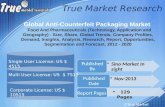

External Anti-counterfeit standards July 14th 2015

Transcript of External Anti-counterfeit standards July 14th 2015

1 GE Title or job number

05/03/2023

Anti-counterfeit standards summary July 2015 Prepared by: Jo VannIEC TC107 WG3 ‘Counterfeit electronic parts; avoidance, detection, mitigation, and disposition in avionics applications’ convener , see http://www.iec.ch/dyn/www/f?p=103:14:0::::FSP_ORG_ID,FSP_LANG_ID:5736,25Member of SAE: G19A, G19AD, G19C, G19CI, AMPC, IAQG

2 GE Title or job number

05/03/20232

The Avionics Supply Chain

1. Parts & Materials Suppliers

2. Board Assemblers

3. Avionics OEMs,

Logistics, Maintenance

and Repair

4. Platform Integrators

5. Operators & Regulators

Parts

Boards

Contract Mfg.

Suppliers CustomersSolder etc. SuppliersCustomers

15 - 40 yrLifecycle

3 - 6 yrLifecycle

IEC/TS 62668-1/SAE AS5553A Anti-counterfeit and IEC/TS 62239-1

ECMP

Most life cyclecosts are incurred here and managed by ECMP

Global Supply ChainSAE AS5553A counterfeit avoidance

Requirements flow-down vs.

products flow-up process is

disrupted here

Aerospace Captive

To build products that must meet mil-aero requirements

(what we must control)

Using COTS components targeted for other markets (what we cannot control)

Aerospace Electronics• Depends on

materials and components developed for other industries

• Vastly different lifecycle applications

3 GE Title or job number

05/03/2023

What is the problem? • In 2010/2011 the USA DoD identified upwards of a million counterfeit

components in their Military supply chain. This resulted in the 2012 NDAA section 818 anti-counterfeit clause which

was published May 2014 as DFAR 252.247.7007 • Researcher IHS analysed electronics industry data in 2013 concerning

counterfeit parts that were reported from 2001 until early 2012: More than 12 million counterfeit parts have been reported over

the last five years to 2013 57% of counterfeit part reports involved obsolete or end of life

parts. Nearly 37% of counterfeit parts involve components still being

produced by manufacturers. A single incident of a counterfeit part can cause up to 64 weeks of

production line downtime and cost up to $2.1 million to resolve. Counterfeit parts are mostly sold on the open market.

4 GE Title or job number

05/03/2023

Recycling - typically occurs in China

5 GE Title or job number

05/03/2023

International anti-counterfeit standards SA

E IEC

IEC/TC10

7 WG3

G-14 AAQS

C

IEC/TS62668-2

G19A

IEC/TS62668-1

G19AD G19C

AS6171 Test Metho

ds

AS6496 Franchis

ed distribut

or

AS6301,AS6462audit

checklists

G19CI

AS5553

electronic compone

nts

G21

AS6174

materiels

AS9100 Rev D

for publicati

on 2016/17

6 GE Title or job number

05/03/2023

Military Supply Chains and contract flow-down

USA Militar

y

UK Militar

y

DFARS in

contracts

DEF STAN 05-135

anti-counterfe

it

DFAR 252.246.

7007 electrica

l anti-counterf

eit

OEM

SAE AS5553

flow-down to supplier

s

OEM supplier

s

SAE AS6496

Franchised

distributors

ARP 6178 non-

franchised

distributor

SAE AS6171 Material

s

7 GE Title or job number

05/03/2023

Anti-counterfeit standards summaryStandard Market

sectorDescription Comments

AS/EN/JISQ9100

Avionics OEMS

General Quality Management System

All Avionics OEMs are expected to operate to this standard which is currently at rev C. Next revision (rev D) for publication in 2016/2017 will include anti-counterfeit management requirements for material, mechanical and electrical components

SAE AS5553 General industry but mainly used by Avionics OEMs

Set of 11 mandatory detailed requirements for how to buy, manage, and dispose of electronic components with reporting mechanisms when counterfeits are found

Currently at revision A. Can be used to satisfy AS9100 rev D electrical component anti-counterfeit requirements. Next revision is in process to align it better with DFAR 252.246.7007. Mandated by most USA Prime Contractors.

SAE AS6174 General industry but mainly used by Avionics OEMs

Similar to SAE AS5553 for the procurement, management and disposal of electronic components but modified for material and mechanical components

Can be used to satisfy AS9100 rev D anti-counterfeit requirements. Use rev A. It is recognised this is a WIP as many appendices are not yet complete. Please join the committee if you have concerns contact Robert Tipton, [email protected]

USA DFAR 252.246.7007

Military US supply chain OEMs

Set of 12 mandatory detailed requirements for how to buy, manage, and dispose of electronic components with reporting mechanisms when counterfeits are found

Used in US Military contracts. Set of mandatory rules for covering how to buy and dispose of electronics components with reporting rules when counterfeits are suspected or found. Exceptions not allowed. Can use SAE AS5553 and /or IEC/TS 62668-1 and IEC/TS 62668-2 to comply

8 GE Title or job number

05/03/2023

Anti-counterfeit standards summaryStandard Market

sectorDescription Comments

UK Defence Standard 05-135

UK Military supply chain OEMs

General overall anti-counterfeit requirements

Used in UK Military contracts. Part of the UK Counterfeit Avoidance Maturity model which is used to assess how ‘counterfeit aware’ suppliers are. Can use SAE AS5553 and /or IEC/TS 62668-1 and IEC/TS 62668-2 to comply

IEC/TS 62668-1

Avionics OEMs Anti-counterfeit requirements for the purchase and management of electrical components, management of the products IP and control of spares and repairs

Allows the use of SAE AS5553 plans for components coming into a business and will allow the use of AS/EN/JISQ anti-counterfeit plans. Considered to provide a more ‘holistic’ approach to anti-counterfeit and recycling component management . Preferred by European Prime contractors and suppliers who do not want to work to SAE AS5553.

IEC/TS 62668-2

Avionics OEMs Risk assessment of electrical components purchased from non-franchised sources

Complements SAE AS5553 which has no risk assessment process for non-franchised purchases and IEC/TS 62668-1.

9 GE Title or job number

05/03/2023

Anti-counterfeit standards summaryStandard Market

sectorDescription Comments

SAE AS6496 Franchised distributor for high reliability, Aerospace and Defence market

Fraudulent/Counterfeit Electronics parts: Avoidance, Detection, Mitigation and Disposition- Authorised/Franchised Distribution

Released 2014

SAE AS6171 Component Test Houses for any market

Test Methods Standards; Counterfeit Electronic Parts

WIP- several individual test methods are ready for release: Test method I – External visual, Test method II- XRF .Debate about risk mitigation method and whether it should be part of SAE AS5553B.

AS6081 Non-franchised distributors

Fraudulent/Counterfeit Electronics parts: Avoidance, Detection, Mitigation and Disposition- Distributors; Counterfeit Electronic Parts: Avoidance Protocol, Distributors

Parts are offered by non-franchised distributors with some basic testing which Avionics OEMs need to review in their application risk assessment process. Considered an input into SAE AS5553 or IEC/TS 62668-2 risk assessment

ARP 6178 Non-franchised distributors

Fraudulent/Counterfeit Electronic Parts: Tool for Risk Assessment of Distributors

Very useful Excel spread-sheet with macro to remotely audit non-franchised distributors. Considered an input into SAE AS5553 or IEC/TS 62668-2 risk assessment

10 GE Title or job number

05/03/2023

Anti-counterfeit standards summaryStandard Market

sectorDescription Comments

AS6462A Auditing bodies and OEMS

AS5553A Counterfeit Electronic Parts: Avoidance, Detection, Mitigation and Disposition Verification Criteria

Audit checklist for SAE AS5553A for use by OEMs and Third party auditing bodies.

AS6301 Auditing bodies and OEMS

AS6081 Fraudulent/Counterfeit Electronics parts: Avoidance, Detection, Mitigation and Disposition- Distributors Verification criteria

Issued in 2014

AIR6273 For everyone using other SAE anti-counterfeit standards

Terms and Definitions- Fraudulent/Counterfeit Electronic parts

Draft – still WIP

11 GE Title or job number

05/03/2023

2015 anti-counterfeit supply chain

12 GE Title or job number

05/03/2023

• Personal liability for employees of companies under the new charge of trafficking in counterfeit military goods: Fines and imprisoned (up to 20 years if claim ‘not guilty’ and later found

guilty). Impacts countries with weak extradition laws to the USA, e.g. the UK.

• Potential DFAR implementation issues: ‘Traceability back to the original component manufacturer’ clause :

Prime contractors i.e. air-framers are finding this clause a massive challenge and are seeking to limit this to just the traceability to the first assembly of a LRU. This has been agreed.

A revision to SAE AS5553 rev A was started last year to incorporate any many DFAR requirements as possible. The draft was also streamlined significantly. However this failed an SAE ballot in November. Further discussions with the DoD have been held with a way forward. The G19 committee has just started up again working to create SAE AS5553 rev B with an optimistic target publication date of December 2014.

• DFAR definition of counterfeit (same in SAE AS5553A), also includes fraudulent components in addition to fraudulent recycled components and is unique to the USA.

USA Military DFAR rule 252.246.7007 includes:

13 GE Title or job number

05/03/2023

USA prosecutions in 2014• Vision Tech in Florida in 2010, discussed last year• June 2014 Massachusetts-based distributor Peter Picone of

Epic International Electronics Inc., pleaded guilty to trafficking in falsified ICs that had been resurfaced to change the date code and to affixing counterfeit marks destined for military equipment. The counterfeit parts bore the trademarks of legitimate companies such as Xilinx, National Semiconductor and Motorola. He faces 46 months in jail after pleading guilty.

This is the second prosecution on the new charge of trafficking in counterfeit military goods, see http://www.law.cornell.edu/uscode/text/18/2320

The court has taken the unprecedented step of publishing all the components Mr. Picone ever sold to the US Navy and it implicates nearly all the non-franchised distributors in the USA.

• The DFAR resulted from the 2012 Section 818 National Defence Authorization Act (NDAA) signed by President Obama on Dec 31st 2011. Some parts of this legislation are still outstanding

14 GE Title or job number

05/03/2023

NDAA section 818 DFARS For US Military Programs

The latest open DFAR Cases register is located at http://www.acq.osd.mil/dpap/dars/opencases/dfarscasenum/dfars.pdf which contains several impending DFAR cases related to section 818 legislation approved by President Obama As of June 0th 2015 the following are pending:

2015-D020 , DoD use of Trusted Suppliers for Electronic parts. Status report due data extended to 6/24/2015

2014-D005, ‘Detection and Avoidance of Counterfeit Electronic Parts-Further Implementation’, requiring that electronic parts be obtained from ‘trusted suppliers’: The Case manager has forwarded a draft final DFARS rule to the processing manager.

2014-D021, Item Unique Identification (IUID) Prescription Correction, to modify DFAR 252.211-7003, as some wording was lost. Report due extended to 6/3/2015.

Audit activities are part of the Purchasing Systems evaluation see DFAR 252.244.7001 where it is thought that DCMA may develop a new counterfeit detection and detection systems checklist

15 GE Title or job number

05/03/2023

UK Defence Standard 05-135 – Avoidance of counterfeit material, published July 2014 • High level language requiring a clear requirement to manage the

risk in supply chains depending on the criticality of the material in relation to performance and safety where the supplier is aware of the final use of the materiel.

• The supplier shall be able to demonstrate the materiel meets the original qualification requirements and the safety and performance of the deliverable materiel and ensure it is not degraded.

An anti-counterfeit policy Flow-down to suppliers Appointment of a management representative Training Purchasing controls Test and verification Control of non-conforming product Reporting

16 GE Title or job number

05/03/2023

IEC committee TC107 WG3 Counterfeit electronic parts• see http://www.iec.ch/dyn/www/f?p=103:14:0::::FSP_ORG_ID,FSP_LANG_ID:5736,25

• Published a revision in 2014, explaining when recycled components become fraudulent recycled components for the Chinese National Committee.

IEC/TS 62668-1, ‘PROCESS MANAGEMENT FOR AVIONICS – COUNTERFEIT PREVENTION – Part 1: Avoiding the use of counterfeit, fraudulent and recycled electronic components

Allows the use of SAE AS5553A plans for components coming into the business.

Enables OEMs to have one overall plan for SAE AS5553A and IEC/TS 62668-1 Discusses when recycled components become fraudulent components and

why the Avionics industry cannot use them. A revision is on-going in 2015 to add in references to the DFAR, Defence

Standard, AS9100 rev D and remove the Chinese RECS scheme which is not being maintained.

Refers to the now published IEC/TS 62668-2 ‘PROCESS MANAGEMENT FOR AVIONICS – COUNTERFEIT PREVENTION – Part 2: Managing electronic components from non-franchised sources.

Used as the IEC/TS 62668-1 non franchised distributor risk assessment process.

Can also be used as a risk assessment process for the following: o SAE AS5553A, o DFAR rule 252.246.7007 o DEF STANDARD 05-135

17 GE Title or job number

05/03/2023

SAE International Anti-counterfeit Specifications • SAE AS5553A for Electronic components• See http://www.sae.org/

• G-19 committee has active membership mainly from the USA and UK • SAE AS5553A was published in January 2013 superseding SAE AS5553

which has misleading definitions.• Manages components coming into a business only.• Targeted at general industry and AS9100 requirement is not

mandatory.• Revision B was started to incorporate DFAR 252.246.7007 to the

extent that general industry will allow, but recent ballot of Nov 2014 failed. Further meetings are planned with the DOD in Washington DC in March.

• The SAE has no Third Party auditing activities and is only publishing standards and auditing checklists.

• Was endorsed for use by the DoD for USA Military supply chains in 2013 but there is dispute about whether the new revision B will be adequate.

• The audit checklist for SAE AS5553A is published as SAE AS6462A.

• IECQ WG06 has started to create the administration documents for SAE AS5553 auditing

18 GE Title or job number

05/03/2023

How oneanti-counterfeit plan can address:

DEF STD 05-135DFAR 252.246.7007 SAE AS5553A IEC/TS 62668-1

using the non-franchised risk assessment processfrom: IEC/TS 62668-2

19 GE Title or job number

05/03/2023

Key elements for an anti-counterfeit plan Publish a plan addressing each requirement of the external standard and/or

provide a cross reference matrix . This protects your business in legal court cases. Establish company standard Purchase Order notes which state unambiguously that ‘

no counterfeits or recycled components are allowed’. Orders shall be placed for traceable components from OCMs or franchised

distributors or franchised aftermarket distributors. Traceability can be demonstrated by the C of C’s , packing slips, shipping label

information, part marking information ( lot date codes etc.) and are required for each part of the supply chain back to the original manufacturer.

Accurate part numbers on the PO to the internal component database information or BOM to that on the received C of C or Packing slip are required to prove traceability. Each part of the supply chain has to provide this level of traceability back to the original component manufacturer. Distributors who automatically default to their internal part number and ship against this, loose supply chain traceability and cannot be used.

Accurate, clear Shipment labelling, C of Cs, packing slip details are required from the Distributors.

Transcription errors, truncated part numbers, bad handwriting, unexplained quantities or quantities that do not add up after a stock split will results in parts being identified as ‘suspect’ when they are possibly just badly labelled.

Supply chain anti-counterfeit audits have started. Non-franchised distributors require a risk assessment and every order placed

may need anti-counterfeit testing for example to IEC/TS 62668-2 or SAE AS7171 or SAE AS6081 . Special test specifications will be required. Approval from customers may be required.

20 GE Title or job number

05/03/2023

Overview

21 GE Title or job number

05/03/2023

Anti-counterfeit summary 2012

Contact information: Jo Vann, TC107 WG3 Anti-counterfeit convenor, CEO- Component Technology , GE Aviation Systems Ltd., T +44 (0)1242 632927F +44 (0)1242 661151E [email protected]/aviation