2870 0.7 -1.0870

0.5249 1.5889 0.9755 -1.3075

0.9927 2.0677 1.5081 -1.6398

2.1990 2.9571 2.8019 -2.2126

4.6599 4.2652 5.3409 -3.0019

7.1476 5.2629 7.8580 -3.5669

9.6477 6.0757 10.3528 -4.0065

14.6689 7.3487 15.3318 -4.6579

19.7051 8.2802 20.2963 -5.0952

24.7506 8.9388 25.2582 -5.3595

29.8051 9.3651 30.2011 -5.4759

34.8529 9.5591 35.1484 -5.4373

39.9049 9.5279 40.0957 -5.2435

44.9547 9.2891 45.0453 -4.9083

50 8.8704 50 -4.4576

International Journal of Mechanical Engineering and Technology (IJMET), ISSN 0976 –

6340(Print), ISSN 0976 – 6359(Online) Volume 3, Issue 3, Sep- Dec (2012) © IAEME

495

55.0398 8.2975 54.9618 -3.9167

60.0704 7.5947 59.9296 -3.3102

65.0937 6.7793 64.9070 -2.6576

70.1060 5.8748 69.8949 -1.9859

75.1089 4.9056 74.8911 -1.3257

80.1017 3.8978 79.8983 -0.7122

85.0848 2.8821 84.9152 -0.1918

90.0595 1.8851 89.9405 0.1844

95.0289 0.9336 94.9721 0.3309

100 0 100 0

L.E. Radius = 1.473 percent c

Slope of Mean Line at LE = 0.1685

0 2 0 4 0 6 0 8 0 1 0 0

- 6

- 4

- 2

0

2

4

6

8

1 0

Air

foil O

rdin

ate

s

A i r f o i l S t a t i o n s

U p p e r S u r f a c e V a l u e s

L o w e r S u r f a c e V a l u e s

Fig: 1 NACA 63-415 Airfoil Upper and Lower Surfaces

developed from Ordinates and Stations

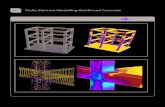

3. FINITE ELEMENT ANALYSIS OF SMALL WIND TURBINE BLADES

Finite element analysis is carried out for all blade varieties to extract the behavior of

the blades when they are subjected to loading. The solid models of R21 and R22 blade

varieties are developed in pro/engineer software and they are shown in Figures 2 & 3.

Using ANSYS static analysis was carried out and the Vonmises stresses and

corresponding blade deformations are calculated. Figure 4 and 5 shows the values of

displacement and Vonmises stresses corresponding to SWT blade from R22 profile, GFRP

with epoxy resin UV sandwiched material.

The vibration characteristics of the blades are analyzed by performing modal

analysis. Further the excitation forces on the blades caused by the stochastic wind loads are

imposed on the rotor model and the stable response of the system is calculated by harmonic

analysis. Mode shapes developed for R22 GFRP + Epoxy + SW are shown in Figures 6, 7,

8, 9 and 10. Harmonic analysis results for the same blade are shown in Figures 11, 12, 13,

14, 15 and 16. Tables 2, 3, 4, 5, 6 and 7 show the frequency values for different modes for

all blade varieties.

International Journal of Mechanical Engineering and Technology (IJMET), ISSN 0976 –

6340(Print), ISSN 0976 – 6359(Online) Volume 3, Issue 3, Sep- Dec (2012) © IAEME

496

Fig: 2 R21 SWT Blade Assembly

Fig: 3 R22 SWT Blade Assembly

Fig:4 Static Analysis of R-22- GFRP + Epoxy + SW

Blade - at 0.02450 N/mm2 Wind Pressure - Displacement

Fig:5 Static Analysis of R-22- GFRP + Epoxy +

SW Blade - at 0.02450 N/mm2 Wind Pressure -

Vonmises Stress

Fig:6 Modal Analysis of R-22- GFRP + Epoxy + SW

Blade – I Mode

Fig:7 Modal Analysis of R-22- GFRP + Epoxy +

SW Blade – II Mode

Fig:8 Modal Analysis of R-22- GFRP + Epoxy + SW

Blade – III Mode

Fig:9 Modal Analysis of R-22- GFRP + Epoxy +

SW Blade – IV Mode

International Journal of Mechanical Engineering and Technology (IJMET), ISSN 0976 –

6340(Print), ISSN 0976 – 6359(Online) Volume 3, Issue 3, Sep- Dec (2012) © IAEME

497

Fig:10 Modal Analysis of R-22- GFRP + Epoxy + SW Blade – V

Mode

Fig: 11 Harmonic Analysis of R-22- GFRP + Epoxy +

SW Blade – Root– at 0.02450 N/mm2 Wind Pressure

- Displacement

Fig: 12 Harmonic Analysis of R-22- GFRP + Epoxy + SW Blade

– Mid – at 0.02450 N/mm2 Wind Pressure - Displacement

Fig: 13 Harmonic Analysis of R-22- GFRP + Epoxy +

SW Blade – Tip– at 0.02450 N/mm2 Wind Pressure -

Displacement

Fig: 14 Harmonic Analysis of R-22- GFRP + Epoxy + SW Blade

– Root– at 0.02450 N/mm2 Wind Pressure - Vonmises Stress

Fig: 15 Harmonic Analysis of R-22- GFRP + Epoxy +

SW Blade – Mid – at 0.02450 N/mm2 Wind Pressure

- Vonmises Stress

Fig: 16 Harmonic Analysis of R-22- GFRP + Epoxy + SW Blade

– Tip– at 0.02450 N/mm2 Wind Pressure - Vonmises Stress

Fig: 17 Partial Deflection of the Blade

International Journal of Mechanical Engineering and Technology (IJMET), ISSN 0976 –

6340(Print), ISSN 0976 – 6359(Online) Volume 3, Issue 3, Sep- Dec (2012) © IAEME

498

Fig: 20 Failure at the Root of Blade in Cyclic

Load Test

-10 0 10 20 30 40 50 60 70

0

100

200

300

400

500

600 Load D eflection Tes t

Load App lied a t T IP

B lade Pro file - R 22

Materia l - GFRP+EPO XY+ SW

De

flection

in

'mm

'

Load in 'Kgs'

T ip

M id

Root

Fig:21 Load Deflection Test - R-22 - GFRP +

Epoxy + SW Blade – Load Applied at Tip

-10 0 10 20 30 40 50 60 70 80

0

20

40

60

80

100

120

140

160

180

Load in 'Kgs'

Load Deflection Test

Load Applied at MID

Blade Profile - R22

Material - GFRP+EPOXY+ SW

De

flection

in

'mm

'

T ip

Mid

Root

Fig:22 Load Deflection Test - R-22 - GFRP +

Epoxy + SW Blade – Load Applied at Mid

0 20 40 60 80

0

10

20

30

40

50 Load Deflection Test

Load Applied at ROOT

Blade Profile - R22

Material - GFRP+Polyester + SW

De

flection

in

'mm

'

Load in 'Kgs'

T ip

M id

Root

Fig:23 Load Deflection Test - R-22 - GFRP +

Epoxy + SW Blade – Load Applied at Root

4. LOAD DEFLECTION TEST

The moments, thrust torque and power on the rotor can be produced from the various

forces that cause loads on the small wind turbine rotor system are aerodynamic forces,

centrifugal forces and gravitational forces. For small wind turbine rotors aimed to produce

the power approximately 1 kW, their blades which actually experience these forces are to be

tested for their ability in withstanding them. The turbine blades can be tested for their

ultimate strength by conducting load deflection test. A fixture setup is constructed, to hold

the blade at its root section.

Fig: 18 Cyclic Load of 15 Kg. Applied on the

Blade

Fig:19 Cyclic Load of 25 Kg. Applied on the

Blade

International Journal of Mechanical Engineering and Technology (IJMET), ISSN 0976 –

6340(Print), ISSN 0976 – 6359(Online) Volume 3, Issue 3, Sep- Dec (2012) © IAEME

499

Table 2 R21 GFRP + Polyester Solid Blade - MODE Frequency Values

Sno Mode Frequency (Hz)

1 I 23.607

2 II 100.775

3 III 110.642

4 IV 233.534

5 V 300.236

Table 3 R21 - GFRP + Polyester + SW - MODE Frequency Values

Sno Mode Frequency (Hz)

1 I 24.801

2 II 105.709

3 III 115.140

4 IV 243.166

5 V 311.784

Table 4 R21 GFRP + Epoxy + SW - MODE Frequency Values

Sno Mode Frequency (Hz)

1 I 25.134

2 II 107.128

3 III 116.686

4 IV 246.430

5 V 315.969

Table 5 R22 GFRP + Polyester Solid Blade - MODE Frequency Values

Sno Mode Frequency (Hz)

1 I 17.471

2 II 72.585

3 III 83.156

4 IV 187.266

5 V 259.289

Table 6 R22 GFRP + Polyester + SW - MODE Frequency Values

Sno Mode Frequency (Hz)

1 I 22.051

2 II 91.441

3 III 104.551

4 IV 235.532

5 V 323.911

Table 7 R22 GFRP + Epoxy + SW - MODE Frequency Values

Sno Mode Frequency (Hz)

1 I 22.437

2 II 93.043

3 III 106.381

4 IV 239.661

5 V 329.595

The blade resembles a cantilever beam when it is fixed, critical sections are

identified on which the load is to be applied and corresponding deflections are measured.

International Journal of Mechanical Engineering and Technology (IJMET), ISSN 0976 –

6340(Print), ISSN 0976 – 6359(Online) Volume 3, Issue 3, Sep- Dec (2012) © IAEME

500

The three critical sections are at tip, middle and root. The experiment is conducted for all

blade varieties and it contains three phases initially the load is applied at tip of the blade,

deflections are measured at tip, mid and root. In the second phase the load is applied at mid

section and the deflection is measured at tip, mid and root. In the final phase the load is

applied at root and the deflection is measured at three locations. The load is increased with a

unit value from 0 Kgs, and is continued till the blade fails. The experimental setup showing

the partial deflection of the blade when the load is applied at the tip is represented in Figure

17. Table 8 show the measured distances for R21 and R22 profile blades at which the load

should be applied and the deflections are to be measured.

Table 8 Distance Measurement from Fixed End to Critical Sections Sno Blade

Profile

Distance from the fixed

end to Root Section

Distance from the fixed

end to Mid Section

Distance from the fixed

end to Tip Section

1 R21 150 mm 610 mm 950 mm

2 R22 200 mm 660 mm 1030 mm

The load deflection test results for R22 profile blade produced from GFRP + Epoxy +

SW material are represented in Figures 21, 22 and 23.

5. CYCLIC LOAD BENCH TEST

A wind turbine blade is subjected during life time a large number of dynamic loads

produced by the rotation and turbulent nature of wind on blades[3]. Fatigue comes in to

picture for wind turbine blades as they are subjected to cyclic loading. These loading cause

failures of blade like cracks and rupture and it is very much essential to identify the fatigue

behavior of the wind turbine blades [7,8] .

As there is no standard procedure for determining the spectrum loads on small wind

turbines, cyclic load bench test was developed to understand the behavior of the blade based

on the failures by causing strain on the blades[6]. The cyclic load bench test setup is shown

in the Figures 18 and 19.

5.1 Cyclic Load Test Procedure

The bench can be used for small wind turbine blades with a maximum length of 1.5

meters. The test bench is having a load cell located at the top portion of the setup. A fixture

is also developed for holding the blade at its root section and the blade is instrumented with

strain gauges to measure the deformation. In the test a cyclic load will be applied on the

International Journal of Mechanical Engineering and Technology (IJMET), ISSN 0976 –

6340(Print), ISSN 0976 – 6359(Online) Volume 3, Issue 3, Sep- Dec (2012) © IAEME

501

blades with constant number of cycles (30000) and the load which is applied on the blade

will be further increased once the blade can withstand the cyclic loads.

The test procedure is performed based on “constant cycles-incremental load-strain

measurement”, will be continued till the crack or any other failure occurs. The strain

measurement is carried out after the completion of prescribed number of cycles at each

magnitude of load applied on the blade. The experimental results are shown in Figures 24,

25, 26, 27, 28 and 29.

0 5000 10000 15000 20000 25000 30000

-6

-5

-4

-3

-2

-1

0

1 C yclic Load - D e flection T esti - R 21-

G F R P + P olys te r S o lid B lade

De

flection in 'm

m'

N um ber of C yc les

3 K g . 6 K g .

9 K g .

12 K g.

15 K g.

Fig.24 Cyclic Load Test Results of R-21 –

GFRP + Polyester Solid Blade

0 5 0 0 0 1 0 0 0 0 1 5 0 0 0 2 0 0 0 0 2 5 0 0 0 3 0 0 0 0

-6

-5

-4

-3

-2

-1

0

1 C y c l ic L o a d - D e f le c t io n T e s t i - R 2 2 -

G F R P + P o ly s te r S o lid B la d e

Deflection

in 'm

m'

N u m b e r o f C yc le s

3 K g .

6 K g . 9 K g .

1 2 K g .

1 5 K g .

Fig.25 Cyclic Load Test Results of R-22 –

GFRP + Polyester Solid Blade

0 5 0 0 0 1 0 0 0 0 1 5 0 0 0 2 0 0 0 0 2 5 0 0 0 3 0 0 0 0

-4 .5

-4 .0

-3 .5

-3 .0

-2 .5

-2 .0

-1 .5

-1 .0

-0 .5

0 .0

0 .5

1 .0 C y c lic L o a d - D e f le c t io n T e s t i - R 2 1 -

G F R P + P o ly s te r + S W B la d e

De

flection in 'm

m'

N u m b e r o f C yc le s

3 K g . 6 K g .

9 K g . 1 2 K g . 1 5 K g .

Fig.26 Cyclic Load Test Results of R-21 –

GFRP + Polyester + SW Blade

0 5 0 0 0 1 0 0 0 0 1 5 0 0 0 2 0 0 0 0 2 5 0 0 0 3 0 0 0 0

- 6

- 5

- 4

- 3

- 2

- 1

0

1 C y c lic L o a d - D e f le c t io n T e s t i - R 2 2 -

G F R P + P o ly s te r + S W B la d e

De

flection in 'm

m'

N u m b e r o f C y c le s

3 K g . 6 K g . 9 K g .

1 2 K g . 1 5 K g . 1 8 K g .

Fig.27 Cyclic Load Test Results of R-22 –

GFRP + Polyester + SW Blade

0 5 00 0 10 00 0 1 50 00 200 00 2 50 00 3 00 00

-1 8

-1 6

-1 4

-1 2

-1 0

-8

-6

-4

-2

0

2C yc lic L oa d - D e flec tio n T es ti - R 2 1 - G F R P + E p o x y + S W B la d e

De

fle

ctio

n in

'mm

'

N u m ber o f C ycles

3 K g. 6 K g.

9 K g. 1 2 K g .

1 5 K g .

1 8 K g . 2 1 K g .

Fig.28 Cyclic Load Test Results of R-21 –

GFRP + Epoxy + SW Blade

0 5 0 0 0 1 0 0 0 0 1 5 0 0 0 2 0 0 0 0 2 5 0 0 0 3 0 0 0 0

-1 7

-1 6

-1 5

-1 4

-1 3

-1 2

-1 1

-1 0

-9

-8

-7

-6

-5

-4

-3

-2

-1

0

1

C y c lic L o a d - D e fle c t io n T e s ti - R 2 2 - G F R P + E p o x y + S W B la d e

De

fle

ctio

n in

'mm

'

N u m b e r o f C yc le s

3 K g .

6 K g . 9 K g .

1 2 K g .

1 5 K g . 1 8 K g .

2 1 K g . 2 5 K g .

Fig.29 Cyclic Load Test Results of R-22 –

GFRP + Epoxy + SW Blade

International Journal of Mechanical Engineering and Technology (IJMET), ISSN 0976 –

6340(Print), ISSN 0976 – 6359(Online) Volume 3, Issue 3, Sep- Dec (2012) © IAEME

502

CONCLUSIONS

The paper shows a specific methodology to determine the load deflection

characteristics and the cyclic load behavior of small wind turbine blades. The following are

some of the important conclusions drawn from the experiments

� All the blades are capable to bear maximum loading value when applied at the root

section and the blades will fail at lower magnitude of loading, when the load is

applied at tip of the blade.

� It is observed that all the blades when subjected to loading irrespective of the location

at which the load is applied, the failure crack is observed near the root of the blade.

The blade tends to fail by creating a crackling sound.

� When the load deflection test results are compared for all varieties, the R22 profile

blade produced from GFRP + Epoxy + SW is showing more structural strength.

Even in R21 profile also the produced from the same material is showing more

structural strength.

� In cyclic load bench test, the GFRP + Epoxy + SW blades have shown a better

performance in both R21 and R22 blade profiles. Out of all the six varieties of blades

R22 profiled based blade fabricated from GFRP + Epoxy +| SW has shown the

leading performance by with standing a cyclic load of 25 Kgs. with a deflection of

16mm below the reference point, at 30000 cycles.

� In R21 profile, the blade fabricated from GFRP + Epoxy +| SW has shown the

leading performance by with standing a cyclic load of 21 Kgs with a deflection of

16.75 mm below the reference point, at 30000 cycles.

REFERENCES

1) T.Y. Kam, J. H. Jiang, H. H. Yang, R. R. Chang, F. M. Lai, and Y. C. Tseng,

“Fabrication and Testing of Composite Sandwich Blades for a Small Wind Power

System”, PEA-AIT International Conference on Energy and Sustainable

Development: Issues and Strategies (ESD 2010), June 2010.

2) Jorge Antonio Villar A1e, Gabriel da Silva Simioni, Joao Gilberto Astrada Chagas

Filho, “Procedures Laboratory for Small Wind Turbines Testing”.

3) Jorge Antonio Villar A1e, Carlos Alexander dos, Santos, “Aerodynamic Loads of

Fatigue of Small Wind Turbine Blades: Standards and Testing Procedure” EWEA

2011-Europe’s Premier Wind Energy Event 14-17-March 2011, Brussels, Belgium.

International Journal of Mechanical Engineering and Technology (IJMET), ISSN 0976 –

6340(Print), ISSN 0976 – 6359(Online) Volume 3, Issue 3, Sep- Dec (2012) © IAEME

503

4) Brian Hayman, Jakob Wedel-Heinen, Povl Brondsted, “Materials Challenges in

Present and Future Wind Energy” Harnessing Materials for Energy, MRS Bulletin,

Volume 33, April 2008.

5) Jayantha A Epaarachchi and Philip D Clausen “Accelerated full scale fatigue testing

of a Small Composite Wind Turbine Blade using a Mechanically operated test rig”

SIF-2004 Structural Integrity and Fracture.

6) DET Norske Veritas “Design and Manufacture of Wind Turbine Blades, Offshore

and Onshore Wind Turbines”– October 2006.

7) Jayantha A. Epaarachchi, Philip D. Clausen “An empirical model for fatigue behavior

prediction of glass fiber-reinforced plastic composites for various stress ratios and test

frequencies” Journal of Applied Science and manufacturing – 2003.

8) P.Rajaram 1 A.Murugesan 2 and G.S.Thirugnanam “Experimental Study on behavior

of Interior RC Beam Column Joints Subjected to Cyclic Loading” International

Journal Of Applied Engineering Research, Dindigul Volume 1, No 3, 2010 Research

Article Issn 09764259.

9) Nitin Tenguria 1 , Mittal.N.D 1 , Siraj Ahmed 2 “Design and Finite Element Analysis

of Horizontal Axis Wind Turbine blade” Journal of Materials Processing Technology

167 (2005) 463–471

10) M. Grujicic, G. Arakere, E. Subramanian, V. Sellappan, A. Vallejo, and M. Ozen

“Structural-Response Analysis, Fatigue-Life Prediction and Material Selection for 1

MW Horizontal-Axis Wind-Turbine Blades” – 2009.