Example1 Feasibility Report

-

Upload

komal-gada -

Category

Documents

-

view

219 -

download

0

Transcript of Example1 Feasibility Report

-

8/8/2019 Example1 Feasibility Report

1/29

1Final Thesis Report 2008, UNSW@ADFA

Feasibility of Parachute Recovery Systems for Small UAVs

Kirk Graham Stewart Cartwright

University of New South Wales

Australian Defence Force Academy

School of Aerospace, Civil and Mechanical EngineeringCanberra, ACT 2600, Australia

Damage to model UAV research aircraft, whether it is structural or systems damage can be

costly. To combat this problem this project focuses on determining the mechanical

feasibility of a parachute recovery system for small model UAV research aircraft. The

economic feasibility of such a system will also be briefly considered. The findings of this

project indicate that a PRS is capable of recovering these aircraft within an appropriate

altitude. The low cost of implementation for a PRS also make it financially cost effective.

This project extends from the initial task of designing and constructing a model aircraft for

competition in the SAE Aero Design Competition. The design criteria for this competition

were to develop a remote control aircraft with set engine and geometric limitations to lift

maximum payload up to a takeoff weight of 25 kg.

NOMENCLATURE

m = mass [kg]

g = gravity [ms-2]

Cd = drag coefficient

S = surface area [m2]

Do = nominal parachute diameter [m]Dp = inflated parachute diameter [m]

a = semi-major axis length [m]

b = semi-minor axis length [m]

V = velocity [ms-1]

= density [kg/m3]Fd = drag force [N]

x = parachute filling distance [m]

tf = parachute filling time [s]

n = canopy fill constantCx = opening force coefficient

X1 = opening force reduction factor

A = ballistic parameter

dv/dt = acceleration

d/dt = rate of change of attitude = attitude angle

= power of filling function

PRS = Parachute Recovery SystemUAV = Unmanned Aero Vehicle

SAE = Society of Automotive Engineers

ADFA = Australian Defence Force Academy

-

8/8/2019 Example1 Feasibility Report

2/29

2Final Thesis Report 2008, UNSW@ADFA

CONTENTSNomenclature ................................................................................................................................................................ 1 I. Introduction .......................................................................................................................................................... 3

A. Aim .................................................................................................................................................................. 3B. Scope................................................................................................................................................................ 3C. Background & Justifications ............................................................................................................................ 3D. Methodology .................................................................................................................................................... 4E. Assumptions and Limitations .......................................................................................................................... 4F. Management..................................................................................................................................................... 4

II. Literature Review ................................................................................................................................................. 5A. Canopy Shape .................................................................................................................................................. 5B. Parachute Activation ........................................................................................................................................ 5C. Inflation Characteristics ................................................................................................................................... 6D. Parachute Filling Distance ............................................................................................................................... 7E. Attachment Considerations .............................................................................................................................. 7F. Summary .......................................................................................................................................................... 7

III. Concept Selection ............................................................................................................................................ 8A. Introduction ...................................................................................................................................................... 8B. Concept 1 Uncontrolled Deployment............................................................................................................ 9

C. Concept 2 Ballistic Deployment ................................................................................................................... 9D. Concept 3 Spring Release ........................................................................................................................... 10E. Concept 4 Pilot Chute Deployment ............................................................................................................ 11F. Conclusion ..................................................................................................................................................... 11

IV. System Design ............................................................................................................................................... 13A. Parachute System Configuration .................................................................................................................... 13B. Canopy Sizing ................................................................................................................................................ 14C. Pilot Chute Design ......................................................................................................................................... 15D. Initiation Method ........................................................................................................................................... 15E. Containment ................................................................................................................................................... 16F. Deployment Bag ............................................................................................................................................ 17G. Canopy Inflation Predictions ......................................................................................................................... 17H. Summary ........................................................................................................................................................ 19

V. Testing and Analysis .......................................................................................................................................... 20A. Introduction .................................................................................................................................................... 20B. Method ........................................................................................................................................................... 20C. Results and Validation ................................................................................................................................... 20D. Analysis ......................................................................................................................................................... 22E. Summary ........................................................................................................................................................ 25

VI. Cost Benefit Analysis .................................................................................................................................... 26A. Purpose .......................................................................................................................................................... 26B. Scope.............................................................................................................................................................. 26C. Proposed System ............................................................................................................................................ 26D. Costs .............................................................................................................................................................. 26E. Benefits .......................................................................................................................................................... 26F. Summary ........................................................................................................................................................ 26

VII. Conclusion ..................................................................................................................................................... 27A. Concluding Remarks ...................................................................................................................................... 27B. Future Direction ............................................................................................................................................. 27C. Recommendations .......................................................................................................................................... 27

VIII. Acknowledgements ........................................................................................................................................ 28References ................................................................................................................................................................... 29

-

8/8/2019 Example1 Feasibility Report

3/29

3Final Thesis Report 2008, UNSW@ADFA

I. IntroductionA. AimThe aim of this project is to determine if a Parachute Recovery System is a mechanically and economically feasible

method of safely recovering the ADFA SAE aero UAV from flight failure. An aircraft parachute recovery system(PRS) is a procedure that relies on the deployment of a parachute to aerodynamically decelerate an aircraft allowingfor a safer touchdown (Knacke, 1992).

B. ScopeThis project ultimately began with group design and construction of the ADFA SAE Aero UAV. Once completedindividual projects were selected for all group members. The scope of this individual project begins with theexamination of existing PRSs, and a review of the principles involved with PRS design. The development of initialconcepts will follow, then a focus on system design. More detailed design of the chosen concept will be pursuedwith the aid of experimental results, gathered through testing. The testing results will be aimed at determining themechanical feasibility of the PRS. The ability to safely recover UAVs in the event of flight failure is of significantimportance.

Research will also go into the benefit of a PRS for such small research UAV platforms. A determination of howbeneficial such a system will be to small UAV research will try to be reached by carrying out a brief cost timebenefit analysis.

The revised tasks within the scope of this thesis are listed below;

Obtain design details and develop the design requirements analysis. (Group) Design and construct the aircraft. (Group) Flight test the aircraft. (Group) Review existing parachute recovery systems. (Individual) Design a system suitable for this aircraft. (Individual) Test validity of design. (Individual) Determine feasibility of the design. (Individual)

The ultimate goal of this project is to determine if a PRS can safely recover this small balsa constructed UAV withinan appropriate altitude. Because radio controlled aircraft operate at low altitudes it is unknown if a parachute canopen quickly enough to save the aircraft. Furthermore, is it worth the school of ACME investing in a system thatmay turn out to be more expensive than the UAVitself?

C. Background & JustificationsThe initial task leading up to this project was todesign, build and test a UAV to compete in the2008 SAE Aero East Competition. This task waspredominantly undertaken by three students, at the

Australian Defence Force Academy ChristopherKourloufas, Gerad Markham and Kirk Cartwright.The design report for this vehicle is attached inANNEX A. Each student was entrusted withdifferent aspects of the UAV design, and oncecompleted; individual project research wasundertaken in different areas pertaining to theaforementioned UAV.

Figure 1 - ADFA SAE Aero UAV

-

8/8/2019 Example1 Feasibility Report

4/29

4Final Thesis Report 2008, UNSW@ADFA

The design and construction of the ADFA SAE aero UAV was completed in early march 2008, after several monthsof work. As demonstrated in Fig. 1 the UAV consisted of a canard design, powered by a single piston engine, withconventional tricycle undercarriage.

After the construction of the UAV, there was reluctance for the flight testing to begin for fear of damage to theaircraft as a result of flight failure. This reluctance stemmed from the need for an intact aircraft fuselage to be testedwithin the scope of another students thesis project. It was suggested that a PRS could be used to reduce the risk oftotal aircraft damage if flight failure were to occur. The justification for this individual project stems from this needto reduce the risk of total aircraft damage during flight testing.

Furthermore, the University of New South Wales at the Australian Defence Force Academy already owns andoperates several small UAV research aircraft similar in size and weight to the ADFA SAE Aero UAV. Furtherjustification for this project is a direct result of damage to one of these aircraft, during a flight test. The damagedaircraft was a small research UAV with a gross weight of no more than 25kg, which crashed due to radio controlledinterference. Damage caused to the aircraft was considerably costly, and the inability to continue testing causeddelays in research.

D. MethodologyThe overall goal of this project is to determine the mechanical and economic feasibility of a PRS for the ADFA SAEAero UAV. The methodology used to reach this goal is to;

1. Carry out preliminary design of a suitable PRS for the ADFA SAE Aero UAV.2. Develop a method of testing the effectiveness of this design3. Test the design.4. Analyse the test results to determine the mechanical feasibility of the design.5. Undergo a brief cost benefit analysis as a supporting document to determine the economic feasibility.

This methodology outlines the basic structure of this project.

E. Assumptions and LimitationsTo ensure that the basic requirements for the PRS remain the same throughout the design process, it will be assumedthat the ADFA SAE Aero UAV is the dominant aircraft that the system is designed for. This will provide a constantbase aircraft to design from. The adaptability of the PRS to different platforms will still be considered during thedesign process.

Due to the scope of this project, coupled with the time constraints associated with its completion, the design will belimited in its depth and detail. The project will be more focused on the overall system design, with an underlyinggoal of determining the feasibility of a PRS. The design however, must be sufficiently in depth to determine boththe mechanical and economic feasibility of a PRS for use on small research UAVs.

F. ManagementAppropriate management documentation has been attached in ANNEX G

-

8/8/2019 Example1 Feasibility Report

5/29

5Final Thesis Report 2008, UNSW@ADFA

Figure 2 - Cruciform Canopy Configuration

(Wyllie, 2001).

II. Literature ReviewPRSs are not a new concept, and there has been significant research undertaken into several of the more complex problems associated with their design. While keeping the aims of the project in mind, this literature review

summarizes some of the research that has occurred in this area.

Parachute terminology is used quite extensively throughout this review, so to aid understanding; a diagram ofparachute parts is attached in ANNEX B.

A. Canopy ShapePrincipally, UAV PRSs use three different canopy shapes; cruciform or cross-type canopies, hemispherical canopiesand parafoils (Wyllie, 2001). Parafoils are gliding parachutes, designed to be steerable, allowing for a small level ofnavigation after deployment. Their internal cell structure is ram-air inflated which forces the parafoil into a classicairfoil shape. To operate as intended parafoils need to stay inflated and are therefore constructed out of a low porosity fabric (Wyllie, 2001). This causes an increase in theopening shock forces experienced during inflation and a complexreefing mechanism is generally required to reduce these loads.Deployment is further complicated by the need to protect thecontrol line servos from these opening loads (Wyllie, 2001). Afollow on effect of inputting systems to reduce parachuteopening loads causes a much slower deployment speed andtherefore greater height loss during deployment.

Cruciform canopies are the simplest of the three canopy shapesconsisting of two pieces of rectangular cloth overlaid and sewntogether as shown in Fig. 1. These canopies have the smallestdrag coefficients, and lower opening forces. The small openingforces, attributed to gentler parachute inflation, means that the falling body losses more height before full inflation isattained. Cruciform canopies produce lower oscillation than hemispherical canopies, which is one of the reasonsthey have been researched for use in precision airdrop systems are used as drogue stabilizing parachute (Keith Stein,2001).

Hemispherical canopies have high drag and opening force coefficients (Wyllie, 2001), affording them the advantageof better reliability on opening. Hemispherical non-steerable parachutes are used for aircraft recovery because theirsimplicity enhances their reliability. Simplicity pertains not only to the parachutes reliability but also to ease ofconstruction and packing, an imperative requirement for this project.

B. Parachute ActivationParachute activation refers to the method of deployment prior to inflation. It can be assumed that a key factor of parachute deployment systems is reliability. Three principal deployment methods are forced ejection systems,drogue or pilot parachute systems, and rocket extraction systems (Huckins, 1970).

Forced ejections systems are common extraction methods due to their simplicity. The mortar, catapult, and pressure bellows are examples of mechanisms designed to produce a forced ejection of the packed parachute (Huckins,1970). These systems tend to be heavy and they also produce high reaction loads, which is important whenconsidering the platform in which the system will fire.

Parachute deployment using a drogue or pilot parachute has numerous advantages. The system is quite flexiblesince the parachute extraction force is applied continuously over the entire deployment sequence, and the system isalso lighter. This system relies on aerodynamic force to extract the main parachute, thus problems may arise due topilot chute interference with the wake turbulence of the descending body (known in skydiving as hesitation). Usedin tandem, individual extraction systems increase their effectiveness as demonstrated by the Gemini Spacecraft,which used a drogue gun to launch a drogue parachute to stabilize the re-entry vehicle, until a height at which thepilot chute was extracted, pulling out the main chute (Vincze, 1966).

http://en.wikipedia.org/wiki/Airfoilhttp://en.wikipedia.org/wiki/Airfoil -

8/8/2019 Example1 Feasibility Report

6/29

6Final Thesis Report 2008, UNSW@ADFA

Figure 3 - Dis-Reefing of a Hemispherical Canopy (Cao & Xu, 2004).

Figure 4 - G-Loading Plot Experienced by a Recovery Vehicle During Canopy

Inflation (Mohaghegh & Jahannama, 2008).

Arocket extraction system for parachute deployment has all the advantages of a drogue parachute system, but doeshave a slight weight penalty. Furthermore, the rocket extraction system produces very light reaction loads, and isonly slightly dependent on the characteristics of the vehicle wake (Huckins, 1970). The rocket extraction doeshowever increase the risk of damaging the parachute fabric on extraction, and has the added complexities of dealingwith pyrotechnics.

C. Inflation CharacteristicsIn view of the fact that parachute inflation is a very complex and unsteady process, it is well known that parachutetheory is a difficult problem in the aerodynamic field (Calvin, 1984). PRSs in UAVs require parachute inflation tobe reliable and quick, to ensure minimum loss of height during opening. In manned PRSs, such as the BallisticRecovery System (BRS) used in the Cirrus SR20 (Ballistic Recovery Systems Inc.), complex dis-reefingmechanisms are put it place to slow the inflation process and reduce shock forces caused by the opening canopy.The process of dis-reefing shown below in Fig. 2 is done to reduce the forces felt by the manned occupants, and isimportant for unmanned PRS design from s structural integral aspect.

Reefing a parachute slows the inflation, meaning more height loss, however there is another reason for reefing a parachute aside from reducing shock forces. There is a phenomenon called wake recontact, sometimes calledcanopy collapse. This phenomenon occurs when the parachute decelerates the payload so rapidly that the airbehind the parachute catches up to the canopy: causing it to deform (collapse) and lose drag (Peterson, Strickland,& Higuchi, 1996).

One of the single most important aspects in aiding the canopy inflation process is the use of a parachute deployment bag. A deployment bag ensures a controlled deployment phase. The deployment bag also ensures a lines firstdeployment. This ensures that the canopy only begins inflation after the suspension lines have reached full stretch.If a lines first deployment is not followed the canopy often gets tangled in the suspension lines and fails to inflateending in catastrophic PRS failure.

The increase in drag area of the parachute canopy during theopening process causes adeceleration of the recoveryvehicle. A simulation of thedeceleration experienced by therecovery vehicle was carried out

and a plot of a typical g-loadingexperienced is shown in fig 11.This plot will be referred to later inthis document, when the g-loadingcurve for this PRS is plotted.

-

8/8/2019 Example1 Feasibility Report

7/29

7Final Thesis Report 2008, UNSW@ADFA

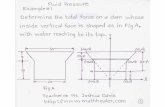

D. Parachute Filling DistanceParachute filling distance is defined as the distance required for the parachute canopy to open, taken from the pointof initial line stretch to full inflation. Fig. 4 demonstrates this definition (Mohaghegh & Jahannama, 2008). Muellerand Scheubel reasoned that, based on the continuity law,parachutes should open within a fixed distance, because agiven conical volume of air in front of the canopy is

required to inflate the canopy (Knacke, 1992). With theconfirmation of drop tests the parachute filling distance wasfound to be proportional to the inflated parachute diameterDp, multiplied by the canopy fill constant n, as shown inEq. 1 below (Mohaghegh & Jahannama, 2008).

(1)

The canopy fill constant, typical for each parachute type, is an indicator of the filling distance as a multiple ofnominal parachute diameter. Having found the canopy filling distance only one further step is required to determinethe canopy filling time. Given speed is distance over time, the canopy filling time is simple given as Eq. 2(Mohaghegh & Jahannama, 2008).

(2)

Canopy filling distance and canopy filling time are very important in PRS because they are a direct reflection of howmuch height loss may occur during the inflation process. Small UAV research aircraft have to operate at lowaltitudes and it is therefore imperative that the campy opens is a short distance.

E. Attachment ConsiderationsThe attachment of the parachute to the UAV directly affects the operation of the system. The attachment pointsdetermine the behaviour of the aircraft during canopy inflation, and also the attitude at which the UAV will fall onceinflation is complete and the PRS is in the steady state condition.

Conventional PRSs deploy in such a way that the aircraft falls undercarriage first in order to protect the airframe;however this is not always the case. The Phoenix UAV, for example, has a PRS that allows the aircraft to roll over

and land upside down (Wyllie, 2001). This is done to protect some of the sensor equipment underneath the aircraft.Manipulation of the aircraft attitude during steady state descent is generally achieved by changing the position of thePRSs attachments in relation to the aircrafts centre of gravity. This allows the designer the freedom to choose howthe aircraft touches down; main undercarriage, or nose wheel first for example. In general however, PRSs areattached at several points with the centre of gravity of the aircraft roughly in the middle to keep the system balanced.From a structural perspective it is important to make sure that the attachments are connected to structurally soundaircraft fixtures, able to handle the large forces that can be experienced due to the rapid deceleration of the aircraftduring canopy inflation.

The attachments to the aircraft are also vitally important during the inflation stage, where careful placement of theattachment points can protect the parachute canopy from entering the wake of the aircraft. If the parachute isattached forward of the centre of gravity, deployment will cause a strong pitch up moment forcing the canopy intothe wake of the aircraft. This situation may even cause the to aircraft fall backwards through the suspension lines,

tangling the parachute. When attached behind the centre of gravity it causes a pitching down moment allowing thecanopy to inflate in the free stream air and also stopping the aircraft from stalling. If used carefully the attachmentmethod can be instrumental in controlling the pitch dynamics of the aircraft during the deployment cycle.

F. SummaryIt is apparent from the literature review that there has been extensive research carried out on the subject of PRSs.There is little research however available on the use of PRSs for small balsa constructed UAV aircraft. There have been PRSs used for large scale UAVs, but the research available for UAVs under 25kg is very limited.

Figure 5 - Canopy Filling Distance Diagram (Mohaghegh &

Jahannama, 2008 .

-

8/8/2019 Example1 Feasibility Report

8/29

8Final Thesis Report 2008, UNSW@ADFA

III. Concept SelectionA. IntroductionThe purpose of this chapter is to consider the different concepts available for the design of a PRS. Each concept will

have merits, however the design will be chosen on its suitability for balsa wood constructed model aircraft.Therequirements of the PRS will give the design process a direction. Listed here are the PRS customer requirements.These requirements have been used to generate engineering specifications, attached in ANNEX C

1. Minimise Damage to airframe on ground impact2. Deploy Reliably3. Minimal impact on aircraft aerodynamic stability when attached4. Capable of decelerating a 25kg payload within respectable g-loading limits5. The possibility of adaptation for different aircraft6. Light weight7. Minimal Height loss during parachute inflation

The first stage of a PRS is the deployment phase. Parachute deployment denotes the sequence of events that beginswith the opening of a parachute compartment and continues with the extraction of the parachute until the canopy and

the suspension lines are stretched behind the recovery vehicle and the canopy is ready to start the inflation process.The deployment system must achieve this sequence of events in a progressive manner so as to reduce the shockforces felt by the UAV. The system must also and more importantly release the parachute into the airflow withsufficient speed so as to allow inflation to occur before the UAV losses to much altitude. This requirement is ofsignificant importance to the design of this PRS as it is to be utilised for low altitude recovery of small modelUAVs.

A good parachute deployment system provides the following benefits as outline by the PRS Design Manual(Knacke, 1992):

1. Minimizes the parachute snatch force by controlling incrementally the deployment of the parachute,and by keeping the parachute canopy closed until line stretch occurs.

2. Keeps Tension on all parts of the deploying parachute.3.

Minimizes opening time.4. Supports uniform deployment.

Once the deployment phase is complete the system is ready for inflation and the most problem prone phase of theworking system is over. It is apparent why the selection of the deployment system defines and directs the remainderof the PRS design.

Four separate parachute deployment system concepts will be analysed, the best system for the use on the ADFASAE Aero UAV will be selected for further design.

-

8/8/2019 Example1 Feasibility Report

9/29

9Final Thesis Report 2008, UNSW@ADFA

Figure 6 - Uncontrolled Deployment (Cartwright, 2008).

Figure 7 - Ballistic Deployment (Cartwright, 2008).

B. Concept 1 Uncontrolled DeploymentThis method of deployment essentially releases the parachute into the free-stream and the forward moving airflowdoes the work in opening the parachute to full inflation. It is therefore given the name uncontrolled deployment.The simplified diagram below demonstrates an uncontrolled deployment.

The appeal of this method of deployment for use on a UAV is its simplistic and lightweight design. An uncontrolleddeployment would allow for a very fast developmental phase and also reduce the cost of the overall PRS.Furthermore, this deployment method could be constructed with very few components and would in turn allow thePRS to occupy a very small proportion of the recovery vehicle.

This system is not without its downfalls however. Due to the uncontrolled nature of this concept, there has beenresearch that has shown it is only effective for parachutes less than 5 feet in diameter (Knacke, 1992). When largerparachutes are released using this method it results in high shock forces and partial canopy inflation prior to the fullline stretch of the suspension lines. It is possible to account for these problems by clever design of a complicatedreefing system and sophisticated packing methods; however this would undermine the simplicity of the systemwhich was one of the major reasons for its consideration.

C. Concept 2 Ballistic DeploymentBallistic deployment refers to the deployment of a parachute by the use of some kind of pyrotechnics. There are twomain types of ballistic deployment systems, and although they are subtly different their principle is essentially thesame. The diagram below shows the two main ballistic deployment systems, rocket deployment on the left anddrogue gun deployment on the right.

-

8/8/2019 Example1 Feasibility Report

10/29

10Final Thesis Report 2008, UNSW@ADFA

Figure 8 - Spring Release Method (Cartwright, 2008).

Rocket deployment uses an angled nozzle rocket to pull out the main parachute. This is a very high speeddeployment, and has been used successfully for larger aircraft PRS. The benefit of the rocket deployment system isthat it provides a constant pulling force over the whole deployment cycle. The disadvantages of this system arenumerous when considering the type of vehicle in which it is intended for. The small balsa constructed ADFA SEAAero UAV does not have a large amount of space in which a rocket could be mounted. Rockets also produce veryhot exhaust gasses that may be an added risk for the internal balsa structure and electronic equipment such as servos.

Drogue gun deployment is a method that fires a weighted slug from a drogue gun to pull out the main parachute in avery similar way to the rocket deployment system. This method is advantages in that the explosive energy iscontained within the drogue gun and it leaves with the slug in the form of kinetic energy. As shown in the diagramabove the slug is tethered to the main deployment bag and pulls out the main parachute from its compartment withinthe UAV. Unlike rocket deployment the slug relies on its inertia to provide the pulling force needed over the wholedeployment. Problems with this method may arise due to the large reaction forces that occur due to the large slugbeing fired from the drogue gun. The simple balsa frame would struggle to support the drogue gun and damage mayoccur during deployment.

Ballistic deployment has its merits with regards to a favourable deployment time. Having a fast deployment is paramount for low level UAVs and ballistic deployment has proven effective in this area. The complexity of

ballistic deployment however, makes it less of a viable option for such a small scale recovery vehicle. The lack ofspace within the ADFA SAE Aero UAV also means that the system must have as few components as possible.Another consideration is the overall weight of a ballistic system, which, if installed, would require the aircraft tosacrifice this weight in the form of its payload carrying capacity.

D. Concept 3 Spring ReleaseThis spring release method, represented diagrammatically below, was an attempt to combine the high speedsassociated with ballistic deployment with the simplicity of the uncontrolled deployment. This concept uses a highpowered spring internally mounted to eject the main parachute into the free stream airflow.

The side effect of using the spring release method is the weight of the internal mechanical components. Onepossible solution is to use compressed air instead of a mechanical spring however, problems also may arise withmounting the system within the ADFA SAE UAV fuselage, and although much less than a ballistic deployment thereaction force may still prove significant.

One further point to note is that force provided by the spring to deploy the parachute must be significant enough tocomplete the whole deployment. Unlike a Rocket deployment where the force extracting the parachute is constantthroughout the extraction phase, the spring release mechanism merely ejects the parachute and allows the airflow tocomplete the unfurling process. This reduces the reliability and repeatability of the deployment.

-

8/8/2019 Example1 Feasibility Report

11/29

11Final Thesis Report 2008, UNSW@ADFA

Figure 9 - Pilot Chute Deployment (Cartwright, 2008).

E. Concept 4 Pilot Chute DeploymentThe final concept to discuss is the method of pilot chute deployment. During this method of deployment a smallparachute called a pilot chute is used to drag out the main parachute as demonstrated in the diagram below.

The pilot chute, which is generally about a quarter of the size of the main parachute, is small enough that it can bereleased at high speeds without producing large shock forces. The pilot chute then helps to decelerate the fore bodywhile pulling out the main parachute so that when the main canopy opens the speed is slowed enough such that theshock forces are significantly reduced when compared to an uncontrolled deployment. The pilot chute utilises thedrag force it creates when in the free airstream to deploy the main parachute and as a result has the benefit of havinga constant force throughout the whole deployment phase. This does mean however, that at the very slow speeds thepilot chute can fail to produce enough drag to deploy the main parachute fully. This is one of the reasons that someaircraft PRSs have an operational envelope that defines its limitations.

The issue of containment space is less of a problem using this method. Because the pilot chute is made of the samematerial as the main canopy it can be folded to take up very little space within the fuselage of the recovery vehicle.This naturally applies to the weight of the PRS. Because the pilot chute is made of lightweight material the overall

deployment system is very light.

The simplicity of this system is a direct result of the number of components required for its function. Thedeployment system is essentially two parachutes of different sizes opened one after the other. The construction andinstallation of it is therefore greatly simplified and as a result the cost is reduced. Using a pilot chute for the mainparachute deployment does however, have a certain unknown quality to its function. Because the parachutes aredifferent sizes, unique to their specific function; and the recovery vehicle has a known range of speeds defined by itsoperational envelope, the inflation times and distances are not known with great accuracy. For this type ofdeployment system testing would be required to determine the feasibility for use on a small balsa UAV.

F. ConclusionFour concepts have been introduced within this chapter and one will be selected for further design. Uncontrolleddeployment is easily the least complex system and would require very little detailed design. It would be a costeffective design and would require very few resources to take it from concept to construction. The possiblecomplications do however make this a poor choice for further design. The over simplification of the deploymentleads to a loss of tension on the suspension lines and canopy which causes entanglement between different parts ofthe parachute.

The speed of a ballistic deployment system would provide a good range of altitudes from which the aircraft could berecovered. The better performance achieved in deployment speed is far outweighed by the increased complexity ofthe design. Both rocket and drogue gun methods also increase the risk of damaging the aircraft during the violentdeployment phase. Ballistic deployment methods carry an inherent risk and as a result the expense of its

-

8/8/2019 Example1 Feasibility Report

12/29

12Final Thesis Report 2008, UNSW@ADFA

Concept 1

Uncontrolled

Concept 2

Ballistic

Concept 3

Spring

Concept 4

Pilot Chute

Reliability* 8 4 6 2

Speed of Deployment* 8 2 6 4

Lines First Deployment* 8 4 6 2

Complexity 1 4 3 2

Reaction Forces on Aircraft 1 4 3 2

Adaptability to Other Aircraft 1 2 4 3

Weight 1 4 3 2

Cost 1 4 3 2

Results 29 28 34 19

Table 1 Concept Selection table (Cartwright, 2008).

implementation is significantly increased. Unfortunately this makes it a poor choice of deployment system for thistype of UAV. To make the PRS a viable option it is necessary to make it as cost effective as possible.

The goal behind the spring release method was to reduce the risk of a ballistic deployment by using a mechanicaltype system to release the parachute into the free airstream. The side effect of using an internal spring system is thata large force must be produced at the start of the deployment to allow the parachute to complete its full unfurling process. This large force has to occur over a very small period of time, resulting in large impulse, which thefuselage was not deigned to handle. To produce a large impulse it would require the use a large and heavy springsystem that would make this method of deployment a bad choice for an aircraft application.

The final concept shows the most promise for further development. It is the method that uses a pilot chute to extractthe main parachute. This system is simple, lightweight and has the potential to be very cost effective. There ishowever the question of inflation times and distances, and testing will be required to confirm if it is a feasiblesystem. Pilot chute deployment is used primarily for personnel parachutes, which is a testament to their reliability,an important factor considering its intended purpose as an emergency recovery system.

The table below is a method of comparing the individual concepts to help with an informed selection. Each conceptis ranked against the amended system requirements. The essential requirements carry greater weight in the selectionprocess and are therefore doubled within the table. The best concept for a given system requirement is given a scoreof 1 and the worst a score of 4. The values attained are summed and the concept with the smallest total number is

the concept that best fulfils all system requirements. Table 1 below is the results of the concept selection analysis.

This method of selection confirms what the logic predicts, that concept 4 the pilot chute deployment system is the best system for this application with a score of 19. Ballistic deployment is the second choice; however itscomplexity rules it out as a viable option.

-

8/8/2019 Example1 Feasibility Report

13/29

13Final Thesis Report 2008, UNSW@ADFA

IV. System DesignA. Parachute System ConfigurationDuring the conceptual design phase outlined in chapter 4 of this document, it was decided that the PRS would use a

pilot chute deployment method. A more detailed breakdown of the parachute recovery system configuration isrepresented below.

A. Main Canopy ShapeUnderstanding that this PRS is to be used as a lower atmosphere, subsonic aerodynamic decelerator steers the choiceof parachute canopy shape to three different options. These options are Para foil, Cruciform, and hemispherical parachutes. As discussed in the literature review parafoil shaped designs, common in sports parachutes, aresteerable systems, unnecessary for this application. The parafoil design also adds unnecessary complexity to theconstruction of the intended PRS.

Cruciform or hemispherical parachutes are more commonly used in aircraft recovery systems. This PRS will use ahemispherical parachute design due to the larger drag coefficient than the cruciform parachute allowing for the useof a smaller parachute for the same descent speed. The cruciform parachute has a smaller opening force coefficientwhich means less shock force occurs during parachute inflation; however this is outweighed by the reliability of thehemispherical parachute.

Hemispherical parachutes also have a lower canopy filling constant which reduces filling distance. Therefore lessheight is lost during inflation. Further reasons for choosing a hemispherical parachute shape are listed below.

1.Ease of construction.2.Ease of packing.3.Better consistency on opening.4.Large inflation shock forces acceptable due to unmanned aircraft.5.Large Drag coefficient.

Figure 10 - PRS Layout (Cartwright, 2008).

6. Main Canopy7. Main Parachute Deployment Bag8. Pilot Chute Bridle9. Pilot Chute Swivel10. Pilot Chute

1. Recovery Vehicle2. Shock Force Attenuation Bridle3. Main Parachute Riser4. Main Parachute Swivel5. Main Parachute Suspension Lines

-

8/8/2019 Example1 Feasibility Report

14/29

14Final Thesis Report 2008, UNSW@ADFA

Canopy Sizing

Parameter Value Units

Mass 25.00 kg

Gravity 9.81 m/s^2Density 1.23 kg/m^3

Descent Velocity 5.00 m/s

Drag Coefficient 0.70

Surface Area Required 22.88 m^2

Nominal Parachute Diameter 5.40 m

Inflated Parachute Diameter 3.56 m

Table 2 - Main Canopy Sizing Data (Cartwright, 2008).

One negative aspect of using hemispherical parachutes is their tendency to oscillate. Oscillation is a result of anunstable parachute where the vortex shedding initiates a rocking motion back and forth. Hemispherical parachutesoften have a tendency to have large oscillations, up to 30. Research has shown however that these oscillationsonly occur at the higher descent velocities ( 9m/s), which is as much as 4 m/s faster than the descent velocity thisPRS is designed to achieve.

B. Canopy SizingHaving decided that the canopy shape will be hemispherical, the initial canopy sizing can be evaluated with theobjective of calculating inflated parachute diameter. Parachutes rely on the aerodynamic drag force, represented byEq. (3), to slow the descent of a body. Assuming that the parachute is in a steady state descent means that the dragforces Fd can be equated to the weight of the descending body, as represented by Eq. (4). Rearranging Eq. (4) forsurface area yields Eq. (5).

(3)

(4)

(5)

The unknowns in Eq. (5) are, payload mass m, and descent velocity V. All other variables in the equation arealready known quantities, =1.225kg/m3, CD=0.7(standard for hemispherical parachutes) (Knacke, 1992), andg=9.81m/s.

Payload mass can be reasoned out by understanding that the ADFA SAE Aero UAV gross weight must not exceed55lbs (25kg), therefore m=25kg. The descent velocity can be obtained from historical data, which shows thataircraft PRSs have descent velocities between 4-6 m/s (Wyllie, 2001). Taking the average and using 5 m/s for Vmeans that surface area can be quantified.

Now that surface area is calculated the nominal parachute diameter can be found. The nominal diameter of aparachute is simply a reference diameter found by using Eq. (6), (Knacke, 1992) below.

(6)

Using table 5-1 (Knacke, 1992), found in ANNEX D, the ratio between inflated diameter Dpand nominal diameterDofor a hemispherical parachute is highlighted. This allows for the calculation of the inflated diameter using theEq. (7) below.

(7)

The excel spreadsheet shown in table1 was used to calculate the parachute

data, using the equations outlinedpreviously.

The excel spreadsheet shows that for a5m/s rate of descent, a parachute witha 3.56m inflated diameter is required.Research has shown that this methodof parachute sizing is highly accurate,and conforms well to the results of parachute drop tests. Knowing the

-

8/8/2019 Example1 Feasibility Report

15/29

15Final Thesis Report 2008, UNSW@ADFA

Pilot Chute Sizing

Parameter Value Un

Main Parachute Mass 1.40 kg

Gravity 9.81 m/s^2

Density 1.23 kg/m^3

Descent Velocity 4.00 m/s

Drag Coefficient 0.70

Surface Area Required 2.00 m^2

Nominal Parachute Diameter 1.60 m

Inflated Parachute Diameter 1.05 m

parachute dimensions it was possible to purchase a hemispherical parachute of the appropriate size. The parachutewas purchased early as it was known that testing would be required before the conclusion of this project. The maincanopy cost a total of $350 including suspension lines and mounting bracket.

C. Pilot Chute DesignThe pilot chute is a small parachute designed topull out the main parachute during the deployment phase. Now that the main parachute has beensized and purchased the pilot chute can bedesigned using the main parachute data. Twodifferent methods have been used to confirm thesize requirement of the pilot parachute. The firstmethod of sizing uses historical data from many parachute tests to determine a Pilot-to-main parachute drag area ratio. Table 3, right is takenfrom the Parachute Recovery System DesignManual, and was used to get a first estimate of thepilot chute size.

The first method estimated that a pilot

chute with an inflated diameter of 0.62mwas required.

The second method is a mathematicalmethod similar to that of the calculationof the main parachute size. Given thatthe main canopy had been purchased wecould get an accurate weight by a simplemeasurement. The parachute including bridle has a total weight of 1.4 kg.Knowing the weight of the main parachute and assuming the worst casescenario, that the pilot chute must have

the ability to pull out the main parachuteat the stall condition of the aircraft(approx. 4 m/s), it is a simplecalculation to solve for a surface area. This calculation was performed in parallel to the main canopy sizing methodusing Microsoft Excel and is displayed in table 4.

The mathematical calculation determined that a hemispherical pilot chute of 1.05m diameter would be required for asuccessful deployment at stall speed. This size is 40% larger than the pilot chute diameter determined usingstatistical data.

To ensure the reliability in deployment of the PRS and to build in another level of safety it was decided to use thelarger of the two values. Hence the pilot chute is set at a diameter of 1.05 meters. The pilot chute was alsopurchased so that its reliability could be tested at a later stage within the scope of this project.

D. Initiation MethodFrom the conceptual design chapter a pilot chute system was selected for use as the deployment method. Theinitiation system is characterized by the functions of the PRS that occur up to and including deployment of the pilotchute. Several simultaneous actions must occur prior to the start of the deployment process. First the PRS must beinitiated by the observer on the ground. A signal will be sent to the UAV that will release the pilot chute and alsokill the engine. The engine will be killed to prevent line tangling in case the suspension lines come in the vicinity ofthe propeller.

Table 3 - Pilot-to-Main-Parachute Drag Area Ratio (Knacke,

1992).

-

8/8/2019 Example1 Feasibility Report

16/29

16Final Thesis Report 2008, UNSW@ADFA

Figure 11 - Folded Pilot Chute and Compressed

Release Spring Inside Release Hatch

(Cartwright, 2008).

Figure 13 - ADFA SAE Aero Fuselage with PRS Location (Kourloufas, 2008).

The pilot chute is ejected by using a very lightweight springmechanism. The spring is sewn into the pilot chute crownarea and collapses for easy storage at the rear of the aircraftfuselage just behind the aft bulkhead. The pilot chute springis compressed and held in place by the release hatch. Therelease hatch is pinned closed and a small electronic servo ismounted in place to release the hatch when required. Thediagram right shows the folded pilot chute and spring aft ofthe rear bulkhead.

The entire PRS is initiated by the pulling of a pin which holdsthe release hatch to the recovery vehicle. The hatch fallsaway as the pilot chute is sprung into the free airflow and thedeployment process begins. The servo that pulls the release pin to activate the system is run off an independent powersource and is also wired in to an independent radio receiver. This is to try and avoid accidental parachute release byradio interference.

E. ContainmentNow that the main parachute and pilot chute have been purchased, elements of how the system will be contained

within the aircraft can be considered. To ensure that the PRS has no effect on the aircraft during normal flyingoperations, an internal storage will be used. The ADFA SAE Aero UAV does not have large amounts of fuselagespace. By looking at the constructed fuselage the best location for containment can be determined. The newlydesigned fuselage for the ADFA SAE Aero UAV, designed by Christopher Kourloufas is shown below.

The different sections annotated above indicate the lack of space within the main fuselage section. The two sectionswhere it would be possible to fit the parachute internally are the internal electronics mounting space, or over thewing carry through section. To facilitate deployment it is important that the parachute be in a location where it candeploy quickly into the free airstream and be unaffected by aircraft appendages such as the wings or canards. Thismakes the obvious choice for the parachute containment at the rear of the aircraft, such that it can deploy already

Figure 12 - ADFA SAE Aero UAV Fuselage (Cartwright, 2008).

-

8/8/2019 Example1 Feasibility Report

17/29

17Final Thesis Report 2008, UNSW@ADFA

Figure 16 - Main Parachute in Deployment

Bag with Pilot Chute Attached (Cartwright,

2008).

Figure 14 - Unpacked Main Parachute and

Deployment Bag (Cartwright, 2008).

Figure 15 - Main Parachute Packed in

Deployment Bag (Cartwright, 2008).

Figure 17 - Deployment Bag with Red Sirt

Hesitation Band (Cartwright, 2008).

free and clear of the wings, avoiding possible suspension line tangling. Figure 13 is a sectioned cut-away of thefuselage design which indicates the PRS location within the UAV.

Knowing the location of containment produces the need to design a method of storing the parachutes. This requiresthe design of a deployment bag.

F. Deployment BagUsing a Parachute deployment bag has many advantages. Itallows for a repeatable parachute unfurling process and as a resultincreases the reliability of deployment. It has been shown toprovide the most frequent and successful method of producing acontrolled deployment (Knacke, 1992). A deployment bag also permits easy handling, packing, rigging and storage of theparachute assembly.

The deployment bag contains the parachute and holds it until it isready to be unfurled. This means that it must have a few veryspecific qualities to allow for a good controlled deployment.Firstly the deployment bag must be light. The pilot parachuteattaches to this bag and pulls it out of the containment area, so the

lighter the bag the smaller the pilot chute required. Thedeployment bag must also have a low porosity. This ensures thatthe main parachute canopy can easily slide past the bag whenunfurling is required.

The deployment bag also ensures that the canopy only inflatesafter the suspension lines are at full stretch. As brought up in theliterature review, a lines first deployment is imperative to reduceshock forces and ensure reliable canopy inflation.

Generally speaking a deployment bag is specifically made for themain parachute. In this case an existing product was available thatadequately performed all of the necessary functions of adeployment bag. A 2.4 Litre plastic bottle was found to be anexcellent deployment bag for this situation. The bottle was light,cheap, fitted perfectly into the allowable space, and has asufficiently low porosity to allow the parachute to unfurl quickly.The deployment bag encompasses the main parachute into a smallspace and has the added benefit of easily being attached to the pilot chute. Figures 14-16 show the deployment bag, and itslocation within the PRS.

The final requirement for the deployment bag is to ensure a linesfirst deployment. This is achieved by using a method called skirthesitation. This design uses a tensioned band around thesuspension lines at the base of the deployment bag. It isdemonstrated in the figure 17. This red band prevents the skirt of

the parachute leaving the deployment bag until line stretch occurs.At line stretch the suspension lines are pulled out from underneaththe band and the parachute can be deployed.

G. Canopy Inflation PredictionsThe canopy inflation process is by far the most complex aspect ofthe PRS. There are several mathematical models to help predict theeffect of the canopy inflation process and some of these modelswill be utilised within this preliminary design chapter, however the

-

8/8/2019 Example1 Feasibility Report

18/29

18Final Thesis Report 2008, UNSW@ADFA

Figure 18 - Mathematically Predicted Canopy Inflation Times

(Cartwright, 2008).

canopy inflation process must, and will be supported by testing. The reason for such focus on the canopy inflationprocess is to try and answer the question will this PRS deploy quickly enough before the aircraft looses too muchaltitude. There is also a need to calculate the opening forces of the canopy for the use in stress analysis of both the parachute and airframe. As discussed in the literature review regarding canopy inflation time and distances, asimple equation exists to give estimate the canopy inflation time. This equation is shown below;

(8)

Do is the parachute nominal diametercalculated earlier this chapter. V is thevelocity at line stretch and n is the canopyfilling constant. Using this technique the firstestimation of canopy filling time for both themain parachute and the pilot chute wascalculated for different deployment velocitiesand displayed in the Figure 18.

This mathematical prediction of canopy fillingtime indicates that for speeds above 5m/s both

parachutes will inflate in less than 5 seconds.

Based on the continuity law parachutes shouldopen within a fixed distance; because a givencollum of air in front of the canopy must beused to inflate it. This distance is proportionalto the diameter of the parachute (Knacke,1992) and by using the equation below;

(9)

A constant value or parachute opening distance for the main canopy of 14.25 m is predicted. This equation was alsoapplied to the pilot chute and a much smaller canopy inflation distance of 4.21m was calculated.

This method of calculating canopy inflation time and distance is used only as an initial estimate for the design.Given that it predicts the main canopy will inflate in a distance as little as 14.25m it provides evidence that this PRSdesign will deploy to full inflation even at low altitudes. It is imperative that these initial estimates however bevalidated by testing.

Now that inflation times and distances have been estimated, parachute opening forces should also be considered.The inflation distance calculation gave an indication as to whether the canopy could open within a given altitude.Canopy opening force calculations will help determine whether or not a small balsa constructed UAV can handle theopening forces of a parachute at a given deployment speed. This force calculation will be important in trying todetermine the mechanical feasibility of this PRS.

There are several methods of determining the maximum canopy opening force. The method used here is known asthe Pflanz Method, which was developed during WWII by E. Pflanz (Knacke, 1992). This method makes the

assumption that the aircraft if flying on a horizontal path at the time of deployment. The first problem is todetermine how much velocity decays from the UAV after the parachute is deployed but prior to the commencementof canopy inflation. This is done by using the equation below;

(10)

-

8/8/2019 Example1 Feasibility Report

19/29

19Final Thesis Report 2008, UNSW@ADFA

Figure 19 Mathematically Predicted Parachute Opening/Shock Forcesfor Different Deployment Speeds (Cartwright, 2008).

Velocity decay was found to occur prior to the inflation process. The magnitude of the velocity decay was takenaway from the initial deployment speed and the resultant was used in the remainder of the opening force calculation.The amended velocity was now appropriate to use within the force equation below;

(11)

The force equation above is very similar to the standard drag force equation 3. The different variables are theopening force coefficient Cx and the force reduction factor X1. The opening force coefficient is a tabulated valuein ANNEX D, and the force reduction factor is found by calculating the dimensionless ballistic parameter, A usingthe equation shown.

(12)

The force reduction factor can now befound by using the relationship betweenforce reduction factor and thedimensionless ballistic parameter Adisplayed in ANNEX E. Using this valuefor force reduction factor the parachuteopening force can be determined for givendeployment velocities and was graphedusing excel to give the graph in figure 19.

The mathematical data predicts a peakparachute opening force of approximately800N at 20m/s deployment velocity. Thisindicates that even for lightweightrecovery vehicles there is a substantialcanopy opening force. Because this forceoccurs within the short time that the

canopy inflates it is often referred to as theshock force. A deployment at 20m/s willproduce considerable shock force and themaths indicates that a shock force attenuation system may be required. This may be in the form of an aerodynamicreefing system, or even a simple system such as an elastic riser to absorb some of the shock force during opening.

H. SummaryThe major components of the PRS have been designed within this chapter. These components include the maincanopy, pilot chute and deployment bag. At the very least these systems needed to be designed prior to determiningif it were possible for a PRS to safely recover the UAV.

To begin to understand if the PRS can safely recover the UAV in an appropriate altitude some preliminarycalculations were made to determine the parachute filling times and opening distance. Canopy opening force

predictions were also made which seem to indicate that the PRS may produce too much opening force for theairframe to handle.

More accurate predictions about how much altitude will be lost and the amount of force the airframe will receiveduring a parachute deployment, need to be made. The chapter to follow is aimed at answering these questions sothat an indication of the feasibility of the PRS can be deduced.

-

8/8/2019 Example1 Feasibility Report

20/29

20Final Thesis Report 2008, UNSW@ADFA

Figure 20 - Captured Image from Dynamic Test Run

(Cartwright, 2008).

Deployment

Speed (km/h)

Inflation

Time (s)

Inflation

Distance (m)

10.0 4.60 12.8

20.0 1.87 10.4

30.0 1.63 13.6

40.0 1.25 13.9

50.0 0.85 11.8

Table 3 - Experimental Results (Cartwright,

2008 .

V. Testing and AnalysisA. IntroductionDue to the nature of the flight envelope of small model UAV research aircraft questions arise as to the suitability of

PRSs. The mathematical calculations in the previous chapter seem to indicate that it is possible for a parachutecanopy to fully inflate without losing to much altitude. These calculations are only an estimate however and testingneeds to occur to back up the mathematics.

This chapter describes the appropriate strategies, and methodologies used to plan, and execute testing of theparachute opening characteristics, to determine their mechanical feasibility for model aircraft. The objectives of thetesting is to gain an insight into the;

Parachute inflation times. Parachute inflation distances. Parachute reaction to wake flow. Confirmation of parachutes structural integrity. Parachute Recovery System Reliability and Repeatability. Deployment method verification.

B. MethodThe most common method of testing parachutes is in the wind tunnel. This off coarse is the safest method andproduces good reliable results. Unfortunately you are limited by the size of the parachute that can fit inside a windtunnel, and using a smaller model parachute can compromise the dynamic similarity and give meaningless results.For this reason, along with the limited resources that are available at the Australian Defence Force Academy, asimple method designed to reproduce the effects of a wind tunnel test. The basic test approach will involve dynamicparachute testing. The method will make use of a motor vehicle to induce different parachute opening speeds. Theparachute will be contained in the deployment bag until the vehicle reaches the appropriate deployment speed. Oncethis occurs the parachute will be deployed and allowed to inflate, while being recorded for analysis. This will berepeated several times at different deployment velocities. A frame by frame demonstration of the parachute inflationprocess resulting from the testing method is displayed in ANNEX F.

C. Results and ValidationThe testing occurred on a calm day to ensure that theresults would be as reliable as possible. All of thetest runs were filmed for later analysis. The freezeframe image in figure 20 illustrates the fully inflatedcanopy during a test run and demonstrates how thetesting was carried out.

Runs were conducted, at 10km/h and increased in10km/h intervals until 50km/h was reached. Eachdeployment speed was repeated several times so thatan average of the results could be attained. Theaverage of the results is displayed in table 4.

-

8/8/2019 Example1 Feasibility Report

21/29

21Final Thesis Report 2008, UNSW@ADFA

Figure 21- Plot Showing Predicted and Measured Canopy Inflation Times (Cartwright, 2008).

Fi ure 22 - Parachute O enin Times Knacke, 1992 .

The tabulated data from the testing of the parachute filling times is plotted in figure 21, and the full accumulated testdata is attached in ANNEX H.

The Blue line in figure 21 is the data that was collected from testing and the red dashed line is its trend line. TheGreen line is a plot of the values calculated from the math in the previous chapter. There is a very prominent anddirect correlation between the experimental data and the mathematical model. The shape of the curve is verypromising and the calculated data is on average only 15% larger than the experimental data below 30km/h. The testrun at 20 km/h seemed to produce an inflation time that is much faster than its predicted value. It is most likely thatduring this run there was a slight headwind, which would have increased the effective airspeed felt by the parachute.The vehicle wake seems not to have affected the results.

The correlation between the mathematical model and the experimental data also applies to the canopy fillingdistance. The mathematical model predicted a canopy filling distance of 14.25m and an experimental average fillingdistance of 12.5m was observed. The experimental filling distances also appeared to remain constant, regardless ofthe deployment speed. This further supports the prediction made in the mathematical model that states that aparachute will inflate in a constant distance regardless of deployment speed.

The experimental and mathematical datahave supported each other veryadequately; however, it is possible that theexperimental method produced a singularresult. To determine if the experimentwas valid it needs to be compared toexisting validated experimental results.

The graph shown right is experimentalresults for a flat circular parachute. Flatcircular parachutes are very similar inconstruction to hemispherical parachutes.The actual values taken from this graphare meaningless because the size of theparachute used in the experimentation wasmuch larger than the parachute used inthis project, and the deployment speeds

-

8/8/2019 Example1 Feasibility Report

22/29

22Final Thesis Report 2008, UNSW@ADFA

Figure 24 - PRS Deployment Cycle Stage 1

(Cartwright, 2008).

Figure 23 - PRS Deployment Cycle Stage 2 (Cartwright, 2008).

Figure 25 - PRS Deployment Cycle Stage 3 (Cartwright, 2008).

are much greater. However, the shape of the curve is very similar to the shape of the curve found by ourexperimental results. This supports our experimentation method and provides further validation to the accuracy ofthe results.

The reliability of the system was also tested during the experimentation. A total of over 40 runs were conducteddeploying the parachute at different speeds and using different deployment methods. Of all the runs the parachutefailed to inflate only twice. The first time a failed inflation occurred the parachute was deployed at a very lowvelocity (5km/h). This deployment velocity failed to provide enough clean airflow to the skirt of the parachute. It isunknown if the vehicle wake had more of an effect at this low speed, which may have prevented inflation. Theintended UAV operates at much greater velocities than this test was performed, however it does indicate that thereare limits to the PRSs operational envelope.

The second failed inflation occurred when an uncontrolled deployment was tested. When the canopy was released itbegan to inflate prior to line stretch. This caused a line inversion, which meant that only half the canopy inflated.Although the parachute did eventually correct itself and inflate, it was after a considerable distance, and wasconsidered a failed inflation.

Overall however, the testing demonstrated the reliability of the pilot chute deployment method. It also demonstratedthe importance of the deployment bag in ensuring line stretch occurs prior to canopy inflation.

Now that the mathematical model has been supplemented by valid experimental data, a profile of how thedeployment will occur can be reasoned out. Using the experimental data in conjunction with the mathematicalmodel to fill in the gaps where experimentation is not available, predictions can be made about the overalldeployment cycle with more confidence.

D. AnalysisThe overall object of this project was to determine the feasibility of a PRS for small UAVs. The objective of thetesting was to get a better indication of how much altitude would be lost during the deployment phase. In chapter 4a pilot chute deployment concept was selected and designed in chapter 5. The diagrams below demonstrate thecycle of deployment and indicate the horizontal distances covered during deployment.

Stage one shown in figure 23 is the deployment of the pilotchute from the rear of the UAV. The pilot chute is small andas a result inflates very quickly. The average distance travelled

of the recovery vehicle during pilot chute inflation is 6.5meters. The pilot chute is small enough that the opening shockforces can be considered negligible. Stage two in figure 24sees the pilot chute pull the deployment bag out of its container

within the recovery vehicle and reach the point oflines stretch. The suspension lines of the main parachute determine the distance that this phasetakes up. The main parachute has 4 meters worthof suspension lines. This is the point just prior tothe start of canopy inflation. Stage three now

occurs shown in figure 25 andthe main canopy inflates. Thisoccurs in a distance of 14.25

meters regardless of UAV speed.The data predicts that the PRSwill go from full containment tofull main parachute inflationwithin 25 meters. This distancecalculated assumes the UAVmaintains a horizontal path.

-

8/8/2019 Example1 Feasibility Report

23/29

23Final Thesis Report 2008, UNSW@ADFA

Figure 25 - PRS Free Body Diagram (Cartwright,

Figure 26 - G-Loading Experienced by UAV during Deployment

at 15m/s (Cartwright, 2008).

To determine how much altitude is lost during deployment, predictions need to be made about the path or trajectorythat the recovery vehicle is likely to take. This is a fairly complex mathematical task. First the entire system mustbe modeled as a deceleration system in space. This means that angle and acceleration relationships can be appliedby the free body diagram shown right. In the diagram, W is the weight of the system, F is the drag force created by the parachute, and D is the drag of the UAV/recovery vehicle. If the forces are summed in the free bodydiagram the following equations for acceleration arededuced;

(13)

The above equation represents the deceleration of therecovery vehicle and solving it requires an expression for theinstantaneous force of the parachute during each stage of theinflation process. This is very difficult to predict because theincrease in the area of the parachute canopy during inflationis difficult to model.

A simplification however does exist. The experimental dataestablished an accurate measurement of the main parachuteinflation time. Using this inflation time in a ratio to theamount of time passed from the start of main canopy inflation an estimate of the instantaneous drag force can bemade by using equation 14.

(14)

Assuming that the drag created by the recovery vehicle is small in comparison to the drag created by the parachute,it is acceptable to it negligible, and substituting the parachute drag equation 14 into the acceleration equation 13yields;

(15)

This differential equation was solved numerically using Microsoft excel with a time step of 0.01 seconds. Thecanopy inflation time data was gathered from theexperimental results.

The acceleration curve in figure 17 is the g-loading therecovery vehicle experiences during canopy inflation ata 15m/s deployment velocity. The shape of this curvewhen compared to existing parachute g-loading curvesas demonstrated in the fig 3 of the literature review

indicate that this method of numerical analysis isaccurate. This graph indicates that the UAV mustwithstand a 1.6g deceleration during a recovery at15m/s. A deployment speed of 15m/s was used as it isthe maximum cruising speed of the UAV and thereforewill produce the largest g-forces.

Given that the instantaneous acceleration of the PRSduring inflation is now calculated, the orientation of the

-

8/8/2019 Example1 Feasibility Report

24/29

24Final Thesis Report 2008, UNSW@ADFA

Figure 27 - Instantaneous Angle of the PRS to Horizon (Cartwright, 2008).

Figure 28 - Path of UAV During Deployment (Cartwright, 2008).

recovery vehicle during parachute deployment can be determined. This will help determine the altitude loss duringa deployment.

Going back to the free body diagram shown in figure 26, the equation for change in angle with respect to time isdeduced as;

(16)

This is another differential equation.Knowing the acceleration found byequation 15 and integrating to findvelocity at different stages during thedeployment is simple. With velocityknown Microsoft Excel can numericallysolve for using the same time step of0.01 seconds. This gives theinstantaneous angle with the horizon ofthe PRS during the deployment. Theresults of this simulation are displayedin figure 28 with diagrams alongside toaid in understanding.

Figure 28 demonstrates the vectordirection of the recover vehicle at anygiven time during the deployment cycle.Knowing the vector direction and velocity at any given time allows for the calculation of distance for a given timestep, in that direction. If the vertical component of the distance travelled in one time step is found usingtrigonometry, all subsequent vertical components can be summed to give an overall vertical distance travelled. Thisvertical distance travelled will be the altitude lost during the deployment of the PRS. This calculation can also beperformed for horizontal distance. Using Microsoft Excel to plot the Vertical height loss of recovery vehicle against

-

8/8/2019 Example1 Feasibility Report

25/29

25Final Thesis Report 2008, UNSW@ADFA

the horizontal distance travelled gives the path of the UAV during the canopy inflation.

The path plot above shows that a height loss of 3 meters will occur for a deployment at 15 m/s. It is important tounderstand that the analysis is point analysis and does not take into consideration the length of the complete systemafter deployment. The parachute, UAV and suspension lines are approximately 6 meters in length. The implicationof this is that although an altitude loss of 3 meters was predicted, the PRS will require a minimum of 9 meters invertical height to deploy at its full line stretch. Furthermore, to allow the pendulum effect of the canopy to wear off,it is my recommendation that the PRS not be deployed below 20 meters of altitude.

E. SummaryAs a result of the testing carried out, and the analysis that followed, it has been determined that a PRS can recover aUAV from an appropriate altitude. The analysis shows that an altitude of 20 meters is sufficient for a full inflationof the main canopy and a successful recovery. Furthermore, the forces experienced by the aircraft during such arecovery are estimated to be below 2g (see figure 27) and therefore it can be said that this PRS is acceptable for useon small balsa constructed model aircraft.

-

8/8/2019 Example1 Feasibility Report

26/29

26Final Thesis Report 2008, UNSW@ADFA

VI. Cost Benefit AnalysisA. PurposeThe purpose of this analysis is to determine the potential benefit of integrating a PRS onto ADFA model UAV

research aircraft. While the project will seek to place a dollar figure on the PRSs benefit to the ADFA UAVresearch program, it will also outline non-quantifiable benefits.

B. ScopeThe scope of this analysis will take into consideration ADFA UAV platforms of similar weight category as theADFA SAE Aero UAV. The analysis will take into consideration the consistency of failure of these aircraft, and theconsequences of such damaging incidents. This cost benefit analysis will be assuming the costs as pertinent to theADFA Telemaster UAV aircraft. This aircraft is of very similar weight category to the ADFA SAE Aero UAV.

C. Proposed SystemCurrently there is no system in place to protect the UAV from flight failure. In the event of a catastrophic aircraftcrash, a new and complete UAV must be purchased.

The proposal is to integrate a PRS onto the ADFA UAV research platforms. The PRSs main role is to save the veryexpensive internal systems onboard the UAV. Protecting the airframe from catastrophic damage will also be a mainpriority; however, some damage will be expected.

D. CostsOne objective of the PRS design is to reduce the cost of installation such that it becomes an economically feasibleinvestment. If this project remains at the undergraduate thesis level, the cost of installation, and personnel costsreduce significantly. If the responsibility of the project is undertaken by an undergraduate then there is norequirement to train specific personnel in the operation of the PRS. This means that no staff training costs areincurred by the school of ACME.

There will however be a non recurring equipment cost as the initial PRS equipment is purchased. This cost has beenestimated to be no more than $500 AUS. Once this initial cost is covered, the PRS has no further operational costsduring its life. Due to the nature of the design, even after a deployment, the PRS can simply be re-used time and

time again.

E. BenefitsThe most fundamental benefit of having a PRS is the safe recovery of the UAV if a flight failure occurs. The cost ofa research UAV such as the ADFA Telemaster is as high as $6000 AUS, including all internal autopilot computers.If the PRS manages to save the aircraft from damage once, the system has paid for itself, several times over.