1990 The application of granulation to fine coal preparation

Fine Coal Refuse 25 Years of Field and Laboratory Testing ...

Transcript of Fine Coal Refuse 25 Years of Field and Laboratory Testing ...

©2017 GAI CONSULTANTS, INC. transforming ideas into reality®

Fine Coal Refuse – 25 Years of

Field and Laboratory Testing

Data and Correlations

October 1, 2018

Blaise E. Genes

Gonzalo Castro, Ph.D., P.E.

Thomas O. Keller, P. E.

Fatma Ciloglu, Ph.D., P. E.

©2017 GAI CONSULTANTS, INC. transforming ideas into reality®

1. Introduction

2. Upstream-Constructed Coal Refuse

Impoundments and Key Design Aspects

3. Fine Coal Refuse (FCR) In-Situ Field and

Laboratory Testing

4. FCR Field and Laboratory Data Application

Summary

5. FCR Data Correlations

6. FCR Undrained Strength Analyses Examples

Presentation Outline

©2017 GAI CONSULTANTS, INC. transforming ideas into reality®

Evaluated FCR tailings at numerous WV, KY and IL

impoundment sites since 1991 – 10 WV, 2 KY, 3 IL.

Amassed a database of field and laboratory data

from 15 large, high-hazard upstream-constructed

impoundments.

CPT-based evaluations and undrained strength

analyses performed to evaluate:

Material characteristics;

Liquefaction triggering;

Post-earthquake stability; and

Construction loading rate.

Introduction

©2017 GAI CONSULTANTS, INC. transforming ideas into reality®

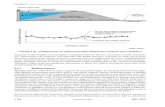

02

03

Oldhouse Branch

02

03

Delta

Delta

Stage J Embankment

Upstream-Constructed Coal Refuse Impoundments

Some of the tallest earth

structures in the world;

Unique characteristics;

FCR hydraulically-

deposited and used as

foundation for subsequent

embankment construction;

FCR requires sufficient

time to settle and excess

pore pressure to dissipate;

Undrained conditions

control upstream pushout

and seismic loading;

©2017 GAI CONSULTANTS, INC. transforming ideas into reality®

Key design aspects:

Developing and implementing risk-appropriate

in-situ field and laboratory testing;

Evaluating FCR material characteristics, i.e., does

FCR behave more sand-like or clay-like;

Estimating undrained shear strength and Su/s’v ratio;

Evaluating if strength loss is triggered due to

undrained loading event;

Evaluating post-earthquake stability with appropriate

Su and corresponding safety factor; and,

Evaluating incremental Su required vs. Su gained due

to excess pore pressure and consolidation.

Upstream-Constructed Coal Refuse Impoundments

©2017 GAI CONSULTANTS, INC. transforming ideas into reality®

Field Testing Methods

In-Situ Field Testing Methods:

Cone Penetration Testing

(CPT);

Shear wave velocity

measurements;

Pore-pressure dissipation

and vane shear testing;

Fixed-piston undisturbed

sampling; and,

In-situ/in-tube void ratio.

©2017 GAI CONSULTANTS, INC. transforming ideas into reality®

PS-CPT Field Testing Data

FP

FP

FP

FP

FP

FP

©2017 GAI CONSULTANTS, INC. transforming ideas into reality®

Laboratory Testing Methods

Laboratory Testing:

Grain-size, Atterberg limits, moisture content,

specific gravity;

CU triaxial shear strength:

Peak, Sup and steady-state, Sus undrained shear

strength;

Peak shear strain, e; and,

Sup/s’v. and Sus/s’v strength-to-effective stress

ratios.

©2017 GAI CONSULTANTS, INC. transforming ideas into reality®

Characterizing FCR From Lab Testing

Key Differences – Sand-like or Clay-like Behavior:

Strain at peak undrained shear strength

Abruptness of the drop-off in shearing resistance

Material characterization depends on laboratory data

(% passing #200, plasticity, peak strain), which

influence behavior.

MSHA. 2009

©2017 GAI CONSULTANTS, INC. transforming ideas into reality®

P. K. Robertson and C. E. (Fear) Wride, (1998).

Characterizing FCR From CPT

Site 6

Site 7

Site 8

Site 9

Site 10

Site 12

Site 13

Site 14

Site 15

After MSHA. 2009

©2017 GAI CONSULTANTS, INC. transforming ideas into reality®

Characterizing FCR From CPT

P. K. Robertson and C. E. (Fear) Wride, (1998).

Zone A: Loose sand-like;

Liquefaction Possible – Depends

on EQ M and duration.

Zone B: Clay-like; Liquefaction

Unlikely – Check other criteria,

i.e., cyclic stress/strain.

Zone C: Sensitive Clay-like;

Liquefaction Possible – Depends

on plasticity and EQ M.

Soils with Ic > 2.6 and F > 1.0%

are Likely Non-Liquefiable.

Site 6

Site 7

Site 8

Site 9

Site 10

Site 12

Site 13

Site 14

Site 15

Normalized Tip Resistance (Q) and Friction

(F) Ratio for FCR Materials/Sites

After MSHA. 2009

©2017 GAI CONSULTANTS, INC. transforming ideas into reality®

Peak Undrained Strength vs. Shear Strain

0

1

2

3

4

5

6

7

8

9

10

0 2 4 6 8 10 12 14 16 18 20 22 24 26 28 30 32 34 36

Pea

k U

nd

rain

ed S

hea

r S

tren

gth

, S

up, k

sc

Shear Strain at Peak Strength, %

Peak Undrained Shear Strength vs Shear Strain

Site 1

Site 2

Site 3

Site 4

Site 5

Site 6

Site 7

Site 8

Site 9

Site 10

Site 12

Site 13

Site 15

Sand-Like Clay-Like

Summary of Shear Strain Range for Laboratory Tested FCR Samples

©2017 GAI CONSULTANTS, INC. transforming ideas into reality®

Characterizing FCR

High quality undisturbed samples used to measure

Sus and Sup.

Sus measured in the laboratory will be higher than in-

situ.

Disturbance accounted for by correcting laboratory

Sus back to the in-situ Sus , which requires:

1. Careful measurement of void ratio during

sampling and handling; and,

2. Estimating slope of the Steady-State Line

(De/DlogSus).

Laboratory-Derived Undrained Strength

©2017 GAI CONSULTANTS, INC. transforming ideas into reality®

Laboratory-Field Undrained Strength

Correction of Sus from Laboratory to In-Situ Void Ratio

MSHA. 2009

©2017 GAI CONSULTANTS, INC. transforming ideas into reality®

Laboratory-Derived SSL

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1

1.1

1.2

1.3

1.4

1.5

1.6

1.7

1.8

0.01 0.1 1 10

Vo

id R

ati

o D

uri

ng

Sh

ear

Undrained Steady State Shear Strength, Sus, ksc

Undrained Steady State Shear Strength vs Void Ratio During Shear

Sites 1, 2

Site 3

Site 4

Site 5

Site 6

Site 7

Site 8

Site 9

Site 10

Site 11

Site 12

Site 14

0.11

0.13

0.14

0.11

0.11

0.14

0.11

0.11

0.11

0.24

0.11

0.53

De/DSus

Steady-State Line – WV, KY and IL Sites

©2017 GAI CONSULTANTS, INC. transforming ideas into reality®

Characterizing FCR

CPT data and Sup/s’v or Sus/s’v used in engineering

analyses to evaluate:

Liquefaction…will the undrained loading trigger

a strength loss in FCR?

Yes…Use Sus/s’v

No…Use Sup/s’v

Post-earthquake stability factors of safety; and,

Pushout strength required for 1.3 safety factor

in construction stability.

Applications for Testing Data

©2017 GAI CONSULTANTS, INC. transforming ideas into reality®

Post-Earthquake Stability Analyses

Sup

/s’v

or Sus

/s’v

s’v

s’v

s’v

s’v

Downstream Stability

Upstream Stability

©2017 GAI CONSULTANTS, INC. transforming ideas into reality®

Laboratory-Derived FCR Sus

0

1

2

3

4

5

6

7

8

9

10

11

12

0.0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0 5.5 6.0

Est

ima

ted

Ver

tica

l E

ffec

tiv

e S

tres

s, k

sc

Undrained Steady State Shear Strength In-Situ, Sus, ksc

Undrained Steady State Shear Strength In-Situ vs Estimated Vertical Effective Stress

Site 1

Site 2

Site 3

Site 4

Site 5

Site 6

Site 7

Site 8

Site 9

Site 10

Site 12

Sus = 0.16 s'v

Sus min = 0.03 s'v Sus max = 0.27 s'v

Undrained Steady-State Shear Strength to Effective Stress Strength Ratio

©2017 GAI CONSULTANTS, INC. transforming ideas into reality®

Laboratory-Derived Undrained Strength

Literature Correlations of Sus/s’v from Failure Cases

Sus

/s’v

Correlations - References

MSHA. 2009

©2017 GAI CONSULTANTS, INC. transforming ideas into reality®

Laboratory-Derived FCR Sup

0

1

2

3

4

5

6

7

8

9

10

11

12

0.0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0 5.5 6.0

Est

imate

d V

erti

cal

Eff

ecti

ve

Str

ess,

ksc

Peak Undrained Shear Strength In-Situ, Sup ksc

Peak Undrained Shear Strength In-Situ vs Estimated Vertical Effective Stress

Site 1

Site 2

Site 3

Site 4

Site 5

Site 6

Site 7

Site 8

Site 9

Site 10

Site 12

Site 13

Site 14

Site 15

Sup = 0.24 s'v

Sup min = 0.19 s'v Sup max = 0.35 s'v

Peak Undrained Shear Strength to Effective Stress Strength Ratio

©2017 GAI CONSULTANTS, INC. transforming ideas into reality®

Laboratory-Derived Undrained Strength

Sus vs. Soil Behavior Index, Ic Sus vs. Laboratory Fines Content

0

0.5

1

1.5

2

2.5

3

3.5

4

0.0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0

Su

s, k

sc

Ic, dim

Sus vs. Ic

Site 6

Site 7

Site 8

Site 9

Site 10

Site 12

Site 13

y = 0.589x - 1.0939

R² = 0.0995

0

0.5

1

1.5

2

2.5

3

3.5

4

0 10 20 30 40 50 60 70 80 90 100

Su

s, k

sc

Fines Content, %

Sus vs. FC Lab

Site 6

Site 7

Site 8

Site 9

Site 10

Site 12

Site 13

y = 0.0111x

R² = -0.328

Fines Data Correlations – Sus

©2017 GAI CONSULTANTS, INC. transforming ideas into reality®

Laboratory-Derived Undrained Strength

Sus vs. N1,60 Relationship Sup vs. N1,60 Relationship

0

0.5

1

1.5

2

2.5

3

3.5

4

0 5 10 15

Su

s, k

sc

N1,60, bpf

Sus vs. N1,60

Site 6

Site 7

Site 8

Site 9

Site 10

Site 12

Site 13

y = 0.2715e0.1003x

R² = 0.2872

Lower Bound,

Seed & Harder

Lower Bound, GEI

0

0.5

1

1.5

2

2.5

3

3.5

4

0 5 10 15

Su

p,

ksc

N1,60, bpf

Sup vs. N1,60

Site 6

Site 7

Site 8

Site 9

Site 10

Site 12

Site 13

y = 0.6601e0.0697x

R² = 0.4033

Lower Bound,

Seed & Harder

Lower Bound, GEI

Data CorrelationsN1,60

Data Correlations – Sus

and Sup

©2017 GAI CONSULTANTS, INC. transforming ideas into reality®

Laboratory-Derived Undrained Strength

Undrained Steady-State Shear Strength, Sus vs. Shear Wave Velocity, Vs

0

0.5

1

1.5

2

2.5

3

3.5

4

4.5

5

5.5

6

0 100 200 300 400 500 600 700 800 900 1000

Un

dra

ined

Ste

ad

y-S

tate

Sh

ear

Str

eng

th, S

us,

ksc

Shear Wave Velocity, Vs, m/s

Undrained Steady-State Shear Strength vs Shear Wave Velocity

Site 3

Site 4

Site 6

Site 7

Site 8

Site 9

Site 10

Site 12

y = 0.0044x

R² = -0.049

Vs

Data Correlations – Sus

©2017 GAI CONSULTANTS, INC. transforming ideas into reality®

Laboratory-Derived Undrained Strength

Literature Correlations of Sus with SPT and CPT Data

Sus

and Sus

/s’v

Correlations References

MSHA. 2009

©2017 GAI CONSULTANTS, INC. transforming ideas into reality®

Staged Construction Stability Analysis

Su required for stability FS=1.3

©2017 GAI CONSULTANTS, INC. transforming ideas into reality®

Staged Construction Stability Analysis

Su required for stability FS=1.3Su required for stability FS=1.3

©2017 GAI CONSULTANTS, INC. transforming ideas into reality®

Staged Construction Stability Analysis

Su required for stability FS=1.3Su required for stability FS=1.3

©2017 GAI CONSULTANTS, INC. transforming ideas into reality®

Staged Construction Stability Analysis

Su required for stability FS=1.3

©2017 GAI CONSULTANTS, INC. transforming ideas into reality®

Staged Construction Stability Analysis

Su required for stability FS=1.3

©2017 GAI CONSULTANTS, INC. transforming ideas into reality®

Upstream-constructed impoundments must endure

high level of scrutiny particularly for seismic and push-

out construction undrained loading conditions.

25+ years of consistent field and laboratory testing of

FCR yielded a significant volume of high quality data.

FCR data and correlations present ranges to evaluate

peak and steady-state undrained shear strength in

absence of, or for data comparison.

Risk-appropriate site-specific testing should be

performed to estimate undrained shear strengths.

Site-specific FCR strength ultimately control

undrained strength analyses.

Conclusions