EXECUTION OF CONCRETE WAFFLE SLAB RECYCLED … · in the production of no structural precast...

Transcript of EXECUTION OF CONCRETE WAFFLE SLAB RECYCLED … · in the production of no structural precast...

2nd International RILEM Conference on Progress of Recycling in the Built Environment 2-4 December 2009, São Paulo, Brazil

253

EXECUTION OF CONCRETE WAFFLE SLAB RECYCLED AGGREGATE TO BE USED IN PRECAST ELEMENTS IN SPAIN

Pelufo, M. J. (1), Serna, P. (1), Jacquin, C. (1), Ulloa, V. A. (1) and López, F. (2) (1) Universidad Politécnica de Valencia, Departamento de Ingeniería de la Construcción y Proyectos de Ingeniería Civil, Spain (2) Universidad de Oviedo. Departamento de Construcción e ingeniería de fabricación, Spain

ABSTRACT Given the importance of standardization of the use of recycled aggregate and for the

successful deployment and management of these aggregates in the civil engineering works, the UPV within the GEAR project, led by GERD, performs a quality assessment of recycled aggregates from construction and deconstruction waste and the requirements to be met if used in the production of no structural precast elements. At the laboratory level, equipment for the manufacture of waffle slab with recycled aggregate available in the market was designed in order to validate its use in prefabricated elements once an appropriate methodology on requirements and implementation of precasted elements was established. The quality of recycled aggregates and their effect on the quality of the final products was studied to establish a selection and classification of materials that can generate dosage criteria for the manufacture of waffle slab under vibro-compression parameters. From experiences with recycled aggregate from concrete precast industries it is verify that its use to produce no structural precast elements may conduce to very good results with similar results than in actual production with natural aggregates without any variation. The use of other recycles aggregates may be generalized but more researches are needed to validate this asseveration.

Keywords: Non-structural concrete, recycled aggregates, Mechanical properties. 1. INTRODUCTION

In Spain, 35 million tons of construction and deconstruction waste were generated in 2007. Approximately 15% of them were recycled and transformed, while almost 50% of them were eliminated with no control at all according to GERD yearly study on costs and fares in construction waste management. Managing construction and deconstruction is, therefore, an activity that adds value to sustainable development. With this in mind, Europe and particularly Spain are making efforts to potentiate the use of this waste, paying attention to previous experiences in other countries like Holland, Denmark, Germany or Austria where waste management policies are in a more advanced stage and waste is considered another source of raw materials.

Management of construction and deconstruction waste leads not only to a solution for a social and environmental problem in relation to deposition locations, but also helps to reduce the rate of natural materials extraction and to prevent the exhaustion of natural resources [1].

Normalization of raw materials and products is fundamental for their introduction into the market. A proper implementation of the recycled aggregates in the construction of buildings

2nd International RILEM Conference on Progress of Recycling in the Built Environment 2-4 December 2009, São Paulo, Brazil

254

and civil engineering works finds a difficulty in the lack of regulation. The GEAR project (Spanish Guide for Recycled Aggregates) [2] is currently being developed in Spain with the aim of contributing to the use of recycled aggregates coming from construction and deconstruction waste in many fields like pavements or precast concrete elements, where the material can comply with the required properties [3][4][5][6]. The authors of this paper co-operate with this project in the assessment of the quality of recycled aggregates that are currently commercially available in Spain, and also in the definition of requirements that all these recycled materials should comply with in order to be used in non-structural prefabricated concrete elements.

2. APPROACH AND OBJECTIVES

Using recycled aggregates for structural concretes is subject to some conditions [7]. It is usually required that these aggregates come exclusively from concrete, their use is restricted only as a substitution of coarse aggregates and, within these, it is usually recommended not to exceed a substitution ratio of natural aggregates with recycled aggregates of 20%. All that implies logistic problems and reduces the profitability of the application. Excessive selection implies more advanced equipments, a greater diversification of materials and a greater number of stock points. Furthermore, the importance of the role of structural concretes makes engineers feel not comfortable with the idea of using recycled products in their works.

Introduction of recycled aggregates into the production of precast non-structural elements can be a more effective option. Within this group there are products like masonry blocks, waffle slabs, kerbs, etc. These products enter the market in agreement with specific regulations that usually do not refer to the quality of the raw materials that are used for their production, being the quality control usually focused on the final product. To comply with the requirements, dry concretes, with low cement contents and low strength levels are normally used. Requirements for the aggregates to be used are not a fundamental aspect and, consequently, using recycled aggregates that do not come specifically from concrete or even fine aggregates is a possibility. In addition to that, concretes with higher substitution ratios can be used.

Such approach would allow the use of waste from precast elements industry to be generalized. This waste would be reused even in the place they appear, without need of any transportation. It would also allow the reuse of important amounts of waste produced in recycling plants whose processes are not very strict or accurate.

The aims of this paper are to analyze a series of options to reuse recycled aggregates in the production of precast concrete elements with no structural purpose, to analyze the minimum requirements the recycled aggregates would have to comply with, and to propose design criteria for mixes that would be useful. The production of precast waffle slabs and kerbs is also studied.

3. REUSE OF RECYCLED AGGREGATES TO PRODUCE KERBS 3.1 Approach

A local company includes kerbs among the elements they produce. On the other hand, during the production of other elements, waste is generated in the form of defective units. It has been proposed to recycle the concrete these units are made with and use it as a substitution for natural aggregates.

2nd International RILEM Conference on Progress of Recycling in the Built Environment 2-4 December 2009, São Paulo, Brazil

255

This epigraph deals with the analysis of the possibility of producing concretes with the same characteristics of those that the company currently uses by using recycled aggregates from its own production, the more the better.

Concretes that are intended to be produced are quite dry, their consistency is similar to that of humid soil and they are to be cast by vibro-compression. Normalized test procedures to test consistency or to cast specimens cannot be applied to these concretes. As a consequence, specific methods that allow an adequate checking of the material’s properties have to be defined. 3.2 Materials used and mix designs considered

In this case there are two different provided recycled aggregates: M and F; two different natural sands and one coarse aggregate. Table 1 shows their size distributions, their densities and their absorption coefficients.

Table 1. Aggregates size distributions

Sieve size Crushed sand 0/4

Aggregates 4/12

Silica Sand

Recycled M

Recycled F

12,5 100 100 100 100 100 10 100 96 100 98 100 8 100 87 100 90 98 4 98 36 100 62 87 2 73 17 98 40 68 1 45 12 96 26 46

0,5 28 10 88 17 29 0,25 18 9 51 12 18 0,125 13 8 15 8 9 0,063 10 7 6 5 4

Densidad 2,6 2,6 2,4 2,3 2,2 Absorción (%) 1,5 1,3 0,3 6,4 7,7 The mix design currently used to produce 200 x 300 x 500 mm kerb units was chosen as

reference mix design or base dosage. A study is proposed consisting of four different substitution ratios of natural aggregates with recycled aggregates (0%, 20%, 50% and 100%) upon the reference mix design, keeping the siliceous sand amount constant. Mix designs considered are shown in Table 2 and Figure 1. Each one of them was analyzed considering three different water / cement ratios (0.3, 0.325 and 0.35) which are close to the one currently assumed for production in the plant considered.

2nd International RILEM Conference on Progress of Recycling in the Built Environment 2-4 December 2009, São Paulo, Brazil

256

Tabla 2. Dosage analyzed

Substitution Crushed sand

Crushed Aggregate

Silica Sand Cement

Recycled M

Recycled F

0 % 1600 250 150 220 0 0 20 % 1450 0 150 220 400 0 50 % 950 0 150 220 450 450

100 % 0 0 150 220 0 1850 3.3 Requirements for the concrete to be produced

24 cubic specimens (100 mm dimension) were extracted from several kerb modules provided by the plant. These were used to determine the material’s density and were tested under compression in different axis, thus considering the strength in different positions during the concrete pouring.

Test results show density values with very little dispersion, being the average value of 2222 kg/m3 and the coefficient of variation approximately 2%. The average strength has been of 22,2 MPa, being these results more dispersive than those of density: the coefficient of variation has reached 20%.

0%

20%

40%

60%

80%

100%

0,01 0,1 1 10

Sieve size (mm)

0%

20%

50%

100%

Figure 1. Size distributions of the mix designs considered.

Assuming a coefficient of equivalence of 0.8 between cubic 100mm side specimens and

cylindrical 150 x 300 mm specimens, the required compressive strength is 17.8 MPa.

3.4 Tests carried out Of each one of the mixes, 8 specimens were casted: 4 of them were tested under

compression 7 days after mixing, 2 of them were tested under compression 28 days after mixing, and the other were subject to the splitting test 28 days after mixing (Figure 2).

2nd International RILEM Conference on Progress of Recycling in the Built Environment 2-4 December 2009, São Paulo, Brazil

257

Compressive strength test

Splitting test

Figure 2. Tests that have been carried out. Specimens to be subject to compressive strength tests and splitting tests were compacted

by using a Kango hammer and demoulded just after the compaction process had been completed, thus simulating the production process of dry concretes in plant (figure 3).

a) b)

Fig. 3 a) Compaction with Kango hammer; b) Demolded specimen. 3.5 Results obtained

The average of all density values obtained for all the mixes analyzed (including all those with different water/cement ratios and with different substitution ratios) is 2137 and the coefficient of variation is 2.3%. This means that the average density and the dispersion of results are very close to those of the standard production process.

Compressive strength values at the age of 28 days are shown in figure 4. If they are analyzed all together, the average strength is 18.2 MPa and the coefficient of variation is 12.4%. That is, the average compressive strength is close to the value that was intended, and dispersion of the results is even less than that calculated from the specimens tested in plant.

Although a slight decrease in the strength values can be perceived when the natural aggregate is 100% replaced with recycled aggregate, differences are not conclusive, and it is worth noting that the greatest strength values are obtained for substitution ratios of 20% and 50%. No clear tendency is observed in the compressive strength in relation to water / cement ratio, at least within the variation limits considered.

Similar conclusions can be deduced from splitting tests results (Figure 5).

2nd International RILEM Conference on Progress of Recycling in the Built Environment 2-4 December 2009, São Paulo, Brazil

258

0

5

10

15

20

25

0,3 0,325 0,35 0,3 0,325 0,35 0,3 0,325 0,35 0,3 0,325 0,35

0% 20% 50% 100%

Com

pres

sive S

tren

gth

MPa

)

% Substitution - w/c Figure 4. Compressive strength values at the age of 28 days.

Results obtained clearly show that using recycled aggregates in elements of this kind does

not substantially modify the concrete’s mechanical properties, even for high substitution ratios.

Average values of the properties studied comply with the objectives, and the dispersion observed is even less than that obtained from the testing of elements produced in plant.

0

0,5

1

1,5

2

2,5

3

0,3 0,325 0,35 0,3 0,325 0,35 0,3 0,325 0,35 0,3 0,325 0,35

0% 20% 50% 100%

TTen

sile

Stre

ngth

(M

Pa)

% Substitution - w/c Figure 5. Splitting test results at the age of 28 days.

Results obtained clearly show that using recycled aggregates in elements of this kind does

not substantially modify the concrete’s mechanical properties, even for high substitution ratios.

Average values of the properties studied comply with the objectives, and the dispersion observed is even less than that obtained from the testing of elements produced in plant.

2nd International RILEM Conference on Progress of Recycling in the Built Environment 2-4 December 2009, São Paulo, Brazil

259

4. CURRENT APPLICATION OF RECYCLED AGGREGATES TO THE PRODUCTION OF WAFFLE SLABS

One of the companies that co-operates with this project produces waffle slabs with concretes whose aggregate is totally replaced with recycled aggregate coming from waste of another company of the same group. These recycled aggregates have a density of 2.2 kg/l, a coefficient of absorption of 6.3% and a Los Angeles coefficient of 37.2. They use an automatic system of production of these kind of elements that operates by filling, vibrating and compacting the concrete within vertical moulds that are fixed to the main device. They use the same system to produce other elements likes blocks, kerb modules, etc.

The process begins in the mixing central. Once the concrete has been mixed, this is transported by means of a mobile tray into the main device, which initiates the process of filling, vibrating and compacting the concrete within the moulds, so that the concrete takes the form of the mould. After that, the resulting concrete elements are carried into the drying chambers, where they are kept usually for 24 hours in order to reach enough strength to be transported once again by means of an automatic system that organizes the elements unto different pallets. This ways, the elements are ready to be commercialized.

This type of elements requires a bending test as checkup. In plant, the test is carried out 24 hours after the specimens have been produced. To do so some elements are supported upon two wooden bars and a load of 2000kN is applied unto them. The waffle slabs must undergo no damage at all, and these tests verify that.

Thus, large-scale experience validates the use of recycled aggregates in waffle slabs as well as in other prefabricated elements, and supports the interest for these researches to be continued (figure 6).

Figure 6. Stages of production.

5. APPLICATION OF COMMERCIAL RECYCLED AGGREGATES TO WAFFLE SLABS PRODUCTION

It is intended to widen the range of recycled aggregates that are used to make waffle slabs to include other marketable recycled materials, not necessarily coming from concrete waste.

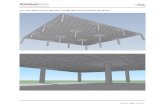

To do so, a device to produce concrete blocks and waffle slab has been acquired and trials experiences are developed at the laboratory scale. Device and waffle slab section to be produce is show in Figure 7.

2nd International RILEM Conference on Progress of Recycling in the Built Environment 2-4 December 2009, São Paulo, Brazil

260

Waffle production machine Waffle section

Figure 7. Waffle to be produced at the laboratory scale.

5.1. Concrete dosage and elements casting process optimization.

The optimization process has been started with a series of tests on mix designs similar to those used by companies of the kind.

Variables for this phase are: concrete water content, admixtures type and dose, needed vibration time, other procedure activities.

Recycled aggregates used are aggregates easily found in waste sorting plants. Nowadays some results products with an acceptable final aspect final have been achieved.

Figure 8 shows a picture of made products. More production process variables and quality recycled aggregate levels will be analyzed

in a future program. As concrete quality control specimens to be subject to compressive or splitting tensile

strength tests will be compacted by using a Kangoo hammer and simulating the production process.

Figure 8. Some results of the preliminary waffle slab production.

6. CONCLUSIONS AND PERSPECTIVE From experiences with recycled aggregate from concrete precast industries it is verify that

its use to produce no structural precast elements may conduce to very good results. Compressive strength must reach similar values than in actual production with natural aggregates without any variation.

2nd International RILEM Conference on Progress of Recycling in the Built Environment 2-4 December 2009, São Paulo, Brazil

261

Although a slight decrease in the strength values can be perceived when the natural aggregate is 100% replaced with recycled aggregate, differences are not conclusive, even if a part of the sand is also substituted by recycled fine aggregate.

The use of recycled aggregates normally produced in a waste management plant is acceptable for the use of concrete with until a 50% substitution, without a significant influence on the properties that should meet when made with natural aggregates.

Large-scale experience validates the use of recycled aggregates in waffle slabs as well as in other prefabricated elements, and supports the interest for these researches to be continued.

Studies to evaluate the effect of using recycled aggregates made of wastes different than concrete on quality of precast concrete elements are in process.

ACKOWLEDGEMENTS

This experimental work will be part of the use of recycled aggregate for GEAR project. This experience has been supported by the General Direction of Quality and Environmental Evaluation of the Ministry of Environment and GERD in Spain.

REFERENCES [1] Rakshvir M. y Barai S. Studies on recycled aggregates-based concrete. Waste Management & Research, Vol. 24, No. 3, pp. 225-233. India. (2006) [2] Ministerio de Medio Ambiente. Guía Española de Áridos Reciclados procedentes de residuos de construcción y demolición. 202/PC08/3-03.2. Programa nacional de proyectos de desarrollo experimental. Subprograma de medio ambiente y Eco innovación 2008-2010. GERD. [3] Montoya, H.D., Pino C.L. y Valdés G.A., Reutilización de residuos del hormigón, BIT 12 (41), pp. 44-47, (2005). [4] Aguilar, C., Muñoz, M.P. y Loyola O., Uso de hormigón reciclado para la fabricación de hormigones, Revista Ingeniería de Construcción 20 (1), pp. 35-44, (2005) [5] Topcu, I.B. y Sengel, S., Properties of concretes produced with waste concrete aggregate, Cement and Concrete Research 34 (8), pp. 1307-1312. Turquia. (2004). [6] Sánchez, M. y Alaejos, P., Influencia del árido reciclado en las propiedades del hormigón estructural, Cemento y Hormigón (889), pp. 54-61, España. (2006). [7] Instrucción de Hormigón Estructural EHE 08. Real Decreto 1247/2008, de 18 de julio, publicado el 22 de agosto, en el Fascículo Primero del Suplemento del BOE núm. 203. 2008. [8] AENOR: UNE-EN 12697-32:2003, “Métodos de ensayo para mezclas bituminosas en caliente- Parte 32: Compactación en laboratorio de mezclas bituminosas mediante compactador vibratorio”, diciembre de 2007. [9] González B.: “Hormigones con Áridos Reciclados Procedentes de Demoliciones: Dosificación, Propiedades Mecánicas, y Comportamiento Estructural a Cortante,” tesis doctoral. E. T. S. I. Caminos Canales y Puertos, Universidad Politécnica A Coruña, 2002. [10] Pedro Serna: “Utilización de áridos reciclados en la fabricación de elementos con fines no estructurales. Aplicación especifica a bordillos y tubos,” Universidad Politécnica de Valencia, Icitech y Gadea Hermanos, 2006.

2nd International RILEM Conference on Progress of Recycling in the Built Environment 2-4 December 2009, São Paulo, Brazil

262

[11] Gonzalo A. Valdés y Jorge G. Rapimán. Propiedades Físicas y Mecánicas de Bloques de Hormigón Compuestos con Áridos Reciclados. Informacion tecnológica, Vol 18 (3) pp 81-88. 2007. Chile.