F2 Revision

-

Upload

eko-saranghae -

Category

Documents

-

view

237 -

download

1

Transcript of F2 Revision

-

8/4/2019 F2 Revision

1/21

FORMULAE SHEET

Regression analysis

Economic order quantity

Economic batch quantity

a=y

n-

bx

n

b=nxy-xy

nx -(x)

r=xy-xy

(

2 2

nnx -(x) )(ny -(y) )2 2 2 2

=2C D

C

0

h

=2C D

C (1-D

R

0

h))

n

PAPER F2 JUNE 2011 REVISION

-

8/4/2019 F2 Revision

2/21

OVERHEAD ALLOCATION AND ABSORPTION

Jones Ltd has allocated overheads between departments as follows:

Dept $

A 336,000

B 210,000

Repairs 42,000

Maintenance 28,000

In addition there are general overheads of $308,000 which should be apportioned:

A: 40%; B: 30%; Repairs: 20%; Maintenance: 10%.

A & B are production departments. The repairs and maintenance service production department as follows:

A B Repairs Maintenance

Repairs 60% 40%

Maintenance 40% 40% 20%

Budgeted labour hours:A: 40,000 hrs; B: 8,000 hrs

Budgeted machine hours:A: 5,000hrs; B: 60,000 hrs

(a) Calculate an overhead absorption rate for each production dept.

(b) Smith Ltd has budgeted overheads of $200,000 and budgeted labour hours of 50,000. Actual hours workedwere 48,000 and actual overheads were $205,000.

Calculate the amount of over or under absorption of overheads

PAPER F2 JUNE 2011 REVISION

-

8/4/2019 F2 Revision

3/21

OVERHEAD ABSORPTION - SERVICE DEPARTMENTS

After allocating and apportioning overheads, the total overheads for each department are:

X Y Stores Canteen

280,000 196,000 84,000 56,000

Stores and Canteen are service departments, and are used by other departments as follows:

X Y Stores CanteenStores 80% 10% 10%

Canteen 60% 36% 4%

Reallocate the service department costs

PAPER F2 JUNE 2011 REVISION

-

8/4/2019 F2 Revision

4/21

BREAKEVEN ANALYSIS

Skully Ltd has produced the following (summarised) P&L A/C for 2010:

$ $

Sales (20 000 units) 560,000

Production costs:

Variable 252,000

Fixed 84,000336,000

Gross Profit 224,000

Non-production costs:

Variable 84,000

Fixed 84,000

168,000

Net Profit $56,000

(a) What is breakeven sales volume for 2010?

(b) What is the margin of safety in 2010?

(c) What is C/S ratio in 2010

(d) Draw

(i) profit volume chart

(ii) breakeven chart for 2010

PAPER F2 JUNE 2011 REVISION

-

8/4/2019 F2 Revision

5/21

PROCESS COSTING

A In process X, 8,000 units were started during the month. There is a normal loss of 10% of input. All losses aresold for $1 p.u. Actual units completed during the month were 7300u.Costs incurred during the month:

Materials: $20,000Labour and overheads: $3,840

(There was no W.I.P at start or end of month)

Write up the Process account and Loss account for the month

B In process Y, 6,000u were started during the month.W.I.P. at the start of month:

400u [Materials 100% complete: $1,600Labour 30% complete: $240]

W.I.P. at the end of month:600u [ Materials 100% complete

Labour 60% complete]

Expenditure during the month:Materials: $30,000Labour: $18,120

(There were no losses during the month)

Write up the process account, using FIFO

PAPER F2 JUNE 2011 REVISION

-

8/4/2019 F2 Revision

6/21

JOINT COSTS AND BY-PRODUCTS

Jackson Ltd produces 2 products (& a by-product) in a joint process.

During 2010, production was as follows:

S.P. (per kg)

A 10,000 kg $10

B 40,000 kg $14By-product 10,000 kg $1.40

The costs incurred in the process are $460,000

Product A needs a further $3 per kg to be spent before it is ready for sale.

For products A & B, calculate the stock value per kg splitting the joint costs

(i) on the basis of weight

(ii) on the basis of sales value

PAPER F2 JUNE 2011 REVISION

-

8/4/2019 F2 Revision

7/21

LINEAR PROGRAMMING

Mulder Ltd manufactures 2 products - X & Y with the following unit costings:

X Y

Selling price 20 15

Variable costs 14 5

Contribution $6 $10

Labour usage 2 hrs 4 hrs

Material usage 5 kg 3 kg

Maximum demand: 3,000 u 12,000 u

If labour hours are restricted to a maximum of 8,000 hours, and material is restricted to a maximum of

13,000kg, what is the optimum production schedule?

PAPER F2 JUNE 2011 REVISION

-

8/4/2019 F2 Revision

8/21

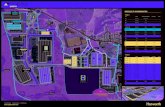

LINEAR PROGRAMMING

CONSTRAINTS:

Labour: 2x + 4y 8.000Material: 5x + 3y 13.000Demand: x 3000; y 12.000Non-negativity: x 0; y 0

OBJECTIVE:

Maximise contribution:C = 6x+10y

[Contribution line: if C = $15.000, then: x=0; y=1500y=0; x=2500

BUT use any value for C - slope will be the same]

The demandfor y constraintis obviouslyredundant

DemandFor x

y

4333

2500 2600 4000 x

A

C

Objective

2000

1500

E

DB

Material

Labour

PAPER F2 JUNE 2011 REVISION

-

8/4/2019 F2 Revision

9/21

LINEAR PROGRAMMING

Optimum production schedule occurs at point E on the graph

At point E:

2x + 4y = 8,000 (1)

and 5x + 3y = 13,000 (2)

(1) x 2.5 gives: 5x + 10y = 20,000 (3)(3) (2) gives 7y = 7000

y = 1000

Substitute for y in (1): 2x + 4000 = 8000

2x = 4000

x = 2000

Optimum production schedule:Produce 2000 units of product X

and 1000 units of product Y

PAPER F2 JUNE 2011 REVISION

-

8/4/2019 F2 Revision

10/21

STOCK CONTROL

X plc needs to purchase 1,800 units a year. The purchase price of each unit is $25.

Delivery costs per order: $32

Stock holding costs p.a.

(as %age of purchase cost): 18 % p.a.

(a) Calculate the optimum order quantity, and the total costs p.a. at that order quantity.

(b) Y Plc has minimum demand of 20 units per day, average demand of 30 units per day, and maximumdemand of 40 units per day. The lead time varies between 10 and 15 days.

(i) What should the reorder level be?

(ii) If the reorder quantity is 1,200 units, what will be the maximum stock level?

buffer (or safety) stock

PAPER F2 JUNE 2011 REVISION

-

8/4/2019 F2 Revision

11/21

REGRESSION

Units Costs

($000s)

x y xy x2 y2

100 40

200 45

300 50400 65

500 70

600 70

700 80

(a) Calculate the regression line

(b) Calculate the coefficient of correlation

(c) Calculate the coefficient of determination

PAPER F2 JUNE 2011 REVISION

-

8/4/2019 F2 Revision

12/21

RELEVANT COSTING

Example 1

500 kg of material are needed for a special contract.There are 200 kg in stock, which was purchased for $2 per kg.. The current purchase price is $2.20 per kg..The material is in regular use.

What is the relevant cost?

Example 2

600 kg of material are needed for a special contract.There are 400 kg in stock, which was purchased for $5 per kg.The current purchase price is $7 per kg, and the current realisable value is $6 per kg.The company has no other use for this material.

What is the relevant cost?

Example 3

A contract needs 200 hours of labour. Labour is paid $8 per hour, and the company has spare capacity.

What is the relevant cost?

Example 4

A contact needs 300 hours of labour. Labour is paid $6 per hour.There is no spare capacity, and the labour would have to be transferred from other work producing units that earna contribution of $14 per unit and take 2 hours per unit to produce.

What is the relevant cost?

SUNK COSTS

OPPORTUNITY COSTS

PAPER F2 JUNE 2011 REVISION

-

8/4/2019 F2 Revision

13/21

LABOUR COSTS

Ratios:

Production Volume Ratio =Expected hours to make output

Hours budgeted

Capacity Ratio =Actual hours worked

Hours budgeted

Efficiency Ratio =Expected hours to make output

Actual hours worked

Piecework: Pay workers per unit produced

Labour Turnover Rate =Employees Replaced

Average Number of Employees

Example

Firm had 200 employees at start of the year, and 160 at the end of the year.During the year 50 employees had left.

Answer

Number of employees fell by 40, so if 50 left 10 must have been replaced.Average number of employees

Average number of employees =200 +160

= 1802

Labour turnover rate =10

100% = 5.56%180

PAPER F2 JUNE 2011 REVISION

-

8/4/2019 F2 Revision

14/21

MARGINAL AND ABSORPTION COSTING

Z Ltd produces desks for which the standard cost card is as follows:

$ pu

Materials 10

Labour 6

Variable overheads 4

Fixed overheads 3$23

During January, Z Ltd produced 50,000 desks and sold 45,000.The profit was calculated at $220,000, using absorption costing

What would the profit be using marginal costing?

PAPER F2 JUNE 2011 REVISION

-

8/4/2019 F2 Revision

15/21

KEY FACTOR ANALYSIS

XX produces 3 products:

A B C

Selling price 42 56 51

Materials 10 18 14

Labour 12 16 12

Variable overheads 8 10 1030 44 36

Contribution p.u. $12 $12 $15

Maximum demand 1,000 1,000 1,000

Labour is paid $4 per hour, and there is a maximum 8,000 hours available.

How many units of each should be produced to maximise profit?

PAPER F2 JUNE 2011 REVISION

-

8/4/2019 F2 Revision

16/21

KEY FACTOR ANALYSIS (2)

YY makes 2 products:

F G

Materials 8 4

Labour 5 10

Variable overheads 3 4

16 18Units required 2,000 2,000

Labour is paid $5 per hour, and there are only 5,000 hours available.

The units may be purchased from a supplier at costs of F:$22p.u., and G: $26p.u.

How many units of each should be produced, and how many purchased from the supplier, in order to

minimise costs?

PAPER F2 JUNE 2011 REVISION

-

8/4/2019 F2 Revision

17/21

VARIANCES MATERIALS

Standard cost of materials:

20 kg at $4 per kg = $80 per unit

During the month we produced 5000 units.

We purchased 120,000 kg of material and paid $500,000We used 105,000 kg in production (the other 15,000 kg are in inventory)

Materials expenditure (price) variance:

Materials usage variance:

PAPER F2 JUNE 2011 REVISION

-

8/4/2019 F2 Revision

18/21

VARIANCES LABOUR

Standard cost of labour:

8 hours at $3 per hr = $24 per unit

During the month we produced 6000 units.

We paid for 52,000 hours of labour at the rate of $3.20 per hour.We worked 49,500 hours.

Labour rate of pay variance:

Labour idle time variance:

Labour efficiency variance:

PAPER F2 JUNE 2011 REVISION

-

8/4/2019 F2 Revision

19/21

VARIANCES VARIABLE OVERHEADS

Standard cost of variable overheads:

6 hours at $2 per hr = $12 per unit

During the month we produced 1,200 units.

We worked for 7100 hours, and paid $13,900 for variable overheads.

Variable overhead expenditure variance:

Variable overhead efficiency variance:

PAPER F2 JUNE 2011 REVISION

-

8/4/2019 F2 Revision

20/21

VARIANCES FIXED OVERHEADS

Our company uses absorption costing, and budgeted to produce and sell 8,000 units.

Standard cost of fixed overheads:

4 hours at $3 per hr = $12 per unit

During the month we produced 9,000 units.We worked for 35,000 hours, and paid $100,000 for fixed overheads.

Total fixed overhead variance:

Fixed overhead expenditure variance:

Fixed overhead volume variance:

Fixed overhead capacity variance:

Fixed overhead efficiency variance:

PAPER F2 JUNE 2011 REVISION

-

8/4/2019 F2 Revision

21/21

VARIANCES SALES

We budgeted to sell 10,000 units.

The standard selling price is $20 per unit.The standard costs are:

Variable costs $12 per unit

Fixed costs $ 5 per unit

The actual sales were 12,000 units at a selling price of $19 per unit

Absorption costing:

Sales price variance:

Sales volume variance:

Marginal costing:

Sales price variance:

Sales volume variance:

PAPER F2 JUNE 2011 REVISION