Extracts From Handbook for the 60-Pr Bl. Gun, Mark I (Land Service)

-

Upload

sean-campbell -

Category

Documents

-

view

46 -

download

27

description

Transcript of Extracts From Handbook for the 60-Pr Bl. Gun, Mark I (Land Service)

-

[All Ri9l~tsI?e$erved.

40

~ri2 /

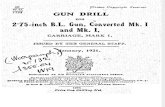

HANDBOOKFOR TIlE

~-1. MA~1926O~PR. B.L. GUN,

(LAND SERVICE.)

ieoe..

LONDON:PRINTED FOE IllS MMESTYS STATIONERY OFFIOR,

BY HARRISON AND SONS, ST. MARTINS LANE,P1ZINT~I~BiN OflfliNARr TO ILI~ ~tAJ2~STY.

And to bo~purcha~ed,either directly or through any Bookseller, fromWYMAN AND 8ONS~LTD., Fi~rrei~LANI~,B.O.; or

~ OLIVER AND BOYD, TWEeDDAL1~COUnT, EDINB~flGII~ orE. PONSONI3Y, 110, Giw~o~SineeT, DUBLIN.

Price One shilling and sixpence.

-

M~R1912)~a p

HANDBOOKFOE TIlE

60-PR. B.L. GTJN, MARK I,

(LAND SEEVIC]~L)

LONDON:PRINTED FOR HIS MAJESTYS STATIONERY OFFICE,

BY HARRISON AND SONS, ST. MARTINS LANE,rnU~TEItS IN ORDINART TO illS 3IAJIiSTY.

Arid to be purchased, either directly or through any l3ookeeller, fromWYMAN AND SONS, LTD., FETTER LANE, E.O.; or

OLIVER AND BOYD, TWEIIODALII CounT, EniNnUnoir; orE. PONSONBY, 116, GRAPT0N STREEr, DUBLIN.

40w.O.S12

1909..

Price One shilling and sispence.

-

Carriage.DescriptionSights .. .. .. .. .. ..Care and Preservation .. .. .. ..Instructions for Testing and Adjusting the Sights

Limber, carriageDescription .. .. .. .. ..

Dimensions and Weights of Carriage and LimberLimber, wagon

Description .. .. -. . - ..Wagon, ammunition

Description .. -. .. . - ..Dimensions and Weights of Ammunition Wagon and Limber

Wagon, general service. Description .. ..Ammunition

Cartridge .. .. .. .. ..Projectiles 25Fuzes .. .. .. . - -. - - . - ... -. .. 26Tubes .. .. .. .,. . - .. . - .. .. .. 30

])rill .. .. .. . . .. .. .. .. .. .. 32Method of Drilling Recruits .. .. .. .. .. .. .. 41Stores carried on Carriage and Limber, and Ammunition Wagon and

Limber .,. .. ... .. .. .. .. - - - - . 42Diagrams of Packing .. .. .. .. .. .. 46

PLATES.

CarriageElevation and Top Plan ..Hydraulic Buffer .. ..Running out Springs .. ..Brake Gear and Draught Connector -.Sights .. .. .. ..

Limber, carriageElevation and Top plan

Wagon, ammunitionLimber, wagonTarget for Testing Sights, and Bush testing sightingCartridge .. .. .. ..Projectiles .. .. .. .. .. . -Fuzes .. .. .. ..Tubes .. .. .. .. .. - -

N0TS.TlIis handbook has been corrected up to March, 1909; any altera-tionB which may be suggested shoisld ~ forwarded to Chief Inspector, RoyalArsenal, Woolwieh, \Jf

CONTENTS.

Description .. .. ..Breech Mechanism .. .. .. ... . -Removing and Rop~acingBreech FittingsCare and Preservation ..

rAna345

..~.- 6

79

1820

1214

15

151017

24

Gun .. .. .. .. ..Breech Mechanism .. .. .. .. -.

III

iirIv

VVI

Vilto XII

XIII& XIVXV & XVI

.. XVIIXVIII

XIXto XXIXXII & XXIII

.Xx1v

-

HANDBOOKToil TIlE

60-PR. B.L, GUN, MARK I.

GUN.(Plate I.)

The gun is made of steel and consists of tubes, a series of layers of~- steel wire, jacket and breech ring. The A-tube is lined with an inner~ A-tube extending from the scat of the obturator to the muzzle, and~ secured longitudinally by means of corresponding shoulders and a breech,~, bush which is screwed into the A-tube at the rear; the breech bush is

also prepared for the reception of the breech screw. Over a portion of~ the A-tube are wound successive layers of steel wire, the ends of which

are secured to steel rings. The jacket is fitted over the exterior of thewire and a portion of the A-tube, and is secured longitudinally by corres-ponding shoulders and the breech ring which is fitted over the rear endof the A-tube and screwed to the jacket.

The breech bush and breech ring are prevented from turning whenin position by means of fixing screws.

The breech ring is prepared for the reception of the breech mechanism,and is provided on the upper side with lugs for the attachment of thehydraulic buffer and running out springs of the carriage.

Longitudinal projections on each side of the jacket form guides forthe gun when in the cradle of the carriage.

The central portion of the chamber is cylindrical, reduced in diameterat the front and rear.

Vertical and horizontal axis lines are cut on the gun at the muzzleand breech.

Planes for clinometer are prepared on the upper surface of thelongitudinal projections on-the jacket at the front.

(5[wo.) A 2

MaterialWeight -. . -Length, total

~calibreBore - - 1 length

IdiameterChamber ~ ieugtii

LcapacityIsystemlength

Rifling J twist..

Firing mechanism

J largest ::1~smallest

~number..~ widthLdepth

Steel (wirc construction).39cwt.168 05 inches,5 inches.160 inches 32 calibres.6 inches.5 3 inches. -21 926 inches.018 75 cubic inches.Polygroove, modified plain section.135 068 inches.Uniform 1 turn in 30 calibres.2!.o 436 inch.OOfiinch.Friction T tube.CII--

-

4BREECh MECHANISM.(Plate II.)

The guns are fitted with Single Motion Breech Mechanism.The mechanism is so arranged that by one pull on a lover the breechscrew is unlocked and the screw and carrier are swung into the loadingposition. After loading one thrust on the same lever inserts tl~obreoch~crowinto the breech opening, and turns it into the locked position.

Breech Closing Mechanism.The breech is closed by a parallel steel screw having four portions

of the thread removed longitudinally, each one-eighth of the circum-ference. The interior of the gun at the breech being prepared in asimilar manner admits of the screw, when the raised portions arc placedopposite the smooth surfaces in the gun, being pushed home and lockedby the eighth of a turn.

A carrier for supporting the breech screw when withdrawn from thegun is hinged by a bolt andbronze bush to the right side of the gun atthe breech, the bolt and bush being arranged to admit of lateral move-ment of the carrier hinge joint in opening and closing the breech. Thebreech screw is attached to the carrier by means of interrupted screwthreads on the carrier and interior of breech screw, and a steel axialT vent passing through the centre of the breech screw. The vent hasa mushroom head at the inner end between which and the front face ofthe breech screw are placed the obturating pad and discs. The ventis retained in position by means of a sleeve, spiral spring, and nut in thecarrier. A steel washer is placed over the outer end of the vent to therear of the vent nut, to prevent jamming between the latter and theinner face of the slide box. The carrier is furnished with a breechmechanism lever, sliding block, and actuating link, by means of whichthe breech screw is worked.

A catch, fitted to the carrier, engages with a corresponding recess inthe rear face of thebreech screw, when thebreech is oyen, and retains the.screw in the unlocked position. The catch is automatically disengagedfrom the screw in closing the breech.

The breech mechanism lever is retained in the closed position bymeans of a flat spring on the carrier.

Firing Mechanism.The firing mechanism is designed for friction firing with T friction

tubes, and is so arranged that the gun cannot be fired before the breechis closed and the breech mechanism lever home.

A slide box, in which the block retaining T tube slides, is securedto the outer end of the vent, the retaining block being pushed intoposition over the vent by means of a guide bolt in the lower end of theblock engaging with a cam groove in the sliding block of the carrier,when the breech is closed. A spring for retaining the T friction tubeis provided in the slide box, and a safety shutter on the right side servesto prevent the lanyard from being hooked on to the tube before thebreech mechanism lever is home. An extractor for releasing theT friction tube from the vent is fitted to the retaining block, and i~actuated automatically in opening the breech.

The lanyard for firing the gun is pulled from the right side.

,Shot Guide.A bronze guide block to facilitate loading is hinged by a hinge screw

to the under side of the bree,h, and is automatically raised to the loading

-

ii

position by meaiis of a lever which engages with a cam groove on the

under side of the carrier hinge joint when the breech is opened.Obturation.

Obturation is obtained by means of an asbestos pad with front andrear protecting discs of copper, front and rear outer rings of steel, andrear inner ring of bronze, fitted in the usual way behind the mushroomhead of the vent. The pad being slightly elastic expands radiallywhen compressed by the action of the gas generated by the fired charge,thus completing obturation.

Thin discs of steel are used to adjust the required thickness of theobturating pad as follows

Should the obturator be found not to fit the cone seating in tile guncorrectly (and this can be ascertained by covering the seating lightlywith grease and seeing that the periphery of the obturator is coveredall round after the breech has been closed and opened again), adjustingdiscs should be added until the breech closes a little tightly throughthe obturator being pressed forward into the seating.

For care and preservation of pads and discs, including dimensionsand replacement limits, see Regulations for Magazines and Care ofWar Materiel.

To Rmiovn TilE BI1EECII Frrriuas.Before commencing to remove the fittings, the breech screw and

carrier must be swung into the loading position.Block, Retaining T Tube.

Pull the guide bolt to the rear until the itlner end is clear of thecam groove in the sliding block, then withdraw the block out of thebox slide in a downward direction.

Box Slide.Turn the box slide one-fourth of a turn to the right or left and

withdraw it to the rear.Wtsher~Anti-Friction.

Withdraw the washer to the rear by means of the withdrawing toolwhich is screwed into a threaded hole prepared in the washer forthis purpose.

Vent, Axial,Unscrew the nut of the vent and withdraw the vent with obturating

pad and discs from the front end of the breech screw. The nut, spiraspring and sleeve can then be withdrawn from the rear.

Breech Screw, Slide Block and Bush.Press in the catch retaining breech screw clear of the recess for it~

reception in the breech screw, and turn the latter into the closed positionon the carrier. Take out the fixing screw of the bracket catchretaining breech screw and remove the bracket in a downward direction.Take out the check screw of the link axis pin and remove the axis pin.Turn the breech screw on the carrier so as to clear the interruptions onthe latter and withdraw the breech screw.

Withdraw the slide block and bush from the carrier.

-

0Lever, Breech Mechanism, and Link, Breech Screw.Remove the keep pin amid nut from the breech rneehiamiismn lever stud

and withdraw time lever and link.Carrier.

Before removing the carrier, it must be swung into, the closedposition. Remove the keep pin and nut from the hinge bolt and with-draw the latter with bronze bush from the hinge joint. Remove thecarrier.

Shot Guide.Take out the hinge screw and withdraw the guide block. Take

out time fixing screws of the bracket supporting actuating lever arid with-draw tue bracket and lever.

To REPLACE BREEd Fir-rinGs.The fittings are replaced in time reverse order.

CARE AND PRESERVATION OF GUN AND FITTINGS.

See Regulations for Magazines and Care ci TVar MaWriel.

Special Instructions not in the above-mentioned Regulations.

All fittings of the gun should be treated withcare; violence and jerksshould be avoided, and no unnecessary force should be employed.

The breech fittings should work easily and be free from cracks andburrs. Should the screw not work easily, the defect may often beremedied by careful filing, but no portion of the thread should be cutaway to remove a crack.

The breech should be kept covered by the canvas Cover to preventdust and grit getting into the imiterstices of the breech fittings.

The following is a list of the oil holes in the breech fittings whichrequire to have the screws occasionally removed and oil poured into thechannels so as to lubricate the parts without removal of the fittings.Care must be taken to replace the screws immediately after oiling

Fittings to be Lubricated. Position of Oil Hole.

Carrier hinge bolt and bush . - .. Top of hinge bolt nut.Stud, breech mechanism lever .. In carrier on right side.Block, sli:ling and bush .. .. In carrier on heft side.LinE, actuating breech screw . . . . Upper side of link.Pin, axis, link actuating breech screw Upper end of axis pin.Screw, breech .. .. .. -. In plain portion of screw.Shot guide .. -. -. .. In boss of guide blook.

-

7OARRIAGE, FIELD, B.L., 60-PR. MARK I.(Plates III to XII.)

The carriage is constructed to allow of 21 30 elevation armd5 degrees depression being given to the gun which recoils axially in acradle, the latter being fitted with a hydraulic buffer to limit the recoil,and running out presses to return the gun to the firing position. Timecarriage is also constructed so that, wiieil limbered up, the carriage body,with cradle and gun, can be run back to a position which will ensure anequitabledistribution of the load between the limber and carriag~wheels.

lime principal parts of tile carriage areTrail. Elevatin~gear.Saddle. Traversimig gear.Carriage body. Brake gear.Cradle. Firing brake shoes.Hydraulic buffer. Sights.Running out presses. Axletree and wheels.

Trail.The trail consists principally of two side brackets connectedby transoms. It is secured by manganese bronze brackets to the axle-tree which passes through them. Time rear end is fitted with lockingplates, lifting handles, solo plate, trail eye, and a fixed spade.Transverse socheets for handspikes are provided for lifting the trail~.and a clamping arrangement with a detachable gun rest to secure timegun in time ruin back position when travelling. When the gun is intime firing position the gun rest must be removed. Movable sigimtingsteps are attached to the trail, one on eacim side at the front, andone to the centre of the left bracket. The upper surface of eachside bracket is prepared for the reception of the saddle. The saddle issecured to the trail in the firing position by a locking bolt on eachside, and in time travelling position by a housing stop fitted to each ofthe side brackets.

Saddle.The saddle is of bronze, and is arranged to slide on theupper surface of the trail. The under side is formed with clipswlmichm grip time top of the trail.

Carriage Body.The carriage body consists primicipally of twotriangular shaped frames connected by transoms. It is provided withbearings for the trunnions of the cradle. Time front end is pivoted fortraversing to the front of the saddle by a pivot pin, and the rear endtraverses over time rear slide of the saddle to which it is clipped.

Time elevating gear bracket is fixed to the left side. On each sidea plate (with a central hole) is fixed, for use with a tackle to run thecarriage up or back.

Cradle.The cradle is of bronze, witim trunnions to pivot it to thecarriage body. Time front and rear portions arc bored above for timespring cases and hydraulic buffer, and below for the gun, time guides ofwhich slide in recesses prepared for timemn. A plane surface is providedon the rear for a clinometer, and a cover of sheet brass protects thatportion of time gun which is exposed between the front mind rear portionsof the cradle. Suitable brackets, with adjustable bushes mind screws,are provided for the reception of time dial aimd fore sights on eitherside al the cradle, Each bracket is recessed to receive a lug on the bush,which admits of a limited rotary motion being given to time sight wimenrequired for adjustment; the desired position being determined by

-

Smneamms of time adjusting screws which are fixed by lookimig wires. Omieeccentric and two plain studs, with set screws, are also provided fortime attachm~mmtof thm~ oscillating sight bracket on the left side. Abracket for the tangent sight clamp is fitted to the right side.

hydraulic Bu/jer.Time hydraulic buffer consm~tsof ~ cylinder,piston, with rod and controlling plunger, and controlling cylinder. Thecylinder is secured to time cradle above time gun; it is closed at the frontend by time controlling cylinder and at time rear end by the gland andstuffing box, which is provided with an L leather and securing ring.Au air hohe with plug is provided at the front end of the cylinder. Timepiston and controlling plunger are in one forging, the plunger being attime front end and the piston formed between the rod mind the plunger.The piston is provided with a port which passes over time valve keyduring recoml and ensures an approximate constant pressure in thecylinder due to time varying depths of time key. Time end of the rod issecured to time breech ring of the gun. The controlling cylinder isscrewed into time front end of the buffer cylinder, and is provided witha tank for storing time liquid, a filling hole, and two air holes, which areclosed by plugs. Time displacement of the liquid in the cylinder by theplunger brings the gun gently to rest when returning to the firingposition. Tue quantity of liquid required is about 5 quarts. Themaximum recoil is 60 inches, and time average working recoil 44~6inches.

Running out Presses.The running out presses are contained insteel cases secured to the cradle imbove the gun, one on each side oftime buffer. Each press consists of two sets of springs, inner andouter, which are held under initial compression by means of a tubular

- spring rod and a compressing screw; each set consists of four springs,separated longitudinally by aim inner case, time inner set being alsodivided by bearings.

The rear end of each running out rod is connected to the breech ringof the gun by a lug and link. The maximum compression for each ofthe inner springs is determined by a distance tube.

On firimig, time running out rods and piston rod mire withdrawn fromthe cases and cylinder respectiveiy, and time recoil is checked by timeresistance of the buffer and springs, the latter being further compressed.The energy stored up in the springs returns the gun to the firing position.

Elevating Gear.Tlme elevating gear is attached to the left sidd oftime carmiage body and is actuated by a handwimeei, which transmitsmotion through worm wheel gearing to an elevating arc fixed to therear emmd of the cradle. A locking arrangement is provided whichpermits of the worm being actuated by the spindle, but instantlycimecks any motion from the worm wheel. The latter is caused by theworm becoming locked by rollers which are jammed between a face onthe worm and another on a bearing fixed to time elevating bracket.The motion of the spindle releases the rollers and then drives theworm. Stops are formed on the saddle, and elevating arc so thatwhen more than I 6~degrees of elevation are required the traverse islimited to 3 degrees ~ighmtor left.

Traversing Gear.The traversing gear consists of a tubular nut witha handwheel working in a swivelled bearing attached to the saddleand an actuating screw working within the nut and pivoted at oneend to the carriage body. The angle of traverse (4maximum on eachside of time centre) is indicated by a pointer amid scale strip.

-

9Brake Gear.The brake gear consists principally of two brake arms,one on each side, with brake blocks and supporting stays pivoted tothe trail and screwed actuating rods with handwheels. The front endof the rod is supported by a bearing in the axletree bracket and therear end works within a nut which is pivoted to the brake arm.

Firing Brake Shoes.The firing brake shoes consist of steel platesgrooved on the under side and fitted with loops and guides for thewimeels on top. Time shoes, when in misc, arc suspended from the axle-tree, amid secured to loops at the front and centre of time trail by wireropes with shackles and ques, and when not in use will be carried intime trail as follows :--The handspikes are first placed in the well of thecarriage and one firing shoe placed upon them with its angle steelguides uppermost. Time second slice is then placed on the first withthe guides underneath. No fittings for securing time shoes are required.

Sights. The cradle is fitted to carry sights (see Plates VII and VIII)as follows :Osciilating sight at the rear, left side; dial sight at thefront, on either the right or left side ; fore and tangent sights on theright side. The front socket on the right side is for either dial or foresight.

Oscillating Siglmt.Thc oscillating sight (Plates IX and X), withtelescope, sighting, No. 5, and telescope carrier attached, is fordirect or indirect forward laying, and is fitted with a levelling arrange.ment to compensate for irregularities in the level of the wheels. Itconsists of the following principal parts :Worm spindle bracket,worm wheel bracket, degree scale plate, yard and degree scale drumand link. The ~orm spindle bracket is fixed to the cradle by threestuds. The lower front stud is formed with an ecceiitric which enablesa slight vertical mOtion to be given to the whole of the sight whenrequired for adjustment. The worni wheel bracket is pivoted to theworm spindle bracket by a worm spindle, withhandwheel and handle;its upper portion is prepared for the limmk and its lower portion fittedwith a levelling nut and screw which is hinged to the worm spindlebracket for transverse horizontal adjustment; the adjustment ischecked by a small spirit level fitted to the yard scale reader, thecentre of the bracket is bored for the worm wheel spindle to whichthe yard and degree scale drum and worm wheel are fixed. Thedrum is provided with a yard and degree scale ring, the requiredmarking being indicated by a reader, witim spirit level, fixed to time wornmwheel bracket. The ring is graduated in yards from 100 to 10,400 inmultiples of 100, and in degrees from 0 to 22in multiples of 5.Time degree scale plate is bored at its lower end for the recep-tion of an eccentric boss formed on the yard scale drum, and isconnected to the worm wheel bracket by a link; the upper portionof time plate is in the form of a disc and is prepared for the receptionof the telescope carrier; it is marked mind numbered in degrees inmultiples of 5, 180 degrees right and 180 degrees left. A recess isformed in the top of the plate for a spirit level which indicates thehorizontal position of the sight longitudinally.

Time error due to drift is compensated for by tho oscillating sightbeing set at an angle 220 to the left of the vertical axis, and thetelescope carrier being set to give 3 right permanent deflection.

By rotating the handwheel on the worm spindle the wormwheel and drum are moved together round the same centre. Theecccmmtrmc on the drum conveys an oscillating movement (modified by

-

10

the link ivluichm nets es a radius bar) to the degree scale piat~andtelescope, time angle betweemm time axis of time gun amid the line of sight

1mm degrees or yards of range being indicated by the pointer on theyard and degree scale ring.

Dial Siglzt.The dial sight (Plates XI amid XTI) is provided forall round laying ; ivhemi it is in use, the telescope, sighting, No. 5,and telescope carrier are attached to the scale plate. The sight consistsprincipally of a stem, crosshead, and degree scale plate. The stem fitsinto the cradle and carries the crosshead on a horizontal spindle. Thecrosshead is provided with two transverse trtmnnions to which the scaleplate is pivoted. The upper portion of the scale plate amid thegraduations on it are the same as time scale plate of time oscillatingsight, and is prepared for time reception of the telescope carrier.To a projecting arm below time plate aim elevatimmg screw is swivelled,which works in a nut pivoted to the crossimead. In conjutmctiommwith time spirit level on the plate, degrees of elevation givento the cradle and gun may be read by means of a graduated ringon a drum with a milled hmead, amid a reader whmichm is fixed to timeelevating nut. Time ring is graduated in degrees from 0 to 22, whicimare sub-divided into 12 divisions, each representing 5 minutes. Alevelling arrangement similar to that on time oscillatimmg sight isprovided to compensate for aumy sligimt unevemimmess in the level of thewheels.

Telescope Carrier.The telescope carrier (Plates IX to XII) is abronze casting fitting around the rimn of the degree scale plate, to whichit is secured by a bronze strap; it is provided with bearings and capsof the usual type for securing the telescope, and with a plate for in-dicating the degrees omi the scale plate.

Fittings are also provided for giving fimme adjustments for deflection,which consist principally of a spiral worm with spindle, spring andmilled hmead, an indicator amid catch plate, amid aim adjustable pointer.The worm in its normal position engages ~vithmteeth cut on the pen-plmery of the degree scale plate of the dial or oscillating sight,but may be readily disengaged by a small releasing handle when amuovememit of more than 5 degrees ma required. The wormmi is actuatedby a milled head, to which is fixed an adjustable circular catch plate.A circular scale plate, wlmichm is bored centrally for the worm spimidle,is fixed to the carrier, and is engraved with markings for 24 degreesdeflection rigimt and left ; each degree is sub-divided into multiples of5 mnimiutes. Time pointer forms part of a steel ring fitting round theoutside edge of the catch plate, to which it is attached by a smallspring catch whichi fits imito one of a numnber of radial grooves cut inthe face of the catch plate. There are 60 grooves each representing5 minutes and each twelfth groove numbered consecutively forward(right) in black and backward (left) in red, I to 4.

When used withthe oscillating sight for direct laying the arrow markon the arrow plate should coincide with zero on the degree scale plate,and time pointer and the arrow on it should coimicide with time zero markon the deflection scale mind catch plate respectively; time milled headmay thmeu he nmmmnipuiated (with time catch engaged with the plate) togive the deflection required.

When used with the oscillating or dial sight for indirectlaying, the angle between the line of fire and the aiming posts (or otherfixed point) is set by disengaging time catcim from the catch plate, and

-

.11

the worm trout time degree scale plate; the carrier is then turned roundthe degree scale plate until the nearest 5 or multiple of 5 below timeactual setting is indicated and the worm re-engaged. The number ofdegrees and minutes to be added to the reading on time degree scaleplate is obtained by. rotating time milled head until time amount isindicated on time catchm plate by time arrow on the pointer, time angle fordeflection being set in the maimer described above.

Telescope, Sighting, No. 5.Mark L

Particulars.Magnification .. .. .. .. 12 diameters.Field of view - - . . .. . . 3 degrees.Length overall .. . . . . 21~5ihmches.Weight.. .. .. .. .. 2 lbs. .13 ozs.

Description.The telescope is of time ordinary erecting type, with aim object glass

and terrestrial eye-piece.The body is fitted with two gunmnetal collars, which accurately fit

the bearings in the telescope carrier of either the dial or os-cillating sights. When the telescope is fixed in the carrier a lineon the rear collar should be opposite to an arrow orm the cap of the rearholder of the carrier.

Folding sight vanes are fitted on the body of the telescope.The eye-piece is fitted with a removable dermatine eye guard to

protect the forehead of the gummm layer from shock when firing.An adjustable diaphragm carrying a needle-shaped pointer is fixed

at the focal length of the object glass.Time object glass is fixed imm the correct position for infinite focus, or,

in other words, for all objects over 100 yards distant. It is protectedby a ray shade.

Mark II.Mark II differs from Mark I in being 05 inch longer and 9 oza.

heavier, and imm having the diaphragmn further fronm the gunmetalcollars. . ,

To Focus the Telescope.Revolve the eye-piece by nmeans of time knurled collar until the

pointer is clearly defined.Tangent Siqht.The tangent sigimt consists of a hollow rectangular

steel bar surmounted by a crossimcad. A yard scale is engraved on therear face and a degree scale on time front face of time bar, amid a toothedrack is formed on oume of time sides. Gradumitioums are marked elm timeyard scale fromum 200 yards to 10,400 yards in immuitipics of 100 yards,and on the degree scale fronm 0 to 22 imu multiples of 10. Thecrosshead is provided witim a gunmetal screwed deflection leafhaving time usual sighting notch, and a traversing screw with milledhead. The rear is engraved with markings for indicating 2 degreesdeflection right amid left, each degree being divided into 12 divisions,each division representing 5 minutes. . The bracket for the tangentsight is bored at mimi angle of, 10 30 to the vertical, plane to com-pensate for drift. Time bar of the tangent sight is secured in thedesired position by an automatic clamp, which consists of a bronze

-

12

socket recessed to receivc time sight bar. Near its upper emmd on tlm~right side is a projection hollowed to receive a spindle enlarged atits iimner end and provided withm a worm to engage time teeth oftime rack on time siglmt bar; time spindle is kept pressed inwards bymeans of a spiral sprimmg, and is provided at its outer end with amilled headed nut by which it is revolved. Tmmrning the milled headcauses time wornm to act on time rack and to raise or lower the sightslowly. By drawimmg tlme milled head outwards time spiral spring uscompressed and time worm withdrawn from time rack of the sight, whichcan then be rapidly raised or lowered by hand; when the milled headis released time spiral spring carries time spindle and time worm inwardsuntil the latter re-engages with the rack of the sight. The clamp isretained in.thme tangent siglmt bracket by a spring catch.

Fore Sight.The foresigimt consists of a pillar, jacket, and sleeve. Thepillar, which is of steel, is secured to the jacket by a screw and keep~)ifl, and is surmounted by arm acorn point. The jacket is of manganesebronze, and is made to move about the pillar; it is provided with aprojectimmg key, whmich fits into a corresponding keyway on time sleeveand adjusting bush and locks time sight in position. The sleeve is ofmanganese bronze and fits into time adjusting bush. It is secured bymeans of a bayonet joint in th adjusting bush.

The sigimts are carried in the limber boxes when travelling.Axletree.The axietree, which is 1st class B No. 3, is a tubular

steel forging, connected to the trail by manganese bronze brackets, oneon each side. The outer end of each arm is flit 3d fora hinch pin, and anadjusting collar which has a number of recesses (through which thehinch pin passes) cut in one face ; the recesses are of varying depthsso that any reduction due to wear in the length of the pipe box may beadjusted.

The drag washier is free to revolve round the nave amid is securedby time dust cap.

Each arm of time axietree is provided witim a rimug carrying a dustexcluder, consisting of an L-shmaped leather ring secured to time carrierring by a securing ring witim screws. The end of the inner flange of thewheel nave is enveloped by the leather L-ring, and prevents dust enteringthe pipe box.

Wheels.The wheels are 1st class B No. 10, 5 feet in diameter,with 14 spokes, manganese bronze nave, removable pipe box and6-inch steel tire with rounded edges. The nave consists of two flangesconnected by 14 bolts. The pipe box passes through the flanges and issecured by a small bolt to the inner flange. A bearing collar for timedrag washer and a dust cap are screwed to the outer end of the pipebox, the cap being secured by two keep pins.

A roller scotch, 42-inch, is attached to the carriage by chains.For list of stores carried on the carriage, see page 42, also Packing

Diagram A.

LIMBER, B.L. 60-PR,, CARRIAGE, MAR1~I.

(Plates XIII and XIV.)The limber consists ofaste~lframe, coupling arr~ngenments,t*oator~

boxes, a 1st class axietree, draught fittings and two field wheehs.The frame consists principally of four futchels (two inner arid two

-

13

outer) connected at time rear to the axietree by flanges, at time front byconnecting plates, and strengthened by diagonal stays. A pintie withpin is fitted to the centre futchels abovethe axletree. The arrangement.for coupling the carriage to the limber consists of a coupling block anda draught bar. The front end of the coupling block is supported by the,body of the pintle, the stem passing through a link formed at the front.,end ; time rear end is box shaped to receive the trail eye of the carriage.The block is coupled to the axietree by a radial draught bar, wimich ispivoted at time front end to a steel strap placed about the centre of theaxietree, and is connected at time rear end to the block by a bolt. Thetrail eye of time carriage is secured to the biock by a loop-headed con-umecting pin attached to a fixed key by a chain. To lock the pin, armopening in the head must be placed over time key and the pin rotated.J,IC plates which connect the futeimels at time front perform time functionsof a splinter bar, and are furnished with draught hooks, outriggers withstays and hooks, and a draught pole socket for four-horse draught.It is also fitted with draught joints with coupling pin and chains forthe attachment of an engine draught connector. To th~rear of timepolo socket two plates are fixed above and below the inner futcheisto support a No. 17, Mark III, draught I)ole, which may be used (insteadof No. 19) on an emergency, and whicim should be further supportedby suitable packing placed around the pole socket. Brackets are fittedto the outer futchels to facilitate the raising of time limber by a lifting

~ jack.~ A box of sheet steel for carrying sights, telescope, spare parts and~ small stores (see list of contents, page 43), is fitted on eacim side; the lid~ opens from the top and is fastened at the rear by a imasp and turn-5 buckle and provided with a padlock. A steel tray and bronze bracket

are fitted to the rear of each box to support a projectile when timecarriage is limbered up in the firing position. The projectile is secured

!~by a strap. A wire net receptacle is fixed below the boxes for carrying~ the drag ropes amid lashings.

A board with waterproof canvas cover and clips for carrying two~ rifles is attached to the frame in front of time boxes.

The axletree, which is 1st class B No. 4, is of tubular steel, and isfixed by flanges to the futchels. Time lineim pin and adjusting collarare the same as for time carriage, and the outer flanges are provided witimdust excluders, which are similar to those on time carriage.

The fittings for draught consist of a No. 19 draught pole,with four No. 11 swingletrees and a No. 3 or 4 pole bar for horsedraught; a connector No 3 is provided for emigine draugimt. Time poleand bar are for use with time R.A. pole draugimt breast harness.Time pole is 12 feet 28 inches long (over all), the front end is protectedby steel wrapping plates; a U -shaped tug is passed through time polefrom time under side and secured by a nut on time top. Time tug forms astop for time pole bar, and its position from the poimit of the poie may bevaried from 26~inches to 14~incimes, in distances of 3 iuiclmes, accordingto requirements. Time front end of the poie is prepared for two stopbolts, which are only required when bullock draught is used. Time No. 3pole bar is 3 feet 9~inches in iengtim, and is fitted at the centre with acircular loop, whietu is formed topass over the front end of the poie andbutt against the tug. Two links are fitted on each side of the loop, bymeans of which the bar is attached to the neck piece of the harness.The No. 4 pole bar is stronger and is 4 feet 3~inches long.The swingletrees are 2 feet 5~8inches hong. The engine draught

-

14

Connector is V-shaped; a coupling bolt (with a volute spring) passesthrough an opening in the apex, and time forked ends are formed withlugs for attachment to the draught joints on the limber.

A yoke end chains for bullock draught can be used with the limberas required. The chains will be attached to time draught joints of thesplinter bar by the hooks or first link as may be found most Convenient.

The wheels are time same as those described for the carriage.The stores carried on time limber are shown at page 43, also on

Packing Diagrams A. B. and C.

DIMENSIONS, &c.

CARIIIAGt: AND Lmiumuuri.Carriage.

Ito axis of gunof dial sightjriglit side --

llei~lit~ line I left side1 of oscillating sight lineof fore and tangent sight line

Iwitliout sights . .\Vidtli (niaxiniurn) . - . . . .

F with gunLength, trail on ground, firing position i without gunElevation (maximum) .. ..Depression (maximum) .. .. . -

LimberHeight . - .. . - ..

Iwith pole .. ..Length .~ without pole .. .. ..of axietree with dust caps -.

Width f outriggers extended ..I. outriggers folded ..Carriage and Limber(with gun in 1 r

travelling ~with ~ P~1~ ..position j i engine draught connector

Length ~ with gun 1I . ipoloin firing ? with i . ,position engine diaught connector -.

l.bet.ween axletrees .. .. .. . -I track ..Wheels ~ . . -i. diameter .. . -

Space required to turn in (diameter of circle)Upsetting angle { ~1rr~age :: ::Upsetting angle of Limber with full lock . -Anglo of lock .. .. .. ..

feet. inches.4 4.45 1O35 11~3O 055 0~9680 6.5

21 710 5

21305

5, 018 5776 0~59970

32 426 8

37 431 213 115250

54. 0330430

29~37

cats. qrs. lbs.91 3 710 2 0

108 1 741 3 ()66 2 720 2 387 3 4015

TVeiahts.

Carriage with wheels and gun and 2 firing shoesLimber with wheels (fully packed) without two projectiles,.Carriage and gun with limber (with pole)

rfore wheel,, gun in travelling positionJ hind wheels gun in travelling positionWeight on1 fore wheels, gun in firing posItion

I,,hind wheels, gun in firing positionWeight on 1)010 at tug 3rd hole from front epd

-

15

CAItIUAGE AND LIMBERContinUed,Carriage owts. qrs. lbs.

Cradlo .. .. .. .. .. .. .. .. 15 2 0Pressure of trail on ground at lifting handles (gun in firing

position) .. .. .. .. .. .. .. 4 3 4Pressure of trail on pintlo of limber (gun in travelling

position) .. .. .. .. .. - - .. 26 0 0Engine drauhit connector, No. 3 .. .. .. .. 0 3 27Pole drauh~t,No. 19 .. .. .. .. .. .. 0 2 7Shoes firir~g .. .. . . .. .. .. each 1 3 17Swinoletrees, No. 11 .. .. .. .. -. ,, 0 o o~Wheel, 1st class B, No. 10 .. .. . . - ,, ~ 0 13

LIMBER, B.L., 60-PR., WAGON.(Plates XV and XVI.)

The limber consists of a steel frame, a limber hmook, a second-classaxictree, draught fittings, an ammunition box, and two field wheels.

Time frame is fitted with a foot-plate, and with draught hooks forthe swingletrees. The limber hook is secured to the rear. A sup-porting prop is attachmed to the front part of the frame.

The axletree No. 36 is of steel, and is provided with drag washersand hinch pins.

Time fittings for draught consist of a No. 17 Mark III pole, a No. 3supporting bar, and two No. 11 swingletrecs, and are suitable for usewith R.A. breast harness.

Time ammunition box is of steel, fitted at the rear with a lid openingdownwards and supported by stays. The hid serves as a shelf forfuzirmg shell, and is provided with a padlock and key. The boxis divided internally into compartments to carry ammunition andstores as detailed on page 44.

The shells and cartridges are secured in their respective compart-ments by retaining straps of the quick release pattern; a strapwith a wooden block fitting over the nose of the shell is provided tofacilitate the withdrawal of time projectile from time compartment. Atray for spare parts is provided in the upper portion of the box.

,A small box is formed under time ammunition box to carry twogrease boxes, and fittings to carry tlmree rifles are provided at time rearabove the ammunition box.

Time wheels are second-class ~ C No. 34 A, 4 feet 6 incimes diameter,with a 3-inch tire. The inner end of the nave is enveloped by a pro-jecting ring on the draught hook stays to prevent time ingress ofdust, &c.

The limber is fmtted to carry stores as detailed on pago 44. (Secalso Packing Diagram D.)

WAGON, AMMUNITION, B.L., 60-PR.(Plates XV and XVI.)

The wagon consists principally of a steel frame with perch andaxletree having 2nd class arms, ammunition box, tire brake, and twofield wimeels.

Time frame is united at time percim by time perch eye, at eacim side ofwhich is provided a handle for lifting. Underneatim are. two supportingprops, one attached to the percim,and time otlmer to time frame at therear.

-

16

The ammunition box is arranged iii two parts, front and rear, eachof which is divided into compartments to carry the ammunition andstores as detailed omi page 44. Time straps for retaining the ammunitioncund withdrawing the projectiles are of time same pattern as those in thelimber. Time front and rear of time box are fitted with a lid providedwith a padlock and key; the front lid being fitted with stays one mmeach side.

The brake consists of a brake bar, two connecting rods, crank shaft,and brake rod. The brake bar, which is supported in bracketsattached to the frame, is fitted at each end witlm east-iron brakeblocks, which act on the whmecls at the rear, The brake is actuatedfrom time near side of time wagon at time rear by an actuating handleand screw attacimed to the brake rod.

The axietree and wheels are of the same pattern as tlmoso for thelimber.

A spare jointed pole and a handspike can be carried under timewagon.

The wagon is fitted t~carry the stores (letajle(j ott page -1~1, (Seealso Packing Diagramn D.)

DIMENSIONS, &c.

W~taoNAMMUNITION ANT) LIMr,En.feet. inches.

Length of wagon and limber witlm polo .. .. .. .. 22 3axletree .. .. .. .. . - .. .. 6 0

between axletrees .. .. .. .. .. .. 7 2}Greatest projection beyond track of wheels.. .. -. .. ~ oMaximum width .. .. .. .. .. .. .. 6 0Wheels

Track.. .. .. .. .. .. .. .. .. S 2.~Diameter .. .. .. .. .. .. .. .. 4 6

Space required to turn in .. .. .. .. .. .. 28 oAnglo of lock

Left .. .. ,. .. .. .. 760Bight.. .~ .. .. .. .. 770

Weiglils.

(Fully packed with ammunition and stores, but withoumt men orpersonal equipment.)

cwts. qrs. lbs.Wagon, ammunition

With spare jeinted pole .. -. -. .. .. .. 29 3 12Without spare jointed pole .. .. .. .. .. 29 1 10

Limber, wagon .. ,. .. .. . - .. .. i~ 1 0Wheel, 2nd class, C, No. 34A .. .. -. .. .. 1 2 12

tEmpty, without ammunition and stores.)Wagon, ammunitionwith 2 fuze boxes, 26 projectile blocks,

two 2incli padlocks, and two 10-It, lashings .. .. .. 13 0 0Limber, wagonwith 2 grease boxes, fuze box, tray spare parts,

12 projectiles blocks, one 2-inch padlock, draught pole, bar,and 2 swingletrees .. ~. .. .. .. .. .. 10 0 0

Tonnage.tons.

Wagon, ammunition, without wheels .. .. .. .. 4.7Limber wagon, s~ithoutwheels . .. .. .. .. 3 P231Wheels (4) .. .. . .. .. . - .. .. 1 3

-

17

WAGON, G 5, MARKS IX TO X~Time Mark IX wagon consists generally of the following parts

body, under carriages, seat, floating raves, brake, axhetrees and wheels.It is fitted witim a 4-incim roller scotcim, wimip socket, and two grease boxes.

Time body is separate from, but rests on, front and rear under.carriages. Allowance is made on the front carriage for slight longi-tudinal motion, to ensure flexibility to the veimicle for rough travelling.Time rear under carriage has two straiglmt guides, wlmicim are continuedshighmtly beyond time body.

A locker is formed on time front part of time wagon ; the locker isbevelled off to allow the fore carriage to have a greater sweep, and thusminimise time space in wimicim time wagon can turn.

Time wagon is fitted for pole drauglmt, which consists of a No. 7Apole, and two No. IOA or 11 swingletrees.

- Time spimnter bar is strengthened by iron stays, whicim are formedwmtim hooks at time front for time attachment of time swingletrees.

Time drivers seat is supported on elliptical springs, to afford easyriding; the springs are fitted to a cross bar, witim ends formed to fitover two wooden standards, and are kept from being too lively by twoleather straps, time scat being fastened to time standards by keys.

Time brake, wimicim acts on the rear of time hind wimecis, is appliedfrom time drmvers seat by a hand lever or from time rear of the wagonby a Imandle operating a screw. Time Imand lever is connected bya flexible wire rope on time oil side of time wagon to a lever secured totime guides of the rear under carriage, and fitting into a loop attachedto time rear axletree bed. A brake screw is connected witim this leverand a wooden cross bar, which carries time brake blocks, and whicim issupported by brackets secured to time end of time guides. Wimen timehand lever is pusimed forward the blocks are forced against time wimeels.A rack retains the hand lever in position when time brake is applied,and a spring fixed beimind time lever serves to ease the blocks off thewheels when the imand lever is released.

Time fore axletree is 3rd class B, No. 171, and the Imind, 2nd class C,No. 200. The wimeeis are 3rd class B, No. 159, and 2nd class C, No. 200,being 3 feet 9 inches and 4 feet 8 inches in diameter respectively, with2k-inch tire.

The cover is made of waterproof canvas, and can be adjusted tosuit varying imeiglmts of loads, having on the oustide two rows of tabs,with eyelet holes, and on time under side and the item side lines ofwimite rope. Brass eyelets arc secured at intervals along the hem.

Time cover is secured to fitmnents on the wagon by lashmings, wimicimshould be passed tlmrough a row of eyelets on eacim side and on the backaccordimlg to the heigimt of time load to be covered.

TIme side lines of white rope on time under side are for use in reelingtime coverwimen small loads are carried in time wagon; time four on theimem nrc to keep the cover clear of the wimeels.

The sides and rear of the cover not required slmould be rolled tip andstowed away inside, the front portion being stowed behind the driver4sseat on full and half loads.

Weight .. .. .. .. .. .. lii cwt. 2 qr.Minimum space in which the wagon can turn LtO ft.Tonna ~ for slupment . . . . . - 6751 tons.g I for transport in boats .. .. 10112Ilectangular sptmce occupied in bont~ ., ., 12 ft. Sins. x Oft. Olin.

m Sft.3in,,(Slwo.)

-

Mark X is generally sinmilar to Mark TX but of rougher make,and is fitted with a swoop bar,

Mark X~is time Mark X wagon provided wmtlt dust oxcitiders, anddust capped wlmeeis, No. 2004 (Imind) and No. 159~(fore).

CARE AND PRESERVATION OF CARRIAGES, &c.See also Regulations for Magazines and Care of War Maiftici.

Special Instructions not in time above-mentioned Regulations.Before running the gun imp to the firing position time firing shoes,

lmandspikes, and rammer, which are carried in the trail, simould beremoved.

Dial and fore sight brackets.The locking wires in the adjustingscrews of the dial and fore sight brackets are so arranged timat timescrews cannot be vnscrewed without breakimmg time wires. To re-adjustthe sight by the screws the following methmod should be olservedInsert the screws in the bracket without time locking wires, andadjust the sight, time screws being tightly screwed up, then removeone screw and fit it with time wire, a sligimt but sufficient tap beinggiven to the top of time spanner (No. 263) to cause the wire todig into the sides of the recess, then tighmtly screw up again. Timeother screw simould then be treated in the same manner. The wiresare of tempered steel and c~neasily be brokemm.

Travelling in a series.1,Vhen it is desirable to travel with two ormore carriages and limbers in a series, an engine draught connectormay be used to couple time splinter bar of a limber to a carriage axietree,which is provided witim a link and pin for that purpose.

To Tighten or Re-pack time Glanmi.(Plate IV.)

If any leakage takes place at the gland, k, it should be tigimtenedif this will not stop time leak, time packing must be renewed.

To repack the gland, pull the gun back a convenient distance to therear, by means of a tackle secured to the lug of time gun and time traileye; unscrew the gland, k, extract the defective packing and insert timenew packing (about 16 inches of ~--in.hydraulic packing will be required).A piece of wood, suitably shaped should be used in forcing the packinginto time stuffing box. Replace the gland, and return time gun to itsnormal position.

To Replace an L Leather Packing Ring in Stuffing Box.Empty the buffer; remove the rear piston rod nut; elevate the

gun slightly; pull the gun back to 6 inches beyond the end of thepiston rod by means of a tackle (as explained above). Remove thefront piston rod nut. Unscrew the stuffing box h from the cylinder.Unscrew the securing ring, n; remove the box from the rod and, theL leather m from the box; place a new L leather on the rod, then thebox; secure the L leather in the box by the ring; screw the stuffingbox into the cylinder, care being taken before doing so that the leatimerwasher, x, is in its correct position in the box. Replace the front piston

rod nut on the rod, return the gun th its m~orma1positio; and r~placerear piston rod, nut and keep pin,

-

1 9

To Fill time Bufler. (Plate IV.)Qmma]mtity of mineral oil :Aboimt 5 qmiarts.Elevate time gull, remove plug A at fiulitmg hole in front, amid air hole

plugs B amid C on top of tank and buffer. Pour in oil until it flows atair imoles. Replace air hole plugs Ii and C and continue pouring in oiluntil the tank is full. Remove air plug D at front of tank, and replaceit when time air imas escaped. Replace filling hole plug A.

Replacenmeat Limits of Running-out Springs.Time normal free length of each running-out spring is us follows

Inner .. .. ., ,, 289 inches,Outer .. .. .. .. 305 incimes.

Any one spring, inner or outer, found witim a permanent set of 2~Oinches and 3 inches respectively (or more) below tile normal freelength of time spring will be replaced.

To Replace a Damagcd Spring. (Plate V.)Special tools required

Tools, assembling springs, B.L., 60-pr.Blocks, wood, V . - . - .. 2Stave, 8 feet ~ 1~,inches diameter (asim) 1Wrench (horse shoe) .. ., .. 1Tommnies, No. 12 .. .. -. 2

To Rcmov~a Spring. Place time press on time wood blocks. Removetime spht pill, v, from time front end by compressing the springs tobring time pin clear of time end plate. This can be done by mnnking adrag rope (double) fast to time shackle end, and at time other end ofsprings, making a Spanish windlass with a hammershaft. Unwind thescrew, c, with spanner, No. 264, and prevent time rod, p, from turningby means of a tommy passed tbmrougim time lug, o, as a stop. Whentime screw is detached from the rod, remnove the damaged spring.

To Assemble the Press. Place the outer springs, a, alternatelyright and left wound, on the inner spring case, e. Pass the rod, p(with the retaining plate, in), into the inner spring case through thebearing f. Place an inner spring, b, a distance tube, r, and adividing bearing, s, within the inner case and over the rod. Repeatthis operation until the inner case is full, using the ash stave to centretime tubes and dividing bearings, and inserting time springs alternatelyright and left wound. Wlmen the spring case is full, place the remainingcomponents on time screw, c, in time following order :bearing ring, g,distance tube, r, inner spring, b, dividing bearing, s, distance tube,and so on till all time parts are assembled. Engage time screw, c, with therod, p, and, with the spanner, No. 264, turn the screw into the rod untiltime front end of the rod engages with the shoulder on time rear end oftime screw, using a tomnmy in time lug, o, to prevent time rod from turning.With the horseshoewrench and a tommy turn time bearing, g, by engagingthe open ends of the wrench with the ribs of time bearing until theImoles through the screw, rod and bearing for the split pin are in the same

~tmaigh~line. Replace the split pin.

Care of Telescope, Sighting, No. 5.The telescopes are issued with all cells, joints; &c,, tightly ~crewecl

up. The glasses should not be unscrewed except in cases of necessity,and then only by a competent person; they will seldom require to ho

(,5lwo.) ii 2

-

cieancd on the inside. Cleammimig should be clone ouiy w-ith chamoisleather, and great care must be taken that no oil or grease touches theglasses, as it can only be eomplcteiy removed by the misc of spirit.

If the object glass is unscrewed for cleanimig purposes, the lensesshould not be removed from the cell, as they may be easily reassembledincorrectly. Time unscrewing of the object glass cell causes defectmvecollimation, rendering the telescope useless end necessitating re-collmma-

qh focussing tubes should on no account be removed by any but

a skilled person, specially appointed to do so. -The body of the telescope must not be cleaned or polished wmth

anything e~ccepta dry clothe and a little oil or v~s~line,care being takenthat tile lenses do not come in contact withany greasy substance.Even fingers, when apparently perfectly clean and dry, nmay leavegreasy marks on the lenses whicim will, impair time definition of thetelescope more than dust. -

Time c1ermn~tineeye guard r~ustbe kept free from grease ; it shouldoccasionally be washed in a weak solution of soda and water.

When not in use time telescope should be closed up and kept in a dryplace,

General Remarks.The telescopes, as issued from Woolwiclm, are tightly screwed up

and accurately collimated; and, provided that none of the screw threadsmire unscrewed or tampered with, the collimation will remain as goodmis wimon first adjusted.

IXSTI1UcTIONS }oP. TESTING AND ADJUSTING THE SIGHTS.(See Plates IX to XII and XVII.)

Any adjustments required must be carried out by an armament artificer.Before army of the following operations are carried out, the carriage

should be placed on a firm platform or on hard level groummd, and nmani-pulated until the gun is level, both longitudinally amid transversely.

Dial Sight.1. Time bubble of time longitudinal level should be in time centre of its

run when the top bearing surface of the degree scale plate is lmorizontal.Test.Remnove the telescope and telescope carrier, manipulate the

sight until time bubble of the lommgitudinai and cross levels are in thecentre of their runs. Place a chinomneter, set at zero, on the degree scaleplate, Parallel to the axis of the gun. The bubble of the clinometershould be in the centre of its run.

AdjustnmentElevate or dpress the sight umitil the bubble of theclinometer is central, and turn the capstan~headednuts at the emmds ofthe longitudinal level until its bubble is central.

2. Time bubble o/the cross level should be in the centre of its run whemmtime top bearing surface of time degree scale plate is horizontal.

Test.Proceed as in test 1, but place the clinometer at right anglesto the axis of the gun. The bubble of the cross level should then bein the cemmtre of its run.

Adjustment.Cross level the sight by menus of the levelling screwummtil the climmomneter hubbla is central, and correct time positiomi ~f timeiross level until its bubble is central, .

-

21

~. Time clevaimo~scale of the siqimt s/mould be at zero when. the (illsthe gun and the bearing surface a/time degree scale plate are both houizonta~.

Test..With gun level, time arrow on the pointer should immdicatezero.

Adjust,nent.If the error is smmiali, erase the arrow and re-markit opposite zero.

Oscillating Sight.Tests 1 and 2, and adjustments 1 and 2 as for dial sight.

3. The elevation scales of the sight should be at zero when time axis ofthe gun and time bearing surface v/the degree scale plate are both horizontal.

Test.With the gun level, the readers of the yard and degree scalesshould indicate zero.

Adjustnzent.There is no quick way of making an adjustment. Ifthe error is small (5 minutes or under) it should be noted, and noadjustment made.

If the error is great, turn the handwheel of time sight until the drumstop prevents it moving farther, adjust the readers so that they comeopposite their zeros. Slacken the nuts on the studs, securing time ~vormspindle bracket to the cradle, remove the nut on the front lower stud(which is eccentric) and the set screw wlmiclm secures it. Turn timeeccentric stud until the bubble of the clinometer (placed longitudinallyon the degree scale plate) is central ; replace, and screw up the imutson the studs, and refix the set screws. Elevate the sight to read22 degrees, set the ciinonieter at 22 degrees, place it longitudinallyon the degree scale plate; the bubble should be in the centre of itsrun. If it is not, the drum stop on the sight is not correct.

Telescope Car, icr.The telescope bearings should be parallel with the under bearing surface

oJthe telescope carrier.Test.~Placethe carrier, without telescope, on time degree scale plate

0f either time oscillating or dial sight (accurately levelled). Place astraigimtedgc, or a bar, testing sight, if available, on the telescopebearings, and upon either place a clinometer set at zero. The bubbleof time clinometer should be in the centre of its run. It is as well torevolve the carrier through a complete circle and see that the clinometerbubble does not move.

Adjustrnent.Carelimliy adjust the telescope bearings.Telc~scope, =

CollinuitioimTest.Place tue telescope iii the bearings of time carrier on either

time dial or oscillating sight. Lay the pointer on some well-definedobject. Revolve the telescope slowly in its bearings through a com-plete circle. The tip of the pointer should remain on exactly thesame point.

Adjustment.If, when the telescope has been revolved half a turn,the tip of the pointer appears to have moved above the point laid on,unscrew the capstan-headed screw beneath the telescope (havingpreviously unscrewed the metal cap covering the capstan-headedscrews) amid screw up the omie above time telescope until the pointer isbrought half way towards the point laid on, thereby depressing the

-

~ight ; move the pointer exactly on to the point laid on. Repeat theprocess until the pointer moves neither above or below the point laidOil.

If the pointer appears to have nmoved below the point laid on, reversetime above procedure.

Revolve time telescope through quarter of a circle, mv on the sanmepoint ; revolve the telescope through half a circle, and if the pointerappears to move above or below time point, proceed as before.

Test again through a complete revolution. See that all the capstan-headed screws are home, and replace themetal protecting cap.

ALIGNMENT OF THE SIGHTS.

In order to carry out the tests for alignment, it is necessary toobtain a line of sight along the axis of the bore of the gun. A pointat the muzzle is obtained by stretciming two fine cords along time verticaland horizontal axis lines cut on the muzzle of the gun, their point ofintersection being on time axis line. Or a sighting hush (see Plate XVII)may, for this purpose, be made locally. The axial vent is used as asighting hole at time breech end, the retaining block having been re-moved. By looking through the hole jim time breech screw, and turningthe disc, it can be ascertained that the pointers of the bush are in timecorrect central position.

Select a clearly-defined object, at least a mile away, to la.y onor, if this is not available, comistruct a target with five circles on it,B, S, 0, R, I,, each circle divided into black and white sectors, thecentres of the circles being the points to lay on (see Plate XVII). Setthe target up at a distance of about 50 yards from the gun, with timebase line horizontal. Lay the axis of the gun on point B.

Fore and Tangent Sights.(a) Direction,Te.st.Set the arrow on the deflection leaf at zero. The line of

sight should fail 0mm the same vertical line as the point S.Adjustment.Move the deflection leaf until time line of sight falls

oim the same vertical line as the point S; erase the arrow on the leafand re-mark it opposite zero.

(b) ElevationTest.Set the sight at zero. The line of sight should fall on the

same horizontal line as time point S.Adjustment.With tangent sight at zero, lift acorn pillar of fore sight

until the line of sight falls on the same horizontal line as the point S.

Oscillating Sight.(a) Direction~Test.Fix the telescope and carrier on the sight. Engage the worm

with the degree scale plate and the spring catch with the deflection scaleplate. Manipulate the sight until the pointer of the telescope is laidon the point 0.

The arrow on the pointer should indicate 3 minutes right deflectionon time catch plate of the carrier. If it does not, correct the error asfollows

Adjustrnent.Set th0 pointer to read 3 minutes right deflection,loosen the three screws inside time milled head, mind with mm suitable

-

spanner on tIme squares of the catch plate turn tIme worm spindle untilthe pointer of the telescope strikes time object, care being taken thattile catcim plate and pointer do not move, tlmen re-tighten the screws.

Slighterrors iii the reading of the degree scaleplate may be neglected,as the scale plate is only graduated to read in multiples of 5 degrees.

(h) ElevationTest.-Lay time pointer of the telescope on the point 0; the reader

of the yard amid degree scale ring should indicate zero.Adjustment.It is not likely that any adjustment w-ill he necessary,

as previous tests ~mndadjustments have made the axis of the telescope,i)earings of the carrier and degree scale plate, and axis of the gunparallel to one another.

If time pointer of the telescope does not appear to be exactly on thepoint 0, it is probably due to the optical test being more accurate thantests with clinometer.

Dial Sights. =(a) DirectionTest..Fix the telescope and carrier on the sight and test it on both

sides of the gun. Set the carrier at 3 minutes right deflection. Seethat time pointer is indicating 3 minutes right deflection on the catchplate, and set the deflection plate at zero. The pointer of the telescopeshould fall on the point L or R. If it does riot, proceed as follows :

Adjustnient.Bring time pointer of the telescope on to the pointL or R by manipulating the set screws in the brackets. See that bothscrews are bearing against time lug on the bush, and replace the lockingwires in the set screws (see also page 20).

(lm) ElevationTcstLay time pointer of the telescope on time point L or II. The

reader on the degree scale should be opposite zero.Adjustnicnt.-It is not likely that any adjustment will be necessary,

as previous tests and adjustments have made time axis of time telescope,bearings of the carrier and degree scale plate, and axis of the gunparallel to one another.

If the pointer of the telescope does not appear to he exactly on thepoint L or B, it is probably due to the optical test being more accuratethan the tests with clinomet~mr~

If the sights do not agree when laid on the target or distant object,and any adjustment is made, time longitudinal levels of time sights mustbe again tested with a clinometer.

In any case, the adjustments should not be disturbed or altered,unless time tests have been most carefully carried out and repeatedtests have shown an error.

-

.~U~:IMUNITfON.

CARTRIDGE.

CARTRIDGE, B.L., 60-rE., 9 Lfl. 7 oz. CoRDITE, M.D., SIzE 16, MARK I.(Plate XVIII.)

Time body of time empty cartridge is made of No. I class silk cloth,and is provided with four hoops of 035 inch silk or shalloon braid.Each end of time cartridge comisists of two rings of No. 1 class silk cloth,sewn to two discs of shmalloon, wimicim are stitched across time centre toform four compartments.

Time charge is built up of M.D. cordite, is cylindrical in shape, andformed with an annular recess ineach end to receive an igniter of about16 dranis of S.F.G.2 (cartridges of earlier manufacture have igmiiters ofR.F.G.2 new or converted powder), contaimied betweemi the discs ofshalloon mentioned above.

Dinme.~sionso/ Filled Cartridge.Lemmgthm (not to exceed) . . . . i7~inches.Diameter (not to exceed) . . . . 4.5

Time cartridges mire packed, 12 iii a Case, powder, mmietal lined,whole.

CARTRIDGE, B.L, -I.INCIr, 5-INCH Cu~on hoWITZER AND GO-rn., 3 um.BLANK (MARK I.)

Time cartridge consists of 3 lb. blammk L.a. powder iii a No. 1 silkcloth bag furnished with four Loops of silk braid and choked with No. 1sewimlg silk.

Length (iiot to CNCee(l) . . . . 675 inches.Diameter (not to exceed) .. 4.3 ,,

It is essential that the gun be sponged oat between each roundfired,

-

[All rn//its reserved.

HANDBOOK FOB TI-TE 6O.PR. B.L. GUN,MAIIT~I (LAND SERVI4~9.

45 MA~1912,. ~

A M F~N I) M

Page 32After lime 22 insert

TO ASCERTAIN TIlE LOWEST RANGE AT WIIICIS rilE TRAJ~lCTOliYWILL CLEAR TIlE CREST.

TO ASCERTAIN W1IETIIE1i THE TIIAJIICTOIIY WILL CLEAR TIlECREST, TilE ANGLE OF SIGhT ANI) RANGE nEING KNOWN.

Page 33J)elete lines 4 and 5.~ lines 10 to 13 substitute The detaclmmneiit consists of 10 men,

wino fall iii two deep, oime pace between ranks, 1 on the right oftine front rank.

Line 21. For three yards substitute one yard and Jorwheels smbstitmite immuzzlo

a~ Page 84~ Line 17. For firing simoes ~ubstjlute the~ Line 22. After use insert Breech and muzzle covers may be~ replaced if mmeeessary.~ Line 36. Delete fining shoes

Lines 47 to 49. Delete, amid n imsertElevatehalt, Trail riqimtIfalt, iCe., and assists inshifting tine gun.

Page 35 :Line 1. Delete attends to time firing shoes, andLine 3. After rams home insert secures the laying stops in

the travelling position, and adjusts them for use when iii action.

Line 6. Delete attends to time firing shoes, andLine 17. Delete (a)i)elete lines 20 amnd 21.Line 28. Delete firing shoesLine 8 from bottom. Delete and firing shoes

P09(1174) 27014237 1,500 1/10 M A Co.

-

2

Page 36 :Line 3. Insert Roar after Action under Section Corn-

umander.Line 3. Delete Fix firing shnoes. under No. 1.For lines 8 to 30 substitute

At the order from 1, Prepare to Unlinmber2 and 3 place their handspikes in time sockets on the trail, 4

and 5 double man them, 6 and 7 stand to support time couplingblock, 7 removes tine connecting pin, 1 gives iiiiiber, (Irive On.Time limber moves as directed in Field Artillery Training.As soon as the trail is clear 1 gives lou~er, amid the trail mumdcoupling l)lockS are lowered gently. Limbers will move at awalk except when unden- fire, or the tactical situatioim necessi-tates thieir moving at a greater speed.

Line 37. Delete fixes front and rear laying steps,Line 38. Delete (if loaded)Line 39. After ready iii semi

During ranging for elevation, as soon as the gmum is reportedRead~j,1 will hold up his Imamid, and, should he see that tine

Section Commander has not observed his signal, he will call hisattemntiomn by reportmg i\o . . Ready.

Line 40. After for loading insert fixes front and rearlayimmg steps.

At bottom of page insert new paragraph Action Riqlmt ammd Left are time same except timat at

Action Riqlmt.The trail is carried round a quarter of a circleoimly.

When oin a side slope, Artion Rear, only, should 1)0resorted to.

Page 37Line 14. Afler fuze insert cianimpiimg them as tigim t as

possible ~ and add footmiote.Time fuzes should be securely clamped to reduce the

chances of prematures, caused by the slipping of time time ring.Delete the asterisk under SIGNALS and time footnote.

Page 38:Delete the second paragraph unler MISS-FIRE, amid insert

Should miss-fires continue, tine breech nmay 1)0 OpeliO(1, l)Utan interval of at least one minute with black powder charges,and of ten minutes with smokeless powder charges, must beallowed to elapseafter time last failure to fire time gull.

None of the detachment should 1)0 directly in rear of timebreech when it is opened.

Line 33. i)elete from and to end of sentence.Line 35. After time gmm insert and secures time haying slops

in tine travelling position.Last line. After . . . Section, insert Rear.

-

Page 39i)elete line 2.1)elete iimies 26 to 29.At bottom of page insert new parngraplis-

TO ASCERTAIN TIlE LOWEST RANGE AT WHICH THE TnmAJEcToRvWILL CLEAR TIlE CiIEST.

Lay gum omm crest with tamigemmt siglmt set to a liberal estimmiateof range to erest or obstacle. The resulting quadrant elevationminus the angle of sight is time elevation due to tine lowest ramigethat will ailow tine trajectory to clear. This range eamn he readon the range drum.TO ASCERTAIN WIIETIIER THE TRAJECTORY WILL CLEAR TIlE cIIEST,

TIlE ANGLE OF SIGHT AND RANGE DEING mcNowN.Lay gumi with the quadrant elevation due to time angle of

sight + range. Set taimgennt sight to a liberal estimate of tinerange to the crest or obstaCle. If this line clears the crest thetrajectory will do so.

Page 40:Line 17. 1)elete remove tine firing shoe \vinen the wheel is

elear, andDelete from 4 a~md5 inn line 26 to ropes. iii line 27.Line 29. Delete on to tine firing shoes, and aftem- tine stores

a0sert arePage 42

Delete hines 23 to 35. -

War Office,Wimitelmahi, S.W.

31st I)eeember, 1900.

~uauC IV~RYUFViCiURt/.

-

hANDBOOK FOR THE 60-Pit. ILL. GUN, MARK 1(LAND SERVICE).4:. 1000.

-p. __

~ Page 87, line 14, qjter fuze. addclamping them as tight as iowdble.t

Add footnotet Timefuses should besecurely clampedto reduce she chance, of premature.,

~ caused kv the sUpping of the (line ring.(1145) Wt 256142011,300 ia 31 t Coo

-

25

C?

C?

C)

0

C)N

C)0C?

0ICPCPC

*

N0

0 0 0CO CO CO CO CO

NP

-C)

if*

0 0

CO 0 0

~4 ~ 0

l~ 0~I~ L~ )~

4) CCC? C)-~ --C) -C)

-C)0 ~-. 0

C,. t~ C,. I. I..C) C) C) C) C).4, ~,

C?C))

C?

4

P4)k~

a: ki

~.

-P0

I..4)C)C) -~ . I~ )~ C~I. ~PI C~C

%~) IC)

H ~

C)

I HH5

-

ComimloN SHELL.Mark 1.ThIs shell is intended for practice purposes; it is made of

cast iron. It is provided with time same copper driving band as timelyddite and shrapnel shells, which is pressed into a groove havingfour waved ribs. The interior of time shell is Velvrihled.

Mark II differs from Mark I in being longer and thinner in thewails, thus allowing a greater capacity for the bursting charge.

Com~soNLYDDITE SHELL.

(Plates XIX and XX.)Mark 1.This shell is made of forged steel with a solid base, and is

fitted at the nose with a gunmetal fuze socket screwed to the G.S. fuzehole gauge. it is provided witha copper driving band, which is pressedinto a groove having four waved ribs.

When filled the shell will take an Exploder, lyddite shell, 3~oz.Mark Ii differs from Mark I in being longer and thinner in the walls,

thus allowing a greater capacity for the bursting charge.Wlmen filled this shell will take an Exploder, lyddite shell, 41 oz.,

without primer.

SHRAPNEL SHELL.

(Plate XXI.)The body of the shell is of forged steel, and has a recess in the base

to contain a bursting charge of 4~oz. of powder contained in a tin cup.The head is of steel, fitted witha wood block resting on a felt washer,

and is attached to the body by means of screws and twisting pins. Ithas a metal fuze socket screwed to the 2-inch fuze hole gauge, and fittedwitim a fixing screw for securing the adapter.

A central tube conveys the flash from the fuze to the burstingcharge in the base.

The shell contains about 9f~0bullets (35 to 37 per lb), and is providedwith a copper driving band, which is pressed into a groove having fourwaved ribs.

When using a No. 62 T. and P. fuze with this shell an Adapter,2-inch fuze hole must be employed.

FUZES.Fuza, PERcussIoN, DIIn~cT AcTIoN, WITH CAP, No. 1, MARKs 1*,

I~*,II AND 111.(Plate XXII.)

Mark 11.This fuze is immtended to act on direct impact; it cannotbe depended on to act on graze unless fired at angles of elevation of10 degrees~and upwards.

It is made of gunmetal,, turned all over, and screwed below thehead to fit the G,S. fuze bole. The interior is bored out at the lower

-

27

cud for the powder charge, and closed with a screw base plug. A recessin the upper part of the fuse is charged with detonating composition,and the holes communicating witlm the magazine are filled witlm powderpriming. The fuse is fitted with a steel needle, passing through andsecured in a copper suspending disc 0032 inch thick. The lower partof the fuze is filled with pistol or R.F.G.2 powder. A gunmetal cap,having a T-simaped slot cut out in each side to fit over time projectingpins in the head of time faze, is securedover the top.

On striking time object, the suspending disc is driven in and timeneedle is forced against time detonating composition, thereby explodingthe faze.

Mark III differs from Mark II in Imaving a removable detonator,a single pointed needle, and a shiglmtly smaller magazine, containing65 grains of powder.

Weight .. .. .. .. 7~oz.These fuzes are issued one in a tin cylinder for this equipment.Marks 1* and J** fazes may also be used.

FusE, Tm~mu AND PiiIicUssIoN, No. 62 MARKs I AND II.

(Plate XXIII.)The Mark II fuze principally consists of the following parts, which

arc made of gunmetal, except where otherwise stated; body, detonatorplug with detonator, percussion pellet with needle plug and steelneedle, brass safety pellet, brass ball, base plug, time composition rings(upper and lower), brass springs, dome, brass washer, cap, two safetypins, and leather washer.

Time body is screwed at the lower end to G.S. fuzehole gauge, andbored from the bottom to receive the percussion pellet and base plug.Two holes are bored beyond time recess for the percussion pellet, one fortime detonator plug, the other for time safety pellet. The hole bored fortime detonator plug is continued horizontally to form a small magazine,which is filled with fine grain powder; the hole then leads upwards tojoin the time rings, and contains perforated pellet powder. The stemof the body is fitted with two studs to engage correspondingslots in time upper ring to prevent it revolving and is screwedto take the cap, two featherways being cut in top end ofstem to receive corresponding feathers on the brass washer overdome. A small tablet of fine white paper is secured with shellacto the body of the fuse over the perforated powder pellet, and overthis tablet are two washers, one of fine white paper, and the other ofcalfskin, which are secured with shellac, a hole being cut tlurougim timewashers and tablet immediately over time powder pellet; similar tablet,pellet and washers exist on top of the lower time ring.

The detonator plug is screwed on the outside to fit the hole preparedfor it, and contains a detonator, which consists of a copper cap with fireholes filled with 3~grains of detonating composition, with a ~0O5-inchbrass disc under the composition and a tinfoil disc over it, to preventthe composition working through time holes.

The percussion pellet Imas a slot in the side for the safety pellet, andbrass ball to fall into wimen set in action. For additional safety a holeis made transverseiy through time percussion pellet and fitted with abrass retaining or centrifugal bolt, which engages in time body, and is

-

held, in positiolm by a brass spiral sprilmg the outer end being timeheavier part of the bolt, it disengages itself from time body in fiigimt.Time percussion pellet contains a 5?~ grain perforated powder pellet,having under the latter a muslin disc and brass washer, and over it oumegrain of fine grain powder, and timen the needle plug which is screwed in,time latter is perforated witim six fire lmoles and contains time steel needle.A small set screw in the body fits into a slot in the percussion pellet toprevent time latter turning in flight. Two spiral springs prevent timepercussion pellet creeping forward during flight and causing prematureexplosion; these springs have a seating in a simahiow recess in top of thepellet, and the opposite end in a corresponding recess in the fuse body.

The safety pellet imas a slot cut in the side to clear time brass ball, andis suspended iim time body by a timin copper wire which passes timroughit. A imoic is also bored in time body and upper part of pellet for thepercussion safety pin ; time hole in time body left by time removal of timesafety pin is closed by a brass pellet having above it a spiral spring incompression.

Time base plugcontains a perforated powderpellet ; over time latter aretwo discs, one paper, the otimcr muslin, and a brass wasimer, and underthe pellet a simalloon disc and a brass washmcr. Time base of time faze isclosed by time plug, wimicim is made secure by being stabbed in threeplaces.

Time composition riiiqs Imave eimcim a channel, which is lined withasbestos paper, for time fuse composition, and a hoie is provided whichallows the gas direct escape outside ; this escape hole is iigimtly closedby means of a brass disc covered without by Iettman cement.