EXHIBIT 17 - Ecology and Environment, Inc. · EXHIBIT 17. 3.5 Determining the Number of Redredging...

Transcript of EXHIBIT 17 - Ecology and Environment, Inc. · EXHIBIT 17. 3.5 Determining the Number of Redredging...

EXHIBIT 17

3.5 Determining the Number of Redredging Attempts

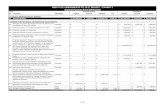

Residual sediment samples will be collected afterobtaining the design cut elevations and after eachsuccessive redredging attempt, and within seven daysafter dredging is completed. In the event that the Tri+PCB concentrations exceed the action levels in theResiduals Standard, additional dredging andresampling may be required, as shown on Figure 3-1and Table 3-2. However, a limit must be placed on

Redredging will be limited to twoattempts under the ResidualsStandard, unless theconstruction managerdetermines that additionalattempts are likely to provide thedesired reduction in contaminantconcentrations.

the number of redredging attempts and a contingency option must be provided after thatnumber of attempts has taken place, due to the impact on the productivity rate and projectschedule as well as the diminishing returns reported in environmental dredging casestudies. For example, in the Reynolds Metals project, reduction of PCB residualconcentrations was not found after the fifth attempt. At the GM Massena site, the greatestimprovement was experienced through the second dredging attempt.

For the Residuals Standard, redredging is limited to two attempts following the initialresidual sampling event, based on both engineering judgment and case study findings,with the understanding that case study site conditions will differ from those in the UpperHudson River to varying degrees. The possible exception to the two-attempt limit is in acase where the construction manager determines that additional redredging attemptscould provide a desired reduction in contaminant concentrations. Modification could alsobe made based on the experience and observations collected on the site during Phase 1dredging.

3.6 Engineering Contingencies for the Residuals Standard

In the event that the sediment removal operations are unsuccessful in achieving amean residual concentration of approximately 1 mg/kg Tri+ PCBs, engineeringcontingencies are to be implemented. To maintain flexibility and facilitate adherenceto the productivity schedule, it is appropriate to allow residuals to be addressed in situat concentrations greater than the ROD’s requirement of 1 ppm. There are severalcontingency actions appropriate for control of dredging residuals that should beimplemented in a tiered approach, based on the concentration of Tri+ PCBs in theresiduals. In order of increasingly rigorous response, they are:

- backfilling with confirmatory testing of the surface of the backfill.- capping with an isolation cap.- additional sampling at depths greater than 6 inches followed

redredging.by

To direct the dredging, the Residuals Standard is organized in three layers, with limits foran individual sample concentration, the average concentration of any 5-acre CU, and amoving 20-acre (comparable to the HUDTOX segment size) evaluation area weighted

Hudson River PCBs Superfund SiteEngineering Performance Standards

43 Malcolm Pirnie/TAMS-Earth TechVolume 3: Residuals - April 2004