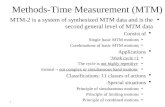

Ethical Productivity · 2020. 8. 4. · MTM Instructor is a person who has completed training in...

Transcript of Ethical Productivity · 2020. 8. 4. · MTM Instructor is a person who has completed training in...

-

Ethical Productivity

Tips and Advice for Prospective

MTM Users, Prospective MTM

Coaches and MTM Instructors

”What is measured is improved, what is not measured expires "

-

Content

18/07/2020 IMD EWD 2

Page Description

3 Purpose of method and value-adding work - EWD4 Use of MTM systems country by country5 Objectives for training in MTM-EWD6 Qualifying ladder MTM roles7 Description of practitioners and MTM Coach8 Description of Instructor and Master Instructor9 Significance of METHOD10 Rörelsekonomi11 Material handling and logistical thinking12 MTM system present - vision - ideal 13 MTM system and method level14 A real profitability and efficiency15 IMD-EWD founder16 Description of IMD-EWD abbreviations17 Different timing systems18 IMD-EWD Organization19 IMD-EWD methodology platform20 Videos - Examples

Page Description

21 The significance of the method22 Exercise 123 Exercise 124 Exercise 125 Exercise 226 Exercise 227 MTM Time Building Block28 MTM-Lean coupling29 IMD EWD philosophy30 Lean Focus31 Improvement of the workplace32 The difference between MTM and Lean33 Details of work instructions34 ILO recommendations35 Comments on the ILO recommendations36 Hierarchy of the workplace37 Accuracy in MTM system38 Method Improvement39 Examples of savings in time and money

Page Description

42 Accuracy with different time measurements44. How do I think about profit?46. Line Balancing mindset47. Critical performance indicators MTM48. IMD-EWD Summary50. Tips on pedagogy for teachers55. Description of all MTM techniques60. MTM's future (timing)61. How time is used62. IMD-EWD regulations for the use of MTM63. MTM systems in brief64. Background to MTM 1 (and other systems)

Ethical Productivity

-

Founder of IMD-EWD defines job analytics: Exclusion of operators' participation in connection with work analyzes leads to reduced productivity (France, Spain, Turkey, Nordic countries, Switzerland )

Tim

e sp

ent

Value-adding time

Do a little Do better

Do not Do more

Ethical Workplace Planning is about finding the BEST The method of work , health and ergonomics for the person performing the work.Elementary time systems take care of time, distance, weights and normal performance (100% MTM)

Ethics is about: • {0 / {1} Shelf /}• Value Increasing • Person oriented • Person focused • Person sinnad

Ethical Productivity

-

Ethical Productivity Use of MTM systems worldwide

-

Ethical Productivity

4 hrs

16 hrs

40 hrs

16 hrs

120 hrs

80 hrs 34.5 days education

-

Ethical Productivity

All MTM trainings have the same purpose and goals:

• Classification of MTM in management work of productivity and personal efficiency• Structures within MTM training and how different MTM systems are built• Education and Examination for the various systems• Course materials and effective use of these• Types of teaching and learning, how to prepare for an MTM course• Different media that can be used in connection with training• Course participants with different backgrounds receive relevant support as needed

• Participants in courses for teachers can systematically plan, prepare and implement a course• Participants in courses for teachers can set goals and follow up the students' learning process• Participants in courses for teachers can explain MTM educations and MTM process building blocks

• Skill - The ability to follow decided method• Performance - The will to work• Fitness - General surroundings in the workplace• Stability - Even performance over working hours

MTM The systems are based on the operator's and workplace's:

-

Ethical Productivity Education, Tests and Rules

MTM Technician (Practitioner) MTM Technician is a person who has completed an official MTM course and may be limited to one technique (eg MTM SAM).MTM Technicians must pass an approved theoretical test and complete a practical timing of a work that lasts at least one minute. The practical timing can be a video, workplace or a method description. Passed tests qualify for a license, Blue Card. The issuer of the Blue Card is the National MTM association.

MTM Coach MTM Coach is a person who has completed an official MTM course and is limited to one technique (eg MTM SAM).The MTM Coach must pass an approved theoretical test and complete a practical schedule of work that lasts at least one minute. The practical timing can be a video, workplace or a method description. MTM Coach will also go through an IMD-EWD teacher training on pedagogy and a brief introduction to other MTM systems. MTM Coach teaches employees the technology for which he / she is licensed. Passed tests qualify for a license, Blue Card. The issuer of the Blue Card is the National MTM association.

-

Ethical Productivity

Education and Test Rules

MTM Instructor MTM Instructor is a person who has completed training in all MTM courses in the IMD-EWD Methodology Platform. (MTM 1, MTM 2, MTM 3, MTM SAM, MTM UAS, MTM Logistic, Ergonomic).MTM Instructor must pass an approved theoretical test in all MTM systems and complete practical schedulesin all systems on a job that lasts at least one minute. The practical timing can be a video, workplace or a method description. Passed tests entitle to an Instructor license, Green Card. The MTM Instructor is entitled to train within his company internationally (Company Instructor), otherwise within the area of the National MTM association. The issuer of the Green Card is the National MTM association.

IMD-EWD Master Instructor IMD-EWD Master Instructor is a person who has completed a course in all MTM systems and all courses in the IMD-EWD Methodology Platform. IMD-EWD Master Instructor trains MTM Instructors.The IMD-EWD Master Instructor is eligible to train internationally, worldwide.The IMD-EWD Master Instructor is approved by the IMD-EWD board through an oral knowledge test and CV where it is clear that the person has sufficient qualifications. Passed tests qualify for a license, Gold Card.

-

Ethical Productivity

Meaning of the method

Accuracy in times is not more important than how the working method is completed and followed.

If the goal is to increase productivity, reducing the content of work is more important than measuring time to every centimeter.

Imagine that times are extremely accurately measured and the operator follows the method to 80%, what have you won then?

Method analysis by eliminating non-valuable work is the first thing to do. Then a new method description and timing.

-

Ethical Productivity

"Movement economics" MTM studies movements and postures

• Every hand movement must be coherent, continuous and harmonious• Two-handed movements should be as compact as possible - hands close together• Light lifting should be done with hands and wrists rather than arms and shoulders• Movements should be compliant and smooth, not jerky• Work must be performed in as small a semicircle as possible in front of the operator• Postures should be natural and ergonomic• The hands must be free from colliding with objects, open workplace

• Layout must be flexible regarding product changes and adapted for long and short operators• Move items horizontally, avoid vertical moves• Use gravities to move materials (sloping racks)• Make a choice between clockwise and counterclockwise how the operator's movement is in relation to the machine (s).

-

Ethical Productivity Logistics and material handling is a clear method issue

Handle material 3 or repeatedly

Handle material 2 times

Direct delivery to work

-

Present - Vision - Ideal - Ultimate

{0 / Present} {Vision 1 /} {0 / Ideal}

MTM 1MTM 2MTM - UASMTM - SAMModaptsMostMTM - MEKMTM - SDMTM - VMTM - MModaptsMostWF

Work Measurement

PTS - AdvancedPTS - MediumWM - Easy

EWD - AdwancedEWD - Easy

Line balancing - AdvancedLine balancing - Easy

One PTS

One EWD

One Line balancing

Ultimate

E-learning trainingVirtual trainingSimulationSensorsUltra NoiceDigitalConnectivitySoftware investigationspictograms

Software One Software

WF = Work FactorPTS = Predetermined Time systemWM = Work Measurement (Stopwatch)EWD = Ethical Work DesignIdeal = Not always reachable

Ethical Productivity

-

Ethical Productivity Different MTM systems have different applications and time required to analyze

MTM 1

MTM2

Tim

e re

qu

ired

to

an

alyz

e 1

min

wo

rk

MTM UAS

MTM SAM

15 min

MTM 3

MTM X

Trai

nin

g

80 tim

16 tim

40 tim

40 +24 tim

40 +24 tim

24 hours

MTM 1 is the oldest MTM system and times are very accurate and detailed. MTM 1 is suitable for short cycle times and mass production of large volumes. 1600 codes with times.350 min

20 min

40 min

130 min

MTM 2 is a Swedish MTM system. Analyzes can be done for both hands at the sametime. Relatively easy to use, has 39 unique codes.

MTM UAS is a Swiss German Austrian system. Suitable for small batches, requiresSimilarity between products. 77 unique codes. Not suitable for non-repetitivemovements.

MTM SAM is a Swedish system. Analyzes in the sequence in which the activities are performed. Provides a very good job and method description directly. 12 codes. 1995 reworked.

Developing

Developing.

-

Understand the importance of the working method

It is extremely important to first create a working method that is effective, before Work Measurement takes place.

The best method should be without losses, without unnecessary movements, without unnecessary steps, twists,without disturbances and stops and have good ergonomics and ethics.

Only after everyone who works at a workplace is satisfied with working methods, a work measurement must be carried out.

A TRUE Profitability and Efficiency

True efficiency means that we only manufacture the number of parts or products that can be sold with the least possible number of human resources and machines / equipment.

True profitability is only possible when we adapt our resources and follow demand as linearly as possible.The linearity is created by correct times for all activities.

Ethical Productivity

-

France Spain Sweitz Turkey

Code of Conduct (IMD)

Good Practices (IMD)

Code of Ethics (EWD)

• Educations, Content and length• Certificate• Development of the systems• Ratifications and validations• Design of the work (method)• National associations, Large companies,• Stamp, Blue Card, Green Card, Gold Card

Nordic

Ethical Productivity

-

IMD EWD 16

IMD EWD International Motion Time Measurement Development - Ethical Work Design

IMD EWD: Name of the organization

MTM EWD: Global philosophy. In general, MTM - EWD performance is multiplied by Distribution Time

MTM: Technical tool to determine Standard time

EWD: Various facts that are added depending on the nature or forms of work in order for the work to take the

greatest possible account of human well-being.

Ethical Productivity

-

IMD EWD 17

Work Measuring

systems

Estimation

Time Studies

Performance

Rating

Predetermined

Time Systems

Elementary

times

MODAPTS

MOST

MTM

Time and

movement

Frequency

study

STATISTICAL

DATA

HISTORICAL

DATA

MTM1

MTM2

MTM UAS

MTM SAM

MTM MEK

MTM SD

MTM 3

MTMLog

International Motion Time Measurement Development - Ethical Work Design

Ethical Productivity

-

Ethical Productivity

International level

National level

Course supplier level

IMDEWDBoard

NMTMANMTMA NMTMANMTMA

Universitycolleges

Consulting company

The companies' internal teachers

SocietyConsultants

individualteacher

IMD-EWD Entity

OtherMembers

{0 / General} {0 / Assembly}

Annual Meeting

Developmentmeetings

-

(1) {0 / Exception}: Assistants from same Company and level with ME background and small groups (max. 8) (2) UAS, SAM or Stopwatch previous knowledge

Methodology Platform IMD-EWD

Introduction to MTM EWD

• Introduction to Work Analysis (4 h)

• Ergonomics (4 h)• MTM-1 (4 h)• Definition of Indicators:

KD, KE, KI, KA (2h)Recommended: 16 h{0 / Minimum}: 16 h (1)

MTM 2 Recommended}: 40 h Minimum}: 32 h (1)

MTM 3 Recommended}: 40 h Minimum: 24 h (1)

MTM UASRecommended}: 40 h Minimum}: 24 h (1)

MTM-SAM (no MTM 1 needed) Recommended: 40 h{0 / Minimum}: 24 h (1)

MTM-1 Mandatory: 80 h for Instructor

LOGISTICRecommended: 16 h{0 / Minimum}: 12 h (1)

MTM UAS (2)

MTM SAM (2)

STOPWATCH}

EWD

-D

IPLO

MA

Pra

ctit

ion

er

on

sit

e (

40

h)

EWD

-C

ERTI

FIC

ATE

+ =

MTM PATH

MODULE 2 :

STOPWATCH CONCEPTS

Mandatory: 8 h

MODULE 3 :

PACE RATING & STOPWATCH PRACTICE (video movies)

Mandatory: 16 h

MODULE 1 :

INTRODUCTION TO WORK ANALYSIS

Mandatory: 8 h

EWD

-D

IPLO

MA

STOPWATCH PATH {0 / OTHERS} Static Line Balancing

2 days

Dynamic Line

Balancing 2 days

MTM Sewing 3 days

MTM SOD

On-site 2 days

Ergo-ILO 2 days

Ergo-OCRA 2 days

Ergo-EAWS 5 days

Ergo-SAM 1 days

Ethical Productivity

-

Ethical Productivity

Method gives time - MTM SAM gives the opportunity to improve the

method !!

Film 1 shows the methods of the future, but human movements and

postures are there.

Film 2 shows a mixture of different methods between man and robot

Method and instructions belong together -→"Movie 1"

→”Film 2”

https://youtu.be/0m67O1Em7dYhttps://youtu.be/vjQLxYSn930

-

Ethical Productivity

The most important thing is that our students understand the importance of the method in the time spent.

MTM is a procedure that analyzes which manual operation or method is distributed in the movement

elements, required to execute it.

MTM gives a predetermined standard time, which is determined by the natural motion and during which

conditions the movements are performed.

MTM time is a standard time that an accustomed, average and educated person can perform work without

need extra energy or effort.

MTM is an international standard.

-

Ethical Productivity

Method gives time - MTM SAM gives the opportunity to improve the

method !!

bolts

Nutfinished

bolts

Tray

Current Workplace

How can we develop this workplace?

Exercise 1

-

Ethical Productivity

1st Describe the method, time the method with MTM-SAM !!

2nd Discuss method improvements !!

-

Ethical Productivity

bolts

nuts

traysFinished

bolts

bolts

nuts

trays

Developed Workplace

Fixture to keep the bolt aligned

1st Improved method

2nd Describe the method and time it !!

3rd Discuss!

-

Ethical Productivity

Method description - Timing with clock

Cycling time in seconds to mount a pen?

Capacity per hour?

Exercise 2

-

Ethical Productivity

Increased customer needs from 1200 pcs / 8 hours to 1800 st / 8 hours

What can we do?

Method improvement without investment?Construction improvement not possible?

Timing with MTM-SAM

-

Ethical Productivity

-

Ethical Productivity

MTM

Lean

potential

MTM + Lean

Focus

Focus MTM

-

Ethical Productivity

Planning

Estimate

MTM Calculation

Workplace

, Presentation

Calculated

Lines EfficiencyAdministativ

Efficiency

Indirectly

Efficiency

KD KE KI KA

BU

DG

ET

TIM

E

Valu

e A

ddin

g

tim

e

Theore

tical tim

e

Allo

cati

on

tim

e

Resourc

e A

llocation

Non

value

ethical

aspects

Policy

UH

Quality

support

Other

loss

Fixed costs

MTM Philosophy-Ethical Productivity

Real Analysis

LEANMTM

-

Ethical Productivity

Lean Focus on losses:

• Overproduction

• Waiting

• Transport / Relocation

• Over Processing

• Unnecessary movements

• Inspection, Rework, Cassation

• buffers

• flow

Overload

waste

{0 / Fluctuation} Capacity

-

Ethical Productivity

Knowledge

Understanding

Theory

• Theoretical input of MTM

• Understand the method and how it

is usedCurrent

PRODUCT

application

Analysis

Inte

rnship

• MTM application for optimization

of the current method in the

workplace including tools,

materials (analysis form,

checklists, instructions)

• Systematic optimization of the

workplaceAgreement

curren

t w

orkp

laceO

ptim

ized

wo

rkplace

Optim

izatio

n tim

e w

ith

MT

M

refle

ctio

n

• Presentation of each optimization

• Critical reflection of one's own

optimization compared to other

solutions

Evaluation

Work place Planning

-

Ethical Productivity

• Overproduction

• Waiting

• Transport / Relocation

• Over Processing

• Unnecessary movements

• Inspection, Rework, Cassation

• buffers

• flow

• 5S

• Method

• Correct times (international Standard)

• movements

• Ergonomics

• Normal performance

• Quality in work

• working Quality

• Standardized work

• Need for rest (distribution times)

• Method improvements

• 5S

• Instruction

MTM LEAN

-

1

2

3

4

5

6

40TOTAL

1

2

12

14

3

8

Både vä och hö hand

Rengör topp för varje cykel

Säkerställ riktning

1/1 Linjal

Kontrollera båda sidor1/1 visuellKontroll och placera i box

42 40

Cykeltid Std WIP

3TidNotering

Ta arbetsstycket och placera i

fixturen

Lossa färdigt stycke och placera ett

nytt

Kontroll av konturer

Lossa färdigt stycke och placera ett

nytt

Lossa färdigt stycke och placera ett

nytt

#

ArbetselementFrekvens Instrument

Takt tidKvaliteskontroll Kvalitet

Säkerhet

STD WIP

ArbetsledareDatum Avsnitt Teamledare

Arbets InstruktionProdukt nr och namn Kund behov

550

Manuellt 3 sekunder

Auto 18 sekunder

Ethical Productivity Instruction for standardized work

-

Ethical Productivity

▪ Work smarter not harder By thinking about the physiological load

▪ Ethical Productivity: by choosing the right method

Results of IMD-EWD can be summarized as follows:

-

Ethical Productivity

ILO Recommendation of recovery breaks percent of Standard Time

% supplement MTM analysis

1. CONSTANT DISTRIBUTION TIMEIndividual timeFatigue, Fatigue, Blur

54

Total 9

2nd SUPPLEMENT FOR UNCOMFORTABLE STATUS:StandingSlightly awkward DifficultVery awkward constant (horizontal, up and down)

2027

3rd Lifting based on weights in kg2.5

510

12.51520

01346

10

4th Light conditionsSlightly below recommendedUnder recommendedHighly below recommended

025

% supplement MTM analysis

5th Good Air quality Poor ventilationWork near hot objects (ovens, radiation)

05

5-15

6th Visual stress low accuracy Careful workVery careful and precise work

025

7th Sound Stress within guideline valuesVarying, high variation, loud soundLoud peaks (sounding beats)

025

Eighth Mental stress, Normal complex processComplex process, wide range of attentionVery complex and complicated

148

9th Monotony (mentally) lowMediumHigh

014

10th Monotony (physically) a lot of variationLight variationNo variation

025

-

Ethical Productivity

Comments on ILO Recommendations

These recommendations are there to protect people if the workplace is not of a good standard.

The purpose is that workplaces have a good design based on human well-being.

Parts of these recommendations are taken care of by MTM in that times are based on movement

length and the object's weights.

Work organization can "zero" certain supplements. For example, group work with team leaders who

can replace a person for individual needs.

Think about work rotation, work enrichment, breaks and breaks.

-

Ethical Productivity

Job level

Task level

Element level

Bass movement element

level

Fitter

Station

Activity

Hand / arm

movementMTM 1 (Reach, Grasp, Move, Position, Release, Disengage, Turn,

Apply pressure, Eye travel, Eye focus, Reading, Body, Leg, Foot, Simultaneus motions, Each movement on its own line )

MTM-SAM (An activity is written on a line in the order work is performed, but basic movements are included, activities in sequence)

Hierarchy of Work Activities

Difference between systems

-

Ethical Productivity

Accuracy in MTM analyzes

General rule:

Random errors , evens out, occurs constantlySystematic errors , severe, affecting time

Example equalization time: MTM-2 GB 30 = 14 TMU MTM 1 = 11 TMU →Equalization 3%

Deviation%

Analysis time

5%

Equalization period in TMU(MTM SAM 150 TMU out of 3000 TMU)

MTM Equalization Times: Time required to analyze 1 minwork

MTM 1 = 0 2.5-3 hoursMTM 2 = 1600 TMU 1.5 hoursMTM 3 = 9000 TMU 20 minutesMost = 6200 TMU 1.0 hoursMTM SAM = 3000 TMU 30 minutes

-

Ethical Productivity Important to remember to teach MTM-SAM

Method gives the time →Good method gives the time for the good method

Method gives the time →Bad method gives the time for the bad method

"Small steps"Each step in Method Improvement requires that the person (operator) must learn the new method!

-

Ethical Productivity Method improvement

Each TMU is worth€ 0.0005

Savings0.017 € / part

-

Ethical Productivity

Each TMU is worth€ 0.0005

Savings0.01 € / part

Method improvement

-

Ethical Productivity

Each TMU is worth€ 0.0005

Savings0.005 € / part

Method improvement

-

Ethical Productivity

estimates

Historical data

frequency Studies

Elementary Time System (MTM)

Clock study with performance

evaluation

Standard data system (MTM)

Accuracy in time records

Unreliable OK Good Very goodRelatively accurate

-

Ethical Productivity

Standard timeAnalyzed standard times

Normal time for task

Work Element time

Bass Movement Element Time MTM 1 Time

Normal time

Standard time

MTM 1 Time

Normal time

Standard timesystem

Complete fromprevious clock

studies

Elementary Movement time only Developed standard data system

Set Default time

-

Ethical Productivity

How to think about profit?

CO

ST

AW

AR

D

AW

AR

D

waste

waste

waste

waste

CO

STP

RO

FIT

Waste = Non-value creationDaily Efficiency Work

Not analyzed

analyzed

Cost + Profit = Price Profit = Price - Cost

-

Ethical Productivity Line Balancing

Line Balancing reduces variations within a production line. Balanced production line is sufficiently stable and

flexible to receive changes.

For example if customers want to change withdrawals in volumes, in the sense that pace of time changes,

different operations or elements can be quickly moved between them

a. Calculate hourly rate = Hourly rate by dividing the customer's needs with available production hours 2400/40 = 60 units / hourct = 3600 seconds / 60 units = 60 sec / unit.

b. Calculate the theoretical minimum number of stations, Construction time / unit = 244 seconds244 seconds / 60 sec / unit = 4.067 →5 stations

{0 / c}. Calculate the efficiency of the line = 244 seconds / (5x60 ) * 100 = 81.3%

Customer demand = 2400 units Weekly production time = 40 hours

-

Ethical Productivity

Line Balancing Example

Before

After

{0 / {1 Ct} /}

{0 / {1 Ct} /}

Continue moving activities between stations up to cycle time (Ct)→fewer stations

-

Ethical Productivity CPI (Critical Performance Indicator) example

Efficiency Actual production timeAvailable production time

Active availability Cycle time * Required number of detailsReal time to produce

Part-time per detail Sum of all hours worked / Number of details produced (over a period of time)

Number of persons

Time-increasing time Time analysisNon-value-added time Time analysis

Number of method changes Method improvements

-

The context makes the details understandable

Every detail becomes comprehensible in a specific context. Therefore, teachers need to know what context they want students to learn.

Repetition is the mother of all knowledge

The second part that stands out is repetition. The repetition must be based on productive knowledge, ie knowledge that is easy to use to

understand and explain many different phenomena and events.

Repeat knowledge in different contexts

Variation in learning is about the knowledge to be repeated must be used in different contexts. It gives two wins.

Emotional commitment makes knowledge stick more easily

The fourth part that makes students better able to remember what we want to teach them is that the student becomes emotionally involved in

the teaching.

Too much detail leads to surface learning

Remember the motto less is more. If we try to teach students too much detailed knowledge, they risk using surface learning strategies and

missing out on deep learning.

Experts' tips for learning:

Exemplify and show context (productive knowledge)

Repeat and vary

Enables emotional engagement

Drag down on the details

Decide what you want to teach

Be creative and think unusual

Find out how digital learning materials can make it easier for you as an educator

Let students solve problems themselves (digitally)

Offer regular breaks

Being a teacher

-

Teaching is one thing - teaching is another.

Many have deep knowledge in their own special area and many organizations have a large internal source of knowledge that could easily be spread to others.

A knowledge reserve and a potential.

How, then, can specialists be strengthened in their ability to teach?

One basis is to understand principles for learning and to be able to structure their knowledge so that others can absorb it.

The following are six tips for you who are a specialist and intend to teach what you can to others.

Being a teacher

-

1. What is the target group's level and needs? Think about the target group's input values. What do you know today and where do you stand your level of knowledge? You can find out

this more precisely through some questions that participants can answer before. A number of knowledge questions, or some questions that

on a scale - ex 1-7 value where you stand in your knowledge in any area. "I master a timer clock" - Scale 1-7

2. Set a clear goal The clearer the goal, the easier it is to plan both the pedagogy and the approach in detail. Based on your research and knowledge

inventory, you can define a goal picture and a level of ambition that matches both your target group's needs and the time frame available.

If it is not possible to make an inventory or that you as an educator set goals and frameworks for the education yourself, it is nevertheless

important that the goal is clearly defined and described so that you can follow up and steer towards it in your planning. A goal can be either

an attitude, knowledge, behavioral or performance goal.

For example, “The goal of the MTM-SAM training is that the participants should gain in-depth knowledge of the method and elementary

timing standard MTM-SAM and that they should be able to act independently to choose the method and time with MTM-SAM . " Here is both

a knowledge goal and a behavioral goal.

{3. What time frame and what pedagogy leads to the goal? Assess from the goal picture which time frame is realistic for the goal to be achieved. There needs to be time here to also give the

participants a chance to absorb the new. Just listening makes it difficult to fully understand and remember what is being said. A fact session

and lecture session need to be interspersed with discussions, reflections and exercises.

Active learning is preferable for lasting knowledge. An approach where you alternate different pedagogical approaches and make a large part

of the learning session into exercises where the participants are active.

Being a teacher

-

4. Adaptation to learning styles We are all different and this also applies to the way we learn. When we take in new messages and new knowledge, we use our senses. Some of

us are better at seeing and reading (Visual), others are better at listening and talking (Auditive) and a third would rather do and try (Kinesthetic /

Tactile). By adapting exercises and pedagogy to the different learning styles, you ensure adaptation to your participants' different needs.

5. Schedule one hour at a time When you make your "driving schedule", make a plan for the whole with a clear goal . Then break down your day or half day into clear units and

plan for about an hour at a time. Set a goal for each "learning session" as well. The goal gives you guidance on how to set up your passport.

How much training or discussion is needed to reach the goal? Should one be able to actively do and apply what you teach or is the goal just to

have insight into something overall?

Make an introduction to your passport that clearly states what it contains. Make a brief introduction, or a brief review of the facts. Think about

how the group or participants can then take the knowledge a little deeper. Can they practice anything? Discuss something? Solve a task

together? In this way, the participants get the opportunity to really start to understand what you have learned.

A good guideline is to spend as much time on training or active participation - or a little more - than the time you yourself talk and tell.

6. Provide conditions for further learning Think about how you can enable the participants to continue their learning and training at home. To only absorb the knowledge on a single

occasion is seldom enough for it to "get stuck".

Give tips on exercises to do yourself, guide with tips and advice, do knowledge tests to rehearse and complete. The faster new knowledge is

applied in daily life - the more certain that it becomes something lasting and that the process of internalizing knowledge begins.

Being a teacher

-

Being a teacher

How do you capture the interest of the audience? How do you convey a message? How to plan a course or a presentation? What aids do you need? Which forms of work are suitable for a specific target group? How to create a favorable environment for learning? How to follow up the learning opportunity? How to create lasting learning?

A simple presentation in the daily work. A more comprehensive education. Important pedagogical driving rules. E n source of inspiration. Different mediation situations. The art of appearing and communicating

Book recommendations: Handbook in learning, addresses everyone who teaches, informs, supervises and lectures.

-

Being a teacher MTM in the Future

Production systems Time setting / Method Improvement

AutomationCollaboration Human - RobotTeamworkShort product life cyclesreconfigurationsBalanced flowsNew technologyNew ProductsInternationalizationAGREEMENT between the parties

Industry 4.0

Machine times - MTM for the manual (Man-Machine)Machine times and MTM timesMTM times for balancingMTM times to track costs (linearity)MTM times make it easier to relocateMTM times as a reasonMTM times for investmentsMTM times for pricingMTM as a company standardEasy to get the same picture

Development of MTM systems and software

-

Being a teacher Time usage

Time for Order

Time for adjustment

Adjustment base time

Adjustment time for work

Adjustment Manual time

Adjustment Process time

Waiting time

Conversion Distribution time

Turnaround

Time per unit

Bass time

Time for work

Manual time Process time

Waiting time

Fördelningstid

-

Being a teacher

IMD-EWD Rules for MTM use and training

1. A technician must be trained and certified in the MTM system he / she must use (Blue Card)2. The MTM association in the Nordic region (National MTM association) is responsible for Training Materials and Certifications.3. MTM teachers in MTM SAM must, in addition to passing the regular course in MTM SAM, have an MTM 1 Basic course. (Green Card)4. MTM Coach for a system must, in addition to passing the regular course in the current system, have an MTM course for teachers and

3 approved practical analyzes with the current system (Blue Card)(MTM Coach in the Nordics applies to MTM SAM)

5. MTM Instructor must have completed a fully approved MTM 1 course and a minimum of 2 approved completed courses in other MTM systems. (Green Card)

National MTM Associations are responsible within their territory that IMD-EWD rules for MTM courses are followed regarding Course content, course length and certifications.

NMTMF is also responsible for minimizing the unauthorized use of MTM systems and reprimanding if irregularities are suspected.

-

MTM systems

MTM 1

30° 45° 60° 75° 90° 105° 120° 135° 150° 165° 180°

T-S 2.8 3.5 4.1 4.8 5.4 6.1 6.8 7.4 8.1 8.7 9.4

T-M 4.4 5.5 6.5 7.5 8.5 9.6 10.6 11.6 12.7 13.7 14.8

T-L 8.4 10.5 12.3 14.4 16.2 18.3 20.4 22.2 24.3 26.1 28.2

TMU

8.5

19.1

7.1

0.5

17.0

0.2

D E D E D E D E O W O W O W O W O W O W

34.1 A, E

0.4 B

C, D

A, Bm

18.6 B

C

1A, 2, 5

37.2 1B,1C

4

1S

1SS, 2S

29.0 1NS, 2SS,2NS

31.9 1E, 1D

2

69.4

76.7

34.7

43.4

15.0

17.0

EF

W: within the area of normal vision

Eye Travel and Eye FocusCopyrighted! – Reprint not permitted! – © Copyright 1955 ... © 2008

Code TMU DescriptionMTM Association for Standards and Research

ET

7.3 Eye Focus

15.2 × T/D

maximum 20.0 TMU

Eye Travel

T: distance between points from and to which the eye travels

D: perpendicular distance from the eye to the line of travel T

O: outside the area of normal vision D Disengage: any class may be difficult if

care must be exercised to avoid injury or

damage to object

STD Stand from sitting position = Difficult to perform simultaneously

even after long practice.

Allow both times.

E: easy to handle

W - P per pace Walk D: difficult to handle

W - PO per pace Walk obstructed and/or with load > 23 kg

AP Apply Pressure:each case must be analyzed AB, AS, AKOK Disengage

D P3 Position:always difficultKBK Kneel on Both Knees = Easy to perform simultaneously. D3 Disengage:normally difficult

AKBK Arise from Kneel on Both Knees = Can be performed simultaneously

with practice.

RL Release:always easy

SIT Sit

Case I: complete when leading leg contacts floor.

TBC 2 Case II: lagging leg must contact floor before next Motions not included in above table:

motion can be made. T Turn: normally easy with all motions except when Turn is controlled or with Disen-gage

Position

PB, S, KOK

Bend, Stoop or Kneel on One Knee

Arise from Bend, Stoop, Kneel on One Knee

Turn Body 45 to 90 degreesMove

MTBC 1

Grasp

G

2NS

30 cm Case I:complete when leading leg contacts floor. 2SS

SS-C2 30 cm Case II: lagging leg must contact floor before nextReach

Reach additional cml motion can be made.

each additional cm

1S 41B

1C

1A

2

5

Simultaneous MotionsSide Step lateral motion of the body Disengage Position Grasp Move Reach

LM-

up to 15 cm

Leg Motion hinged at knee or hip in any direc-tioneach additional cm

Use Reach or Move.

- -

1 667,7 - 1 -

FMP with heavy pressure 27,8 1

B21E

1D

1NS1SS

2S

D P G M R

C

Body, Leg and Foot Motions

Code Motion Length Description

minute hour

FM up to 10 cm 1 0,036 0,0006

less than 30 cm

A

Bm

C

DB

A

ESS-C1

IMD-EWD

Turn - T

CodeForce/Weight

(daN/kg)

Time in TMU for Angular Degrees Turned

(International Motion Time Development

Ethical Work Design)

0,00001

Foot Motion pivoted at ankle TMU

Stenbocksv 12

Small: ≤ 1 54148 Skovde (Sweden)

Medium: >1 up to ≤ 5

Large: >5 up to ≤16

seconds

100 000 - - 1

Time Units

The time values in this data card are

equivalent to a per-formance of 100 % LMS

Do not attempt to use this chart or apply Methods-Time Measurement in any way unless you understand the proper application of the

data. This statement is included as a word of caution to prevent difficulties resulting from misapplication of the data.

https://imdewd.one/

MTM-1

Data Card ( SI – metric system )

-

MTM systems R-C mR-A mR-B mM-B in daN/kg Static Const. DynamicR-D R-Am R-Bm M-Bm up to SC in TMU Factor

2 or less 2.0 2.0 2.0 2.0 1.6 1.6 0.4 2 or less 2.0 2.0 2.0 1.7 0.34 3.4 3.4 5.1 3.2 3.0 2.4 1.0 4 3.1 4.0 4.5 2.8 1.26 4.5 4.5 6.5 4.4 3.9 3.1 1.4 6 4.1 5.0 5.8 3.1 1.98 5.5 5.5 7.5 5.5 4.6 3.7 1.8 8 5.1 5.9 6.9 3.7 2.210 6.1 6.3 8.4 6.8 4.9 4.3 2.0 10 6.0 6.8 7.9 4.3 2.512 6.4 7.4 9.1 7.3 5.2 4.8 2.6 12 6.9 7.7 8.8 4.9 2.814 6.8 8.2 9.7 7.8 5.5 5.4 2.8 14 7.7 8.5 9.8 5.4 3.116 7.1 8.8 10.3 8.2 5.8 5.9 2.9 16 8.3 9.2 10.5 6.0 3.218 7.5 9.4 10.8 8.7 6.1 6.5 2.9 18 9.0 9.8 11.1 6.5 3.320 7.8 10.0 11.4 9.2 6.5 7.1 2.9 20 9.6 10.5 11.7 7.1 3.422 8.1 10.5 11.9 9.7 6.8 7.7 2.8 22 10.2 11.2 12.4 7.6 3.624 8.5 11.1 12.5 10.2 7.1 8.2 2.9 24 10.8 11.8 13.0 8.2 3.626 8.8 11.7 13.0 10.7 7.4 8.8 2.9 26 11.5 12.3 13.7 8.7 3.628 9.2 12.2 13.6 11.2 7.7 9.4 2.8 28 12.1 12.8 14.4 9.3 3.530 9.5 12.8 14.1 11.7 8.0 9.9 2.9 30 12.7 13.3 15.1 9.8 3.535 10.4 14.2 15.5 12.9 8.8 11.4 2.8 35 14.3 14.5 16.8 11.2 3.340 11.3 15.6 16.8 14.1 9.6 12.8 2.8 40 15.8 15.6 18.5 12.6 3.045 12.1 17.0 18.2 15.3 10.4 14.2 2.8 45 17.4 16.8 20.1 14.0 2.850 13.0 18.4 19.6 16.5 11.2 15.7 2.7 50 19.0 18.0 21.8 15.4 2.655 13.9 19.8 20.9 17.8 12.0 17.1 2.7 55 20.5 19.2 23.5 16.8 2.460 14.7 21.2 22.3 19.0 12.8 18.5 2.7 60 22.1 20.4 25.2 18.2 2.265 15.6 22.6 23.6 20.2 13.5 19.9 2.7 65 23.6 21.6 26.9 19.5 2.170 16.5 24.1 25.0 21.4 14.3 21.4 2.7 70 25.2 22.8 28.6 20.9 1.975 17.3 25.5 26.4 22.6 15.1 22.8 2.7 75 26.7 24.0 30.3 22.3 1.780 18.2 26.9 27.7 23.9 15.9 24.2 2.7 80 28.3 25.2 32.0 23.7 1.5

Fit E D

G1A 2.0 S 5.6 11.2

SS 9.1 14.7

NS 10.4 16.0

G1C1 7.3 S 16.2 21.8

G1C2 8.7 Ø ≥ 6 up to ≤ 12 mm SS 19.7 25.3

G1C3 10.8 Ø < 6 mm NS 21.0 26.6

G2 5.6 S 43.0 48.6

SS 46.5 52.1

NS 47.8 53.4

G4A 7.3 > 25x25x25 mm

G4B 9.1 ≥ 6x6x3 up to ≤ 25x25x25 mm Code TMU

G4C 12.9 < 6x6x3 mm AF 3.4

APA 10.6 DM 4.2

APB 16.2 RLF 3.0

Code Fit E D

Code TMU Code TMU Case Description D1 Loose 4.0 5.7

D2 Close 7.5 11.8

D3 Tight 22.9 34.7

Normal effort, slight recoil up to approx. 12 cm

Considerable effort, hand recoils markedly up to approx. 30 cm

ComponentsCase Description

Without Regrasp

With Regrasp

Case Description

Very slight effort, blends with subsequent move up to approx. 2.5 cm

Dwell Minimum

Release Force

AF+DM+RLF

G2+APA

P2

P3

Position - P

Apply Pressure - AP

Disengage - D

Code TMUDescription

Apply Force

Close

Tight

without secondary engagewith secondary engage

No pressure required

Light pressure required

Heavy pressure required

≤ ± 1.5 mm

> ± 1.5 up to ≤ ± 6.0 mm

Not applicable

SymmetryCodeClass of Fit Handling

LooseP1

20 14.9 1.46

22 16.4 1.51

1.17

12 8.8 1.27

16 11.9 1.36

14 10.4 1.32

18 13.4 1.41

A Move object to other hand or against stop.

B Move object to approximate or

indefinite location.

Total Clearance > 25 mm

C Move object to exact location.

Total Clearance

> 12 up to ≤ 25 mm

1 0.0 1.00

2 1.6 1.04

4 2.8 1.07

6 4.3 1.12

10 7.3 1.22

8 5.8

Move - M

Motion

Length

in cm

TMU

M-A M-B M-C m(B)

with Force/Weight

Case Description

Contact release0.0RL2Normal release performed by opening

fingers as independent motionRL1 2.0

Select Grasp: object jumbled with other objects

so that search and select occur.

Release - RL

Case Description

Code TMU Case Description

G1B 3.5 Pick-up Grasp: object very small or lying close against a flat surface.

Pick-up Grasp: any size object by itself, easily grasped.

Grasp - G

B Reach to single object in location which may

vary slightly from cycle to cycle.

C Reach to object jumbled with other objects

in a group so that search and select occur.

D Reach to very small object or where

accurate grasp is required.

E Reach to indefinite location to get hand in

position for body balance or next motion or

out of way.

G3

G5 0.0 Contact Grasp: (sliding or hook grasp).

5.6

Ø > 12 up to ≤ 25 mm

Regrasp: change grasp without relinquishing control.

Transfer Grasp: control transferred from one hand to the other.

Pick-up Grasp:

interference with Grasp on bottom and one side of

nearly cylindrical object.

Reach - R

Motion

Length

in cm

TMU

R-A R-B R-E m(B)Case Description

A Reach to object in fixed location, or to

object in other hand or on which other hand

rests.

MTM 1

-

MTM systems

The systemThe system was released after many years of extensive research on the 1948 publication of the book "Methods of Time Measurement". By releasing the system in this far-sighted way, MTM became the first open source Predetermined Motion Time System (PMTS), enabling everyone to learn and practice the technology without infringing copyright. However, in order to protect against abuse and to prevent incompetent application of the system, the origins of the International MTM Directorate were born in 1953. Nowadays, IMD-EWD monitors the application of the system.

MTM-1 is officially described as "a procedure that analyzes each manual operation or method in the basic movements required to perform it and assigns to each movement a predetermined time standard determined by the nature of the movement and the conditions under which it is manufactured".

The predetermined data values fall within the following framework where each "movement" is further underclassed according to theparameters that affect the time required for the average operator to perform it. Each of these movements has a unique code and time value ranging from 2.0 TMU = 0.07 seconds (unit of measurement) up to the maximum value of 53.4 TMU = 1.9 seconds, which is displayed on the MTM 1 data card for the highest value for "Position". There are about 28 TMU in a second.

MTM 1

-

MTM systems

The 17 basic MTM-1 movements

Fingers or hand ReachGraspReleaseMovePlaceTurnDisengageUse pressure

Eye movements Eye FocusEyes movement

Body Movements foot movementleg movementsidestepTurn bodyBend, Stoop and KneeSit and standStep

In total there is more than 1,600 unique MTM-1 values.

Fingers or Hand REACHGraspReleaseMovePositionTurndisengageApply Pressure

Eye Motions Eye FocusEye Travel

Body Motions Foot MotionLeg MotionSide- StepTurn BodyBend, Stoop and KneelSit and StandWalk

MTM 1

-

MTM systems MTM 2

-

MTM systems MTM 2

MTM-2 is a very simplified form of PMTS, derived exclusively from MTM-1. It is referred to as a second-generation system.

system The system was designed and developed largely by the efforts of the Swedish National MTM Association and was approved by the International Methods Time Measuring Directorate in 1965. Since then, many thousands have been educated.

The complete project report showing the derivation of all data was published in 1971 and is available for inspection through the MTM Association.

The system is exceptionally descriptive of human motion analysis. Although MTM-2 is not as detailed as MTM-1, it still allows analysis of the work in unique micro time elements. Although officially defined as accurate enough to evaluate 0.8-minute work cycles (1,600 TMU), experience has shown that the system has been used successfully for operations of just over 25% of this figure.

{0 / Simplicity} The relative simplicity was achieved by statistically combining, averaging and replacing the basic movements that make up the MTM-1 system to arrive at fewer application codes and time values. MTM-2 has 39 unique codes , while MTM-1 has more than 1,600 codes, each with specific time values.

-

MTM systems MTM 2

The 9 basic MTM-2 movements Get and Get weight - 16 TMU valuesPut and Put Weight - 16 TMU valuesApply pressure *Regrasp *Crank *Eye action *Foot motion *Step *Bend and Arise*

* Note - A single TMU value for these movements

Use speedResearch has shown that a skilled MTM analyst will require between 100 and 150 minutes to perform a detailed MTM-2 analysis of a one-minute work cycle. Therefore, the application speed is about two to three times faster than MTM-1.

The 9 Basic MTM-2 Motions Get and Get Weight - 16 TMU valuesPut and Put Weight - 16 TMU valuesApply Pressure *Regrasp *Crank *Eye Action *Foot Motion *Step *Bend and Arise *

* Note - One single TMU value for these motions

-

MTM systems

MTM 3

MTM-3 Time Motion Unit Table The 10 digits to the right of the code column are TMU values that an observer would assign to different employee movements. The movement types are • Handle without corrections (HA), • Handles with corrections (HB), • Transport without corrections (TA), • Transport with corrections (TB), • Step (SF) and • Bend / Arise (B). If the movement starts and ends without "unintentional stops, hesitations or changes of direction", it can be considered an HA or TA

Distance Code HA HB TA TB

-6 18 34 7 21

Over 15 cm -32 34 48 16 29

Up to 15 cm

SF 18 B 61

-

MTM systems

MTM 3

The fourth generation of MTM was developed by the Swedish Association of MTM during the years 1970. In the same logic as version 3, it consists of a new simplification of MTM while remaining 95% reliable. This makes it possible to be twice as fast as MTM2 , ie to analyze in one day, a work cycle of 4 minutes.

• Handling - H: This is a combination of Get (Release, Reach, Grep) and Put (Move, Position) on MTM2. It is about taking control of an object with your hand or fingers and placing it in another place.

• Transport - T: It is a simplification of movement and position for MTM1. It involves placing the object in a new place with your hand and fingers . The difference with handling is that the hand or finger already has control of the object at the beginning of the movement.

• Step and foot movements (SF): This category combines foot movements and walking on MTM2. The remaining definitions are the same as for MTM2. Regardless of movement, step, foot movement ... we give the value 18 TMU .

• Bending, upwards - B: This category defines a movement in which the body changes its vertical position, whether it is to bend, kneel ... In the same way as for MTM2, regardless of movement, knee, rise ... a time of 61 TMU is assigned .

• Crank , can be understood as a transport . Use pressure, re-entry or even eye movements are included in handling and transport .

-

MTM systems

MTM 3

HA HB

Manipulation with simple

grasp

Handling with difficult

grasp

Up tp 15 18 34

More than 15 34 48

Handle - Table H

Distance in cm

TA TB

Transport without

obstacles or complex

positioning

Transport with a precise

arrival position (

-

MTM systems MTM UAS

1 2 3 1 2 3

1 2 3 1 2 3

HA 25 45 65

HB 40 60 75

TMU seconds minutes hours approx. AA 20 35 50 HC 50 70 85

1 0,036 0,0006 0,00001 loose AB 30 45 60

27,8 1 tight AC 40 55 70 Code 1 2 3

1 666,70 1 approx. AD 20 45 60 BA 10 25 40

100 000 1 loose AE 30 55 70 BB 30 45 60

tight AF 40 65 80

handful approx. AG 40 65 80 Code 1 2 3

approx. AH 25 45 55 ZA 5 15 20

loose AJ 40 65 75 ZB 10 30 40

tight AK 50 75 85 ZC 30 45 55

approx. AL 80 105 115 ZD

loose AM 95 120 130

tight AN 120 145 160 Code

KA

KB

1 2 3 KC

approx. PA 10 20 25

loose PB 20 30 35

tight PC 30 40 45 VA 55

Body Motions

Walk / m

Bend, Stoop, Kneel (incl arise)

Sit and Stand

TMU

25

60

110Place Code

TMU

Visual Control

compound

tighten or loosen

CodeTMU

approximate

loose

tight

Operate

Handle Tool

simple

Motion Cycles

one motion

motion sequence

re-position and one motion

20

≤ 20

> 20

to

≤ 50

> 50

to

≤ 80

Motion Length

in cm

Distance Class

TMU

Case of

Get

Case of

Place

International

Motion Time Measurement Development

Ethical Work Design

© Copyright 2020 IMD-EWD

Get and Place CodeMTM-UAS

Basic Operations

Time Units

Use of these table values without training in MTM-1 and

MTM-UAS will lead to erroneus results.

≤ 1 kg

> 1 kg

to

≤ 8 kg

> 8 kg

to

≤ 22 kg

easy

difficult

> 50

to

≤ 80

Motion Length

in cm

Distance Class

≤ 20

> 20

to

≤ 50

-

MTM systems

MTM UAS

TMU

1

27,8

1 666,70

100 000

1 2 3 1 2 3

1 2 3 1 2 3

HA 25 45 65

HB 40 60 75

approx. AA 20 35 50 HC 50 70 85

loose AB 30 45 60

tight AC 40 55 70 Code 1 2 3

approx. AD 20 45 60 BA 10 25 40

loose AE 30 55 70 BB 30 45 60

tight AF 40 65 80

handful approx. AG 40 65 80 Code 1 2 3

approx. AH 25 45 55 ZA 5 15 20

loose AJ 40 65 75 ZB 10 30 40

tight AK 50 75 85 ZC 30 45 55

approx. AL 80 105 115 ZD

loose AM 95 120 130

tight AN 120 145 160 Code

KA

KB

1 2 3 KC

approx. PA 10 20 25

loose PB 20 30 35

tight PC 30 40 45 VA

Simultaneous movementsHand Right

No control required With required control

Hand

Left

No control

requiredSimultaneous Simultaneous

With required

controlSimultaneous

With Base Operation of

Additional interaction with

Distance Field 1

Visual Control 55

Bend, Stoop, Kneel (incl arise) 60

Sit and Stand 110

approximate

loose

Walk / m

tight

25

Operate

simple

compound

Motion Cycles

one motion

motion sequence

re-position and one motion

tighten or loosen 20

Body Motions TMU

Motion Length

in cm≤ 20

> 20

to

≤ 50

TMU

> 50

to

≤ 80

Distance Class

Handle Tool Code

easy

difficult

> 1 kg

to

≤ 8 kg

> 8 kg

to

≤ 22 kg

Place

1

CodeTMU

Distance Class

Get and Place CodeTMU

≤ 1 kg

Case of

Get

Case of

Place

Motion Length

in cm≤ 20

> 20

to

≤ 50

> 50

to

≤ 80

Time Units

hoursminutesseconds

Use of these table values without training in MTM-1 and

MTM-UAS will lead to erroneus results.

© Copyright 2020 IMD-EWD

0,000010,00060,036

1

1

MTM-UAS

Basic Operations

International

Motion Time Measurement Development

Ethical Work Design

Simultaneous movements requiring a high degree of control are analyzed for the

second hand with an additional Base Operation interaction in distance field 1.

The decision on the evaluation of simultaneous movements must be made based on

the following Matrix.

-

MTM systems MTM UAS

MTM-UAS is known as a 3rd level MTM system and was developed between 1976 and 1978 by a consortium ofSwiss, Austrian and later German MTM associations.

system The system has been developed especially for small batch productions where the analysis speed has priority over methods and operating details.

The data were developed with the following objectives in mind: • High analysis speed• Reproducibility of working methods• Sufficient accuracy for standard operations• Universal application

The system requires the following production characteristics: • Similarity between tasks• Standard workplaces• Good organization of the work• Availability of good detailed work specifications• Skilled workers, trained and motivated

Data were derived from MTM-1 analyzes from films from typical batch production operations

-

MTM systems MTM UAS

UAS (basic operations) Consists of seven activities: • Download and place• Place• Manage tools• Manage• Operating Cycles• body movements• Visual checks

The data card shows a total of 77 unique codes, whose values range from 5 to 160 TMU (0.15 to 4.8 sec).

The accuracy of MTM-UAS, compared to MTM-1, has never been officially defined but in general it is not claimed to be suitable for non-repetitive cycles of less than 1 minute (1 667 TMU) but again, as with MTM-2 it has used successfully for shorter non-repetitive cycles.

-

MTM systems

MTM SAM

-

MTM systems MTM-SAM Form

-

MTM systems MTM SAM

• The purpose of MTM SAM is for operators, designers and preparers without much training, to have a common language and uses the same method of analysis and thinking.

• MTM SAM can be used for method analysis in each phase of a product.• MTM SAM was revised in 1995 and since then experience of more than 12 years of training and use has been integrated.• MTM SAM is the 4th generation MTM system

• Basic activities GET (G)PUT (P)

• Complementary activities APPLY FORCE (AF)STEP (S)BEND (B)

• Repetitive activities SCREW (S)CRANK (CA)TO AND FROM (FA)HAMMER (H)READ (R)NOTE (N)PRESS BUTTON (PA)

Furthermore, several movements can have variables.

-

Movement Definitions and rules

MTM 1

-

75

Definition of REACH (R)

REACH is the basic movement used when the main purpose is to move the hand or fingers to a place or to a general position.

Net REACH distance

m R mEncode:

The hand is in motion at the beginning of REACH

Range (R)

Movement distance in cm

Type of destination

The hand is in motion at the end of REACH

A, B, C, D, E

-

Different cases of REACH

REACH with the hand to an object in a fixed and usual position or in the other hand or that the other hand is resting on.

Fall

REACH with your hand to an object whose position may vary from time to time.

Fall B

-

77

Different cases of REACH

REACH with your hand to an object, mixed with other objects so you have to search and select.

Fall C

REACH with your hand to a very small object or object that requires a very careful grip.

Fall D

-

Different cases of REACH

REACH with your hand to an undefined position to regain balance, or in position for the next movement, or to move it out of the way.

Fall E

-

Definition of GRASP (G)

GRASP is the basic movement performed with the hand or fingers to gain control or change control over an object.

GEncode:

GRASP (G)

Types of grips

Different cases (A, B, C) within the grip type

In case C or grip type 4, there are different dimension classes

1,2,3,4,51,2,3a,

B, CA, B, C

-

80

Different cases of GRASP

G1A

GRASP an object on its own that is easy to understand.

G1B

GRASP an object that is very small or a thin object lying on a flat surface.

G1C_ (1,2,3)

GRASP a cylindrical or almost cylindrical object, where the grip is obstructed by the surface below and on one side.

-

81

Different cases of GRASP

G2 G3

A TRANSFER GRASP is performed when an object is moved from one hand to the other.

G5

CONTACT GRASP is performed when the fingers or hand gain some control over an object only through contact.

REGRASP is performed when the fingers using two or more small movements change the position of the object in the hand.

-

82

Different cases of GRASP

G4 (A, B, C)

HOLDING GRASP is performed when your fingers grip an object that is mixed with other objects in such a way that you have to search and select.

dimension Classes

Case C

1 = Dia. > 12 mm

2 = Dia. ≤12 ≥ 6 mm

3 = Dia. 25 x 25 x 25 mm

B = Objects that are ≤25 x 25 x 25 mm but ≥6 x 6 x 3 mm

C = Objects that are

-

83

Definition of RELEASE (RL)

RELEASE is the basic movement performed with the hand or fingers to release the grip or contact with an object.

RL1

RL2

RLEncode:

Release (RL)

Different cases

1.2

-

84

Definition of MOVE (M)

MOVE is the basic movement used when the main purpose is to move an object with your hand or fingers to a place or to a general position.

m M mEncode:

The hand is in motion at the beginning of MOVE

Move (M)

Movement distance in cm

Different cases of movement

The hand is in motion at the end of MOVE

Effective net weight in kg

A, B, C

over

-

85

Different cases of MOVE

Fall

MOVE an object to a stop or on the other hand.

Hold point-grip point 25 mm

MOVE an object to an exact position.

Fall C

-

86

MOVE under the influence of WEIGHT

sc

The static component of MOVE with weight or resistance is the time element, which is required to tense the muscles to overcome the weight or resistance.

dc

The dynamic component of MOVE with weight or resistance is the increase in time, which is due to the lower speed of movement when moving heavy objects than moving light objects.

over

-

87

MOVE AND POSITION

When the requirement for accuracy is greater than in MOVE case C (

-

88

Definition of POSITION (P)

POSITION is the basic movement performed when the hand or fingers with one or more small movements put an object in a predetermined exact position in relation to another object.

With insertion

PEncode:

Position (P)

positioning degree

Symmetry

manageability

1,2,3 S, SS, NS E, D

Without insertion

-

89

Different degrees of positioning for POSITION

POSITION an object when the play between the object and the hole is small. Some pressure is required.

Grade 2, close

Light pressure

Grade 3, exactly

Significant pressure

POSITION an object when the play between the object and the hole is very small. Significant pressure is required.

Grade 1, coarse

POSITION an object when the play between the object and the hole is large. No pressure required.

-

90

Different degrees of symmetry for POSITION

Examen S

POSITION an object when the cross sections of the object and the hole are shaped so that the insertion can be performed without prior rotation to adjust.

Exam SS

POSITION an object when the cross section of the object and the hole is formed so that the insertion can be performed in a limited number of ways.

Exam NS

POSITION an object when the cross section of the object and the hole is formed so that the insertion can be performed in one position. The maximum rotational movement is 180˚.

Align correctly

Insert

Rotate to adjust

Target set up

Insert

Rotate to adjust

-

91

handle Portability(Manageability)

Manageability is the variable that expresses grip or handling difficulties in POSITION.

Easy to handle (E)

POSITION an object without changing grip and with good control over the object.

Difficult to handle (D)

POSITION an object with the help of a grip change or with insufficient control over the object.

-

92

Position without INSERTION

Position without insertion is to place an object with a line or a point. It is also called SURFACE INSERTION if the post behind the surface does not count. Special rules apply to this type of situation.

1.5–6 mm MC + P1

6–12 mm MC

-

93

Definition of TURN (T)

TURN is the basic movement used to turn the hand - empty or charged - as well as the wrist and forearm, around the longitudinal axis of the forearm.

TEncode:

Turn (T)

Rotate the angle size in degrees in 15 degree increments

The weight of the object

S, M, L

S 0–1 kg

M 1–5 kg

L 5–16 kg

-

94

Definition of APPLY PRESSURE (AP)

APEncode:

Apply Pressure (AP)

Different cases

A, B, C{0 / {}

Force 1

/}

{0 / {1}

Time /}

Apply

force

Complete bike

Keep force at least Cancel force

APB = APA + G2

APPLY PRESSURE is the basic movement performed when the fingers, hand or other body part applies muscle force to an object, overcomes its resistance in a controlled manner, and possibly in connection with this, moves a maximum of 6 mm.

-

95

Definition of DISENGAGE (D)

DISENGAGE (D) are the basic movements performed to interrupt the contact between two objects and are characterized by an involuntary recoil movement.

DEncode:

Disconnection (D)

positioning degree

1,2,3 E, D

manageability

manageability

RELEASE an object without changing grips.

Fall E Fall D

RELEASE an object and in this way the grip is changed.

-

96

The disconnection time varies with the force or effort of separating two objects from each other. This variable is called DEGREE OF POSITIONING.

Different degrees of positioning for DISENGAGE

Positioning degree 1

RELEASE an object with little effort and insignificant recoil.

-

97

Definition of EYE ACTIVITY (E)

EYE TRAVEL is the basic movement performed when the eyes are moved from one object to another object.

Eye transfer (ET)

EYE FOCUS is the basic movement used to fix the eyes of an object and observe a recognizable property of that object.

EYE FOCUS (EF)

-

98

EYE TRAVEL (ET)

mo

vem

en

t le

ngt

h =

T

Sight distance = D

15.2 x T

DTMU

Formula for calculating time values for eye movement

Line of sight

Line of sight

The angle between the lines of sight is limited to 70˚

The time value for each degree of movement of the line of sight is set to 0.285 TMU

Because of this ET never exceeds 20 TMU (70x0.285 = 20)

-

99

Different BODY movements

The group BODY movements include movements with the foot alone, movements to move the foot and leg and movements to move the whole body in different directions.

FOOT MOTION (FM)

FOOT MOTION is the basic movement performed when the foot is moved up or down or sideways with the heel or arch as the shoulder.

Print

Variables = Without pressure or with pressure

LEG MOTION (LM)

LEG MOTION is the basic movement that is performed when the leg is articulated in the knee and / or hip and the main purpose is to move the leg.

Variable = The length of the trajectory

-

100

Different BODY movements

The group BODY movements include movements with the foot alone, movements to move the foot and leg and movements to move the whole body in different directions.

WALK (W)

WALK is the basic movement used when the main purpose is to move the body forward or backward by one or more steps.

Over 23 kg = hindered walk

Variables = Number of steps or meters Obstructed walk

Weight

SIDESTEP (SS)

SIDE STEP is the basic movement performed when the body, without turning, is moved sideways by one or more steps.

Variables = Torso movement (length) With one leg (case 1) With both legs (case 2)

-

101

Additional BODY movements

TWIST BODY (TB)

Rotate the body with leg movement.

Variables: with one leg or with both legs.

-

102

Additional BODY movements

BEND (B)

Bending is performed when the body, from an upright position, bends at the waist and hips, so that the hands reach slightly below knee height.

TRAVEL UP from BENDING (AB)

Ascending from bending is performed to return the body to the upright position from the bending destination.

-

103

Additional BODY movements

RISE FROM STÅ UP (AS)

Ascending from bending is performed to return the body to the upright position from the bending destination.

STOP (S)

Bending is used when the back is bent at the waist and hips at the same time as the knees are bent so that the hands reach close to the floor.

-

104

Additional BODY movements

KNEEL ON A KNEE (KOK)

This fall of the KNEEL is performed by moving one foot forward or backward and the other leg is bent so that the knee is lowered to the floor.

TRAVEL UP FROM KNEELING (AKOK, AKBK)

Rising from the knee is done to return the body to an upright position from the knee destination.

KNEEL with both knees (KBK)

KNEEL case 2 is often performed as KOK followed by a leg movement that lowers the other leg on the floor. KBK ends when both knees have reached the floor and good balance has been achieved.

-

105

Additional BODY movements

TRAVEL UP FROM SITTING (STD)

STD includes no movement other than moving the body from sitting to standing. Like SIT, other movements must be analyzed separately.

SIT (SIT)

SIT does not include any movement from the chair on which one is to sit. It also does not include moving the body to the chair or to a starting point in front of the chair. Leg movements are not included either.

-

106

Definition of SIMULTANEOUS motion (S)

CONTEMPORARY movements are basic movements that are performed simultaneously with other body parts.

CONTEMPORARY movements are usually performed with two body parts, such as two hands. More than two body parts may also be involved, such as two hands and one foot.

CONTEMPORARY movements can mean that the same movement is performed simultaneously with different body parts. This is the case, for example, with symmetrical two hands. Different movements can also be performed simultaneously with different body parts, a REACH movement with the hand and a SIDESTEP with the leg.

![[EWD]class02 0315](https://static.fdocuments.in/doc/165x107/555e0ca7d8b42a99188b4be3/ewdclass02-0315.jpg)