Failure Modes and Effects Analysis - Quality Management...

Transcript of Failure Modes and Effects Analysis - Quality Management...

FAILURE MODES AND

EFFECTS ANALYSIS

Ms Rawia A Abdalla RN MSN CPHQ CPPS

Head of Patient Safety Unit

OUTLINE

Definitions

Benefits of FMEA

History of FMEA

When to use FMEA

What does FMEA include

Steps in FMEA

Common mistakes in FMEA

WHAT COULD GO WRONG

WHAT COULD GO

WRONG

Medication Prescription

Surgical procedure

Blood transfusion

FAILURE MODES AND EFFECTS ANALYSIS

Failure Modes

The ways or modes in which something might fail

It is a concise description of how a part of a process

may potentially fail to perform its functions

( Prescription errors wrong dose route or infusion time

Proper patient monitoring not ordered Prescribed on wrong patient No order received Illegible writing )

Effect Analysis

Studying the consequences of those failures

Failures are prioritized according to its frequency

and seriousness

DEFINITION

Failure Modes and Effects Analysis (FMEA)

is a systematic proactive method for evaluating a

process to identify where and how it might fail

and to assess the relative impact of different

failures in order to identify the parts of the

process that are most in need of change

(Institute of Healthcare Improvement 2004)

Preventing problems is cheaper and easier than

cleaning them up

WHAT IF YOU

STOPPED

GOING

OUTSIDE

BENEFITS

Get it right the first time

Identify any inadequacies in the process

Continuous improvement

Team building

Reduce the likelihood of complications

Reduce maintenance costs

Reduce the possibility of safety failures

Greater customer satisfaction and reduced

complaints

WHEN TO USE FMEA

FMEA should be used

at the conceptual stage

when changes are made to the design

when new regulations are instituted

when customer feedback indicates a problem

HISTORY OF FMEA Developed in the US Military 1949 titled Procedures for

Performing a Failure Mode Effects and Criticality Analysis Failures were classified according to their impact on mission success and

personnelequipment safety

Formally developed and applied by NASA in the 1960rsquos to improve

and verify reliability of space program hardware during the Apollo

program

Initial automotive adoption (Ford)

in the 1970rsquos

Automotive Industry Action Group and

American Society for Quality Control

copyright standards in 1993

Now adopted by many other industries

FMEA IN THE LITERATURE

2006

FMEA IN THE LITERATURE

2007

FMEA IN THE LITERATURE

2011

FMEA IN THE LITERATURE

2011

FMEA IN THE LITERATURE

2011

PCA Over-sedation Application Of

Healthcare Failure Mode Effect Analysis

(HFMEAtrade)

Pam Cronrath MN RN Timothy W Lynch PharmD MS FABC Linda J Gilson BSN RN

CAPA Carol Nishida BSN RN CMSRN M Colleen Sembar MSM BSN RN CCRN Patricia J

Spencer BSN RN BC ONC Daidre Foote West BSN RN CPUM

The changes implemented identified 16 failure

points with a hazard score of 16 or greater One

year later the established system HFMEA goal

was met Reduce oversedation events by 50

fiscal year end 2008

FMEA IN THE LITERATURE

2012

FMEA IN THE LITERATURE

2013 - ONLINE

Health Care Failure Mode and Effect Analysis to Reduce NICU LinendashAssociated Bloodstream Infections

Celeste J Chandonnet RN BSN CCRNabPrerna S Kahlon BDS MPAH CPHQc Pratik Rachh MD MBA CQPA CPHQd Michele DeGrazia PhD RN NNP-BCabe Eileen C DeWitt RNC MS NNP-BCab Kathleen A Flaherty MT(ASCP) BS CICab Nadine Spigel RN BSN CCRNab Stephanie Packard RN BSN CCRNab Denise Casey MS RN CCRN CPNPab Christine Rachwal MSN RN CCRNab and Pankaj B Agrawal MD MMSCace

Since implementing the appropriate action plans the NICU has experienced a significant decrease in CLABSIs from 26 to 08 CLABSIs per 1000 line days

The process of HFMEA helped reduce the CLABSI rate and reinforce the culture of continuous quality improvement and safety in the NICU

WHAT DOES FMEA INCLUDE

FMEA includes review of the following

Steps in the process

Failure modes (What could go wrong)

Failure causes (Why would the failure happen)

Failure effects (What would be the consequences

of each failure)

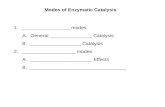

STEPS OF FMEA

1 Select a process to evaluate with FMEA

2 Recruit a multidisciplinary team

3 Review the process

4 List failure modes and causes and its effect on

patients

5 Assign Risk Code

6 Evaluate the results

7 Create actions to reduce risks

8 Assign responsibility for actions

9 Re-assign risk codes (residual risk)

10 Monitor the actions and risk reduction

STEP 1

SELECT A PROCESS TO EVALUATE WITH FMEA

Evaluation using FMEA works best on processes that do not have too many sub processes

Instead of doing FMEA on a large and complex process such as medication management in a hospital try doing an FMEA on sub processes like medication ordering dispensing or administration processes

Select processes with high risk high cost high volume or with wide variation in practice

Process Medication prescription by the physician

STEP 2

RECRUIT A MULTIDISCIPLINARY TEAM

Be sure to include everyone who is involved at any point in the process

Some people may not need to be part of the team throughout the entire analysis but they should certainly be included in discussions of those steps in the process in which they are involved

For example if you want to evaluate VAP prevention you will include pulmonologists respiratory therapy infection control pharmacy nursing

Process Medication prescription by the physician

Team Physician nursing pharmacy

STEP 3

REVIEW THE PROCESS

It may take several meetings for the team to complete

this part of the FMEA depending on the number of

steps and the complexity of the process

Flowcharting can be a helpful tool for outlining the

steps

When you are finished be sure to obtain consensus

from the group

The team should agree that the steps enumerated in

the FMEA accurately describe the process

GRAPHICAL REPRESENTATION

Medication Management

1 Prescription 11 Physician checks results

12 Physician prescribes medication

2 Dispensing

21 Send order to pharmacy

22 Enter order into computer

23 Produce label

24 Prepare medication

25 Check medication before distribution

26 Deliver medication to the units

3 Administration

31 Receive order and transcribe onto medication record

32 Obtain infusion pump

33 Obtain medication

34 Program infusion pump

35 Check medicaition pump settings before administration

36 Administer medication

37 Document administration

38 Monitor side effects adverse events

4 Laboratory Monitoring

41 Laboratory request

42 Serum blood sample

43 label sample

44 Send to the laboratory

45 Checking results by nurses

STEP 4

LIST FAILURE MODES AND CAUSES AND ITS

EFFECT ON PATIENTS

For each step in the process list all possible

―failure modesmdashthat is anything that could go

wrong including minor and rare problems

For each failure mode listed identify all possible

causes

Then for each failure mode listed identify all

possible effects

Sub process Failure Modes Failure causes Failure Effect

Physician

prescribes

medication

Wrong dose route

or infusion time

(fast slow)

Clinical situation not

considered (age renal and

endocrine functions

allergy seizures cardiac

rhythm) concomitant use

of oral drugs knowledge

deficit mental slip

information on drug not

available

Overdose under-dose

improper route

selection ADR allergic

response prolonged

infusion time leads to

delay in therapy very

fast infusion leads to

side effects

Proper patient

monitoring not

ordered

Knowledge deficit mental

slip

Failure to detect

problems early to

prevent harm

Prescribed on

wrong patient

Similar patient names

patient identifier not

clear no identifier

verification

Wrong patient receives

inappropriate drug and

dose ADR allergic

response

No order received Unable to reach on call

physician

Poor patient

management

Illegible writing

(use abbreviations

unclear hand

writing )

Knowledge deficit mental

slip no list of approved

abbreviations

Wrong drug Overdose

under-dose improper

route selection ADR

allergic response delay

in treatment

STEP 5

ASSIGN RISK CODE

Risk Code = Severity X Occurrence

Severity (1= Minimum 5 = Serious)

If this failure mode occurs how likely is it that

harm will occur

Probability of occurrence (1 = Rare 5 = Frequent)

How likely is it that this failure mode will occur

5 X 5 HAZARD SCORING MATRIX

Failure modes with higher hazard scores should

receive the highest priority

Severity

Probability Serious

(5)

Major

(4)

Moderate

(3)

Minor

(2)

Minimum

(1)

Frequent (5) 25 20 15 10 5

Likely (4) 20 16 12 8 4

Possible (3) 15 12 9 6 3

Unlikely (2) 10 8 6 4 2

Rare (1) 5 4 3 2 1

Sub process Failure Modes Failure causes Failure Effect S P Hazard

Physician

prescribes

medication

Wrong dose route

or infusion time

(fast slow)

Clinical situation not

considered (age renal

and endocrine

functions allergy

seizures cardiac

rhythm) concomitant

use of oral drugs

knowledge deficit

mental slip information

on drug not available

Overdose under-

dose improper route

selection ADR

allergic response

prolonged infusion

time leads to delay in

therapy very fast

infusion leads to side

effects

4 4 16

Proper patient

monitoring not

ordered

Knowledge deficit

mental slip

Failure to detect

problems early to

prevent harm

4 3 12

Prescribed on

wrong patient

Similar patient names

patient identifier not

clear no identifier

verification

Wrong patient

receives

inappropriate drug

and dose ADR

allergic response

3 2 6

No order received Unable to reach on call

physician

Poor patient

management

2 2 4

Illegible writing

(use

abbreviations

unclear hand

writing )

Knowledge deficit

mental slip no list of

approved abbreviations

Wrong drug

Overdose under-

dose improper route

selection ADR

allergic response

delay in treatment

4 4 16

STEP 6

EVALUATE THE RESULTS

Hazard scores

1= Low risk 25 = Extreme risk

Failure modes with higher hazard scores should

receive the highest priority and should trigger

consideration of potential action to control the

failure

These are the ones the team should consider first

as improvement opportunities

STEP 7

CREATE ACTIONS TO REDUCE RISKS

Evaluate the causes and see if any or all of them

can be eliminated

Modify other processes that contribute to causes

Actions Control Measures

1 Engineering structural control

(Reconstruction anti slippery floors hood)

2 Administrative changes

(policies protocols job descriptions)

Sub process Failure Modes Failure causes Failure Effect S P Hazard Actions

Physician

prescribes

medication

Wrong dose

route or infusion

time (fast slow)

Clinical situation not

considered (age renal

and endocrine

functions allergy

seizures cardiac

rhythm) concomitant

use of oral drugs

knowledge deficit

mental slip

information on drug

not available

Overdose under-

dose improper route

selection ADR

allergic response

prolonged infusion

time leads to delay in

therapy very fast

infusion leads to side

effects

4 4 16 Clinical pharmacy

program pre-printed

medications protocol

with education on

use easy access to

drug information

feedback mechanism

on substitute drugs

available

Proper patient

monitoring not

ordered

Knowledge deficit

mental slip

Failure to detect

problems early to

prevent harm

4 3 12 pre-printed

medication protocols

with monitoring

guidelines

Prescribed on

wrong patient

Similar patient names

patient identifier not

clear no identifier

verification

Wrong patient

receives

inappropriate drug

and dose ADR

allergic response

3 2 6 Match result to

patient condition

alert for a look-alike

patient names visible

demographics on

identifier

No order

received

Unable to reach on call

physician

Poor patient

management

2 2 4 Proper physician

coverage and

communication

channels

Illegible writing

(use

abbreviations

unclear hand

writing )

Knowledge deficit

mental slip no list of

approved

abbreviations

Wrong drug

Overdose under-

dose improper route

selection ADR

allergic response

delay in treatment

4 4 16 pre-printed

medication protocol

Health Information

Systems list of

approved

abbreviations

STEP 8

ASSIGN RESPONSIBILITY FOR ACTIONS

Assign responsibilities for implementing the

corrective and preventive actions

Set timelines determine the project completion

dates

STEP 9

RE-ASSIGN RISK CODES (RESIDUAL RISK)

Determine what is the risk code after

implementing the actions for each failure mode

The aim is to assist the team in prioritizing

actions and to determine if actions were effective

or not

Sub process Failure Modes Failure causes Failure Effect S P Hazard Actions Responsibility S P Hazard

Physician

prescribes

medication

Wrong dose

route or

infusion time

(fast slow)

Clinical situation

not considered

(age renal and

endocrine

functions allergy

seizures cardiac

rhythm)

concomitant use of

oral drugs

knowledge deficit

mental slip

information on

drug not available

Overdose under-

dose improper

route selection

ADR allergic

response

prolonged

infusion time

leads to delay in

therapy very fast

infusion leads to

side effects

4 4 16 Clinical pharmacy

program pre-

printed

medications

protocol with

education on use

easy access to

drug information

feedback

mechanism on

substitute drugs

available

XXXXXXX 2 2 4

Proper

patient

monitoring

not ordered

Knowledge deficit

mental slip

Failure to detect

problems early to

prevent harm

4 3 12 pre-printed

medication

protocols with

monitoring

guidelines

XXXXXXX 2 3 6

Prescribed on

wrong patient

Similar patient

names patient

identifier not clear

no identifier

verification

Wrong patient

receives

inappropriate

drug and dose

ADR allergic

response

3 2 6 Match result to

patient condition

alert for a look-

alike patient

names visible

demographics on

identifier

XXXXXXX 1 1 1

No order

received

Unable to reach on

call physician

Poor patient

management 2 2 4 Proper physician

coverage and

communication

channels

XXXXXXX 1 1 1

Illegible

writing (use

abbreviations

unclear

hand writing)

Knowledge deficit

mental slip no list

of approved

abbreviations

Wrong drug

Overdose under-

dose improper

route selection

ADR allergic

response delay

in treatment

4 4 16 pre-printed

medication

protocol Health

Information

Systems list of

approved

abbreviations

XXXXXXX 3 4 12

STEP 10

MONITOR THE ACTIONS AND RISK REDUCTION

Monitor to evaluate if the risk reduction

strategies have reduced risk and take additional

actions if necessary to further reduce risk

USES OF FMEA

Use FMEA to plan actions to reduce harm from failure modes

Use FMEA to evaluate the potential impact of changes under consideration ( check the residual risk code)

Use FMEA to monitor and track improvement over time by calculating a risk code for the process and then set a goal for improvement

For example a team may set a goal of decreasing the risk code for the medication ordering process by 50 from the baseline

Phase 1 Phase 2 Phase 3

Processes amp

sub processes

Potential

Failure modes

Potential

Causes

Potential Effects

Seve

rity

Sco

re

Pro

bab

ility

Sco

re

Haz

ard

sco

re

Recommended Actions Responsibility

and target date

Seve

rity

Sco

re

Pro

bab

ility

Sco

re

Haz

ard

sco

re

1 Process

11 Sub-process

12 Sub-process

13 Sub-process

14 Sub-process

15 Sub-process

2 Process

21 Sub-process

22 Sub-process

23 Sub-process

24 Sub-process

25 Sub-process

COMMON MISTAKES IN FMEA

The quality department is the owner of FMEA

The wrong people are selected to participate in the

sessions of FMEA inadequate team composition

The FMEA are done at a wrong time

The FMEA provides the wrong level of detail

(missing the high risk areas or the root causes)

Failure to drive any design or process improvement

Failure to address all high risk failure modes

Failure to produce action and control plans

Improper FMEA procedure

Lack of efficient use of time in the meetings

ADDITIONAL RESOURCES

Please Visit the Institute for Healthcare

Improvement (IHI) Website to see an

interactive FMEA Tool available on IHIorg

PREVENTIVE MEDICINE IS

LESS COSTLY THAN

CURATIVE MEDICINE

REFERENCES

Institute for Healthcare Improvement 2004 Failure Modes and Effects Analysis

(FMEA)

Kimchi-Woods J Shultz J (2006) Using HFMEA to Assess Potential for Patient

Harm from Tubing Misconnections Journal on quality and patient safety 32 (7) 373-

381

Kathy Ouellette-Piazzo K Asfaw M amp Cowen J (2007) CT Healthcare Failure

Mode Effect Analysis (HFMEAreg) The Misadministration of IV Contrast in

Outpatients Radiology management 29 (1) 36-44

Ashley L Dexter R Marshall F McKenzie B Ryan M amp Armitage G (2011)

Improving the Safety of Chemotherapy Administration An Oncology Nurse-Led

Failure Mode and Effects Analysis Oncology Nursing Forum 38 (6) E436 ndash E444

STEELMAN M amp CULLEN J (2011) Designing a Safer Process to Prevent

Retained Surgical Sponges A Healthcare Failure Mode and Effect Analysis AORN

Journal 94 (2) 132-141

Cronrath P Lynch TW Gilson LJ Nishida C Sembar MC Spencer PJ West DF

(2011) PCA oversedation application of Healthcare Failure Mode Effect (HFMEA)

Analysis Nursing economics 29(2) 79-87

Cheng C Chou CH Wang PC Lin HY Kao CL Su CT (2012) Applying

HFMEA to Prevent Chemotherapy Errors Journal of medical systems 36 1543-

1551

Chandonnet C Kahlon P Rachh P DeGrazia M DeWitt E Flaherty K

Spigel N Packard S Casey D Rachwal C Agrawal P (2013) Health Care

Failure Mode and Effect Analysis to Reduce NICU LinendashAssociated Bloodstream

Infections Pediatrics 131(6) 1961-1969

OUTLINE

Definitions

Benefits of FMEA

History of FMEA

When to use FMEA

What does FMEA include

Steps in FMEA

Common mistakes in FMEA

WHAT COULD GO WRONG

WHAT COULD GO

WRONG

Medication Prescription

Surgical procedure

Blood transfusion

FAILURE MODES AND EFFECTS ANALYSIS

Failure Modes

The ways or modes in which something might fail

It is a concise description of how a part of a process

may potentially fail to perform its functions

( Prescription errors wrong dose route or infusion time

Proper patient monitoring not ordered Prescribed on wrong patient No order received Illegible writing )

Effect Analysis

Studying the consequences of those failures

Failures are prioritized according to its frequency

and seriousness

DEFINITION

Failure Modes and Effects Analysis (FMEA)

is a systematic proactive method for evaluating a

process to identify where and how it might fail

and to assess the relative impact of different

failures in order to identify the parts of the

process that are most in need of change

(Institute of Healthcare Improvement 2004)

Preventing problems is cheaper and easier than

cleaning them up

WHAT IF YOU

STOPPED

GOING

OUTSIDE

BENEFITS

Get it right the first time

Identify any inadequacies in the process

Continuous improvement

Team building

Reduce the likelihood of complications

Reduce maintenance costs

Reduce the possibility of safety failures

Greater customer satisfaction and reduced

complaints

WHEN TO USE FMEA

FMEA should be used

at the conceptual stage

when changes are made to the design

when new regulations are instituted

when customer feedback indicates a problem

HISTORY OF FMEA Developed in the US Military 1949 titled Procedures for

Performing a Failure Mode Effects and Criticality Analysis Failures were classified according to their impact on mission success and

personnelequipment safety

Formally developed and applied by NASA in the 1960rsquos to improve

and verify reliability of space program hardware during the Apollo

program

Initial automotive adoption (Ford)

in the 1970rsquos

Automotive Industry Action Group and

American Society for Quality Control

copyright standards in 1993

Now adopted by many other industries

FMEA IN THE LITERATURE

2006

FMEA IN THE LITERATURE

2007

FMEA IN THE LITERATURE

2011

FMEA IN THE LITERATURE

2011

FMEA IN THE LITERATURE

2011

PCA Over-sedation Application Of

Healthcare Failure Mode Effect Analysis

(HFMEAtrade)

Pam Cronrath MN RN Timothy W Lynch PharmD MS FABC Linda J Gilson BSN RN

CAPA Carol Nishida BSN RN CMSRN M Colleen Sembar MSM BSN RN CCRN Patricia J

Spencer BSN RN BC ONC Daidre Foote West BSN RN CPUM

The changes implemented identified 16 failure

points with a hazard score of 16 or greater One

year later the established system HFMEA goal

was met Reduce oversedation events by 50

fiscal year end 2008

FMEA IN THE LITERATURE

2012

FMEA IN THE LITERATURE

2013 - ONLINE

Health Care Failure Mode and Effect Analysis to Reduce NICU LinendashAssociated Bloodstream Infections

Celeste J Chandonnet RN BSN CCRNabPrerna S Kahlon BDS MPAH CPHQc Pratik Rachh MD MBA CQPA CPHQd Michele DeGrazia PhD RN NNP-BCabe Eileen C DeWitt RNC MS NNP-BCab Kathleen A Flaherty MT(ASCP) BS CICab Nadine Spigel RN BSN CCRNab Stephanie Packard RN BSN CCRNab Denise Casey MS RN CCRN CPNPab Christine Rachwal MSN RN CCRNab and Pankaj B Agrawal MD MMSCace

Since implementing the appropriate action plans the NICU has experienced a significant decrease in CLABSIs from 26 to 08 CLABSIs per 1000 line days

The process of HFMEA helped reduce the CLABSI rate and reinforce the culture of continuous quality improvement and safety in the NICU

WHAT DOES FMEA INCLUDE

FMEA includes review of the following

Steps in the process

Failure modes (What could go wrong)

Failure causes (Why would the failure happen)

Failure effects (What would be the consequences

of each failure)

STEPS OF FMEA

1 Select a process to evaluate with FMEA

2 Recruit a multidisciplinary team

3 Review the process

4 List failure modes and causes and its effect on

patients

5 Assign Risk Code

6 Evaluate the results

7 Create actions to reduce risks

8 Assign responsibility for actions

9 Re-assign risk codes (residual risk)

10 Monitor the actions and risk reduction

STEP 1

SELECT A PROCESS TO EVALUATE WITH FMEA

Evaluation using FMEA works best on processes that do not have too many sub processes

Instead of doing FMEA on a large and complex process such as medication management in a hospital try doing an FMEA on sub processes like medication ordering dispensing or administration processes

Select processes with high risk high cost high volume or with wide variation in practice

Process Medication prescription by the physician

STEP 2

RECRUIT A MULTIDISCIPLINARY TEAM

Be sure to include everyone who is involved at any point in the process

Some people may not need to be part of the team throughout the entire analysis but they should certainly be included in discussions of those steps in the process in which they are involved

For example if you want to evaluate VAP prevention you will include pulmonologists respiratory therapy infection control pharmacy nursing

Process Medication prescription by the physician

Team Physician nursing pharmacy

STEP 3

REVIEW THE PROCESS

It may take several meetings for the team to complete

this part of the FMEA depending on the number of

steps and the complexity of the process

Flowcharting can be a helpful tool for outlining the

steps

When you are finished be sure to obtain consensus

from the group

The team should agree that the steps enumerated in

the FMEA accurately describe the process

GRAPHICAL REPRESENTATION

Medication Management

1 Prescription 11 Physician checks results

12 Physician prescribes medication

2 Dispensing

21 Send order to pharmacy

22 Enter order into computer

23 Produce label

24 Prepare medication

25 Check medication before distribution

26 Deliver medication to the units

3 Administration

31 Receive order and transcribe onto medication record

32 Obtain infusion pump

33 Obtain medication

34 Program infusion pump

35 Check medicaition pump settings before administration

36 Administer medication

37 Document administration

38 Monitor side effects adverse events

4 Laboratory Monitoring

41 Laboratory request

42 Serum blood sample

43 label sample

44 Send to the laboratory

45 Checking results by nurses

STEP 4

LIST FAILURE MODES AND CAUSES AND ITS

EFFECT ON PATIENTS

For each step in the process list all possible

―failure modesmdashthat is anything that could go

wrong including minor and rare problems

For each failure mode listed identify all possible

causes

Then for each failure mode listed identify all

possible effects

Sub process Failure Modes Failure causes Failure Effect

Physician

prescribes

medication

Wrong dose route

or infusion time

(fast slow)

Clinical situation not

considered (age renal and

endocrine functions

allergy seizures cardiac

rhythm) concomitant use

of oral drugs knowledge

deficit mental slip

information on drug not

available

Overdose under-dose

improper route

selection ADR allergic

response prolonged

infusion time leads to

delay in therapy very

fast infusion leads to

side effects

Proper patient

monitoring not

ordered

Knowledge deficit mental

slip

Failure to detect

problems early to

prevent harm

Prescribed on

wrong patient

Similar patient names

patient identifier not

clear no identifier

verification

Wrong patient receives

inappropriate drug and

dose ADR allergic

response

No order received Unable to reach on call

physician

Poor patient

management

Illegible writing

(use abbreviations

unclear hand

writing )

Knowledge deficit mental

slip no list of approved

abbreviations

Wrong drug Overdose

under-dose improper

route selection ADR

allergic response delay

in treatment

STEP 5

ASSIGN RISK CODE

Risk Code = Severity X Occurrence

Severity (1= Minimum 5 = Serious)

If this failure mode occurs how likely is it that

harm will occur

Probability of occurrence (1 = Rare 5 = Frequent)

How likely is it that this failure mode will occur

5 X 5 HAZARD SCORING MATRIX

Failure modes with higher hazard scores should

receive the highest priority

Severity

Probability Serious

(5)

Major

(4)

Moderate

(3)

Minor

(2)

Minimum

(1)

Frequent (5) 25 20 15 10 5

Likely (4) 20 16 12 8 4

Possible (3) 15 12 9 6 3

Unlikely (2) 10 8 6 4 2

Rare (1) 5 4 3 2 1

Sub process Failure Modes Failure causes Failure Effect S P Hazard

Physician

prescribes

medication

Wrong dose route

or infusion time

(fast slow)

Clinical situation not

considered (age renal

and endocrine

functions allergy

seizures cardiac

rhythm) concomitant

use of oral drugs

knowledge deficit

mental slip information

on drug not available

Overdose under-

dose improper route

selection ADR

allergic response

prolonged infusion

time leads to delay in

therapy very fast

infusion leads to side

effects

4 4 16

Proper patient

monitoring not

ordered

Knowledge deficit

mental slip

Failure to detect

problems early to

prevent harm

4 3 12

Prescribed on

wrong patient

Similar patient names

patient identifier not

clear no identifier

verification

Wrong patient

receives

inappropriate drug

and dose ADR

allergic response

3 2 6

No order received Unable to reach on call

physician

Poor patient

management

2 2 4

Illegible writing

(use

abbreviations

unclear hand

writing )

Knowledge deficit

mental slip no list of

approved abbreviations

Wrong drug

Overdose under-

dose improper route

selection ADR

allergic response

delay in treatment

4 4 16

STEP 6

EVALUATE THE RESULTS

Hazard scores

1= Low risk 25 = Extreme risk

Failure modes with higher hazard scores should

receive the highest priority and should trigger

consideration of potential action to control the

failure

These are the ones the team should consider first

as improvement opportunities

STEP 7

CREATE ACTIONS TO REDUCE RISKS

Evaluate the causes and see if any or all of them

can be eliminated

Modify other processes that contribute to causes

Actions Control Measures

1 Engineering structural control

(Reconstruction anti slippery floors hood)

2 Administrative changes

(policies protocols job descriptions)

Sub process Failure Modes Failure causes Failure Effect S P Hazard Actions

Physician

prescribes

medication

Wrong dose

route or infusion

time (fast slow)

Clinical situation not

considered (age renal

and endocrine

functions allergy

seizures cardiac

rhythm) concomitant

use of oral drugs

knowledge deficit

mental slip

information on drug

not available

Overdose under-

dose improper route

selection ADR

allergic response

prolonged infusion

time leads to delay in

therapy very fast

infusion leads to side

effects

4 4 16 Clinical pharmacy

program pre-printed

medications protocol

with education on

use easy access to

drug information

feedback mechanism

on substitute drugs

available

Proper patient

monitoring not

ordered

Knowledge deficit

mental slip

Failure to detect

problems early to

prevent harm

4 3 12 pre-printed

medication protocols

with monitoring

guidelines

Prescribed on

wrong patient

Similar patient names

patient identifier not

clear no identifier

verification

Wrong patient

receives

inappropriate drug

and dose ADR

allergic response

3 2 6 Match result to

patient condition

alert for a look-alike

patient names visible

demographics on

identifier

No order

received

Unable to reach on call

physician

Poor patient

management

2 2 4 Proper physician

coverage and

communication

channels

Illegible writing

(use

abbreviations

unclear hand

writing )

Knowledge deficit

mental slip no list of

approved

abbreviations

Wrong drug

Overdose under-

dose improper route

selection ADR

allergic response

delay in treatment

4 4 16 pre-printed

medication protocol

Health Information

Systems list of

approved

abbreviations

STEP 8

ASSIGN RESPONSIBILITY FOR ACTIONS

Assign responsibilities for implementing the

corrective and preventive actions

Set timelines determine the project completion

dates

STEP 9

RE-ASSIGN RISK CODES (RESIDUAL RISK)

Determine what is the risk code after

implementing the actions for each failure mode

The aim is to assist the team in prioritizing

actions and to determine if actions were effective

or not

Sub process Failure Modes Failure causes Failure Effect S P Hazard Actions Responsibility S P Hazard

Physician

prescribes

medication

Wrong dose

route or

infusion time

(fast slow)

Clinical situation

not considered

(age renal and

endocrine

functions allergy

seizures cardiac

rhythm)

concomitant use of

oral drugs

knowledge deficit

mental slip

information on

drug not available

Overdose under-

dose improper

route selection

ADR allergic

response

prolonged

infusion time

leads to delay in

therapy very fast

infusion leads to

side effects

4 4 16 Clinical pharmacy

program pre-

printed

medications

protocol with

education on use

easy access to

drug information

feedback

mechanism on

substitute drugs

available

XXXXXXX 2 2 4

Proper

patient

monitoring

not ordered

Knowledge deficit

mental slip

Failure to detect

problems early to

prevent harm

4 3 12 pre-printed

medication

protocols with

monitoring

guidelines

XXXXXXX 2 3 6

Prescribed on

wrong patient

Similar patient

names patient

identifier not clear

no identifier

verification

Wrong patient

receives

inappropriate

drug and dose

ADR allergic

response

3 2 6 Match result to

patient condition

alert for a look-

alike patient

names visible

demographics on

identifier

XXXXXXX 1 1 1

No order

received

Unable to reach on

call physician

Poor patient

management 2 2 4 Proper physician

coverage and

communication

channels

XXXXXXX 1 1 1

Illegible

writing (use

abbreviations

unclear

hand writing)

Knowledge deficit

mental slip no list

of approved

abbreviations

Wrong drug

Overdose under-

dose improper

route selection

ADR allergic

response delay

in treatment

4 4 16 pre-printed

medication

protocol Health

Information

Systems list of

approved

abbreviations

XXXXXXX 3 4 12

STEP 10

MONITOR THE ACTIONS AND RISK REDUCTION

Monitor to evaluate if the risk reduction

strategies have reduced risk and take additional

actions if necessary to further reduce risk

USES OF FMEA

Use FMEA to plan actions to reduce harm from failure modes

Use FMEA to evaluate the potential impact of changes under consideration ( check the residual risk code)

Use FMEA to monitor and track improvement over time by calculating a risk code for the process and then set a goal for improvement

For example a team may set a goal of decreasing the risk code for the medication ordering process by 50 from the baseline

Phase 1 Phase 2 Phase 3

Processes amp

sub processes

Potential

Failure modes

Potential

Causes

Potential Effects

Seve

rity

Sco

re

Pro

bab

ility

Sco

re

Haz

ard

sco

re

Recommended Actions Responsibility

and target date

Seve

rity

Sco

re

Pro

bab

ility

Sco

re

Haz

ard

sco

re

1 Process

11 Sub-process

12 Sub-process

13 Sub-process

14 Sub-process

15 Sub-process

2 Process

21 Sub-process

22 Sub-process

23 Sub-process

24 Sub-process

25 Sub-process

COMMON MISTAKES IN FMEA

The quality department is the owner of FMEA

The wrong people are selected to participate in the

sessions of FMEA inadequate team composition

The FMEA are done at a wrong time

The FMEA provides the wrong level of detail

(missing the high risk areas or the root causes)

Failure to drive any design or process improvement

Failure to address all high risk failure modes

Failure to produce action and control plans

Improper FMEA procedure

Lack of efficient use of time in the meetings

ADDITIONAL RESOURCES

Please Visit the Institute for Healthcare

Improvement (IHI) Website to see an

interactive FMEA Tool available on IHIorg

PREVENTIVE MEDICINE IS

LESS COSTLY THAN

CURATIVE MEDICINE

REFERENCES

Institute for Healthcare Improvement 2004 Failure Modes and Effects Analysis

(FMEA)

Kimchi-Woods J Shultz J (2006) Using HFMEA to Assess Potential for Patient

Harm from Tubing Misconnections Journal on quality and patient safety 32 (7) 373-

381

Kathy Ouellette-Piazzo K Asfaw M amp Cowen J (2007) CT Healthcare Failure

Mode Effect Analysis (HFMEAreg) The Misadministration of IV Contrast in

Outpatients Radiology management 29 (1) 36-44

Ashley L Dexter R Marshall F McKenzie B Ryan M amp Armitage G (2011)

Improving the Safety of Chemotherapy Administration An Oncology Nurse-Led

Failure Mode and Effects Analysis Oncology Nursing Forum 38 (6) E436 ndash E444

STEELMAN M amp CULLEN J (2011) Designing a Safer Process to Prevent

Retained Surgical Sponges A Healthcare Failure Mode and Effect Analysis AORN

Journal 94 (2) 132-141

Cronrath P Lynch TW Gilson LJ Nishida C Sembar MC Spencer PJ West DF

(2011) PCA oversedation application of Healthcare Failure Mode Effect (HFMEA)

Analysis Nursing economics 29(2) 79-87

Cheng C Chou CH Wang PC Lin HY Kao CL Su CT (2012) Applying

HFMEA to Prevent Chemotherapy Errors Journal of medical systems 36 1543-

1551

Chandonnet C Kahlon P Rachh P DeGrazia M DeWitt E Flaherty K

Spigel N Packard S Casey D Rachwal C Agrawal P (2013) Health Care

Failure Mode and Effect Analysis to Reduce NICU LinendashAssociated Bloodstream

Infections Pediatrics 131(6) 1961-1969

WHAT COULD GO WRONG

WHAT COULD GO

WRONG

Medication Prescription

Surgical procedure

Blood transfusion

FAILURE MODES AND EFFECTS ANALYSIS

Failure Modes

The ways or modes in which something might fail

It is a concise description of how a part of a process

may potentially fail to perform its functions

( Prescription errors wrong dose route or infusion time

Proper patient monitoring not ordered Prescribed on wrong patient No order received Illegible writing )

Effect Analysis

Studying the consequences of those failures

Failures are prioritized according to its frequency

and seriousness

DEFINITION

Failure Modes and Effects Analysis (FMEA)

is a systematic proactive method for evaluating a

process to identify where and how it might fail

and to assess the relative impact of different

failures in order to identify the parts of the

process that are most in need of change

(Institute of Healthcare Improvement 2004)

Preventing problems is cheaper and easier than

cleaning them up

WHAT IF YOU

STOPPED

GOING

OUTSIDE

BENEFITS

Get it right the first time

Identify any inadequacies in the process

Continuous improvement

Team building

Reduce the likelihood of complications

Reduce maintenance costs

Reduce the possibility of safety failures

Greater customer satisfaction and reduced

complaints

WHEN TO USE FMEA

FMEA should be used

at the conceptual stage

when changes are made to the design

when new regulations are instituted

when customer feedback indicates a problem

HISTORY OF FMEA Developed in the US Military 1949 titled Procedures for

Performing a Failure Mode Effects and Criticality Analysis Failures were classified according to their impact on mission success and

personnelequipment safety

Formally developed and applied by NASA in the 1960rsquos to improve

and verify reliability of space program hardware during the Apollo

program

Initial automotive adoption (Ford)

in the 1970rsquos

Automotive Industry Action Group and

American Society for Quality Control

copyright standards in 1993

Now adopted by many other industries

FMEA IN THE LITERATURE

2006

FMEA IN THE LITERATURE

2007

FMEA IN THE LITERATURE

2011

FMEA IN THE LITERATURE

2011

FMEA IN THE LITERATURE

2011

PCA Over-sedation Application Of

Healthcare Failure Mode Effect Analysis

(HFMEAtrade)

Pam Cronrath MN RN Timothy W Lynch PharmD MS FABC Linda J Gilson BSN RN

CAPA Carol Nishida BSN RN CMSRN M Colleen Sembar MSM BSN RN CCRN Patricia J

Spencer BSN RN BC ONC Daidre Foote West BSN RN CPUM

The changes implemented identified 16 failure

points with a hazard score of 16 or greater One

year later the established system HFMEA goal

was met Reduce oversedation events by 50

fiscal year end 2008

FMEA IN THE LITERATURE

2012

FMEA IN THE LITERATURE

2013 - ONLINE

Health Care Failure Mode and Effect Analysis to Reduce NICU LinendashAssociated Bloodstream Infections

Celeste J Chandonnet RN BSN CCRNabPrerna S Kahlon BDS MPAH CPHQc Pratik Rachh MD MBA CQPA CPHQd Michele DeGrazia PhD RN NNP-BCabe Eileen C DeWitt RNC MS NNP-BCab Kathleen A Flaherty MT(ASCP) BS CICab Nadine Spigel RN BSN CCRNab Stephanie Packard RN BSN CCRNab Denise Casey MS RN CCRN CPNPab Christine Rachwal MSN RN CCRNab and Pankaj B Agrawal MD MMSCace

Since implementing the appropriate action plans the NICU has experienced a significant decrease in CLABSIs from 26 to 08 CLABSIs per 1000 line days

The process of HFMEA helped reduce the CLABSI rate and reinforce the culture of continuous quality improvement and safety in the NICU

WHAT DOES FMEA INCLUDE

FMEA includes review of the following

Steps in the process

Failure modes (What could go wrong)

Failure causes (Why would the failure happen)

Failure effects (What would be the consequences

of each failure)

STEPS OF FMEA

1 Select a process to evaluate with FMEA

2 Recruit a multidisciplinary team

3 Review the process

4 List failure modes and causes and its effect on

patients

5 Assign Risk Code

6 Evaluate the results

7 Create actions to reduce risks

8 Assign responsibility for actions

9 Re-assign risk codes (residual risk)

10 Monitor the actions and risk reduction

STEP 1

SELECT A PROCESS TO EVALUATE WITH FMEA

Evaluation using FMEA works best on processes that do not have too many sub processes

Instead of doing FMEA on a large and complex process such as medication management in a hospital try doing an FMEA on sub processes like medication ordering dispensing or administration processes

Select processes with high risk high cost high volume or with wide variation in practice

Process Medication prescription by the physician

STEP 2

RECRUIT A MULTIDISCIPLINARY TEAM

Be sure to include everyone who is involved at any point in the process

Some people may not need to be part of the team throughout the entire analysis but they should certainly be included in discussions of those steps in the process in which they are involved

For example if you want to evaluate VAP prevention you will include pulmonologists respiratory therapy infection control pharmacy nursing

Process Medication prescription by the physician

Team Physician nursing pharmacy

STEP 3

REVIEW THE PROCESS

It may take several meetings for the team to complete

this part of the FMEA depending on the number of

steps and the complexity of the process

Flowcharting can be a helpful tool for outlining the

steps

When you are finished be sure to obtain consensus

from the group

The team should agree that the steps enumerated in

the FMEA accurately describe the process

GRAPHICAL REPRESENTATION

Medication Management

1 Prescription 11 Physician checks results

12 Physician prescribes medication

2 Dispensing

21 Send order to pharmacy

22 Enter order into computer

23 Produce label

24 Prepare medication

25 Check medication before distribution

26 Deliver medication to the units

3 Administration

31 Receive order and transcribe onto medication record

32 Obtain infusion pump

33 Obtain medication

34 Program infusion pump

35 Check medicaition pump settings before administration

36 Administer medication

37 Document administration

38 Monitor side effects adverse events

4 Laboratory Monitoring

41 Laboratory request

42 Serum blood sample

43 label sample

44 Send to the laboratory

45 Checking results by nurses

STEP 4

LIST FAILURE MODES AND CAUSES AND ITS

EFFECT ON PATIENTS

For each step in the process list all possible

―failure modesmdashthat is anything that could go

wrong including minor and rare problems

For each failure mode listed identify all possible

causes

Then for each failure mode listed identify all

possible effects

Sub process Failure Modes Failure causes Failure Effect

Physician

prescribes

medication

Wrong dose route

or infusion time

(fast slow)

Clinical situation not

considered (age renal and

endocrine functions

allergy seizures cardiac

rhythm) concomitant use

of oral drugs knowledge

deficit mental slip

information on drug not

available

Overdose under-dose

improper route

selection ADR allergic

response prolonged

infusion time leads to

delay in therapy very

fast infusion leads to

side effects

Proper patient

monitoring not

ordered

Knowledge deficit mental

slip

Failure to detect

problems early to

prevent harm

Prescribed on

wrong patient

Similar patient names

patient identifier not

clear no identifier

verification

Wrong patient receives

inappropriate drug and

dose ADR allergic

response

No order received Unable to reach on call

physician

Poor patient

management

Illegible writing

(use abbreviations

unclear hand

writing )

Knowledge deficit mental

slip no list of approved

abbreviations

Wrong drug Overdose

under-dose improper

route selection ADR

allergic response delay

in treatment

STEP 5

ASSIGN RISK CODE

Risk Code = Severity X Occurrence

Severity (1= Minimum 5 = Serious)

If this failure mode occurs how likely is it that

harm will occur

Probability of occurrence (1 = Rare 5 = Frequent)

How likely is it that this failure mode will occur

5 X 5 HAZARD SCORING MATRIX

Failure modes with higher hazard scores should

receive the highest priority

Severity

Probability Serious

(5)

Major

(4)

Moderate

(3)

Minor

(2)

Minimum

(1)

Frequent (5) 25 20 15 10 5

Likely (4) 20 16 12 8 4

Possible (3) 15 12 9 6 3

Unlikely (2) 10 8 6 4 2

Rare (1) 5 4 3 2 1

Sub process Failure Modes Failure causes Failure Effect S P Hazard

Physician

prescribes

medication

Wrong dose route

or infusion time

(fast slow)

Clinical situation not

considered (age renal

and endocrine

functions allergy

seizures cardiac

rhythm) concomitant

use of oral drugs

knowledge deficit

mental slip information

on drug not available

Overdose under-

dose improper route

selection ADR

allergic response

prolonged infusion

time leads to delay in

therapy very fast

infusion leads to side

effects

4 4 16

Proper patient

monitoring not

ordered

Knowledge deficit

mental slip

Failure to detect

problems early to

prevent harm

4 3 12

Prescribed on

wrong patient

Similar patient names

patient identifier not

clear no identifier

verification

Wrong patient

receives

inappropriate drug

and dose ADR

allergic response

3 2 6

No order received Unable to reach on call

physician

Poor patient

management

2 2 4

Illegible writing

(use

abbreviations

unclear hand

writing )

Knowledge deficit

mental slip no list of

approved abbreviations

Wrong drug

Overdose under-

dose improper route

selection ADR

allergic response

delay in treatment

4 4 16

STEP 6

EVALUATE THE RESULTS

Hazard scores

1= Low risk 25 = Extreme risk

Failure modes with higher hazard scores should

receive the highest priority and should trigger

consideration of potential action to control the

failure

These are the ones the team should consider first

as improvement opportunities

STEP 7

CREATE ACTIONS TO REDUCE RISKS

Evaluate the causes and see if any or all of them

can be eliminated

Modify other processes that contribute to causes

Actions Control Measures

1 Engineering structural control

(Reconstruction anti slippery floors hood)

2 Administrative changes

(policies protocols job descriptions)

Sub process Failure Modes Failure causes Failure Effect S P Hazard Actions

Physician

prescribes

medication

Wrong dose

route or infusion

time (fast slow)

Clinical situation not

considered (age renal

and endocrine

functions allergy

seizures cardiac

rhythm) concomitant

use of oral drugs

knowledge deficit

mental slip

information on drug

not available

Overdose under-

dose improper route

selection ADR

allergic response

prolonged infusion

time leads to delay in

therapy very fast

infusion leads to side

effects

4 4 16 Clinical pharmacy

program pre-printed

medications protocol

with education on

use easy access to

drug information

feedback mechanism

on substitute drugs

available

Proper patient

monitoring not

ordered

Knowledge deficit

mental slip

Failure to detect

problems early to

prevent harm

4 3 12 pre-printed

medication protocols

with monitoring

guidelines

Prescribed on

wrong patient

Similar patient names

patient identifier not

clear no identifier

verification

Wrong patient

receives

inappropriate drug

and dose ADR

allergic response

3 2 6 Match result to

patient condition

alert for a look-alike

patient names visible

demographics on

identifier

No order

received

Unable to reach on call

physician

Poor patient

management

2 2 4 Proper physician

coverage and

communication

channels

Illegible writing

(use

abbreviations

unclear hand

writing )

Knowledge deficit

mental slip no list of

approved

abbreviations

Wrong drug

Overdose under-

dose improper route

selection ADR

allergic response

delay in treatment

4 4 16 pre-printed

medication protocol

Health Information

Systems list of

approved

abbreviations

STEP 8

ASSIGN RESPONSIBILITY FOR ACTIONS

Assign responsibilities for implementing the

corrective and preventive actions

Set timelines determine the project completion

dates

STEP 9

RE-ASSIGN RISK CODES (RESIDUAL RISK)

Determine what is the risk code after

implementing the actions for each failure mode

The aim is to assist the team in prioritizing

actions and to determine if actions were effective

or not

Sub process Failure Modes Failure causes Failure Effect S P Hazard Actions Responsibility S P Hazard

Physician

prescribes

medication

Wrong dose

route or

infusion time

(fast slow)

Clinical situation

not considered

(age renal and

endocrine

functions allergy

seizures cardiac

rhythm)

concomitant use of

oral drugs

knowledge deficit

mental slip

information on

drug not available

Overdose under-

dose improper

route selection

ADR allergic

response

prolonged

infusion time

leads to delay in

therapy very fast

infusion leads to

side effects

4 4 16 Clinical pharmacy

program pre-

printed

medications

protocol with

education on use

easy access to

drug information

feedback

mechanism on

substitute drugs

available

XXXXXXX 2 2 4

Proper

patient

monitoring

not ordered

Knowledge deficit

mental slip

Failure to detect

problems early to

prevent harm

4 3 12 pre-printed

medication

protocols with

monitoring

guidelines

XXXXXXX 2 3 6

Prescribed on

wrong patient

Similar patient

names patient

identifier not clear

no identifier

verification

Wrong patient

receives

inappropriate

drug and dose

ADR allergic

response

3 2 6 Match result to

patient condition

alert for a look-

alike patient

names visible

demographics on

identifier

XXXXXXX 1 1 1

No order

received

Unable to reach on

call physician

Poor patient

management 2 2 4 Proper physician

coverage and

communication

channels

XXXXXXX 1 1 1

Illegible

writing (use

abbreviations

unclear

hand writing)

Knowledge deficit

mental slip no list

of approved

abbreviations

Wrong drug

Overdose under-

dose improper

route selection

ADR allergic

response delay

in treatment

4 4 16 pre-printed

medication

protocol Health

Information

Systems list of

approved

abbreviations

XXXXXXX 3 4 12

STEP 10

MONITOR THE ACTIONS AND RISK REDUCTION

Monitor to evaluate if the risk reduction

strategies have reduced risk and take additional

actions if necessary to further reduce risk

USES OF FMEA

Use FMEA to plan actions to reduce harm from failure modes

Use FMEA to evaluate the potential impact of changes under consideration ( check the residual risk code)

Use FMEA to monitor and track improvement over time by calculating a risk code for the process and then set a goal for improvement

For example a team may set a goal of decreasing the risk code for the medication ordering process by 50 from the baseline

Phase 1 Phase 2 Phase 3

Processes amp

sub processes

Potential

Failure modes

Potential

Causes

Potential Effects

Seve

rity

Sco

re

Pro

bab

ility

Sco

re

Haz

ard

sco

re

Recommended Actions Responsibility

and target date

Seve

rity

Sco

re

Pro

bab

ility

Sco

re

Haz

ard

sco

re

1 Process

11 Sub-process

12 Sub-process

13 Sub-process

14 Sub-process

15 Sub-process

2 Process

21 Sub-process

22 Sub-process

23 Sub-process

24 Sub-process

25 Sub-process

COMMON MISTAKES IN FMEA

The quality department is the owner of FMEA

The wrong people are selected to participate in the

sessions of FMEA inadequate team composition

The FMEA are done at a wrong time

The FMEA provides the wrong level of detail

(missing the high risk areas or the root causes)

Failure to drive any design or process improvement

Failure to address all high risk failure modes

Failure to produce action and control plans

Improper FMEA procedure

Lack of efficient use of time in the meetings

ADDITIONAL RESOURCES

Please Visit the Institute for Healthcare

Improvement (IHI) Website to see an

interactive FMEA Tool available on IHIorg

PREVENTIVE MEDICINE IS

LESS COSTLY THAN

CURATIVE MEDICINE

REFERENCES

Institute for Healthcare Improvement 2004 Failure Modes and Effects Analysis

(FMEA)

Kimchi-Woods J Shultz J (2006) Using HFMEA to Assess Potential for Patient

Harm from Tubing Misconnections Journal on quality and patient safety 32 (7) 373-

381

Kathy Ouellette-Piazzo K Asfaw M amp Cowen J (2007) CT Healthcare Failure

Mode Effect Analysis (HFMEAreg) The Misadministration of IV Contrast in

Outpatients Radiology management 29 (1) 36-44

Ashley L Dexter R Marshall F McKenzie B Ryan M amp Armitage G (2011)

Improving the Safety of Chemotherapy Administration An Oncology Nurse-Led

Failure Mode and Effects Analysis Oncology Nursing Forum 38 (6) E436 ndash E444

STEELMAN M amp CULLEN J (2011) Designing a Safer Process to Prevent

Retained Surgical Sponges A Healthcare Failure Mode and Effect Analysis AORN

Journal 94 (2) 132-141

Cronrath P Lynch TW Gilson LJ Nishida C Sembar MC Spencer PJ West DF

(2011) PCA oversedation application of Healthcare Failure Mode Effect (HFMEA)

Analysis Nursing economics 29(2) 79-87

Cheng C Chou CH Wang PC Lin HY Kao CL Su CT (2012) Applying

HFMEA to Prevent Chemotherapy Errors Journal of medical systems 36 1543-

1551

Chandonnet C Kahlon P Rachh P DeGrazia M DeWitt E Flaherty K

Spigel N Packard S Casey D Rachwal C Agrawal P (2013) Health Care

Failure Mode and Effect Analysis to Reduce NICU LinendashAssociated Bloodstream

Infections Pediatrics 131(6) 1961-1969

WHAT COULD GO

WRONG

Medication Prescription

Surgical procedure

Blood transfusion

FAILURE MODES AND EFFECTS ANALYSIS

Failure Modes

The ways or modes in which something might fail

It is a concise description of how a part of a process

may potentially fail to perform its functions

( Prescription errors wrong dose route or infusion time

Proper patient monitoring not ordered Prescribed on wrong patient No order received Illegible writing )

Effect Analysis

Studying the consequences of those failures

Failures are prioritized according to its frequency

and seriousness

DEFINITION

Failure Modes and Effects Analysis (FMEA)

is a systematic proactive method for evaluating a

process to identify where and how it might fail

and to assess the relative impact of different

failures in order to identify the parts of the

process that are most in need of change

(Institute of Healthcare Improvement 2004)

Preventing problems is cheaper and easier than

cleaning them up

WHAT IF YOU

STOPPED

GOING

OUTSIDE

BENEFITS

Get it right the first time

Identify any inadequacies in the process

Continuous improvement

Team building

Reduce the likelihood of complications

Reduce maintenance costs

Reduce the possibility of safety failures

Greater customer satisfaction and reduced

complaints

WHEN TO USE FMEA

FMEA should be used

at the conceptual stage

when changes are made to the design

when new regulations are instituted

when customer feedback indicates a problem

HISTORY OF FMEA Developed in the US Military 1949 titled Procedures for

Performing a Failure Mode Effects and Criticality Analysis Failures were classified according to their impact on mission success and

personnelequipment safety

Formally developed and applied by NASA in the 1960rsquos to improve

and verify reliability of space program hardware during the Apollo

program

Initial automotive adoption (Ford)

in the 1970rsquos

Automotive Industry Action Group and

American Society for Quality Control

copyright standards in 1993

Now adopted by many other industries

FMEA IN THE LITERATURE

2006

FMEA IN THE LITERATURE

2007

FMEA IN THE LITERATURE

2011

FMEA IN THE LITERATURE

2011

FMEA IN THE LITERATURE

2011

PCA Over-sedation Application Of

Healthcare Failure Mode Effect Analysis

(HFMEAtrade)

Pam Cronrath MN RN Timothy W Lynch PharmD MS FABC Linda J Gilson BSN RN

CAPA Carol Nishida BSN RN CMSRN M Colleen Sembar MSM BSN RN CCRN Patricia J

Spencer BSN RN BC ONC Daidre Foote West BSN RN CPUM

The changes implemented identified 16 failure

points with a hazard score of 16 or greater One

year later the established system HFMEA goal

was met Reduce oversedation events by 50

fiscal year end 2008

FMEA IN THE LITERATURE

2012

FMEA IN THE LITERATURE

2013 - ONLINE

Health Care Failure Mode and Effect Analysis to Reduce NICU LinendashAssociated Bloodstream Infections

Celeste J Chandonnet RN BSN CCRNabPrerna S Kahlon BDS MPAH CPHQc Pratik Rachh MD MBA CQPA CPHQd Michele DeGrazia PhD RN NNP-BCabe Eileen C DeWitt RNC MS NNP-BCab Kathleen A Flaherty MT(ASCP) BS CICab Nadine Spigel RN BSN CCRNab Stephanie Packard RN BSN CCRNab Denise Casey MS RN CCRN CPNPab Christine Rachwal MSN RN CCRNab and Pankaj B Agrawal MD MMSCace

Since implementing the appropriate action plans the NICU has experienced a significant decrease in CLABSIs from 26 to 08 CLABSIs per 1000 line days

The process of HFMEA helped reduce the CLABSI rate and reinforce the culture of continuous quality improvement and safety in the NICU

WHAT DOES FMEA INCLUDE

FMEA includes review of the following

Steps in the process

Failure modes (What could go wrong)

Failure causes (Why would the failure happen)

Failure effects (What would be the consequences

of each failure)

STEPS OF FMEA

1 Select a process to evaluate with FMEA

2 Recruit a multidisciplinary team

3 Review the process

4 List failure modes and causes and its effect on

patients

5 Assign Risk Code

6 Evaluate the results

7 Create actions to reduce risks

8 Assign responsibility for actions

9 Re-assign risk codes (residual risk)

10 Monitor the actions and risk reduction

STEP 1

SELECT A PROCESS TO EVALUATE WITH FMEA

Evaluation using FMEA works best on processes that do not have too many sub processes

Instead of doing FMEA on a large and complex process such as medication management in a hospital try doing an FMEA on sub processes like medication ordering dispensing or administration processes

Select processes with high risk high cost high volume or with wide variation in practice

Process Medication prescription by the physician

STEP 2

RECRUIT A MULTIDISCIPLINARY TEAM

Be sure to include everyone who is involved at any point in the process

Some people may not need to be part of the team throughout the entire analysis but they should certainly be included in discussions of those steps in the process in which they are involved

For example if you want to evaluate VAP prevention you will include pulmonologists respiratory therapy infection control pharmacy nursing

Process Medication prescription by the physician

Team Physician nursing pharmacy

STEP 3

REVIEW THE PROCESS

It may take several meetings for the team to complete

this part of the FMEA depending on the number of

steps and the complexity of the process

Flowcharting can be a helpful tool for outlining the

steps

When you are finished be sure to obtain consensus

from the group

The team should agree that the steps enumerated in

the FMEA accurately describe the process

GRAPHICAL REPRESENTATION

Medication Management

1 Prescription 11 Physician checks results

12 Physician prescribes medication

2 Dispensing

21 Send order to pharmacy

22 Enter order into computer

23 Produce label

24 Prepare medication

25 Check medication before distribution

26 Deliver medication to the units

3 Administration

31 Receive order and transcribe onto medication record

32 Obtain infusion pump

33 Obtain medication

34 Program infusion pump

35 Check medicaition pump settings before administration

36 Administer medication

37 Document administration

38 Monitor side effects adverse events

4 Laboratory Monitoring

41 Laboratory request

42 Serum blood sample

43 label sample

44 Send to the laboratory

45 Checking results by nurses

STEP 4

LIST FAILURE MODES AND CAUSES AND ITS

EFFECT ON PATIENTS

For each step in the process list all possible

―failure modesmdashthat is anything that could go

wrong including minor and rare problems

For each failure mode listed identify all possible

causes

Then for each failure mode listed identify all

possible effects

Sub process Failure Modes Failure causes Failure Effect

Physician

prescribes

medication

Wrong dose route

or infusion time

(fast slow)

Clinical situation not

considered (age renal and

endocrine functions

allergy seizures cardiac

rhythm) concomitant use

of oral drugs knowledge

deficit mental slip

information on drug not

available

Overdose under-dose

improper route

selection ADR allergic

response prolonged

infusion time leads to

delay in therapy very

fast infusion leads to

side effects

Proper patient

monitoring not

ordered

Knowledge deficit mental

slip

Failure to detect

problems early to

prevent harm

Prescribed on

wrong patient

Similar patient names

patient identifier not

clear no identifier

verification

Wrong patient receives

inappropriate drug and

dose ADR allergic

response

No order received Unable to reach on call

physician

Poor patient

management

Illegible writing

(use abbreviations

unclear hand

writing )

Knowledge deficit mental

slip no list of approved

abbreviations

Wrong drug Overdose

under-dose improper

route selection ADR

allergic response delay

in treatment

STEP 5

ASSIGN RISK CODE

Risk Code = Severity X Occurrence

Severity (1= Minimum 5 = Serious)

If this failure mode occurs how likely is it that

harm will occur

Probability of occurrence (1 = Rare 5 = Frequent)

How likely is it that this failure mode will occur

5 X 5 HAZARD SCORING MATRIX

Failure modes with higher hazard scores should

receive the highest priority

Severity

Probability Serious

(5)

Major

(4)

Moderate

(3)

Minor

(2)

Minimum

(1)

Frequent (5) 25 20 15 10 5

Likely (4) 20 16 12 8 4

Possible (3) 15 12 9 6 3

Unlikely (2) 10 8 6 4 2

Rare (1) 5 4 3 2 1

Sub process Failure Modes Failure causes Failure Effect S P Hazard

Physician

prescribes

medication

Wrong dose route

or infusion time

(fast slow)

Clinical situation not

considered (age renal

and endocrine

functions allergy

seizures cardiac

rhythm) concomitant

use of oral drugs

knowledge deficit

mental slip information

on drug not available

Overdose under-

dose improper route

selection ADR

allergic response

prolonged infusion

time leads to delay in

therapy very fast

infusion leads to side

effects

4 4 16

Proper patient

monitoring not

ordered

Knowledge deficit

mental slip

Failure to detect

problems early to

prevent harm

4 3 12

Prescribed on

wrong patient

Similar patient names

patient identifier not

clear no identifier

verification

Wrong patient

receives

inappropriate drug

and dose ADR

allergic response

3 2 6

No order received Unable to reach on call

physician

Poor patient

management

2 2 4

Illegible writing

(use

abbreviations

unclear hand

writing )

Knowledge deficit

mental slip no list of

approved abbreviations

Wrong drug

Overdose under-

dose improper route

selection ADR

allergic response

delay in treatment

4 4 16

STEP 6

EVALUATE THE RESULTS

Hazard scores

1= Low risk 25 = Extreme risk

Failure modes with higher hazard scores should

receive the highest priority and should trigger

consideration of potential action to control the

failure

These are the ones the team should consider first

as improvement opportunities

STEP 7

CREATE ACTIONS TO REDUCE RISKS

Evaluate the causes and see if any or all of them

can be eliminated

Modify other processes that contribute to causes

Actions Control Measures

1 Engineering structural control

(Reconstruction anti slippery floors hood)

2 Administrative changes

(policies protocols job descriptions)

Sub process Failure Modes Failure causes Failure Effect S P Hazard Actions

Physician

prescribes

medication

Wrong dose

route or infusion

time (fast slow)

Clinical situation not

considered (age renal

and endocrine

functions allergy

seizures cardiac

rhythm) concomitant

use of oral drugs

knowledge deficit

mental slip

information on drug

not available

Overdose under-

dose improper route

selection ADR

allergic response

prolonged infusion

time leads to delay in

therapy very fast

infusion leads to side

effects

4 4 16 Clinical pharmacy

program pre-printed

medications protocol

with education on

use easy access to

drug information

feedback mechanism

on substitute drugs

available

Proper patient

monitoring not

ordered

Knowledge deficit

mental slip

Failure to detect

problems early to

prevent harm

4 3 12 pre-printed

medication protocols

with monitoring

guidelines

Prescribed on

wrong patient

Similar patient names

patient identifier not

clear no identifier

verification

Wrong patient

receives

inappropriate drug

and dose ADR

allergic response

3 2 6 Match result to

patient condition

alert for a look-alike

patient names visible

demographics on

identifier

No order

received

Unable to reach on call

physician

Poor patient

management

2 2 4 Proper physician

coverage and

communication

channels

Illegible writing

(use

abbreviations

unclear hand

writing )

Knowledge deficit

mental slip no list of

approved

abbreviations

Wrong drug

Overdose under-

dose improper route

selection ADR

allergic response

delay in treatment

4 4 16 pre-printed

medication protocol

Health Information

Systems list of

approved

abbreviations

STEP 8

ASSIGN RESPONSIBILITY FOR ACTIONS

Assign responsibilities for implementing the

corrective and preventive actions

Set timelines determine the project completion

dates

STEP 9

RE-ASSIGN RISK CODES (RESIDUAL RISK)

Determine what is the risk code after

implementing the actions for each failure mode

The aim is to assist the team in prioritizing

actions and to determine if actions were effective

or not

Sub process Failure Modes Failure causes Failure Effect S P Hazard Actions Responsibility S P Hazard

Physician

prescribes

medication

Wrong dose

route or

infusion time

(fast slow)

Clinical situation

not considered

(age renal and

endocrine

functions allergy

seizures cardiac

rhythm)

concomitant use of

oral drugs

knowledge deficit

mental slip

information on

drug not available

Overdose under-

dose improper

route selection

ADR allergic

response

prolonged

infusion time

leads to delay in

therapy very fast

infusion leads to

side effects

4 4 16 Clinical pharmacy

program pre-

printed

medications

protocol with

education on use

easy access to

drug information

feedback

mechanism on

substitute drugs

available

XXXXXXX 2 2 4

Proper

patient

monitoring

not ordered

Knowledge deficit

mental slip

Failure to detect

problems early to

prevent harm