electrical resistivity survey: i&w brine well, eddy county, new mexico

Executive Summary - Microsoft...and access road. Oil and/or brine ponds are not planned for the well...

Transcript of Executive Summary - Microsoft...and access road. Oil and/or brine ponds are not planned for the well...

-

Broadview Project Environmental Impact Statement

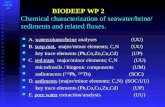

Executive Summary Introduction Canada Golden Fortune Potash Corporation (CGFPC) is proposing to develop a new one million tonnes per year greenfield potash solution mine, referred to as the Broadview Project. The Broadview Project is located on CGFPC’s KL 280 potash lease, located in the southeastern portion of the Saskatchewan potash district and within the Rural Municipalities of Chester (RM No. 125) and Kingsley (RM No. 124). The center of the lease is located approximately 120 km east of Regina. CGFPC retained SNC-Lavalin Inc. (SNC-Lavalin) to complete the Environmental Impact Assessment (EIA) for the proposed project.

CGFPC is a private resource company engaged in the exploration and development of potash mineral deposits in Saskatchewan, Canada. CGFPC's goal is to develop a potash solution mine within Saskatchewan. CGFPC owns 100% of the Crown mineral rights on two potash leases (KL 280 and KL 282) in Saskatchewan. Potassium from potash is used to produce fertilizers that help to meet the growing global demand for food.

The proposed project requires ministerial approval under The Environmental Assessment Act. On 09 June 2017, CGFPC submitted a Technical Proposal (TP) to the Saskatchewan Ministry of the Environment (MOE), including a letter self-declaring the project a “development” pursuant to the Act to commence the EIA. This was followed by a draft Terms of Reference (TOR) to outline the proposed approach to completing the EIA. The TOR was formally accepted by MOE’s Environmental Assessment and Stewardship Branch (EASB). If the project receives ministerial approval to proceed, CGFPC will obtain all other federal, provincial, and municipal permits required for construction, operation, and decommissioning of the project.

The EIA consisted of numerous studies and is organized into a main document and supporting attachments. The main document focusses on the project description and assessment of effects, whereas the individual attachments provide comprehensive documentation of the methods and results for each individual baseline study, modelling study, as well as the community engagement program.

Assessment of Alternatives CGFPC evaluated various options to carry out the project, including potential site locations, several water sourcing options, and trade-off studies for various mining and plant design cases. Studies completed to evaluate project alternatives, included:

Site Selection Study: A site selection study was conducted to determine the optimal location of the TMA and plant site facilities based predominantly on environmental considerations. Hydrogeology and hydrology played a critical role in locating the site to limit potential impacts to groundwater and surface water resources.

Canada Golden Fortune Potash Corp.

ii 631260 October 2018 © SNC-Lavalin Inc. 2018. All rights reserved. Confidential.

-

Broadview Project Environmental Impact Statement

Water Sourcing Studies: The project will require a significant amount of water; and both groundwater and surface water sources were investigated to identify a suitable water source (SNC-Lavalin 2017a, 2017b, and 2018). Studies identified and confirmed that the Hatfield Valley Aquifer, approximately 40 km north of the site, was capable of supplying CGFPC’s water demand.

Trade-off Studies: The trade-off studies evaluated several alternatives with respect to mining methods, including conventional mining vs. solution mining, dual-well vertical caverns vs. horizontal caverns, and non-selective vs. selective mining. The trade-off studies also evaluated alternatives for plant processing design, including MVR evaporators vs. ME evaporators, heat and power cogeneration, crystallization and drying, and brine tanks vs. ponds. Other studies included access road and railway transportation selection.

Project Description The project description has been provided by CGFPC based on their prefeasibility level design. Preliminary assumptions made for this study are being reviewed during the ongoing engineering studies. Project components and dimensions are subject to change based on the outcome of the studies, as well as future feasibility and detailed design studies.

The proposed mine will include a plant site and a well field for potash extraction. The mine well field will be developed in stages with three well pads being developed initially, followed by additional well pads as mining progresses. Each well pad will include injection and recovery well heads, piping and valve stations. Figure E1 shows the proposed location of the plant site and well field.

Construction

Construction of the mine is expected to begin as early as 2019, pending environmental approvals and economic conditions, and is expected to take about three years to complete. Initial potash production is targeted for 2021. The current mine life is 50 years (minimum).

Environmental protection during construction will be managed through the development and implementation of a construction environmental management plan (CEMP). The CEMP will also ensure that all activities associated with construction are in line with relevant regulations and approvals. A temporary construction camp, designed with a total capacity of 1,000 workers, and associated infrastructure is planned to support the construction and commissioning phases of the project. The camp location has not been determined at this time.

Health, Safety, Security and Environment

CGFPC will develop a comprehensive health, safety, security and environment (HSSE) program that will include healthy and safety, emergency response, and environmental management/protection. Employee and contractor training will be a central part of the HSSE program. The HSSE program will be developed for all project phases in accordance with applicable legislation and industry standards, including The Saskatchewan Employment Act, The Occupational Health and Safety Amendment Act, 2012, and The Occupational Health and Safety Regulations, 1996.

Canada Golden Fortune Potash Corp.

iii 631260 October 2018 © SNC-Lavalin Inc. 2018. All rights reserved. Confidential.

-

0 5 102.5Kilometers

1. COORDINATE SYSTEM: NAD 1983 UTM ZONE 13N.2. BASE CADASTRAL DATA ADAPTED FROM HER MAJESTY IN RIGHT OF SASKATCHEWAN ORINFORMATION SERVICES CORPORATION OF SASKATCHEWAN, SASKADMIN2013, SASKGRID2013.3. CADASTRAL BOUNDARIES ARE FOR INFORMATIONAL PURPOSES ONLY AND SHOULD NOT BECONSIDERED SUITABLE FOR LEGAL, ENGINEERING, OR SURVEYING PURPOSES.4. TOPOGRAPHIC FEATURES OBTAINED FROM CANVEC V12.0 DATASET, NATURAL RESOURCESCANADA EARTH AND SCIENCES SECTOR CENTRE FOR TOPOGRAPHIC INFORMATION, 2013-09-30.5. HIGHWAYS AND ROADS OBTAINED FROM THE NATIONAL ROAD NETWORK SASKATCHEWANEDITION 6.0 DATASET, 2012-09-28.6. RAILWAYS OBTAINED FROM THE NATIONAL RAILWAY NETWORK SASKATCHEWAN EDITION 1.0DATASET, 2012-11-07.

LEGEND

RAILWAY

HIGHWAY

WATERCOURSE

KL 280

PROPOSED PLANT SITE

RURAL MUNICIPALITY

WATERBODY

AAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAAA

WATERBODY (INTERMITTENT)

WELL FIELD

KL 280

CANADA GOLDEN FORTUNEPOTASH CORPORATION

BROADVIEW PROJECT

£ ¤47

£ ¤47

£ ¤47

£¤1

£¤1

£¤48

£¤48

17-06-W2

16-08-W2

17-09-W2

16-06-W2

15-09-W2

17-08-W2

16-09-W2

14-08-W2

16-07-W2

15-05-W215-06-W215-07-W215-08-W2

14-06-W2 14-05-W214-07-W214-09-W2

16-05-W2

17-05-W217-07-W2

Canadian Pacific

Canadian National

Adair Creek

EkapoCreek

Pipestone Creek

Roselane

Creek

RM OF CHESTERNo. 125RM OFKINGSLEYNo. 124

RM OFWOLSELEYNo. 155

RM OF ELCAPONo.154

EKAPO LAKE

BROWN HILL RESERVOIR

MARSTON LAKE

FalconGrenfell

Kipling MarshKipling Marsh

Glenavon

Dalzell

Baring

Peebles

Oakshela

Summerberry

NOTES

SASKATCHEWAN

Regina

NorthBattleford

Swift Current

Estevan

Yorkton

Saskatoon

Moose Jaw Weyburn

MelfortLloydminster Prince Albert

HumboldtDETAIL

LM GPWH 2018 04 06

631260-E-02-E-012 0

2018 06 13

ISSUED FOR INFORMATION GP

WH

0

E1

FIG No.

1:150,000

DWG No. Pat

h: \\

sli1

653\

Pro

ject

s\C

GFP

C\6

2419

0 E

IA_K

P43

7\4.

0 E

xecu

tion\

4.5

GIS

and

Dra

win

gs\G

IS\D

RAW

ING

S\E

IS -

Mai

n D

oc\E

IS_E

S\6

3126

0-E

-02-

E-0

12(L

ocat

ion

Pla

n).m

xd

CHK BY

TITLE

CLIENT PROJECT LOCATION

DES BY

SIZE

DRN BY DATE

11x17 REV

SCALE:

LM

REVISIONS

REFERENCE DRAWINGS

REV DATE DESCRIPTION DRN APP

DWG No. DESCRIPTION

DES

-

Broadview Project Environmental Impact Statement

Mining

Solution mining will be used to extract sylvinite from the Prairie Evaporite Formation. The mining plan is to use a selective solution mining technique which consists of selectively extracting KCl from horizontally drilled wells. By utilizing a near-NaCl-saturated injection solvent at an elevated temperature, the injection solvent will preferentially dissolve KCl into solution, leaving the NaCl and insoluble materials in-place. Horizontal caverns will be developed, where each cavern will reach a cross-sectional dimension of 95 m wide by 5 m high. KCl crystal production is achieved when the produced brine is cooled in the processing plant. A total of four mining phases will be used during the solution mining process, including:

1. Non-selective cavern development; 2. Selective solution mining; 3. Enhancement mining; and 4. Batch mining.

A mine plan and subsequent subsidence modelling was conducted for years 10, 20, 30, 40, and 50. Active mining is planned to start from the southwestern corner of the well field, close to the processing plant. Results of the surface subsidence contours were analyzed for year 10, 20, 30, 40, 50, and the ultimate case. Ultimate subsidence, which is the steady-state subsidence, is estimated to occur several years after all caverns have completely closed. CGFPC will monitor and mitigate potential impacts associated with subsidence.

The well field mining components include well pads and underground pipelines to connect the well pads to the plant site. Each cavern is connected through wells to the surface facilities. To minimize above ground disturbance, these surface facilities are grouped together in “pads” from which a number of wells are drilled and equipment is installed for connecting and controlling the caverns. Each pad will be 150 m by 250 m in size and include seven injection well heads, seven return well heads, valve huts (each valve hut containing the valves and instrumentation to control up to two injection or return wells), modular electrical house (each containing sump pump starters, controls system, small power, operators office), run-on/ runoff swale, runoff containment, and access road. Oil and/or brine ponds are not planned for the well pads. No hazardous materials will be stored on the well pads.

Plant Site

The plant site layout is shown in Figure E2; it will include a processing plant, administration buildings, raw water and brine tanks, salt and gypsum storage in the tailings management area, a cooling tower, thermal power station, rail loadout, security, parking, and other features.

Potash Processing

The potash processing will include: (i) evaporators utilizing mechanical vapour recompression (MVR) for brine evaporation; (ii) gypsum treatment to separate gypsum from the mother liquor and treat it with compression and filtration before conveying to the gypsum storage area; (iii) a seven-stage flash crystallizer circuit for KCl crystallization; (iv) centrifuging and drying of KCl; and (v) product storage and loadout. Annual operational time of the processing plant is 320 days, with 45 days planned for maintenance.

Canada Golden Fortune Potash Corp.

v 631260 October 2018 © SNC-Lavalin Inc. 2018. All rights reserved. Confidential.

-

REVISIONS

REFERENCE DRAWINGS

REV DATE DESCRIPTION DRN APP

DWG No. DESCRIPTION

DES

0 250 500125METRES

1. COORDINATE SYSTEM: NAD 1983 UTM ZONE 13N.2. BASE CADASTRAL DATA ADAPTED FROM HER MAJESTY IN RIGHT OF SASKATCHEWAN ORINFORMATION SERVICES CORPORATION OF SASKATCHEWAN, SASKADMIN2016, SASKGRID2016.3. CADASTRAL BOUNDARIES ARE FOR INFORMATIONAL PURPOSES ONLY AND SHOULD NOT BECONSIDERED SUITABLE FOR LEGAL, ENGINEERING, OR SURVEYING PURPOSES.4. SITE LAYOUT PROVIDED BY CGFPC.

LM GPKVG\LC 2018 06 05

631260-E-00-P-006 0

0

2018 06 13

ISSUED FOR INFORMATION GP

KVG/LC

LEGEND

!M& PROPOSED DEEP INJECTION WELLRAIL

PROPOSED FENCELINE

PLANT SITE

CANADA GOLDEN FORTUNEPOTASH CORPORATION BROADVIEW

E2

!M&

PARKING LOT

RAINWATER STORAGETANKS

UNDERGROUND WATER POND

RAINWATERCOLLECTION POND

TMA SALT WATERCOLLECTION POND

COOLING TOWERS

NEUTRALIZING WATER PONDDESALT WATER TANK

RAW BRINE TANK

HIGH MAGNESIUM MOTHER LIQUOR TANKCONDENSATE WATER TANK

MOTHER LIQUOR TANK

GATE 1

GATE 2

SALT STORAGE AREAKClPROCESSINGPLANT

WATER CIRCULATIONSTATION

MAINTENANCE WORKSHOP

EQUIPMENT ANDPARTS STORAGE

ADMINISTRATIONBUILDING

YARD

KCl STORAGE WORKSHOP

GYPSUM STORAGE AREA

RAW WATER AND CHEMICALWATER TREATMENT STATION

SUBSTATIONNATURALGAS PRESSUREREGULATION STATION

THERMAL POWERSTATION

GYPSUM TREATMENTWORKSHOP

CENTRIFUGAL DEHYDRATION FOR NaCl AND HEAT EXCHANGEWORKSHOP

DIW

SW-15-15-07-W2SE-16-15-07-W2

NE-09-15-07-W2

649,000

649,000

650,000

650,000

5,568,00

0

5,568,00

0

5,569,00

0

5,569,00

0

FIG No.

³

NOTES

1:7,500

DWG No. Pat

h: \\

sli1

653\

Pro

ject

s\C

GFP

C\6

2419

0 E

IA_K

P43

7\4.

0 E

xecu

tion\

4.5

GIS

and

Dra

win

gs\G

IS\D

RAW

ING

S\E

IS -

Mai

n D

oc\E

IS_E

S\6

3126

0-E

-00-

P-0

06 (P

lant

Site

).mxd

CHK BY

TITLE

CLIENT PROJECT LOCATION

DES BY

SIZE

DRN BY DATE

11x17 REV

SCALE:

LM

-

Broadview Project Environmental Impact Statement

A Tailings Management Area (TMA) will be used to store salt and gypsum from the processing. These materials will be contained with an engineered dyke, geomembrane and compacted till liner. Liquid wastes include condensate water from KCl processing plant, weak brine during initial cavern development and high magnesium waste brine. The high magnesium waste brine from KCl processing plant will be temporarily stored in the mother liquor tank, and injected into the deep disposal well(s).

Utilities and Services

Utilities and services include power, water, natural gas, rail, an access road, communications, and on-site fuel storage. Ancillary linear project components including the power transmission line, raw water pipeline, gas pipeline, and highway upgrades will be completed by the utility and service providers and subject to separate reviews under The Environmental Assessment Act.

During the normal operation, raw water consumption is estimated to be 421 m3/h, which is approximately 3.2 million m3 of water per year. CGFPC is working with SaskWater to develop a groundwater production well field targeting the Hatfield Valley Aquifer, approximately 40 km north of the plant site. SaskWater and CGFPC will obtain a Water Rights Licence and Approval to Construct and Operate Works from the Water Security Agency (WSA), pursuant to The Water Security Agency Act.

Emissions and Waste

Air emissions were estimated for construction and operation, and air dispersion modelling was conducted to predict ground-level concentrations associated with the project’s operations. Stack emissions are the dominant emissions from the project. Boilers and the drilling rigs are the major sources of SO2, NOX and CO, and dryers and vents are the highest sources of particulate emissions. Air dispersion modelling was conducted to assess the effects of air emissions on nearby receptors.

Greenhouse gas (GHG) emissions include CO2, CH4 and N2O. Direct GHG emissions are estimated to be approximately 9.6 kt CO2e/y during construction and 182 kt CO2e/y during operation. The project’s estimated GHG intensity per kilotonne of potash during operation is 0.18 kt CO2e/y based on the direct emissions.

Noise sources are mainly composed of fixed sources, such as stacks, water tower, etc. and mobile sources, such as trucks, dozers, graders, etc. There will also be an on-site rail loop with trains for the loading and shipment of the potash product. Noise modelling was conducted to assess the effects of noise on nearby receptors. The closest receptors will be subjected to a low or moderate increase in noise over the ambient sound level and mitigation is not required.

Excess brine from the TMA and plant will be disposed of via a deep injection well. Potential migration of brine into the subsurface was evaluated using a 2D groundwater flow and solute transport model. This is discussed further below and in the main document.

Domestic sewage will be treated in an integrated sewage treatment facility. The treatment capacity for this facility is about 40 m3/d.

Canada Golden Fortune Potash Corp.

vii 631260 October 2018 © SNC-Lavalin Inc. 2018. All rights reserved. Confidential.

-

Broadview Project Environmental Impact Statement

The facility will generate solid waste which includes hazardous waste, recyclable waste and domestic waste. A waste management plan will be created outlining management procedures for waste generated during construction and operation.

The plant site will be serviced by catch basins and storm sewers discharging to ditches or the rainwater collection pond. The water from the rainwater collection pond will be treated in the raw water treatment station. Treated water will be used as process water or discharged to the environment after meeting effluent quality criteria.

Design Measures for Climate Conditions

The conceptual design of the project infrastructure takes into account climate (e.g. precipitation, runoff and stream flows) and extreme climate (flooding, storms, and high winds), with the design objective of having the plant and well field reasonably withstand typical and extreme climate conditions. An extensive hydrological assessment was conducted that will support the design measures to account for extreme climate conditions.

The proposed plant site and well field will be situated on locally high topography. Design components will provide storm water management to accommodate peak flows created by a 1:100 year precipitation event. Brine ponds and other embankments will be designed to accommodate precipitation events in accordance with the Canadian Dam Association Safety Guidelines (CDA 2013) and the Saskatchewan Potash Industry Brine Pond Freeboard Guidelines and Reporting Requirements (MOE 2017). If any new mine infrastructure is constructed on a floodplain, it will be constructed at a 1:500 year flood elevation, in accordance with The [SK] Statements of Provincial Interest Regulations under The Planning and Development Act, 2007. The design of all buildings, structures foundations and related facilities will be based on applicable codes, specifications, standards and regulations.

Conceptual Decommissioning and Reclamation

The objectives of decommissioning and reclamation will be to restore the area to a state similar to the surrounding lands that will be both safe and environmentally stable. At the time of facility closure, the following decommissioning activities may be undertaken:

› Mine well fields and subsurface infrastructure will be decommissioned; › Well heads will be cut off and capped; › Water and brine retention ponds will be drained, infilled and landscaped similar to other

disturbed areas. All fluids removed from the ponds will be tested and disposed of appropriately;

› Pipelines will be drained and either dismantled (above ground pipelines) or abandoned in place (underground);

› Reclamation studies for the TMA will be further assessed and may include long-term natural dissolution, backfilling and/or re-injection;

› All buildings no longer required will be demolished; › All salvageable material (e.g. metals, equipment, electronics, etc.) will be sorted and reused,

sold, or recycled. The remaining materials will be removed from site and disposed in an approved facility;

Canada Golden Fortune Potash Corp.

viii 631260 October 2018 © SNC-Lavalin Inc. 2018. All rights reserved. Confidential.

-

Broadview Project Environmental Impact Statement

› All hazardous materials will be identified for recycling or disposal; › Concrete pads and building foundations no longer required will be demolished; › Site roads and rail lines no longer required will be decommissioned and reclaimed; › On-site utilities will be removed; › Areas where contaminated soils may be present will be assessed and remediated as

required; › Surface drainage conditions will be restored similar to pre-existing conditions; › All disturbed areas will be reclaimed. Reclamation will generally consist of re-contouring the

site, replacing topsoil, and re-vegetating to restore the land surface to as near as possible to the original conditions; and

› Salvageable topsoil will be used to re-contour the landscape, where applicable. Plant species selected to provide a vegetative cover on each cap will be compatible with the surrounding vegetation to ensure that the established vegetation will provide a self-sustaining cover.

Progressive reclamation methods will be utilized wherever possible. The decommissioning of individual well pads will be determined after the start of operations. The site may also be evaluated for alternative industrial uses. The timeline for the implementation of a detailed decommissioning plan will be determined in the future.

Community Engagement CGFPC’s community engagement program (CEP) for the project focused on obtaining general acceptance from potentially affected stakeholders, and outlining measures to reduce and/or avoid negative environmental, traditional land use and socio-economic impacts to local and regional communities by incorporating stakeholder feedback. Stakeholder engagement is an integral part of the environmental assessment process for developments within Saskatchewan under The Environmental Assessment Act.

Stakeholder engagement provides an opportunity to present project information to stakeholders, ensures stakeholders are informed about the environmental and regulatory process, and is used to collect feedback to identify local and regional concerns and ideas that can be incorporated into project planning and design. Engagement also provides an opportunity for CGFPC to develop strong working relationships with landowners, local and regional residents, municipal and rural municipal representatives, local indigenous communities and regulators, utility providers and government agencies.

The CEP for the project was divided into three phases:

› Phase I: Focused on providing stakeholders with introductory information about the project and the environmental assessment process;

› Phase II: Focused on providing stakeholders with results of the baseline environmental studies, the location of the proposed plant site and well field, and the location of the proposed utilities; and

› Phase III: Focused on providing stakeholders with the results of the environmental impact assessment, an update on the project timeline, and an update on the location of the proposed utilities.

Canada Golden Fortune Potash Corp.

ix 631260 October 2018 © SNC-Lavalin Inc. 2018. All rights reserved. Confidential.

-

Broadview Project Environmental Impact Statement

Overall, the feedback received during the three phases and ongoing stakeholder engagement demonstrates general acceptance. Stakeholders are typically interested in the project and were generally pleased with the effort CGFPC has dedicated to stakeholder engagement, with stakeholders wanting to be involved in the engagement process as much as possible and continue to be updated on the progression of the project. Memorandum of Understanding’s, which included the supportive consent of the project, were signed between CGFPC and the elected councils for all RM’s, four towns and two villages included in the CEP. Common questions and concerns brought forward during the engagement activities were related to:

› Potential environmental impacts associated with the water source, water usage, groundwater, mining by-products (tailings);

› Potential affects to wildlife and vegetation; and › Potential socio-economic impacts to the local and regional area including increased traffic

and noise in rural communities, increased use of local health care and policing services, and potential increase in crime.

Other common questions received during engagement activities included project timeline, project location, employment opportunities, and local and regional economic benefits. A detailed overview of project personnel responses to stakeholder questions and concerns is presented in the EIS.

CGFPC is committed to conducting meaningful engagement to ensure interested stakeholders are informed about the project. CGFPC will continue to engage with stakeholders to identify local and regional concerns and ideas that can potentially be incorporated into project planning and design following the submission of the EIS.

Effects Assessment Approach The effects assessment is focused on Valued Components (VCs) which are aspects of the natural and socio-economic environment that are valued because of their ecological, scientific, resource, socio-economic, cultural, health, or aesthetic importance and which have a potential to be adversely affected by the project. Effects were evaluated using a stepwise approach:

1. Identification of VCs; 2. Characterization of VCs; 3. Characterization of the project; 4. Characterization of potential interactions between the project and the VCs; 5. Design of mitigation measures to remove an interaction or limit effects. First and foremost,

avoidance was selected as the preferred mitigation measure. Where interactions cannot be avoided, mitigation measures focused on reducing potential effects. Compensation measures were considered where mitigation is not feasible;

6. Significance assessment of residual effects, which are effects that remain after implementation of mitigation measures. The significance of residual effects were evaluated by identifying each effect’s direction, magnitude, spatial extent, duration, frequency, reversibility and likelihood of occurrence for the construction, operation, and decommissioning phases of the project;

Canada Golden Fortune Potash Corp.

x 631260 October 2018 © SNC-Lavalin Inc. 2018. All rights reserved. Confidential.

-

Broadview Project Environmental Impact Statement

7. Assessment of cumulative effects which considered the potential residual effects of the project and their interaction with residual effects from other past, present, or reasonably foreseeable future projects or activities; and

8. Monitoring of effects.

VCs that were considered during the effects assessment included:

› Atmospheric environment; › Groundwater; › Surface water; › Soils; › Terrain; › Wetlands; › Vegetation; › Wildlife and wildlife habitat (including fish); › Heritage resources; › Socio-economics; and › First Nation and Métis communities

The following list of project activities was compiled for the assessment of effects:

› Vegetation clearing, topsoil stripping, and earthworks; › Construction of plant site infrastructure; › Construction of well pads and associated infrastructure; › Expansion and development of ancillary linear infrastructure; › Increased vehicular traffic; › Increased noise and / or light; › Use of water / power / gas resources; › Air emissions (dust, GHG); › Plant operation; › Solution mining and subsidence; › Tailings storage; › Deep injection of wastewater; › Decommissioning; › Reclamation; and › Accidental releases.

Potential effects and mitigation have been identified through technical expertise/professional judgement, review of literature and other publicly available EISs, consultation with regulators, and feedback obtained during the community engagement program. Detailed modelling, including air quality, noise, groundwater, surface water, and traffic, was conducted to further characterize effects for VCs. Mitigation measures to avoid or reduce effects of the project were developed using a hierarchy of strategies: avoid, minimize, offset, and reclaim.

Some residual effects may remain after implementation of mitigation measures. The significance of these residual effects were evaluated by identifying each effect’s direction, magnitude, spatial extent, duration, frequency, reversibility and likelihood of occurrence for all phases of the project.

Canada Golden Fortune Potash Corp.

xi 631260 October 2018 © SNC-Lavalin Inc. 2018. All rights reserved. Confidential.

-

Broadview Project Environmental Impact Statement

The majority of project effects are likely to decrease as geographic distance from the disturbance increases. Therefore, potential project effects are likely to be more direct and have greater impact where the plant site, well pads, and associated infrastructure are located.

Assessment of Effects to the Atmospheric Environment The project has the potential to result in the following effects to the atmospheric environment: (i) changes to local or regional air quality; (ii) contribution to climate change / greenhouse gases (GHGs); and (iii) increase in noise levels. Air quality, greenhouse gas emissions, and noise assessments were conducted to support the effects assessment.

Air Quality

The ground-level concentrations associated with the project’s operations were predicted using the AERMOD (American Meteorological Society/Environmental Protection Agency Regulatory Model) dispersion modelling software, Version 16216r. The assessment included the ground-level concentrations from the project (project only scenario) and those from the project plus ambient background (application scenario). AERMOD is recommended by the MOE for dispersion modelling studies of more complex multi-stack facilities, and is considered a ‘refined’ model.

All ground-level air contaminant predictions meet Saskatchewan Ambient Air Quality Standards (SAAQS), with the exception of the PM10 24-hour average. The PM10 24-hour average predictions exceed the standard a total of seven times based on the five years of modelling data (0.4% of the time) because of a high ambient background used for the compliance determination (36.3 µg/m3), where the background value represents 47% of the maximum point of impingement (MPOI).

Baseline air quality data collected near the site over about a year, including ambient PM2.5 and TSP, show that the regional background PM10 value used for the assessment is likely higher than actual and therefore the PM10 24-hour model exceedance is not likely to occur in reality. The PM10 regional background data was determined from Southeastern Zone data (City of Regina); this Zone has numerous industrial facilities and is a concentrated population center with higher emissions (e.g. transportation, industry), relative to the rural setting of the proposed project. However, the modelled PM10 exceedances occur very near the plant site boundary and not on or near any sensitive receptors. These residual effects are not considered significant.

Greenhouse Gases

GHG (greenhouse gas) emissions, including carbon dioxide (CO2), methane (CH4), and nitrous oxide (N2O), were estimated and compared to other Saskatchewan solution potash mines, the Province of Saskatchewan’s total emissions, and the total national GHG emissions.

Greenhouse gas (GHG) emissions include CO2, CH4 and N2O. Direct GHG emissions are estimated to be are estimated to be approximately 9.6 kt CO2e/y during construction and 182 kt CO2e/y during operation. The project’s estimated GHG intensity per kilotonne potash during operation is 0.18 kt CO2e/y based on the direct emissions. These residual effects are not considered significant.

Canada Golden Fortune Potash Corp.

xii 631260 October 2018 © SNC-Lavalin Inc. 2018. All rights reserved. Confidential.

-

Broadview Project Environmental Impact Statement

Noise

A noise assessment was conducted to estimate noise levels at potential receptors (i.e. occupied dwellings/residences), using a receptor-based methodology. The permissible sound levels (PSLs) were evaluated at receptors located within 1.5 km of the project, rather than at the property line of the industry. Noise sources are mainly composed of fixed sources, such as stacks, water tower, etc. and mobile equipment, such as trucks, dozers, graders, etc. There will also be an on-site rail loop with trains for the loading and shipment of the potash product. Construction noise sources will result from excavation, piling foundations, assembly of structural components, and mobile equipment (trucks, cars, cranes, loaders, forklift, etc.). The sound power level (SWL) from each fixed and mobile noise source during construction and operation was identified, and modelled to assess the effects of noise on nearby receptors. The project is predicted to have a negligible to low affect at all occupied dwellings located within the study area; hence, there are no residual effects.

Assessment of Effects to Groundwater The project has the potential to result in the following effects to the hydrogeological environment: (i) changes to groundwater quality; and (ii) changes to groundwater quantity. Hydrogeological drilling, instrumentation and testing, 2D groundwater flow and contaminant transport modelling, and deep well injection modelling were conducted to support the project design, siting, and effects assessment.

Groundwater Quality and Quantity

Modelling was conducted to predict solute migration from the TMA during the operations phase and decommissioning and reclamation phase for a total 150 year simulation period. The conceptual design considers the entire TMA footprint with a conservative (i.e. worst case) interpretation of the underlying hydrostratigraphy applied. Three scenarios were considered to predict solute migration under design constraints in the presence and absence of a composite liner.

A commercially-available, finite element, numerical modelling code was selected for simulating 2D flow and contaminant transport. All simulations were run as an axisymmetric model, with symmetry about a vertical axis of rotation at the centre of the TMA footprint to represent the system in three dimensional space.

The TMA geometry, material properties, boundary conditions, and worst-case hydrostratigraphy were conceptualized to represent a conservative interpretation of the site condition. Saturated-unsaturated conditions, advection, mechanical dispersion, diffusion, and density-dependence were included in the analysis.

Canada Golden Fortune Potash Corp.

xiii 631260 October 2018 © SNC-Lavalin Inc. 2018. All rights reserved. Confidential.

-

Broadview Project Environmental Impact Statement

The 2D groundwater flow and solute transport modelling indicates that at 150 years of simulation for the proposed TMA design, brine migration does not reach an isolated pocket of Upper Floral Aquifer; there are no other users of this isolated aquifer. The proposed TMA location takes advantage of natural containment as verified, from a hydrogeological perspective, by the characterization and modelling.

Long-term brine migration beneath the TMA will likely be unavoidable; however, it can be contained within the general footprint of these facilities using containment measures and the favourable shallow stratigraphy. With good containment, adequate monitoring networks, and good environmental practices at the site, subsurface solute migration outside of the project footprint can be effectively mitigated. The TMA location, design and ongoing monitoring will ensure that local groundwater users are not affected in terms of quality or quantity of groundwater.

Residual effects on groundwater quality and quantity are not considered significant.

Deep Disposal Horizon Carrying Capacity Reduction

Two models were developed to evaluate site-scale and regional scale effects of brine injection on the proposed deep disposal horizon (i.e. the Winnipeg and Deadwood formations). A combination of analytical and semi-analytical techniques and a 3D numerical model were developed to evaluate local and regional formation responses, respectively. Based on an assumed fracture gradient of 18.1 kPa/m, an average well head injection pressure (WHIP) of 13,000 kPa to 14,000 kPa per well was assumed for this assessment. To facilitate planning for this project, the deep brine injection modelling study estimated:

› The number of wells and well spacing required to meet the anticipated disposal volume without exceeding the regulated allowable injection pressure; and

› Potential impacts of the proposed injection disposal on existing injection disposal operations.

Results of the site-scale and regional-scale simulations were:

› One disposal well is expected to meet the anticipated injection rates. › The results of the models are insensitive to the simulated well location. › The nearest neighbouring brine disposal operations using the Winnipeg-Deadwood Horizon

are Mosaic Belle Plaine and K+S Bethune. › The effect of brine disposal by CGFPC is simulated to have a negligible effect on Belle Plaine

and K+S Bethune and vice-versa. › The geochemical modelling work suggests the proposed deep injection of waste fluids over a

50 year operational period into the Winnipeg-Deadwood Horizon is anticipated to be compatible with the formation fluids.

Residual effects on the deep disposal horizon carrying capacity are not considered significant. While cumulative effects are possible due to deep wells disposal, these are also considered negligible. No other cumulative effects are anticipated with respect to groundwater.

Canada Golden Fortune Potash Corp.

xiv 631260 October 2018 © SNC-Lavalin Inc. 2018. All rights reserved. Confidential.

-

Broadview Project Environmental Impact Statement

Assessment of Effects to the Hydrological Environment The project has the potential to result in: (i) changes in surface water flow and distribution, and (ii) changes in water and/or sediment quality. Hydrotechnical modelling was completed to identify any changes to the local and regional hydrology due to the development of the plant site, well field, and related subsidence from the solution mining activities. Raven and MIKE21 FM modelling tools were used to complete the hydrotechnical modelling and evaluated spatial and temporal changes associated with the proposed project.

The area of mine infrastructure is calculated to be 1.9 % of the local study area watershed. The infrastructure that is expected to be isolated from the natural environment is estimated to be approximately 70% of the footprint boundary, resulting in a 3.6 km2 area. The calculated change in monthly flows due to this loss of drainage area is minimal (maximum difference of 0.005 m3/s). These values are based on scaling the existing hydrological Raven model results with the existing drainage area (193 km2) and comparing it to the ultimate subsidence hydrological Raven model results scaled with the post-mine development drainage area (190.4 km2). Additionally, the regional runoff contribution on an annual basis is minimal (i.e. 2.4%), mainly due to the prairie potholes or depression storage that minimizes runoff generation. Therefore, the direct surface water runoff expected to be potentially removed from the Pipestone Creek watershed is considered insignificant. The location of the plant site is proposed on relatively high topography near headwaters of the Pipestone Creek watershed. Therefore, no major diversion of the regional runoff and no third party flooding issues are expected due to the placement of the plant site and well field.

With respect to subsidence, the model results showed that the most significant hydrological changes (i.e. sub-watershed drainage area, monthly runoff, and peak flow) occurred on Tributary B3. These changes were a result of the upstream portion of Tributary B3 watershed shifting northward into the Tributary B2 watershed via culvert C25. The existing Tributary B3 watershed is already part of the Tributary B2 watershed, joining the main stream in NE-08-015-06-W2M. After subsidence, Tributary B3 joins the main Tributary B2 stream about 1.5 km north, in NE-17-015-06-W2M. With mitigation, only slight changes to the monthly runoff distribution from subsidence are predicted for Tributary B3. Possible mitigation options include: 1) install a gate structure at culvert C25 to operate as needed; 2) build a berm on the north side of the large pond south of culvert C25; or 3) deepen the outlet channel of the large pond to encourage flow towards the east. Mitigation elsewhere is not anticipated at this time.

There are no existing or proposed potash solution mines withing the region affected by subsidence; hence, no other projects were assessed for cumulative effects with subsidence. However, agricultural activities have contirbuted to signficant changes in surface water flow, distribution and quality. In comparison to the existing effects, the project’s effects on surface water flow and distribution will be minor once mitigation activities are completed. Similarly, the magnitude of water or sediment quality changes caused by this project is expected to be minimal compared to the changes caused by agriculture in the area.

Residual effects on surface water flow, distribution and quality are not considered significant.

Canada Golden Fortune Potash Corp.

xv 631260 October 2018 © SNC-Lavalin Inc. 2018. All rights reserved. Confidential.

-

Broadview Project Environmental Impact Statement

Assessment of Effect to Terrain and Soils The project has the potential to result in: (i) loss or physical alteration/degradation of soils, (ii) changes in soil quality, and (iii) soil-borne disease transfer and/or weed propagation. A desktop terrain and soils baseline study was conducted, as part of the baseline biophysical study, to support the effects assessment.

Soil loss and alteration is likely to occur over the course of the project through landscape clearing and subsidence. The plant site infrastructure occupies an area of approximately 22 ha, which will be reclaimed at the end of the project. The soils under the TMA may lose some productivity due to the increase in salinity, however, the 34.5 ha TMA only comprises 3% of the plant site and well field.

Numerous mitigation measures have been identified to minimize effects to soils. Residual effects on terrain and soils are not considered significant.

Assessment of Effects to Terrestrial and Wetland Vegetation The project has the potential to result in the following effects to terrestrial and wetland vegetation: (i) terrestrial vegetation and vegetation habitat loss and alteration, (ii) wetland loss and alteration, (iii) direct mortality to plant Species of Conservation Concern (SOCC) and loss / alteration of habitat, and (iv) the spread of invasive and weedy plant species. A terrestrial and wetland vegetation study was conducted, as part of the baseline biophysical study, to support the effects assessment.

The project is located within the Aspen Parkland Ecoregion of the Prairie Ecozone (Acton et al. 1998). This ecoregion has been drastically altered by the conversion of native vegetation to cropland and pastureland. Agricultural activity has been transforming the landscape since the late 1800s, and approximately 80% of the landscape is currently under cultivation. On a local scale, an estimated 77% of the proposed plant site and 79% of the well field study area has been has been cultivated for the production of cereal, oilseed, and forage crops. Extensive agricultural land use across the prairies has resulted in widespread loss of natural habitat and the native woodland, grassland, and wetland plant communities found therein.

All arable land within the proposed plant site had been converted to cropland or seeded to tame forage grasses Approximately 57 ha of wetlands were mapped within the proposed plant site, which includes the entirety of any wetlands that fall in part or in whole in the plant site. Five provincially tracked SOCC were detected in the well field, including downy paintbrush, small yellow lady’s slipper, plains rough fescue, pale bulrush, and crowfoot violet. One prohibited weed (hound’s tongue [Cynoglossum officinale]), 18 noxious weeds (including leafy’s spurge, kochia, etc.), and four nuisance weeds designated in accordance with The [Saskatchewan] Weed Control Act were encountered within the well field study area.

Canada Golden Fortune Potash Corp.

xvi 631260 October 2018 © SNC-Lavalin Inc. 2018. All rights reserved. Confidential.

-

Broadview Project Environmental Impact Statement

Numerous potential effects on terrestrial and wetland vegetation were evaluated and mitigation measures identified. Residual effects include:

› Terrestrial and wetland habitat located in unavoidable areas will be cleared and stripped. There is potential for some SOCC habitats to be lost or altered/fragmented during the construction of the well pads, associated infrastructure, and ancillary linear infrastructure.

› Plant site development will result in the loss of approximately 10 ha of modified grassland as well as fragmented aspen stands occurring within cropland.

› Approximately 57 ha of wetland habitat within the plant site boundaries will be infilled, resulting in a loss of plant and wildlife habitat as well as hydrological function.

› Subsidence may result in changes in shape, size, and/or water depth of wetlands, affecting wetland plant community diversity, and plant SOCC populations may be lost due to soil moisture regime alterations.

› Because the project is located in an area containing prohibited and noxious weeds (e.g. leafy splurge), it is anticipated that weedy and invasive species will be present throughout the lifespan of the project. The weed management program is expected to minimize the spread of weeds, but total eradication is not possible. Linear infrastructure may crate pathways for the spread of invasive and weedy species into terrestrial, wetland, and plant SOCC habitat even after weed control measures are applied.

Numerous mitigation measures have been identified to minimize such effects. Residual effects on terrestrial and wetland vegetation are not considered significant.

Assessment of Effects to Wildlife and Wildlife Habitat The project has the potential to result in the following effects to wildlife and wildlife habitat: (i) habitat loss and alteration, (ii) disruption of wildlife movement, (iii) direct mortality to wildlife, (iv) attractants, (v) sensory disturbance, and (vi) exposure to chemicals. A baseline wildlife and wildlife habitat study was conducted, as part of the baseline biophysical study, to support the effects assessment.

The project is located within the Aspen Parkland Ecoregion of the Prairie Ecozone (Acton et al. 1998). This ecoregion has been drastically altered by the conversion of native habitat to cropland and pastureland. Agricultural activity has been transforming the landscape since the late 1800s, and approximately 80% of the landscape is currently under cultivation. On a local scale, an estimated 77% of the proposed plant site and 79% of the well field study area has been has been cultivated for the production of cereal, oilseed, and forage crops. All arable land within the proposed plant site had been converted to cropland or seeded to tame forage grasses. Extensive agricultural land use across the prairies has resulted in widespread loss of natural habitat and the native woodland, grassland, and wetland plant communities found therein.

Field surveys included snow tracking, grassland birds, common nighhawk, yellow rail, and amphibian auditory surveys. Field surveys identified 29 wildlife species of conservation concern (SOCC), including 10 species at risk (SAR); these include one mammal species (American badger), one amphibian species (northern leopard frog), and 27 bird species. Residual effects include:

› Habitat will be lost or altered as a result of clearing, stripping and grading.

Canada Golden Fortune Potash Corp.

xvii 631260 October 2018 © SNC-Lavalin Inc. 2018. All rights reserved. Confidential.

-

Broadview Project Environmental Impact Statement

› Wildlife movement may be disrupted as a result of clearing, stripping and grading. › Some individuals, nests, residences may be destroyed as a result of clearing, stripping and

grading. › Sensory disturbance due to equipment and vehicle noise and construction site lighting may

result functional habitat loss or alteration for some species. › Direct mortality may occur as a result of wildlife-vehicle collisions. › Subsidence may result in changes in shape, size, and/or water depth of wetlands, affecting

wildlife habitat availability. › Some wildlife may be attracted to the TMA and come in contact with brine resulting in injury

or death.

Numerous mitigation measures have been identified to minimize such effects. Residual effects on wildlife and wildlife habitat are not considered significant.

Assessment of Effects to Fish and Fish Habitat The project has the potential to affect fish and fish habitat through: (i) habitat loss, alteration, or degradation, (ii) direct mortality, and (iii) changes in water quality. A baseline fish and fish habitat study, as part of the baseline biophysical study, was conducted to support the effects assessment.

The well field borders Pipestone Creek, and contains two unnamed tributaries (Tributary A and B) and three oxbow lakes formed by a former meander of Pipestone Creek. Pipestone Creek is a medium-sized watercourse that flows from west to east through primarily pastureland and farmland before it empties into the Lower Souris River. Fish habitat quality in Pipestone Creek is classified as moderate. Five species of fish were collected from Pipestone Creek, its tributaries, and/or the oxbow lakes, including fathead minnow, pearl dace, brook stickleback, Iowa darter, and white sucker.

The proposed plant site avoids Pipestone Creek, its tributaries, and/or the oxbow lakes. Residual effects to fish and fish habitat are limited to potential waterbody crossings by linear infrastructure in the well field (pipelines, roads), and ancillary linear infrastructure. Construction through and/or draining of waterbodies may cause direct mortality to fish or eggs and effects to fish and fish habitat. Minor changes to sub-watershed boundaries from subsidence will occur, but should not affect fish or fish habitat. Potential exists for accidental releases in all project stages to cause fish injury or death if releases enter watercourses or waterbodies.

If watercourses and waterbodies cannot be avoided during construction and operation of the well field and ancillary linear infrastructure, numerous mitigation measures have been identified to minimize such effects. Mitigation for subsidence and other project activities is planned to mitigate potential effects on fish and fish habitat due to subsidence. Residual effects on fish and fish habitat are not considered significant.

Assessment of Effects to Heritage Resources The project has the potential to result in the following effects to heritage resources: (i) disturbance to archaeological sites and (ii) disturbance to paleontological sites. A heritage

Canada Golden Fortune Potash Corp.

xviii 631260 October 2018 © SNC-Lavalin Inc. 2018. All rights reserved. Confidential.

-

Broadview Project Environmental Impact Statement

resources impact assessment (HRIA) was conducted to support the effects assessment and obtain project clearance from the Heritage Conservation Branch (HCB).

A project referral was submitted to the HCB, identifying 104 quarter sections within the proposed plant site and well field. The HCB determined that no archaeological work was required at the proposed plant site because it is deemed to be not Heritage Sensitive; however nine quarter sections in the well field required assessment. These nine quarter sections are grouped together along an unnamed coulee that drains north into the Pipestone Valley, and contain areas of apparently undisturbed aspen parkland that could contain undisturbed heritage resources. The remaining 95 quarter sections submitted in the referral did not require a HRIA. A palaeontological review was also conducted, however, none of the land deemed to be paleontologically sensitive is located within the proposed plant site or well field.

Five heritage resources were identified during the assessment in the northwest corner of the well field. Four of these contain prehistoric period artifacts (two artifact find sites, two artifact scatters) and one is a historic period archaeological site with a single feature (EbMr-8). While the project plans to avoid these areas, should disturbance be required, further archival research and site testing is recommended for one of these sites (EbMr-8). No further work is required at the other four sites. The CEMP will outline mitigation measures to manage heritage resources if additional resources are found during construction. No residual effects are anticipated with respect to heritage resources.

Assessment of Effects to the Socio-economic Environment The project has the potential to result in the following effects to the socio-economic environment: (i) land cover and land use alteration, (ii) changes to employment and labour market, (iii) changes to education, skills development and training, (iv) changes to community infrastructure and services, (v) changes to housing factors, (vi) changes to the economy, and (vii) changes to traffic conditions. A baseline socio-economic study and a traffic assessment were conducted to support the effects assessment.

Potential effects associated with land cover and land use alteration include the development of the plant site on approximately 222 ha of land, as well as construction of well pads/associated infrastructure and ancillary linear infrastructure. This land will no longer be available for agriculture. The plant site and TMA will affect the visual aesthetics of the landscape.

There will be positive effects to the economy, including: increased employment; opportunities for education, skills development and training; increased gross domestic product (GDP); increased financial revenue to the province and RMs through various types of taxes and tax distribution system; and payments for freehold mineral right leases.

Negative effects may include: increased pressure on community infrastructure and services; increased pressure on the housing market; increased traffic; increased noise; increased crime; and air/dust emissions.

Canada Golden Fortune Potash Corp.

xix 631260 October 2018 © SNC-Lavalin Inc. 2018. All rights reserved. Confidential.

-

Broadview Project Environmental Impact Statement

Many of the residual effects with respect to socio-economic aspects are considered positive. Numerous mitigation measures have been identified to minimize adverse effects, and residual effects are not considered significant.

Environmental Monitoring CGFPC will develop environmental management, protection, and monitoring plans for construction, operation, and decommissioning & reclamation (D&R). CGFPC will employ experienced environmental management to promote and enforce environmental protection measures and maintain compliancy with the environmental management plan during construction/D&R and the Environmental Protection Plan (EPP) during operation. CGFPC will continue to work with MOE to maintain regulatory compliance and minimize environmental effects throughout the life of the project.

CGFPC will exercise adaptive management throughout the project lifecycle. Adaptive management is a planned and systematic process for continuously improving environmental management practices by learning about their outcomes. Adaptive management provides flexibility to identify and implement new mitigation measures or to modify existing ones during the life of a project (Canadian Environmental Assessment Agency 2009). In general, the purpose of an adaptive management strategy is to address project uncertainty through ongoing observation, monitoring and corrective action where necessary.

Commitments Register CGFPC had developed a detailed commitments register which outlines monitoring, mitigation, and other commitments that will be conducted to avoid or reduce potential environmental effects resulting from the project.

References Acton D.F., Padbury G.A., and C.T. Stushnoff. 1998. The Ecoregions of Saskatchewan. Hignell

Printing Ltd., Winnipeg, MB.

Canadian Dam Association (CDA). 2013. Dam Safety Guidelines 2007. 2013 Edition. ISBN 978-0-9936319-0-0.

Canadian Environmental Assessment Agency. 2009. ISBN: En106-83/2009E-PDF. URL: https://www.ceaa-acee.gc.ca/Content/5/0/1/50139251-2FE4-4873-B6A1-A190C103333D/Adaptive_Management_Measures_under_the_CEAA.pdf (accessed June 2018).

SNC-Lavalin Inc. 2017a. Preliminary Desktop Surface Water Sourcing Report. Broadview Project. Prepared for Canada Golden Fortune Potash Corporation. Project No. 632257. 10 May 2017.

SNC-Lavalin Inc. 2017b. Desktop Groundwater Sourcing Study. Broadview Project. Prepared for Canada Golden Fortune Potash Corporation. Project No. 632257. 9 May 2017.

Canada Golden Fortune Potash Corp.

xx 631260 October 2018 © SNC-Lavalin Inc. 2018. All rights reserved. Confidential.

https://www.ceaa-acee.gc.ca/Content/5/0/1/50139251-2FE4-4873-B6A1-A190C103333D/Adaptive_Management_Measures_under_the_CEAA.pdfhttps://www.ceaa-acee.gc.ca/Content/5/0/1/50139251-2FE4-4873-B6A1-A190C103333D/Adaptive_Management_Measures_under_the_CEAA.pdf

-

Broadview Project Environmental Impact Statement

SNC-Lavalin Inc. 2018. Groundwater Sourcing Field Investigation. Broadview Project. Prepared for Canada Golden Fortune Potash Corporation. Project No. 644108. June 2018.

Canada Golden Fortune Potash Corp.

xxi 631260 October 2018 © SNC-Lavalin Inc. 2018. All rights reserved. Confidential.