Fabrication of polyaniline nanofiber via electrospinning for the development of carbon monoxide...

-

Upload

university-of-the-philippines-los-banos -

Category

Documents

-

view

542 -

download

1

description

Transcript of Fabrication of polyaniline nanofiber via electrospinning for the development of carbon monoxide...

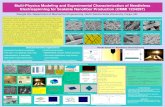

A TERMINAL REPORT

Office of the Vice Chancellor for Research and Extension Building

February 23, 2011, 8:30AM

forging the foundations for the future

Fabrication of Polyaniline

Nanofiber via Electrospinning

for the Development of

Carbon Monoxide Sensor

People

Project leader Marvin U. Herrera

Proponent IMSP IC

Prof. Emmanuel A. Florido

Ms. Melody Joy Gamboa

Ms. Diane Denise Tabernilla

Mr. Francis Emralino

Mr. John Cerry dela Rosa

Dr. Ernesto J. del Rosario, Jr.

Mr. Jesse Cervantes

Materials Physics Laboratory, Physics Division

Institute of Mathematical Sciences and Physicson study leave for PhD at Kyoto University

Funding Details

Implementing Unit Institute of Mathematical Sciences and Physics

Cooperating Unit Institute of Chemistry

Funding Source PCASTRD Fellowship Grant

Project Duration February 1, 2009 to January 31, 2010

Total Budget PhP 500,000.00

WALKTHROUGHPolyaniline Nanofiber via Electrospinning for the Development of Carbon Monoxide Sensor

A Terminal Report

PANI SYNTHESIS

STUDIES

PEOPLE/FUND

SPINNER eSPUN FIBERS

WB-type CHEMISTOR

V

Resistor 1

Resistor 2

PANI fiber

Resistor 3

power supply

ABSTRACTA WheatstoneBridge-type

chemistor was fabricated to

measure the sensitivty of

electrospun PANI fiber.

Several electrospinning

parameters were varied to

produce fibers with nanometer

diameter. Fiber morphology

and composition were

analyzed as parameters were

adjusted.

AbstractDevelopment of a Wheatstone Bridge-type Chemistor

Characterization of electrospun fibers

Fabrication of electrospinning set-up

PANI synthesis

Abstract

syringe pump

PANI synthesis

Development of a Wheatstone Bridge-type Chemistor

Characterization of electrospun fibers

Fabrication of electrospinning set-up

syringe

aluminum foil (anode)

needle (cathode)

DC power supply

AbstractFabrication of electrospinning set-up

Characterization of electrospun fibers

Development of a Wheatstone Bridge-type Chemistor

V

Resistor 1

Resistor 2

PANI fiber

Resistor 3

power supply

AbstractFabrication of electrospinning set-up

Development of a Wheatstone Bridge-type Chemistor

Characterization of electrospun fibers

Pictures insert here

PANI synthesis

Polyaniline-emeraldine was synthesized following standard oxidative

polymerization by Stejskal (2005).

APS

aniline HClO4mixed while in ice bath

added dropwise

polyaniline solution

stored under 4oC

washed

filtered

vacuum dried

PANI powder

The Spinner

Custom-built vertical electrospinning set-up

The Spinner

Syringe pump

The syringe pump controls the flow rate being

ejected from the needle.

INSERT UNIT

The Spinner

Syringe

Contained in the syringe was the solution of certain

concentration. Needle gauge was chosen so as to

produce the desired fiber diameter. The needle

was connected to the positive terminal of the

power supply.

The Spinner

Collector

The collector used in the study is a commercially

available aluminum foil. This allowed the

researchers flexibility in setting the area for

collection of electrospun fibers. It also gave ease in

extraction/harvesting of fibers. The aluminum foil

served as ground which was connected to the

negative terminal of the high power supply.

The Spinner

Collector holder

To vary the distance between electrodes (needle

tip and collector), the aluminum foil was fixed to an

adjustable holder. The holder could be translated

along the vertical position.

The Spinner

Power supply

A high voltage power supply (AHV 100) was utilized

in the study. The instrument is capable of providing

constant voltage supply from 0 to 100kV.

The Spinner

Stand

The stand supports the components described

earlier into place. It is made of wood to prevent

short circuiting and unwanted random deposition of

fibers onto it.

The Spinner

Cover

A plastic sheet for safety covers the entire anode-

cathode system. It contains off-course fibers from

flying off. This also prevented accidental contact

with the electrodes while running an experiment.

The Spinner and its parameters

Parameters varied

1.voltage

2. tip to collector distance

3.viscosity

Wheatstone Bridge-Type Chemistor

V

Resistor 1

Resistor 2

PANI fiber

Resistor 3

power supply

Schematic diagram of Wheatstone bridge-type chemiresistor

Wheatstone Bridge-Type Chemistor

V

Variable resistors

Three variable resistors (R1, R2, and R3) along with the

PANI fiber were connected to form a Wheatstone bridge.

The resistances were adjusted to balance the bridge.

Voltage across the bridge was measured using a high

precision nanovoltmeter (Keithley).

Wheatstone Bridge-Type Chemistor

Power supply

A constant dc voltage (Keithley 2410C) is supplied

across the bridge.

Wheatstone Bridge-Type Chemistor

Chemiresistor

Electrospun PAni fibers fixed on an interdigitated

copper tracks.

etch PCB

Interdigitated circuit

fix e-spun pani

Wheatstone Bridge-Type Chemistor

Sensing

Gas chamber

to the bridge and voltmeter

CO generator

valve

reaction chamber

Electrospun PAni fibers fixed on an

interdigitated copper tracks.

Wheatstone Bridge-Type Chemistor

Sensing

Electrospun PAni fibers fixed on an

interdigitated copper tracks.

Voltage difference before and during

exposure to CO is measured across the

bridge.

Sensitivity of the device is determined

following

S = |VCO-Vi| / Vi X 100%

VCO voltage across the bridge in the

presence of CO

Vi voltage before exposure

S sensitivity

Gas chamber

to the bridge and voltmeter

CO generator

valve

static gas chamber

Electrospun Fibers

Electrospinning

PAni powder were dissolved in NMP were mixed with different polymers (i.e. PVC, PVAc).

Binder Solvent Mixture (volume) Stirring time

PANI:binder

polyvinyl acetate none varied 20-30 minutes

polyvinyl chloride tetrahydrofuran 1:2 10 minutes

Elastomer none 1:1 ~

Electrospun Fibers

Morphology

PAni-PVC PAni-PVAc Pani-elastomer

Scanning electron microscope images of composite fibers.

Electrospun Fibers

Morphology: Electrode voltage and fiber diameter of Pani-elastomer

Electrospun Fibers

Morphology: Electrode distance, solution conductivity, and

fiber diameter of PAni-PVC

Electrospun Fibers

Morphology: Viscosity and fiber diameter of PAni-PVAc

Electrospun Fibers

Sensitivity: Solution conductivity and sensitivity

FIBER 1

FIBERS

high fiber gap suggests high barrier gap prevents conduction

Active material Pani-EB Pani-ES

CO sensitivity (%) 93.45 29.72

Standard deviation 8.10 1.31

|Stdev/Sensivity| (%) 8.67 4.40

FIBER 1

FIBERS

Electrospun Fibers

Sensitivity: Solution conductivity and sensitivity

Active material Pani-EB Pani-ES

CO sensitivity (%) 93.45 29.72

Standard deviation 8.10 1.31

|Stdev/Sensivity| (%) 8.67 4.40

COCO

COCO

CO CO

COCO

CO

CO

COCO

COCO

CO

CO CO

COCO

CO

CO

CO “connects” the fibers thus changing the bulk electric resistance

FIBER 1

FIBERS

Electrospun Fibers

Sensitivity: Solution conductivity and sensitivity

Active material Pani-EB Pani-ES

CO sensitivity (%) 93.45 29.72

Standard deviation 8.10 1.31

|Stdev/Sensivity| (%) 8.67 4.40

COCO

COCO

CO CO

COCO

CO

CO

COCO

COCO

CO

CO CO

COCO

CO

CO

Or, CO blocks oxidation sites in the PAni structure, thus, decreases

resistance

FIBER 1

FIBERS

Electrospun Fibers

Sensitivity: Solution conductivity and sensitivity

Active material Pani-EB Pani-ES

CO sensitivity (%) 93.45 29.72

Standard deviation 8.10 1.31

|Stdev/Sensivity| (%) 8.67 4.40

COCO

COCO

CO CO

COCO

CO

CO

COCO

COCO

CO

CO CO

COCO

CO

CO

Lastly, CO acts as dopant.

Summary

A custom-built electrospinning set-up was assembled. The set-up was

made such that electrospinning parameters like voltage and tip-to-

collector distabce could be varied.

A Wheatstone Bridge-type chemiresistor was successfully fabricated as

CO sensor.

Fiber diameter are as follows: PAni-PVAc, 100 nm; PAni-PVC, 200nm,

and PAni-elastomer, 250nm.

Fiber diameter grows exponentially with electrode voltade in Pani-

elastomer.

Summary

Decrease in fiber diameter as distance between electrodes was varied in

PAni-PVC. Smallest fiber diameter was observed at 16-cm tip-to-

collector distance.

Bead formation was observed in PAni-PVAc with low viscosity.

PAni-EB was observed to be more sensitive in detecting CO than

H2SO4-doped PAni.

Studies conducted

Student

Ms. Melody Joy Gamboa

Ms. Diane Denise Tabernilla

Mr. Francis Emralino

Mr. John Cerry dela Rosa

Mr. Jesse Cervantes

Mr. Nathaniel Carolina

Ms. Stephanie Tumampos

Acknowledgement

PCASTRD for the grant.

Dr. EJ del Rosario for allowing the students to work in his lab at the Institute of

Chemistry-UPLB.

Prof. AKG Tapia for continuing and supervising the work on heme assisted CO

sensing.