Fatigue Bolted Connections

Transcript of Fatigue Bolted Connections

04/09/23 Fatigue Failure of Bolted Connections Chris Meisl

2

Presentation Outline

The Fatigue Process Sequence of Fatigue Failure

Behavior of Fatigue Loading S-N Curves Factors Affecting Fatigue

Bolted Connections in Tension Location of Failure Preloading and Contact Area Prying Action

Bolted Connections in Shear Preloading Stress Concentration and Failure

Locations

Anchor BoltsDesign Codes

04/09/23 Fatigue Failure of Bolted Connections Chris Meisl

3

What is Fatigue?

Caused by the repeated application of loads that are not large enough to cause failure in a single application.

Generally caused by repeated cycles of tensile loading.

Failure occurs suddenly.

Fracture surface of a paper clip broken by ~6 cycles of repeated bending (80 X)

04/09/23 Fatigue Failure of Bolted Connections Chris Meisl

4

Stages of Fatigue Failure

Failure will only occur if the following essential conditions are present:

Cyclic tensile loads Stress levels above a threshold

value Flaw in the material

Stages of fatigue failure:1. Crack initiation

2. Crack growth

3. Crack propagation

4. Final rupture

04/09/23 Fatigue Failure of Bolted Connections Chris Meisl

5

Behaviour of Fatigue Loading

The fatigue life = the number of repeated cycles of loading (N) that a material will undergo before it fails.

Higher the fatigue stress level, the fewer number of loading cycles required to cause failure.

Major factors that effect fatigue life:

1. Shape of the connection

2. Magnitude of stress variations

3. Mean stress level

4. Choice of materialS-N Curve for varying magnitude of altering stress

04/09/23 Fatigue Failure of Bolted Connections Chris Meisl

6

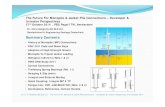

Bolted Connections in Tension – Failure Locations

Crack is initiated at areas of high stress concentrations.

Potential failure sites:a. Head-shank transition

b. Run-out of thread

c. Thread at nut

Failure is most likely to occur at the first engagement of the threads of the bolt and nut.

04/09/23 Fatigue Failure of Bolted Connections Chris Meisl

7

Bolted Connections in Tension – Influences

The magnitude of the load on the bolt depends on:

1. The magnitude of the external tension load.

2. The bolt-to-joint stiffness ratio (KB/KJ).

3. Whether or not the external tension load exceeds the critical load required to separate the joint (depends on initial preloading).

4. Location of the contact area.

04/09/23 Fatigue Failure of Bolted Connections Chris Meisl

8

Bolted Connections in Tension – Non Preloaded Bolts

Flange connection with non-preloaded bolts

The external tensile force Ft applied on the connection will be transferred

directly to the bolts, Fb.

04/09/23 Fatigue Failure of Bolted Connections Chris Meisl

9

Bolted Connections in Tension – Preloaded Bolts

Flange connection with preloaded bolts

Preload decreases the load variation in the bolt, until the contact forces Fc are exceeded.

04/09/23 Fatigue Failure of Bolted Connections Chris Meisl

10

Bolted Connections in Tension – Contact Area

If the flange thickness is to thin bending may occur, leading to contact areas.

Contact area at the centre: KJ > KB

Low variation of load on bolt until preload is exceeded.

Contact area at edges: KJ < KB

High variation of load on bolt.

Contact areas located at edges are more susceptible to fatigue.

04/09/23 Fatigue Failure of Bolted Connections Chris Meisl

11

Bolted Connections in Tension – Contact Area

Contact force in centre Contact forces located at flange edges

04/09/23 Fatigue Failure of Bolted Connections Chris Meisl

12

Bolted Connections in Shear

Non-Preloading Load transferred

via bearing of bolt shank.

Can not be used in variable load conditions.

Preloaded: Load transferred

by friction between plates.

Use HSFG bolts.

Can be used in variable load conditions.

04/09/23 Fatigue Failure of Bolted Connections Chris Meisl

13

Bolted Connections in Shear

Non-Preloading Stress

concentration at hole.

Fatigue cracks near hole, or shearing of bolt.

Preloaded: Low stress

concentration near hole.

Fatigue cracks at gross section of plate.

04/09/23 Fatigue Failure of Bolted Connections Chris Meisl

14

Anchor Bolts

Behave in the same way as normal bolts.

Bolt diameter and thread size has little effect.

Method of forming thread influences fatigue strength

Rolled threads better than cut due to residual compressive stress.

Double nut increases fatigue resistance.

Must consider prying effects.

04/09/23 Fatigue Failure of Bolted Connections Chris Meisl

15

Code Requirements – CAN/CSA-S16.1-94

Based on detail categories, number of load cycles, and the corresponding S-N curve.

Considers fatigue failure to occur in the connecting material.

Parameters: = fatigue life constant [Table 4(a)]

n = number of stress range cycles [Table 4(b)]

N = number of passages of the moving load

Fsrt = constant amplitude threshold range

FsrnN

1

3

04/09/23 Fatigue Failure of Bolted Connections Chris Meisl

16

Code Requirements – AISC LRFD 1999

Based on detail categories, number of load cycles, and the corresponding S-N curve.Considers fatigue failure to occur in the connecting material and bolt.Parameters:

Fsr = design stress range

Cf = constant [Table A-K3.1]N = number of stress range fluctuations

Fth = threshold fatigue stress range [Table A-K3.1]

At = net tensile areaP = pitch

db = nominal diameter

Shear

Fsr Fth

TensionCategory E’ – Cf = 3.9E8

Fth = 48MPa

Include prying effects

At4

db 0.9382P( )2