LIMESTONE - Lime Finishes | Lime Plaster Solutions | Lime ...

Final danny krueger lime energy july 2010

-

Upload

limeenergysurveys -

Category

Documents

-

view

308 -

download

4

description

Transcript of Final danny krueger lime energy july 2010

Energy Efficiency in Corporate Facilities

City of Industry April 7, 2009

The Cleanest and Greenest Energy Is Energy Not Used

• Energy efficiency is the quickest, safest, most cost-effective way to immediately reduce the emission of greenhouse gases

– Immediate

– Verifiable

– Economical

Lime: Less Is More Efficient

Who Are We?

• Leading provider of energy efficiency and renewable energy design/build solutions with:

– National footprint

• 370 employees in 14 offices throughout the U.S.

– Broad array of services

• energy engineering, lighting, HVAC, water, weatherization, renewable energy

– Blue-chip customer base

• Over 75 years combined experience in energy conservation and efficiency

What Do We Do?

• Design, engineer, and install proven best-of-breed technologies in existing facilities. These measures:

– Reduce direct operating expenses

– Provide immediate financial results with high ROIs

– Improve work space and employee productivity

– Enhance the value of the facility

– Reduce environmental footprint

Who Do We Do It For?

• Commercial and Industrial Businesses– Corporations, Manufacturers, Property Owners, Property

Managers, Utilities

• Energy Service Companies (“ESCOs")– Federal, State and Municipal Government Agencies

• US Post Office, Schools K-12, Private and Public Universities, Public Housing, Correction Facilities, Military Facilities

5

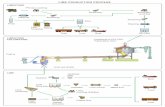

Opportunity

LightingHVAC/

Mechanical

Lime is focused on delivering high ROI energy efficiency solutions that target some of the largest energy expense line items on its customers’ P&L.

Electrical

Services

Energy Savings

Water WeatherizationRenewable

Energy

Delivery Process

• Opportunity Assessment

Performance Period

• Site Survey• Conceptual

Design• Final Cost &

Scope

• Execute scope of work

• Demonstrate ROI • Handle

documentation for rebates and incentives

DevelopmentOrigination Implementation

Why Lime Energy?

Why we win…

• Intellectual capital and experience to identify and analyze opportunities

• Systems and processes in place to deliver efficiently & cost-effectively

• Strong, referenceable relationships

• Ability to develop on a national scale but implement locally

Feeling Like This?

Why Energy Efficiency?

• Promote energy efficiency as available now – no need to wait for promising new technology.

• No matter how you measure financial merit, energy efficiency probably has the highest return on investment of anything you can do in your business.

Other Reasons Beyond Payback

A warehouse operation in Seattle improved their selection accuracy from 99.4% to 99.9% after the lighting retrofit.

A recent survey of 538 senior business executives and 18 in-depth interviews that “almost three-quarters (73%) of firms polled will make energy efficiency a high or moderate priority over the next two years in a bid to cut costs.”

An office tower will be using their new lighting fixtures to reduce glare and avoid worker complaints – and the new fixtures will be paid for out of energy savings.

A food products factory in Chicago installed the new lights when their primary customer asked them what they are doing to help the environment.

Energy Efficiency Today

Building energy costs run $1.50 to $3.50 per square foot.

What is your energy cost per square foot?

1. Find out and track it.

2. Create a team to investigate options.

3. Act on projects that have a good return on investment

Your Energy Costs

Your energy cost today does not have to be as high as it is.

Make an objective

Manage as if you want to reach that objective

Seven Reasons for Energy Efficiency

Reason number 1

Don’t throw your cash in the trash

Seven Reasons for Energy Efficiency

Reason number 2

Your employees will be happier

“The new lights seem to have energized the workers. I have been here 20 years and I can’t say enough good things about how this went, plus it was very economical with a fast payback,” said Bill Fuson, Facilities Maintenance Manager, Orcon Aerospace Co.

Seven Reasons for Energy Efficiency

Reason number 3

Tax deduction

Seven Reasons for Energy Efficiency

Reason number 4

You get new stuff

Seven Reasons for Energy Efficiency

Reason number 5Your facility is more valuable

“If you look at the impact, you are getting higher rent, lower energy costs and lower vacancy costs,” says [CoStar CEO Andy] Florence. “You have three things working on the income statement to the positive. You are going to have a much higher valuation of the building.”

Higher Building ValuationsHow much higher valuation? The report found that an ENERGY

STAR building sold for an average of $351.60 per square foot in 2006, 30 percent higher than a non-ENERGY STAR building, which sold for an average of $270.15 per square foot. Since 2003, ENERGY STAR buildings also have been appreciating in value faster than non-ENERGY STAR buildings.

Source: CoStar report on Energy Star performed for the US DOE

Reason number 5 (continued)

Net Operating Income and Value Go UP

Increase in Value =

Seven Reasons for Energy Efficiency

$1 millionIncrease in NOI

Cap Rate

$100,000

0.10==

Also, a higher NOI helps you on your debt coverage ratio.

NOI goes up because expenses go down.

Imagine a project that saves $100,000 per year.

Seven Reasons for Energy Efficiency

Reason number 6

Do some publicity

Join the companies that make a point to promote their sustainability agenda to their customers.

Seven Reasons for Energy Efficiency

Reason number 7

Make it a financial winner

Some Good Projects Available Today

Lighting retrofit – production areaMetal halide to fluorescent has a 30% to 50% return on investment – save $0.50 to $1.00 per sf every year.

Lighting retrofit – office areaEven if you have T-8 you can get a 20% to 30% ROI and upgrade your fixtures to indirect/direct for less glare.

Lighting retrofit – dock area, outdoor30% return on investment and lights last a decade.

Some Good Projects Available Today

HVAC ControlsUse web-based tools to be sure units only operate when you want them to, and watch for signs that they need service

HVAC unit change-outFor units that are more than 10 years old, consider replacing them for higher efficiency and less maintenance

Process motorAre your motors that operate all of the time the highest efficiency possible?

Air compressorCompressed air networks leak and have giant pressure drops if they have been added onto – don’t pay for leaky air and higher pressure

Motors and Drives

• Speed Kills so change your speed if you can– If you pump twice as much, you will use 8 times more

energy.

– If you pump ½ as much, you will use 1/8 of the energy.• Use the premium efficiency motors if over 4,000 hrs/yr• Use the right belts (V, cogged, or synchronous)

– Be sure you are pumping the right amount and with the best choice motor and drive.

• Operate at the lowest pressure allowed• Find and eliminate leaks• Reduce system pressure drop (2 to 4 PSI is ideal)

– Re-circuit if needed– Use lower delta P devices such as oil separators

• Improve part-load performance – Right-size the compressor and tank– Variable speed drive

• Replace timer solenoid drains with zero air loss drains• Replace outdated compressors and motors

Compressed Air

Measuring Hourly Electricity Use

Hourly KW Demand - 9/10/06 to 9/16/06

0

200

400

600

800

1000

1200

1400

1600

Midnight 4 8 12 16 20time of day

KW

10-Sep11-Sep12-Sep13-Sep14-Sep15-Sep16-Sep

Steps to Success

1) Start with your bill – how much per square foot?2) Audit your building, what are the biggest categories of

energy use?• Indoor lighting• Outdoor lighting• Process motors• Air conditioning• Heating• Other electrical

3) Decide what you want your bill to be next year 4) Take the steps to get there5) Track your progress

Climate Change

McDonald Packaging

Harrah’s Rincon Casino

• Our industry is hiring while others are firing.

• Our installations have a payback.

• Our product improves the air quality and fights global warming.

• Energy efficiency makes companies more competitive.

• Significant federal money is available to our industry.

• Our installations provide benefits beyond simple payback.

The Future of Energy Efficiency