Fine Woodworking - 243Nov-Dec2014

-

Upload

wahomelngari1746 -

Category

Documents

-

view

284 -

download

1

Transcript of Fine Woodworking - 243Nov-Dec2014

-

7/24/2019 Fine Woodworking - 243Nov-Dec2014

1/92

Side table from

a single board,p. 58TAUNTONS

ec. 2014 No. 243

ww.finewoodworking.com

Greene and Greene

blanket chestTricks for tough glue-ups

Make custommoldings by hand

Midsize routers

Build a desk

nto any dresser

MASTER CLASSAn easier,strongerchair joint

OOL TEST

ec. 2014 No. 243

ww.finewoodworking.com

Greene and Greene

blanket chestTricks for tough glue-ups

Make custommoldings by hand

Midsize routers

Build a desk

nto any dresser

MASTER CLASSAn easier,strongerchair joint

-

7/24/2019 Fine Woodworking - 243Nov-Dec2014

2/92

STAND BEHIND YOUR WORKTM

5 50 + S ER VI CE CE NT ER S N AT IO NW ID E I ND US TR Y- LE AD IN G W AR RA NT IE S E XP ER T T EC HN IC AL SE RV IC E

SEE MORE ATJETTOOLS.COM/17

INTRODUCING THE 17"WOODWORKING DRILL PRESS

DESIGN THATPERFORMS

5 INCHSPINDLE TRAVEL

QUICK & EASYSPEED CHANGES

INTEGRATEDDEPTH STOP

EFFICIENTPOLY-V BELT DRIVE

-

7/24/2019 Fine Woodworking - 243Nov-Dec2014

3/92

See the videoleighjigs.com

800-663-8932

Leigh FMT Pro

Chairs?No problem.Leigh Mortise & Tenon Jigs makechallenging joinery projects like

chairs incredibly easy.

N OV E M B E R / D E C E M B E R 2 0 1 4www.fi newoodwor k ing. com

-

7/24/2019 Fine Woodworking - 243Nov-Dec2014

4/92

TOOLTEST

contents

up front

NOVEMBER/DECEMBER 2014 ISSUE 243

features30 Build a Greene and Greene

Blanket ChestIts all about the details. Our expert showshow to get them right

B Y D A R R E L L P E A R T

38 Tame Tricky Glue-UpsCustom cauls can handle every angle and curve

B Y M I C H A E L F O R T U N E

46 Desk in a DrawerAdd a pull-out desk to any chest of drawers

B Y C H R I S T I A N B E C K S V O O R T

52 Midsize, Fixed-Base RoutersGreat combination of power and control

B Y M A R C A D A M S

58 Make a Table from a BoardStylish side table is a great lesson in gettingthe most out of your lumber

B Y M I C H A E L P E K O V I C H

66 The Why of the WindsorA veteran maker explains the roots,the rationale, and the powerful appealof Americas classic chair

B Y C U R T I S B U C H A N A N

COVERSTORY

6 On the Web

8 Contributors

10 Letters

14 Methods of Work

Easy jig for squaring tablesaw

miter gauge

Rubber-band brush wiper

18 Tools & Materials

Stout contractors saw

with smart features

Self-cleaning vacuum is quiet

and efficient

Tenon saws are a great value

24 Handwork

Custom moldings with hand toolsB Y C U R T I S B U C H N N

18 NEW TABLESAWFROM RIKON

Cover photo: Steve Scott

14MITER-GAUGESQUARING JIG

-

7/24/2019 Fine Woodworking - 243Nov-Dec2014

5/92

74 Readers Gallery

78Q & A

Fix for a wandering handsaw

Router table is better for small sho

Seal your project with dewaxed

shellac

82 Master ClassPowerful new joint: Housed double

tenons are strong and simple to ma

90 How They Did It

The back cover explained

Back Cover

Chair Story

in the back

ONE-BOARDTABLE PROJECT

38 CAULS FORTRICKY GLUE-UPS

52 MIDSIZEROUTERS

58

46PULL-OUT DESKIN A DRAWER

Your feed back i s valu able t o

LIKE THIS APP

-

7/24/2019 Fine Woodworking - 243Nov-Dec2014

6/92

-

7/24/2019 Fine Woodworking - 243Nov-Dec2014

7/92

QUALITY WOODWORKING TOOSUPPLIES ADVICE

To Find Your Local Woodcraft Store Or For A Free Catalog, Visit woodcraft.com Or Call 1-800-225-1

14WW12D

SawStops new Sliding Crosscut Table attachment greatly expands the capabilityof existing SawStop Table Saws. SawStop owners can easily handle and cut large

sheet goods with the sliding cross cut table that features a massive 55" travel,

which gives the user 48" of crosscut capacity.

Features:

Designed With Multiple Bearings For Silky

Smooth Operation

Sliding Table And Fence Made of T-6 Aircraft-

Grade Extruded Aluminum

43"-Long Fence Can Expand Past 58; Position

Anywhere Along Length Of Table

Comes With 2 Large Flip-Stops, Scale, and

Magnied Lens For Accurate, Repeatable Cuts

861677

SawStop Sliding Crosscut Table

Vacuum Pressing Systems, Inc.

553 River Road,Brunswick, ME 04011 800-382-4109

vacupress.com

The leader in vacuum technologyfor woodworking offers innovativeproducts for:

VENEERING LAMINATING

CLAMPING

Vacuum Presses, FlipTop Tables,Veneering Accessories and Videos

C ENTER f o rFURN I TURE

CRAFT SMANSH I P

Rockport, Mainewww.woodschool.org

Teaching Creative Excellence

Incredibly accurate

Wood Carving Duplicators

Furniture Gunstocks Millwork Decoys Musical

Instruments Propellers

CarvedFigures

Thousands of uses! 505-948-0571

www.RadarCarve.net

www.RadarcarveR.com

N O V E M B E R / D E C E M B E R 2 0 1 4www.f inewoodwor k ing. com

-

7/24/2019 Fine Woodworking - 243Nov-Dec2014

8/92

Group Publisher Anatole Burkinaburkin@taunton.

VP, Advertising Sales Rick Straface

rstraface@taunton

Digital Ad Sales Manager Noelle Kennedy203-304-3530nkennedy@taunto

Custom Solutions Brenden DelaneyManager 203-304-3590

bdelaney@taunton

Senior National Linda AbbettAccount Manager 203-304-3538

Advertising Sales Diana MackeyAssistant

Director of Advertising Karen LutjenSales Marketing

Advertising Marketing Laura HoltAssociate

Member AuditBureau of Circulation

Digital Marketing Sara Ezrin LarsenDirector

Senior Director, Michael StoltzInteractive

Web Design Director Jodie Delohery

Independent publishers since 1975

Founders, Paul & Jan Roman

President Timothy Rahr

Chief Digital Officer John Brown

Group Publisher Anatole Burkin

Group Publisher Maria Taylor

SVP, Creative & Editorial Susan Edelman

SVP, Operations Thomas Luxeder

VP, Single Copy Sales Jay Annis

VP, Advertising Sales Rick Straface

VP & Controller Wayne Reynolds

VP, Human Resources Carol Marotti

VP, Fulfi llment Patricia Williamso

VP, Product Engineering Nancy Kopfenstein

Publishers of magazines, books, videos, and on

Fine Woodworking Fine Homebuilding

Threads Fine Gardening Fine Cooking

taunton.com

contributors

We are a reader-written magazine. To

learn how to propose an ar ticle, go to

FineWoodworking.com/submissions.

For more information on our contributors,

go to FineWoodworking.com/authors.

His earliest memories were of sawing and hammering, so its

natural that Garrett Hack(Handwork: Custom moldings with

hand tools) became a furniture maker. But first he studied

civil engineering and architecture at Princeton University, and

later attended Boston Universitys Program in Artisanry. He is a

contributing editor to FWW, former chairman of the New Hampshire

Furniture Masters, and teaches throughout the United States as well

as in Canada, England, Germany, Italy, Australia, Austria, and Japan.

Those who work with executive art director Michael Pekovich

(Make a Table from a Board) at FWWknow him as a talentedfurniture maker and graphic designer who is committed to bringing

complicated subjects to our readers in the clearest way possible.

Hes also the go-to guy for solutions to our own furniture-making

snafus. But on his own time, Mike is building quite a resum as a

teacher. This year hes taught a long list of classes, from weekend

workshops on hand-tool skills to weeklong classes at Connecticut

Valley School of Woodworking and the Marc Adams school.

Our editors love visiting the expansive shop of contributing editor

Michael Fortune(Tame Tricky Glue-Ups), which sits on a quiet

log-cabin homestead 100 miles outside Toronto. And everyone

learns the rules. There are mandatory coffee breaks in the morning

and afternoon, which include excellent cookies made by Michaelswife, Janice. Coffee cups must be left by the shop door so they

make it back to the house each night. And after all that coffee,

if you need to head out the back door to the woods, you are not

allowed back in without three pieces of firewood.

Curtis Buchanan(TheWhy of the Windsor,

How They Did It, and

the back cover) makes

chairs full time in the

small shop he built behind

his house in the heart of

Tennessees oldest town,

Jonesborough. He also

tends a robust vegetable

garden and occasionally

sells some of his produce

at the thriving weekly

Jonesborough farmers market, which he co-founded. He and his wife, Marilyn, have

two daughters: Summer, a key employee at the Jonesborough library, and Maria, a

singer and actor in Asheville.

What advice do you give to aspiring chairmakers?You can do it! Find yourself a

small town and settle down right in the middle of it; theyll be happy to adopt you.

F I N E W O O D W O R K I N G8

-

7/24/2019 Fine Woodworking - 243Nov-Dec2014

9/92

800-225-3982 whitesiderouterbits.com

Whiteside Machine Co.Claremont, North Carolina

American Made for the

American Woodworker

ULTIMATE Flush Trim/Pattern Router Bits

ULTIMATE Trim Bits are perfect when working with

templates or when using a router to flush trim match-

ing wood surfaces. Whitesides compression spiral

design, along with a ball bearing guide, makes this

bit easy to use in the router and produces a superiorquality trimmed edge. The ULTIMATE Trim series

brings industrial engineered bits, previously manufac-

tured for CNC machines, right into your shop.

154275 (A) Flush Trim154276 (B) Pattern/Plunge154274 (C) Combination

(C)(A)

7/8" Diameter x 11/8" Cut Length x " Shank

ULTIMATETrim Bits

(B)

Introducing the SprayPort6000 Seriesfor a Flawless Finish

Compact and robust 2 or 3-stage turbine

Pro-8non-bleed gun in gravity or pressure-fedoptions for superior atomization

25 25

6000www.earlex.com

Lightweight and flexible HyperFlex hose

PROFESS

IONAL

HVLP

N O V E M B E R / D E C E M B E R 2 0 1 4www.fi newoodwor k ing. com

-

7/24/2019 Fine Woodworking - 243Nov-Dec2014

10/92

Festool coverage: Fair or foul?

I was pleased to see your recognitio

the Festool Domino (Domino Cha

the Game, FWW#242). In the pastyears, I have seen many articles in

woodworking publications address

methods of joinery. I couldnt beliethe Domino wasnt mentioned agai

and again.

The Festool Domino has all the

makings of a fantastic product whecompared with other mortise-and-t

techniques. It saves time. It delivers

more uniform, accurate result. It is easy to understand. And it enables

joinery of large and small pieces.

Kudos forfinally

delivering a

much overdue

article on theDomino.

JACK VIT ELLI ,

Mendota H eights,

Minn.

A six-page ad for Festool? Really? Gyou should have put them on the c

too. Next time put an advertiseme

bug on each page.GEORGE DENNIS, Denve

Nail drawbore offset with a punch

I look forward to every opportunitylearn from Steve Latta, and his meth

for drawboring tenons was no exce

(Drawbore Your Tenons, FWW#241), but I might suggest one mod

refinement. Rather than marking th

offset hole in the tenon with the drbit, and then having to eyeball a se

mark with an awl, I make a single m

with a suitable size transfer punch.So, for example, if the dowel hole i38in. dia., I use a 1964-in.-dia. punch

making sure its firmly pressed agai

the shoulder side of the hole. I thenhave a single mark thats offset the

fat 32nd Steve recommends. And

certainly agree that drawboring tenmakes glue-ups less stressful. I wou

confident in the long-term integrity

those joints, even if I wasnt sure I remembered to glue them.HOWARD SKILLINGTON, Winston-Sale

Anatole Burkin, Fine Woodworkings publisher, has decided to leave the company and

head back home, to the West Coast. Some people here speculate that he wanted

to leave Connecticut before the next harsh winter hit, but the truth is he wanted

a change and to be closer to family. Anatole has strong roots at the magazine,

starting as an associate editor and quickly moving up the ranks to the chief editor

position. As the lead editor, he noticed my interest in woodworking and encouraged

me to take a chance and jump from copy editor to associate editor, a move that Ive

never regretted. He was a great mentor, and a strong leader and advocate for our

franchise. Most of all, though, he is a friend who will be missed.

TOM MCKENNA, edi tor

FOND FAREWELL

When I was hired by The Taunton Press in 1996, I immediately hit the road,

documenting the work of the folks who put the fine in Fine Woodworking.

Oh, it wasnt all gossamer shavings and dust-free finishes, mind you. There were

times when just getting to the authors shop was a trial, be it from delayed flights,

broken light kits, or poor directions (or sense of direction)at least before we all

had GPS in our pockets.

Capturing the detail of a woodworkers progress required countless requests

to make yet another spare part and one more awkward slow-motion movement to

get just the right photo. Fair to say, on photo shoots patience was a virtue tested to

the limit.

Imagine then coming back from the shoot and anxiously waiting for the film to be

developed (in the old days when we used film) only to realize that the author was

wearing orange and green plaid. My first art director thought I was color blind.

Paring the authors precious words into an article that fit the constraints of a

magazine wasnt always a picnic, either. I still remember receiving a chilling fax

message from an author with a drawing of Dirty Harry, revolver in hand, and the

scrawled words: Go ahead, make one more change!

Well, it is time for one more change. I am leaving The Taunton Press and moving

back to the West Coast, where Ill put to good use all the tips and techniques

provided by woodworkers patient enough to work with editors like myself.

Thanks for the memories.

ANATOLE BURKIN, publ isher

Spotlight

letters

F I N E W O O D W O R K I N G10

-

7/24/2019 Fine Woodworking - 243Nov-Dec2014

11/92

To contact us:

Fine Woodworking

The Taunton Press

63 South Main Street

PO Box 5506

Newtown, CT 06470-5506

Tel: 203-426-8171

Send an email:

Visit:

finewoodworking.com

To submit an article proposal:

Write to Fine Woodworkingat the address

above or

Call: 800-309-8955

Fax: 203-270-6753

Email: [email protected]

To subscribe or place an order:

Visit finewoodworking.com/fworder

or call: 800-888-8286

9am-9pm ET Mon-Fri;

9am-5pm ET Sat

To find out about Fine Woodworkingproducts:

Visit finewoodworking.com/products

To get help with online member services:

Visit finewoodworking.com/customerservice

To find answers to frequently asked questions:

Visit finewoodworking.com/FAQs

To contact Fine Woodworkingcustomer service:

Email us at [email protected]

To speak directly to a customer service professional:

Call 800-477-8727 9am-5pm ET Mon-Fri

To sell Fine Woodworkingin your store:

Call us toll-free at 866-452-5179, or

email us at [email protected]

To advertise in Fine Woodworking:

Call 800-309-8954, or

email us at [email protected]

Mailing list:

We make a portion of our mailing list available

to reputable firms. If you would prefer that

we not include your name, please visit:

finewoodworking.com/privacy

or call: 800-477-8727 9am-5pm ET Mon-Fri

For employment information:

Visit careers.taunton.com

The Taunton guarantee:

If at any time youre not completely satisfied

with Fine Woodworking, you can cancel your

subscription and receive a full and immediate

refund of the entire subscription price. No

questions asked.

Copyright 2014 by The Taunton Press, Inc. No

reproduction without permission of The Taunton

Press, Inc.

For a store near you or free catalo

Place your order at Rockler.comby entering promotion code 603 at

checkout or call 1-800-279-4441. Offer expires December 31, 2014.Free shipping offer cannot be applied to previous orders or combined with other promotions includingProfessional Catalog orders. Not valid at Rockler Retail Stores or Independent Resellers. Special shipping chargemay still apply for Express, International, Alaska, Hawaii, and heavy/oversize items.

Have you ever struggled to clamp a board to your bench

and thought: There has to be a better way? Well, this is it.

With Rocklers quick-adjusting Auto-Lock T-Track Clamp,

T-Track Tabletop and T-Track System stops and accessories

you get a versatile system that adapts easily to hold most

any workpiece while saving you time and frustration.

Auto-Lock T Track Clamp(58616) $29.99

FREE SHIPPING!On orders of $25 or more

Introducing the fastestclamping system in the shop

Rockler.com 1-877-ROCKLE

Featuring ha

classes for all skil

taught by nat

known craftsmen in

Will NeSteve

Peter G

DarrellChristopher Scand

www.americanfabricfilter.com 800-367-3591

AMERICAN FABRIC FILTER CO.

UNIQUE SOLUTIONS

Free Design Assistance for All Custom Made Dust Bags

We Fix Dust

CollectionProblems!

Our Dust Bags FeatureOur Dust Bags Feature

Optimum PerformanceOptimum Performance

11--Micron FiltrationMicron Filtration

Custom DesignsCustom Designs

Cleaner AirCleaner Air

Longer LifeLonger Life

Proudly Made In USAProudly Made In USA

Other Products We OfferOther Products We Offer

66--mil Poly Bagsmil Poly Bags

Quick Release Hose ClampsQuick Release Hose Clamps

Self Adhesive Foam GasketSelf Adhesive Foam Gasket

Custom Transfer SleevesCustom Transfer Sleeves

Cartridge FiltersCartridge Filters

N O V E M B E R / D E C E M B E R 2 0 1 4

-

7/24/2019 Fine Woodworking - 243Nov-Dec2014

12/92

letters continued tt rs ontinue

Waterproofing

Fortunes

chair

Michael

Fortunes

garden chair

(Comfortable

Outdoor

Chair,FWW#241)

is outstanding, quite

beautiful, and undoubtedly sturdy. One

minor improvement Id suggest is to coat

the bottom of each leg and the chamfers

with epoxy resin, such as West Systems

or one of the many others. It makes the

exposed end grain in contact with the

ground waterproof and will prevent

water migrating up the legs and

deteriorating the wood.

JAMES S. WALDRON, St . Johns River , Fla.

Keep wood out of the oven, or else

I have been having troubling thoughts

concerning a recent Q&A item (Dry

small parts in your oven,FWW#243).

Just wondered ifFine Woodworkingis

now offering marriage counseling and

discount divorce lawyers as part of its

customer service?

Use the oven for woodworking? For a

few days? I shudder to contemplate the

consequences.

ALLEN NEF F, Brunner , Ont . , Canada

Rust attacks tools inside cabinet

I built the hanging tool cabinet in Tools &

ShopsWinter 2014 (A Cabinet for Hand

Tools,FWW#237). The cabinet is beautiful

and improved my woodworking skills in

many areas.

I did experience one problem. After

finishing and hanging the cabinet, I

placed my planes on the plane till. They

all rusted. Fortunately, I was able to

remove the light rust by sanding.

I finished the cabinet with boiled

linseed oil and two topcoats of shellac.

The cabinet hangs on a concrete block

wall with the back contacting the blocks.

inhibitor (VCI) or desiccant inside th

cabinet to fight moisture. With both

and desiccants, you need to keep the

cabinet closed; otherwise they lose th

effectiveness fairly quickly. For more

information on both, see Other way

manage moisture, FWW#227, p. 3

Router bit for relieved rabbet

How did Gerald Curry make the c

rabbet on the drawer bottoms (Bu

Perfect Drawers,FWW#242, p. 43)

assume that was a router bit, but I

not sure which type and size was u

By the way, that was an excellent a

I plan to study it thoroughly and pu

those techniques into practice.TIMOTHY CALDERWOOD, Crof t

Asa Christiana replies:Curry for

these curve-cornered rabbets with ashaper bit that he custom-ground. B

he says a router bit would also work

one designed for dish-carving (Item

91144 from Rockler), or a panel-ra

bit with a rounded profile.

Wrong price in sprayer article

The price listed for Apollos ECO-3

system with the E7000 gun was inc

(Spray for Less,FWW#242). The

is $649.

The tools have never rusted in my garage

workshop prior to placing in the cabinet.

Your advice is urgently appreciated.JOHN SCHEESSELE, Pi t tsburgh, Pa.

Editor replies:It sounds like youre

locking the moisture inside the cabinet,

where it can attack your tools. There are

a few things you can try. First, you can

treat your tools with a rust-proofer, such

as CRC Industrial 3-36 or Moovit, which

performed best in a test of a variety of

products (Got Rust?, FWW#227). Id

also recommend using a volatile corrosion

About your safety(or elsewhere) until youre certain they are safe for you. If someth

about an operation doesnt feel right, find another way. We want

to enjoy the craft, so please keep safety foremost in your mind.

Working wood is inherently dangerous. Using hand or power tools

improperly or ignoring standard safety practices can lead to permanent

injury or even death. Dont perform operations you learn about here

Revisions to robust table

In the illustration on p. 71

of Robust Kitchen Table

(FWW#241), the bit

diameter should be 12in.,

not 112in. Also, on the

same page, the slot in the

template for the stretcher

mortise should be 314in.

long to yield a flat that is

234in. long.

The corrected drawing

is shown here.

Guide

bushing,1 in. dia.

Straight

router bit,12in. dia.

314in.

234in.

Two rust fighters.VCIs (left) emit molecules

that settle on metal surfaces and form a protec-

tive barrier against moisture. Desiccants (right)

remove moisture from the air. VCIs have a shelf

life and need to be replaced periodically while

some desiccants can be recharged and reused.

About your safety

F I N E W O O D W O R K I N G12

-

7/24/2019 Fine Woodworking - 243Nov-Dec2014

13/92

To order call: 800-321-9841or visit: woodworker.com/honemate-fa

FREE SHIPPING (Within the contiguous 48 states.)

FWA-420 Standard Honemate $26.79FWA-889 Diamond Honemate $50.99

HONE-MATE

KEEP YOUR JOINTER& PLANER KNIVES SHARPWITHOUT REMOVINGTHEM FROM THEMACHINE!

Includes 180 & 400 grit hones. Positive indexing system

maintains proper angle sohones do not bind on knife.

by Leighy eighRouter Table Dovetail Jig

Through Dovetails Half-Blind Dovetails Box Joints

by eigh

leighjigs.com 800-663-8932The new Leigh RTJ400 Quick Easy Precise

Fine Woodworking Classes

with Lonnie Bird

www.lonniebird.com

N O V E M B E R / D E C E M B E R 2 0 1 4www.f inewoodwor k ing. co m

-

7/24/2019 Fine Woodworking - 243Nov-Dec2014

14/92

methods of work ED ITED AND DRAWN BY J IM R ICHEY

I used to use a framing square against theblade to set my tablesaws miter gauge

to 90, but I found this method awkward

because you have to rotate the blade or

raise its height to make sure the square isnt

touching the teeth. This jig makes it easier.

Rip a snug-fitting runner for the right-side

miter-gauge slot and attach it to a piece

of 12-in. MDF that extends past the blade.

Push the MDF through the saw to cut off

the excess, and you have a perfect reference

surface for setting the miter gauge. Now I

use a large plastic drafting triangle, which

is easier, lighter, and more accurate than aframing square.

You can use the same jig to adjust the

rip fence parallel to the blade. Flip the jig

around, bring the rip fence up against it, and

adjust the fence until it is flush with the edge

of the jig.

LARRY SCHALLER, Edger ton, Wis.

Easy jig forsquaring tablesawmiter gauge

Larry Schaller has

been a woodworker

for 40 years. Self-

taught, he loves

making furniture

for his family,

including cradles for

his grandchildren.

His favorite tool

in the shop? Histablesawa gift from

his wife.

BestTip

Send your original tips to [email protected] or to Methods of Work,Fine Woodworking, PO Box 5506,Newtown, CT 06470. We pay $100for a published tip with illustration;$50 for one without. The prize forthis issues best tip was a 48-toothForrest Woodworker II sawblade.

Rotate jig so

reference edge is

on right.

Runner snug

in slot.

Use refere

edge to sq

miter gaug

with triang

Cut off one side to

create reference edge.

Plastic draftingtriangle

12-in. MDF,attached torunner

Align fence

with edge of jig.

1. CREATE ALIGNMENT JIG

2. ALIGN MITER GAUGE

3. ALIGN RIP FENCE

A Reward for the Best Tip

F I N E W O O D W O R K I N G14

-

7/24/2019 Fine Woodworking - 243Nov-Dec2014

15/92

3 GREAT SHOWROOMS!

BELLINGHAM, WAMUNCY, PASPRINGFIELD, MO

TECHNICAL SERVICE: 570-546-9663 FAX: 800-438-5901

16662

14FINE

VIEW VIDEOS AT

grizzly.com FOLLOWUS:

OVER A MILLION SQUARE FEET PACKED TO THE RAFTERS WITH MACHINERY & TO

2 OVERSEAS QUALITY CONTROL OFFICES STAFFED WITH QUALIFIED GRIZZLY ENG

HUGE PARTS FACILITY WITH OVER 1 MILLION PARTS IN STOCK AT ALL TIMES

TRAINED SERVICE TECHNICIANS AT ALL 3 LOCATIONS MOST ORDERS SHIP TH

PURVEYORS OF FINE MACHINERY, SINCE 198

CHRISTMAS SALE

PLEASE GO TO

GRIZZLY.COM

TO SEE ALL SALE PRICES

November 1st -

December 31st

Motor: 3 HP, 220V, single-phase, 12.8A

Blade tilt: Left Table height from floor: 34"

Table size with extension: 27" x 7434"

Arbor speed: 4300 RPM Arbor size: 58"

Maximum dado width: 1316"

Maximum depth of cut @ 90: 318"

Maximum depth of cut @ 45: 2316"

Maximum rip capacity: 50"

Distance from

front of table

to center of

blade: 1714"

Overall dimensions:

40" H x 41" W x 82" L

Approximate

shipping weight: 557 lbs.

G0691$159500ONLY$152500G1023RLW$136000SALE$132500

G1066R$169500SALE$165000

G0555LANV $54500

SALE$44500 G0513ANV $89500 SALE$82500

10" LEFT-TILTINGTABLE SAWWITH CAST IRON ROUTER TABLE

10" CABINET TABLE SAWWITH RIVING KNIFE & EXTENSION RAILS

Motor: 3 HP, 240V, single-phase

Cutting capacity: 8" left, 2558" right of blade Maximum depth of cut @ 90: 3"

Maximum depth of cut @ 45: 218"

Assembled table size: 48" W x 27" D

Base dimension: 2012" x 2012"

Precision-ground and

heat-treated

solid cast iron table

T-slot miter gauge

Dust port: 4"

Magnetic safety switch

One-piece steel cabinet

type stand

Poly-V serpentine drive belt

CSA certified

All sealed ball bearing construction

Approximate shipping weight: 550 lbs.

Motor: 5 HP, 220V, single-phase

drum motor drives 2 aluminum sanding drums

Surface speed of drum: 2300 FPM

Handles stock up to 2312" wide and 414" thick

14HP conveyor motor provides 11 FPM feed rate

Sandpaper installs easily onto the drums

All steel and ball bearing construction

Sandpaper size: 6" x 9512"

Two 4" dust ports for easy

hook-up to a collection system

State-of-the-art, computer

balanced drums

Powder-coated finish

Approximate shipping

weight: 442 lbs.

24" DRUM SANDER

Motor: 2 HP, 110V/220V,

single-phase, TEFC

Precision-ground cast

iron table size: 17" sq.

Table tilt: 45 R, 10 L

Cutting capacity/throat: 1614"

Max. cutting height: 1218"

Blade size: 13112" L (18"1" W)

Blade speeds: 1700 & 3500 FPM

Quick release blade tension lever

Approx. shipping weight: 342 lbs.

INCLUDES DELUXE EXTRUDED

ALUMINUM FENCE, MITER GAUGE,

and 12" BLADE

30THANNIVERSARY SPECIAL

EDITION 17" BANDSAW

ULTIMATE 14" BANDSAW

252923

Motor: 1 HP, 110V/220V,

single-phase, TEFC

Precision-ground cast

iron table size: 14" sq.

Table tilt: 45 R, 15 L

Cutting capacity/throat: 1312"

Max. cutting height: 6"

Deluxe extruded aluminum fence

Blade size: 9212"9312" L (18"34" W)

Blade speeds: 1500 & 3200 FPM

Approx. shipping weight: 196 lbs.

MADE IN TAIWAN

MADE IN TAIWAN

G0555P $54500ONLY$52500

MADE IN TAIWAN

30THANNIVERSARY SPECIAL EDITION

14" DELUXE BANDSAW

177335

Motor: 1 HP, 110V/220V,

single-phase, TEFC

Precision-ground cast

iron table size: 14" sq.

Table tilt: 45 R, 10 L

Cutting capacity/throat: 1312"

Max. cutting height: 6"

Blade size: 9212"9312" L (18"34" W)

Blade speeds: 1800 & 3100 FPM

Approx. shipping weight: 247 lbs.

CAST

IRON

WHEELS

G1030Z2P $43995 ONLY$42500

Motor: 3HP, 240V, single-phase, 3450 RPM, 12A

Air suction capacity: 2300 CFM

Static pressure: 16.7"

7" inlet has removable "Y" fitting

with three 4" openings

Impeller: 1234" cast aluminum

Bag capacity: 11.4 cubic feet

Standard bag filtration:

2.5 micron

Portable base size:

2112" x 4912"

Bag size (dia. x depth):

1912" x 33" (2)

Lower bags: Plastic

Powder-coated finish

Height with bags

inflated: 78"

Approximate shipping

weight: 170 lbs.

3 HP DUST COLLECTOR

Motor: 2 HP, 240V, single-phase,

10.8A, 3450 RPM

Precision-ground cast iron table

measures 1418" x 10" x 716"

Max. planing width: 7"

Max. planing height: 712"

Cuts per minute: 14,000

2 HSS knives

Approx. shipping

weight: 324 lbs.

PLANER/MOULDER WITH STAND

DRUMS ARE

NON-RUBBERIZED!

W1812 $165000ONLY$152000

247570

112HP CYCLONE

DUST COLLECTO

2 HP

MOTOR!

G0703P $82500 ONLY$79500

$79$79shipping

lower48states

$79$79shipping

lower48states

$150$150shipping

lower48states

$150$150shipping

lower48states

$99$99shipping

lower48states

$99$99shipping

lower48 states

MADE IN TAIWAN MADE I

177335

177335

WOOD

MAGAZIN

E

WOO

DMAGAZIN

E

APPR O VE

DAPPR O VED

232857

MADE IN TAIWAN

MADE IN TAIWAN

Motor: 112HP, 110V/220V,

single-phase, TEFC, 3450 RPM

Air suction capacity: 775 CFM

Static pressure at rated

CFM: 1.80"

Intake port : 6" with included

5" optional port

Impeller: 1312"

Height: 6512"

Built-in remote

control switch

Approx. shipping

weight: 210 lbs.

FULLY MOBILE WITH BUILT-INCASTERS

MADE IN TAIWAN

ONLY651/2"TALL!

-

7/24/2019 Fine Woodworking - 243Nov-Dec2014

16/92

methods of work continued

Rubber-band brush wiper

When applying finish from a can, most of us

dip the brush into the finish and then wipe

off the excess on the edge of the can. This

invariably leaves some finish in the rim. Not

only does this waste finish, but the finish

also hardens in the rim and prevents the lid

from getting a good seal, which

speeds up the deterioration of

the remaining finish.

Heres a better way. Stretch a

hefty rubber band around the

open can so that it is taut and

centered over the opening.

Now you can wipe the

brush on the rubber band,

and the surplus finish

will drip back into the

can, keeping the rim

clean.ELISA DE CHECA,

Barcelona, Spain

Extra finish

falls back into

can, not into

the rim.

Stretch rubber

band over mouth

of can.

Magnetic vise-jaw pads prevent bite marksI use a cast-iron machinists vise for a lot of woodworking pro

To keep the steel jaws from damaging my workpiece, I alway

a couple of pieces of scrapwood between the jaws. But I ofte

fumbled to keep them in place while I secured the work.

To solve the problem, I cut two pieces of plywood, drilled tw

shallow 12-in. holes into each one, and glued in rare-earth ma

Now the protective pads are held securely in place on the jaw

while Im working with wood, and can be quickly removed w

Im working with metal.

BILL WELL S, Olympia

Rare-earth

magnets hold

pads in place.

Plywood pad keeps m

jaws from damaging

woodworking.

Black walnut

makes it hard to

see pencil l ines.

White

address label

Address labels highlight layout marks on dark woods

Precise and clear layout lines are essential for crisp joinery. But layout

lines are notoriously hard to see on walnut and other dark woods. To

help, I attach an address label to the wood and lay out the joinery on

that. The white label gives me a nice contrasting background to lay

out my joinery, making it easy to read later on.

Address labels are cheap, come in a variety of sizes, dont leave a

residue on the wood, and can be found at any office-supply store.JACQUES BREAU, Ot tawa, Ont . , Canada

F I N E W O O D W O R K I N G16

-

7/24/2019 Fine Woodworking - 243Nov-Dec2014

17/92

Engrave stunning photos, text and graphics with a touch of a button.

888.437.4564 [email protected] epiloglaser.com/fww

Cabinet In lays Customize ProductsCustom Birdhouse

Epilog Laser systems

make it easy to take your

woodworking shop to

the next level by offering

custom laser engraving

and cutting services.

1.877.943.9663insidepassage.ca

If I were starting my life today asa craftsman, and needed to learn

what matters the most; my choicewould be Inside Passage School.

James Krenov1-800-327-2

www.lie-nielsen.Tapered Carcass Saw

Made in M

Only the 19-38 has these

Exceponal SuperMax Features!

Indexed alignment seng

Easy height adjustments

Extra-wide conveyorDrum will never gooutofalignment

Morespace foreasyaccess to abrasive wrap

19-38 Drum Sander

TheOnlyAwardWinningDrumSander!

T S

U

S

Only $1399 incl. open stand!Check with your local dealer

or order direct.

SANDING CAPACITY

Sand 19 in a single pass, 38 in a double pass

Sand as thin as 1/32, as thick as 4,as short as 2-1/4

Variable Speed Conveyor 0-10 FPM

Drive Motor TEFC 1-3/4 HP

Power Requirements 110V 20 amp

N O V E M B E R / D E C E M B E R 2 0 1 4www.f inewoodwor k ing. com

-

7/24/2019 Fine Woodworking - 243Nov-Dec2014

18/92

tools & materials

Big table.With 40 in. of cast iron, the saws

table is wide enough to support just about

every cut a furniture maker normally makes.

No-hassle throat plate.Held in place by

magnets, the insert pulls up easily. And its 12in.

thick, so making shopmade inserts is no problem.

Quick-change riving knife.Accessing t

mounting hardware is easy, and its a sna

switch to the guard assembly.

locks securely, and has an easy-to-read cursor. Dust collec

was exemplary for a small contractors saw, with a dust po

centered in the bottom of the enclosed cabinet.

There also are a bunch of convenient features such as st

for the T-square rip fence and blade wrenches on the bas

paddle switch that can be located anywhere along the rip

rail, a built-in mobile base, and an easy-to-remove throat pWith its robust construction and smartly designed featur

this saw is a great value.

Roland Johnson is a contributing

Stout

contractors

saw with smart

features

Tablesaw by Rikon

10-201

$1,000

M A C H I N E S

THERE IS A LOT TO LIKEaboutRikons left-tilt contractors

tablesaw. It has a big cast-

iron table, a powerful

motor, stout trunnions, a smooth

belt-drive system, and a well-

designed riving knife.

The three-piece tabletop is 27 in. deep by 40 in.

wide with a rigid understructure thats easy to adjust if you need

to level the top (the saw I tested did not need to be adjusted

after assembly). Under the table is a beefy arbor assembly and

trunnions. A short flat-belt drive, much like youd find in a

cabinet saw, provides smooth, accurate power transfer from the

112-hp motor to the arbor. The motor has ample power, lettingme rip a bunch of thick hardwood with a fairly brisk feed rate.

The riving-knife mount is easy to access and switching from

the knife to the guard is painless. The T-fence moves easily,

F I N E W O O D W O R K I N G18 Photos, this page: Roland

-

7/24/2019 Fine Woodworking - 243Nov-Dec2014

19/92

For building cabinets and finefurniture, nothing beats Forrestsaw blades.

Craftsmen appreciate the way ourblades deliver smooth, quiet cutswithout splintering, scratching, ortearouts. They know our uniquegrade C-4 micrograin carbide,proprietary manufacturing process,

and hand straightening produceexceptional results. In fact,independent tests rate us #1 forrip cuts and crosscuts.

From the first cut on, I realizedthat this blade was a bargain at

any price! Nothing else I havecuts comparably.Calvin Brodie, Spanaway, WA

Forrest Quality ShowsWoodworker IIBest rated,all-purpose blade for rips andcrosscuts.

Chop MasterPerfect for tight,perfectly cut miter joints withoutsplinters.

Order from any Forrest dealer orretailer, online, or by calling directlyOur blades are manufactured in theU.S.A. and backed by our 30-day,money-back guarantee.

www.ForrestBlades.com1-800-733-7111(In NJ, call 973-473-5236)

Woodworker IIFine Woodworking

Chop MasterWoodshop News

Duraline Hi-ATWoodshop News

Dado KingWOOD Magaz

Quality VAKuum Products, Inc.74 Apsley St. Hudson, MA 01749Phone (978) 562-4680 E-mail [email protected]

Instructional

800 547-5484

2 Hour

DVD

Bags : Polyurethane and Vinyl

Frame Presses

Veneering Accessories

Veneering Glue

FREEww

w uai

tyvak.co

m

q l

VAKuum Press ing EquipmentVacuum Pumps : Air-Powered and Electric

.

Furniture Design

Woodworking

Woodturning

Summer Workshops

Residencies

Visiting Artists Program

andersonranch.org 970 .923 .318 1 Snowmass Village, CO

AndersonRanch arts center

N O V E M B E R / D E C E M B E R 2 0 1 4www.fi newoodwor k ing. com

-

7/24/2019 Fine Woodworking - 243Nov-Dec2014

20/92

tools & materialscontinuedontinue

other units we

tested. Convenientfeatures include a cord wrap, onboard storage for optiona

tools, and an effective hose wrap. The unit comes with a

114-in. inside-diameter hose but will also accept 212-in. an112-in. hoses.

Bill Peck is FWWs shop ma

THE NEW BOSCH VACUUMis a compact,

efficient unit with airflow as good as the

top-rated Bosch Airsweep from our most

recent review (Shop Vacuums,FWW#223).We repeated the test used in the review, adding the optional

HEPA filter ($106) and seasoning it before testing.

The Auto Filter Clean feature activates automatically every15 seconds and was very effective at keeping the airflow

through the seasoned filter to about 70 cfm. This feature can be

deactivated if the thumping noise bothers you, but dont leaveit off too long.

In Power Tool Activation mode, the vacuum runs for

7 seconds to clear the dust from the hose after the tool is

turned off. The power draw was only 9.5 amps, leavingalmost 5.5 amps for the onboard tool outlet, more than other

units we have tested. A power broker feature allows you to

dial back the vacuum power to 7.5 amps for use with a largertool or if you dont want to suck a sander down too tight.

The vacuum is quiet, too (77 db.), comparing favorably with

VERITAS IS NOW

SELLING TWO

large tenon saws

(16-in. blades),a 12-tpi crosscut

saw and a 9-tpi ripsaw. To test them, I used both to cut joints

for a chest of drawers from white oak and yellow pine.With both saws, the height of the saw plate helped me keep

cuts plumb. The teeth have minimal set, which is a benefit

when sawing accurately to a line, a crucial component ofjoinery work. I also successfully used the crosscut saw for

general bench tasks such as cutting off excess stock length and

H A N D T O O L S

Tenon saws are a great value

mitering with my shopmade miter box.

Both saws, especially the crosscut, benefit from a light toFortunately, the saws made quick progress through the wo

with minimal downward pressure. Overall, I was pleased

their performance. They are a great value.

Zach Dillinger, a furniture maker in Charlotte,

works exclusively with hand

A C C E S S O R I E S

Self-cleaning vacuumis quiet and efficient

Tenon saws by V

$119 for c

$119

Shop vacuum by

VA

F I N E W O O D W O R K I N G20 Photos, this page and p

-

7/24/2019 Fine Woodworking - 243Nov-Dec2014

21/92

Call for FREE Buyers Guide!TOLL FREE

888-213-0394DRleafvac.com

85019X2

014

LOWEST PRICEEVER on DRLeafVacuums!

Rated #1 in Vacuum PowerEasy, 1-Hand Dumping

Stores Flat in Minutes

Converts to a Utility Trailer

8

2

Now Starting at$1,29999

PLUS

FREESHIPPING!

NEW MODELS!The NEW DRLeaf

Vacuumis designedfrom the top down tomake yard clean upeasier, faster, andmore thorough thanever before. And fora limited time youcan TRY ONE FOR1 YEAR ON YOUR OWN PROPERTY!

FREE VIDEO AND

DRAWINGS TO DOWNLOAD

www.feldergroupusa.com

HOW TO ...

FELDER-GROUP USA

Toll free: 866 792 5288

E-mail: [email protected]

MAKE THISAMAZINGCHAIR?

If you are in awoodworking

businessthis could be the

most valuable tool inyour officesm.

Contact us toreceive your

FREE720 page

Big Book ofWoodworking2014 catalog

Visit pro.woodworker.comor Call 800-321-9841

(Mention code fww14)

18745 Sheldon Rd Middleburg Hts., OH 44130 [email protected]

To order go to our website at www.bereahardwoods.com or call 1.877.736.5487o order go to our website at www bereahardwoods com or call 1 877 736 5487

Berea Hardwoods, Co. Inc.

BereaHardwoods, Co. Inc.S I N C E 1 9 8 0

TM

Duck Call Kits Easy to make Allows you to create realistic duck sounds

These ads work as hard

as the woodworkers

that read them.

wAdvertise Here!

Call 800-309-8954

N O V E M B E R / D E C E M B E R 2 0 1 4ww w.fi newoodwor k ing. co m

-

7/24/2019 Fine Woodworking - 243Nov-Dec2014

22/92

Match the centers.With the

workpiece flat on the table, set

bits height by aligning the cente

on the jig and workpiece.

Magnets hold fast.Theyre strong

enough to keep the jig on the bit, but

not so strong that you cant adjust it

perfectly.

I HAVE USED LOCK-MITER ROUTER BITSfor years. But setting up the

cuts for this exacting joint requires precision. The workpieces mu

perfectly flat and have perfect edges, and the router table must hvery good hold-downs and perfect infeed and outfeed faces. Fin

the bits height and protrusion from the fence must be exact, and

dialing it in requires a lot of trial and error, which eats up test piecesInfinitys Lock Miter Master Jig greatly simplifies the setup job. The jig, w

attaches to the bit with magnets, has engraved lines that help align the centerli

the bit with the workpieces centerline for both horizontal and vertical cuts (a vid

on infinitytools.com shows clearly how to do this). You still need test cuts to diathe setup to perfection, but Infinitys jig gets you closer from the start.

The jig comes in two sizes. The smaller one (LMM-002) works with stock betw38in. and 34in. thick, while the larger jig (LMM-003) is for stock 58in. to 1316in.

Peter Breu is a woodworker in Mancheste

tools & materialscontinued A C C E S S O R I E S

Simple setup jigs forlock-miter joints

Lock-miter jigs by Infinity

$30 each

Our experts, your topicsTune in to our Shop Talk Live podcasts to hearour editors interview experts and answerreader questions.

ShopTalkLive.com

2014 The Taunto

F I N E W O O D W O R K I N G22

-

7/24/2019 Fine Woodworking - 243Nov-Dec2014

23/92

See what the publisher ofFine Woodworking has in store

Books, ebooks, magazines, special issues, DVDs, and more

2014 The Taunton Press

POCKET HOLEJOINERY

MARK EDMUNDSON

BookshelfDay bedMirror/picture frameDresserBathroom vanity...AND MORE!

POCKET HOLE JOINERY

Paperback, Product #071463, $24.95A Taunton Press Title

FINE WOODWORKING

CHESTS AND CABINETSPaperback, Product #071502, $21.95

A Taunton Press Title

W ChestsandCabinets

Editors of

Fine Woodworking

BEAUTIFULBOXESDESIGN andTECHNIQUE

Doug Stowe

BEAUTIFUL BOXES

Paperback, Product #071472, $A Taunton Press Title

You can also purchase our products from these pr

www.TauntonStore.com/shopfw

Order by Product number. Phone orders: 800-888-8286 or

203-702-2204 international. Call Monday-Friday 9AM - 9PM ET,

Saturday 9AM - 5PM ET. Use code M1800155.

Shop online anytime

WEEKEND

WOODTURNING PROJECTSPaperback, Product #071515, $24.95

A Taunton Press Title

TURNING PENS

AND PENCILSPaperback, Product #GM0074, $19.95

A Guild of Master Craftsman Title

TAUNTONS COMPLEILLUSTRATED GUIDETO TURNINGPaperback, Product #071499, $

A Taunton Press Title

Sharpening and Using Tools

Basicto AdvancedTechniques

Spindleand FaceplateWork

TurningBowlsand Boxes

Turning Hollow Vessels

RICHARD RAFFAN

Turning

Tauntons COMPLETE ILLUSTRATED Guide to

WEEKENDWOODTURNING

PROJECTS25 SIMPLE PROJECTS FOR THE HOME

MARK BAKER

N O V E M B E R / D E C E M B E R 2 0 1 4

-

7/24/2019 Fine Woodworking - 243Nov-Dec2014

24/92

Applied molding

have a long his

in furniture ma

and for good r

A molding can

the aesthetic cr

that tops a piece of furnitu

Moldings create a play betw

light and shadow, adding v

interest. They also can serv

a visual grounding, or prov

sense of termination.

Head over to your local

home center and youll fin

a big selection of molding

but those are all sized for

architectural work. To get

moldings proportioned fo

furniture, you need to ma

them. Perhaps the most

common approach is to

rout them, but then yourestuck using the profiles an

proportions of the bits.

A better solution is to fo

the router altogether and

moldings with hand tools.

not as hard as you might t

With a few planes, you

can easily cre

gra

and beautiful custom prof

for your furniture that wou

be difficult or impossible

router bits. And there is no

size limit, which allows yo

to dial in the proportions

to complement the piece

furniture perfectly.

For a piece of furniture,

you probably wont need

more than several feet of

molding. Ive been making

moldings this way for mo

my career. Here, Ill show

how I do it.

handwork

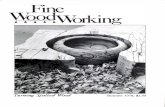

ELLIPSE OGEE AND A HALF-ROUND

34in.

118in.

COVE AND BEAD

1516in.

516in.

2316in.

12in.

316in.

158in.

14in.

2316in.

716in.

58in.

316in.

Make custom moldingsWITH JUST A FEW PLANES,

YOU CAN CREATE BEAUTIFUL PROFILESNOT FOUND IN THE ROUTER-BIT RACK

B Y G A R R E T T

H A C K

F I N E W O O D W O R K I N G24 Photos: Matt Kenney; drawings: John

-

7/24/2019 Fine Woodworking - 243Nov-Dec2014

25/92

Check th

profile.

To ensure

consisten

Hack relie

template

from a th

piece of w

Lay out the profile.Hack does this on themolding blanks leading edge, so he can

gauge his progress as he removes waste at

the tablesaw.

Power up.Angle the tablesaw blade to

remove as much waste as possible in a

single pass.

Plane away the facets.Start with thick shavings along the grain, and finish up with light shavin

which create smaller facets, resulting in a smoother curve.

A block plane works great on convex

curves. Its the only tool you need to

transform the common quarter-round

into a graceful quarter-ellipse.

Elegant ellipsewith everyday tools

A block plane works great on convex

curves Its the only tool you need to

Use hand tools where it counts

The majority (if not all) of

the moldings youll make will

require you to remove a fair

amount of waste material before

you get to the task of shaping

the profile. You could do that byhand, with a shoulder or rabbet

plane, but I dont recommend it.

Instead, use your tablesaw. This

will let you get to the important

jobcreating the graceful lines

of the moldingmuch faster.

Begin with a blank wider

than the molding (youll cut

N O V E M B E R / D E C E M B E R 2 0 1 4

-

7/24/2019 Fine Woodworking - 243Nov-Dec2014

26/92

Refine the cove with a round plane.Match the planes radius to the coves as closely as you can. If the

radius changes across the profile, switch out planes accordingly.

More cuts remo

more waste.Spe

up the work by ta

several cuts with

tablesaw. To keep

the molding stab

throughout the pr

remove the large

of waste on the b

last.

handworkcontinued

Begin the bead with a block plane.Roughing

out the outside edge this way greatly speeds up

the process of cutting the bead. Hack works to

a layout line to rough in the bead.

Complete it with a scratch stock.This is the

most accurate way to form a small bead. The

cove needs to end in a narrow flat, as wide as

the cutter.

Clean up with a scraper.To remove any

ridges or tracks left by the round plane, u

a gooseneck (shown). Rotate and angle t

scraper to match the coves curve.

Cove and beadare a refined pairAll it takes is a scratch stock

to give the common cove a bit

of panache. Size the bead to

complement the coves proportions.

the molding free after its

made). After the tablesaw

has eaten the waste, its time

for the handplanes to turn

the roughed-out shape into a

beautiful molding. The easiest

profiles to handle are fillets

and convex curves. Fillets are

really just rabbets, and you

can clean them up with a

rabbet or shoulder plane. Theright tool for convex curves

is a block plane. (I rarely

use hollow planes. Theyre

troublesome to sharpen and

set up.) Use a coarse setting

to quickly remove material

and get close to the final

profile, and then switch to

a fine cut, which leaves a

smaller facet, making it easier

to get a smooth curve from a

tool that cuts flat surfaces.

Concave curves are nomore difficult than convex

ones, except that you need

All it takes is a scratch stock

to give the common cove a bit

of panache Size the bead to

complement the coves proportions

F I N E W O O D W O R K I N G26

-

7/24/2019 Fine Woodworking - 243Nov-Dec2014

27/92

This limited-time holiday offermakes it easy to give a year-longgift of Fine Woodworking:

Give a gift subscription forjust $25.00

Thats $9.95 offthe regular price ofevery one-year (7-issue) print subscription

Tablet editions are included FREE*

Give as many gifts as you like at this lowprice but dont wait order today!

Tablet editions are included

ive as many gifts as you like at this low

Give the gift of

Fine Woodworking just $25.0Save $9.95 with our once-a-year holiday offer!

Givetheperfectgiftandsave!

FRtablet e

inclu

Gift giving is easyuse the attached card to order today,or call toll-free 888-351-3610.

*Tablet editions available with paid subscription.

Above price for U.S. only. Payable in U.S. funds. Canadian customers, please call toll-free 888-351-3610.

International customers, please call 203-702-1901 (M-F 9 am to 9 pm ET, Sat 9 am -5 pm ET). Offer expires 12/31/14.

-

7/24/2019 Fine Woodworking - 243Nov-Dec2014

28/92

Clean fillet.A rabbet plane removes machining marks left by the tablesaw b

and creates a crisp line where the fillet transitions to the ogee.

Prop up the molding.Resting the molding on a piece of scrap brings the cove section

of the ogee closer to vertical, making it easier to plane.

handworkcontinued

Back to the block plane.Fair the convex

curve, and create a smooth transition into the

concave section.

Make the half-round on a separate piece.

This allows you to create the entire curve with a

block plane, rather then needing a specialized

plane or a very large scratch stock.

Glue on the half-round.Yellow glue and

clamps are all you need. Hack glues the

together on a piece of plywood, making it

to keep the two parts flat and properly a

Beauty built from anogee and a half-round

a specialty plane to create

them efficiently. Ideally, youd

use a round plane with a

radius that closely matches

the moldings profile, but it

doesnt have to be perfect.

Get as close as you can, and

then use a gooseneck scraper

to get the rest of the way. Thetrick with the scraper is to

find the section that matches

the profile most closely, and

then rotate it on its vertical

axis until the scrapers edge is

a perfect match. Or, if youre

up for it, file a scraper to

match the molding.

Finally, hand-sand the

molding to remove any facets

or bumps that are left.

Garrett Hack, a longtimecontributing editor, is a professional

furniture maker in Vermont.

Step away from the standard ogee by

varying the curves radius, and create

greater depth by adding a half-round

at the bottom.

F I N E W O O D W O R K I N G28

-

7/24/2019 Fine Woodworking - 243Nov-Dec2014

29/92

The heaviest. The most powerful. The only saw with an active safety system and 99% dust collection.

Is it any wonder it has been the number one saw for a decade? Discover the pride of ownership.

Visit SawStop.com/10

Buy a new SawStop Industrial Cabinet Saw and receive a FREE Standard Brake Cartridge and

TWO FREE SawStop Titanium Blades! Visit Sawstop.com/10 for details.

$200+in FREE EssentialsOct 1 - Dec 31, 2014

FIRST IN SO MANY THINGS

THAT MATTER.

AM

ER

ICA

S # 1 CA BIN

ET

SAW

2004 TO 2 0

14

10YEARS

-

7/24/2019 Fine Woodworking - 243Nov-Dec2014

30/92

Build a Greene and Greene

Blanket Chest

Its all about the details.

Our expert showshow to get them right

B Y D A R R E L L P E A R T

Ive long been drawn to the work of the brothers Henry Mather Green

Charles Sumner Greene, the early 20th-century architects who de

and furnished some of the countrys most important Arts and Craft

galows. Their furniture stands apart for its elegant fusion of Japanese-in

detail with solid, practical Craftsman design.The brothers designed blanket chests for two California homesth

House in Ojai and the Thorsen House in Berkeley. When I designed my

I used details from each of these two pieces, including the proud, p

finger joints and the lid with raised breadboard ends, along with one

a smaller piece by the Greenesthe Ford House letter case. On that

two leather straps wrap the bottom so it wont scratch the table it sits

thought a similar detail, rendered in wood, could lend visual weight

chests base. Taken together, these details make for a fun and beautiful p

F I N E W O O D W O R K I N G30 Photos: Steve Scott; drawings: Christop

-

7/24/2019 Fine Woodworking - 243Nov-Dec2014

31/92

Edge-glue the s

To assemble eac

template, clamp

straight cauls to

glue-up surface

right angle to cre

a square referen

corner (above). S

blocks help ensuthe finger socke

uniformly deep. A

clamping pressu

top of the glue-u

so the surfaces

flush for smooth

travel.

Router jigs nail the finger jointsMAKE TWO

TEMPLATES

Peart glues up a pair

of router templates,

one for each half

of the finger joint,

from plywood strips.

To ensure a precise

friction fit, he carefully

mills the strips for the

finger sockets slightly

wider than those for

the fingers. Each

template captures the

workpiece between

a pair of registration

blocks that are

screwed in place and

provide a platform for

toggle clamps.

1 in.

Fence

Use spacer

blocks to

align strips.Use clamps to

hold workpiece

for routing.

512in.

1516in.

1516in.

11964in.

11964in.

FOR CASE

FRONT ANDBACK

FOR CASE

SIDES

-

7/24/2019 Fine Woodworking - 243Nov-Dec2014

32/92

The case comes together with finger joints

To create the large finger joints on the case, make apair of routing templates by edge-gluing strips of 34-in.

Baltic-birch plywood or MDF. For a snug fit, cut the

strips for the template fingers about 164in. narrowerthan the strips for the gaps.

After the glue dries, the templates may need flat-

tening with coarse-grit sandpaper. I use a wide-beltsander here, but a belt sander would also work. Then

attach the registration blocks and toggle clamps that

lock in the workpiece. Be sure to cut some test jointsbefore using the templates on your project.

To start the joinery, mark the finger locations on the

blanks and jigsaw away the bulk of the waste between

them. Clamp each blank to the template and rout, usinga 14-in.-dia. spiral flush-trimming bit with a bottom bear-

ing. This leaves the inside corners on each finger with

a 18-in. radius. To create a matching 18-in. roundoveron the mating fingers, remove the workpiece from the

template and rout the finger edges with a miniature

bearing, 18-in.-radius roundover bit (Amana MR0112).The joints should close on dry-fit with medium clamp-

ing pressure. If not, carefully clean up the inside corners

with a rat-tail file.The finger joints are reinforced with screws hidden

by square ebony plugs. To cut the square holes, I use a

hollow punch from Lee Valley. To help align the holes,

I clamp a straightedge to the workpiece. After layingout the peg locations, register the punch against the

straightedge and strike it with a steel hammer to set it

in place. Then use a twist bit inside the punch and drillabout 38in. deep. Remove the bit and punch the tool to

the depth of the drilled hole. You can re-insert the bit

to remove debris, but don't make the hole any deeper.Now sand the case parts to P220-grit. I bring the case

together in stages, first assembling the two opposing

Punch the p

holes.To cre

the square

mortises for

decorative e

plugs, Peart

a hollow pun

which he alig

with a clamp

straightedge

seating the p

with a single

drill through

the desired d

Afterward, st

the punch ag

to drive it to

full depth of

mortise.

Cut the joints

Soften the edges.Peart uses

bearing-guided roundover bit tthe edges on each finger.

Rout the fingers.After removing the bulk of the

waste with a jigsaw, clamp the workpiece into the

template jig and use a 14-in.-dia. flush-trimming bit

to complete the finger pattern on the end of each

piece.

F

trb

18-in.

radiusroundover

bit

Templa

Workpiece

F I N E W O O D W O R K I N G32

-

7/24/2019 Fine Woodworking - 243Nov-Dec2014

33/92

corners with corner clamps and then bringing the halves

together. Because Ill be screwing these joints, I dont

fully glue them. I put just a dab of glue on the inside

of each finger where it will meet end grain in the gap.

Pre-drill into the fingers for a #6 by 114-in. panheadscrew. Make sure the screw head is smaller than the516-in.-dia. plug hole. Do not run screws into the top

and bottom finger of the front and back panelsthese

fingers tend to split. Check for square, but dont fret

if its a bit out. Final squaring will be done when the

bottom is attached.

The base fingers are tablesawnThe chest sits on a decorative base. The corners of

the base are also finger-jointed, and these larger joints

are quick and easy to make using a dado set. I make

the cuts with the workpiece clamped vertically in a

crosscut sled and registered against a stop block. Iposition the stop block to let me complete the joint

with a pair of mirrored cuts, flipping the workpiece

between them. This approach works well only if allthe pieces are exactly the same width, so take care

when milling, and test the setup on scrap.

Start by cutting the centered notch on the ends of the

long sides. I do each one in two passes, flipping the

board and leaving the stop block at the same setting.

To cut the mating finger on the ends of the short sides,leave the dado sets height unchanged and reposition

the stop block. Use the cut notch as a reference. It may

take multiple adjustments to position the stop precisely.

The joint should fit snugly with minimal friction.

Assemble and attach the baseCut peg holes in the base pieces, and round the fingers

with a 18-in. radius roundover bit. To visually suggest

that the base fingers bear the chests weight, I pillow

their shape slightly by sanding with a folded pieceof P80-grit paper. Use a shoe-shine motion until the

roundovers are blended to a gentle arc. Finish-sand

One corner at a time.After finish-sanding the fingers and

applying a dab of glue on each one, Peart secures the joints

with corner clamps, top and bottom (right) . With this done,

he drills a pilot hole in each finger and drives screws to lock

the assembly together.

Build th

base.C

large fin

joints at

tablesaw

a dado s

then ass

the base

the case

Glue and

the oppo

corners,bring the

two halv

together

Add the

bottom,

the bas

With the

upside d

glue and

the bott

to the ca

sides. Th

the base

position

screw it

bottom

the scre

blocks.

Assemble the chest

N O V E M B E R / D E C E M B E R 2 0 1 4www.fi newoodworki ng. com

-

7/24/2019 Fine Woodworking - 243Nov-Dec2014

34/92

#6 by 114-in.pan-head screws

Ebony plugs,516in. by516in.

ARTS AND CRAFTS TREASURE CHEST

Pearts design for this blanket chest incorporates a number of

Greene and Greene details, including the interlocking finger

joinery at the case corners, the offset breadboard ends with

ebony splines, and the faux leather straps that decorate the base.

BASE DETAIL

SIDES

ENDS STRAP

Ebony plug

centered in

width of finger

Ebony plug centered

on width of finger

LID DETAIL

FINGER DETAIL

All pegs centered on thickness of lid panel.

1114in.

Edge trim, 516in. thickby 1516in. wide, with18-in.-dia. roundoveron bottom

Bottom, mahogany plywood,34in. thick by 1734in. wideby 3934in. long, glued and

screwed to caseBase sides, 1 in. thick by3 in. wide by 4314in. long

2212in.4518in.

16316in.

138in.

512in.2116in.

3516in.

1116in.

114in.

1516in.

158in.

114in.

78in.

78in.

218in.

38in.

38in. 3 in.34in.

558in.

11964in.

1516in.

1 in.

No

for

F I N E W O O D W O R K I N G34

-

7/24/2019 Fine Woodworking - 243Nov-Dec2014

35/92

Straps, 1516in. thick

by 2116in. wide by3516in. long

Screw through

blocks to

bottom.

#8 by 3-in. pan-head screws

affix breadboard ends to top.

Ebony

decorativespline

Screw blocks, 34in.thick by 1 in. wideby 5 in. long

Sides, 34in. thickby 1134in. wide by

41 in. long

Ends,

19 in. long

Mitered edging, ends,

1934in. long

Mitered edging, s ides,34in. thick by 1 in.

wide by 4134in. long

Base ends,

2114in. long

Breadboard ends,

1 in. thick by 212in.wide by 2212in. long

Lid panel, 78in. thick by 2218in.

wide by 4018in. long

Splines strengthen

breadboard attachment.

Ebony plugs,14in. by 14in.

Ebony plugs,14in. by 716in.

the base parts to P220-grit, taking the end

to P320-grit.

The base comes together much like the

itself; apply a dab of glue inside each

then clamp. Pre-drill for a screw into the

finger only. Afterward, attach 10 screw

around the inner perimeter, setting them132in. below the top edge.

The bottom of the chest is plywood

solid-wood edging. It is screwed from

to the case, and then the base is screwed

bottom. To do this, start with the asse

case upside down on the bench. Mak

the case is square, then set the bottom in

and add the base, making sure the overh

even all around. Trace the position of the

blocks onto the bottom, and remove the

Secure the bottom temporarily by d

screws through it into two opposing corn

the case. Now predrill for the remaining s

When this is done, back out the first two s

and remove the bottom.

Now run a bead of glue along the bottom

of the case. To reseat the bottom, drive thscrews again until they protrude about

through the panel. With a helper, repositi

bottom using the points of the screws to fin

corresponding holes. Drive the first two

home, then the remaining screws. Now

base back on the bottom, clamp it in plac

attach it with screws through the blocks.

Make the breadboard ends

Mill the lid parts to final size, making sure t

breadboard ends are 18in. thicker than the

and about 38in. longer than the panel is

Use a three-wing slot-cutter to run a groothe splines in the panel and breadboard en

the holes for the square and rectangular

plugs on the outer edge of the breadboar

centering the holes on the thickness of the

not the breadboard end itself. Next, pred

the screws in the center of the holes.

I use multiple splines, leaving gaps be

them for the screws. Make sure the spline

rial is cut so its grain runs in the same dir

as that of the panel. Before assembly, rout

roundovers and sand the panel and bread

ends. The splines are glued to the panel

way across, but are only glued in the centof the breadboard end. Now drive the scr

I rout the mortise for the decorative

spline with a slot-cutter, referencing off th

bottom with the cutter centered on the

Square up the inside corners with a chise

and machine a piece of ebony to fit the

snugly and with enough excess width so

trudes at least 18in. from the mortise. R

Lid-stay torsion hinges

from Rockler (part no.depends on lid weight)

Roundover,316in. dia.

N O V E M B E R / D E C E M B E R 2 0 1 4www.fi newoodworki ng. com

-

7/24/2019 Fine Woodworking - 243Nov-Dec2014

36/92

the back of the spline on the breadboard end side so

the panel can expand and contract without causing the

ebony to bottom out. Glue the ebony in on the panelside only. Trim the spline with a 12-in. spiral straight

bit. Make one pass with a 34-in. bearing, then switch to

a 58-in. bearing and repeat. This will leave the ebony116in. proud. Finally, tape around the ebony to protect

the surface, ease the edges with a chisel, and sand with

P220-, P320-, and P600-grit.

Fasten the straps

The final touch is a series of L-brackets that fit over the

base and resemble leather straps stretched taut. Each

bracket is shaped with a tablesawn cove on the front

face and other curves created by spindle- and hand-

sanding. I start with long mahogany blanks for thecove cut. I set the tablesaw blade about 316in. high and

guide the stock between a shopmade pair of parallel

On go the ends.One clamp provides the pressure to secure both breadboard eavoid problems with wood movement, apply glue along the whole length of the

the lid panel, but only the center few inches of the slot in the breadboard ends.

Multiple splines make room for screws.Peart leaves 12-in. gaps between th

splines to provide clearance for the long screws that will help hold the breadboa

in place.

Slots first.To hold the splines that align the breadboard

ends, Peart routs slots in the end grain of the lid panel and

in the mating edges of the breadboard ends.

BREADBOARD ENDS

Build the lid

More mortises.When the breadboard ends

come out of clamps, rout the mortise for the

ebony splines that visually connect the ends to

the panel. Peart uses a bearing-guided slot-cutter.

Fit the spline.Bandsaw the inner edge of the spline to roughly fit the stepped contour of the

mortise bottom. With the spline pressed into place, pencil a line for bandsawing the outer ed

to shape. Trim the excess, but leave it proud. A spiral bit with an extralarge bearing follows th

irregular surface where the panel meets the breadboard end, trimming the spline uniformly p

SEAT THE DECORATIVE SPLINE

F I N E W O O D W O R K I N G36

-

7/24/2019 Fine Woodworking - 243Nov-Dec2014

37/92

adhesive-back sandpaper over a scrap with a 18-in. radiused

Run the back of the strap over the paper until the transi

smooth. To make sure each strap fits perfectly on the base

another sandpaper trick. On the edge of the case bottom,

the strap will be applied, I stick a narrow strip of P80-grit ad

sandpaper. In the same location, on the face of the base,

a piece of nonadhesive sandpaper, with its back side facin

Run the strap back and forth acro

sandpaper until the paper stops c

The strap can now be glued in p

Darrell Peart makes furniture in Seattle

fences that straddle the blade at 45 (see top left photo, above).

Once the cove is done, crosscut the individual pieces to length.

I cut the L-shape into the back in two steps. First, at the router

table, I define the short leg of the L using a 38-in.-dia. core-box

bit. This creates a 316-in. radius on the inside corner of the L that

will mate snugly with the rounded top edge of the base. Make

sure to back up the cut and take it in several light passes. Next,

mark out for the curves in the sides and

top of the strap, and shape them at the

spindle sander. Cut the long leg of the

L at the bandsaw. To clean up the in-

side corner, stretch a piece of 80-grit

Glue the straps in

place.No screws are

used to secure theL-shaped brackets.

Install the plugs.After sha

and fitting the plugs, dab w

and tap home with a small

headed mallet.

Cut the cove.Using a push pad and push stick for safety, Peart guides the

stock over the blade. Taking incremental cuts, he ends with the blade high

enough to span most of the stocks width, leaving a narrow flat on each edge.

Cut the short leg of the L.The first step

in creating the straps L-shaped back

is removing material at the top. Peart

makes passes with a core-box router bit.

Finish the L.Peart makes a bands

cut along the straps length to mee

opening created by the router.

Make the straps

Article ExtraLearn more about Peart's finishingmethod for Greene and Greene furniture.

N O V E M B E R / D E C E M B E R 2 0 1 4www.f in ewoodworki ng. com

-

7/24/2019 Fine Woodworking - 243Nov-Dec2014

38/92

Tame Tricky

Glue-UpsCustom cauls can handleevery angle and curve

B Y M I C H A E L F O R T U N E

-

7/24/2019 Fine Woodworking - 243Nov-Dec2014

39/92

Cauls go on first.Clamp on the cauls (above),

aligning them carefully. Then assemble one pair of

sides at a time before marrying the two assemblies

to form a box. Fortune alternates the direction of the

clamp handles to avoid conflicts (right).

On a cabinet with a curved top and straight

sides, Fortune attaches the normal type of

miter cauls to the sides, and uses a flexible

version of the caul on top.

Many woodworkers stop at rect-angular work, preferring to stick

with flat surfaces and right-

angled joints. This is a shame because

curves and angles make furniture stand

out, and they arent as hard as you think.

Most importantly, they are fun.

A few factors keep people in the box.

Even if they know how to cut smooth

curves and precise angles, there still is

the problem of gluing and clamping these

awkward pieces together. There is a lot of

time and material invested at that point,

and an open or misaligned joint can bedevastating.

This is a follow-up to my two articles

on basic glue-ups in FWW#234, which

covered 90 joints and basic miters (Great

Glue-Ups Guaranteed, and Fundamentals:

Gear up for glue-ups). As I pointed out

then, while a dry run is always important

for a glue-up, it doesnt tell the whole

Nonslip cauls for tight case miters

T IP CURVED PANELS, TOO

The miter joint gives a clean, seamless look on contemporary cabinets,

but only if clamped up tight and true. These simple cauls are the ticket.

DIRECT

THE FORC

The clamps

direct the fo

through the

at 90 and

be placed o

centerline o

glue surfac

principles a

same for an

14-in.-thick

plywood

18-in.-thick luan plywoodor bending ply

Hardwood

blocks

90

Centerline of glue joint

14-in.-thickplywood

P100-grit sandpaper,

attached with yellow

glue, stops cauls

from slipping.

Hardwoodblocks

Clamp force