Ethanol production from crude whey by Kluyveromyces marxianus

-

Upload

salman-zafar -

Category

Documents

-

view

241 -

download

1

description

Transcript of Ethanol production from crude whey by Kluyveromyces marxianus

Biochemical Engineering Journal 27 (2005) 295–298

Short communication

Ethanol production from crude whey byKluyveromyces marxianus

Salman Zafar, Mohammad Owais∗

Interdisciplinary Biotechnology Unit, Aligarh Muslim University, Aligarh 202002, India

Received 25 January 2005; received in revised form 31 May 2005; accepted 31 May 2005

Abstract

Kluyveromyces marxianusstrain MTCC 1288 was employed to study the batch kinetics of ethanol and biomass production from crude whey.The yeast was able to metabolize most of the lactose within 22 h to give 2.10 g L−1 ethanol and 8.9 g L−1 biomass. The growth rate reachedthe peak value of 0.157 h−1 during the exponential phase but decreased significantly after the fermentation time of 12 h, presumably due toproduct inhibition. The specific ethanol formation rate attained the maximum value of 0.046 h−1 between 6 and 8 h of batch fermentation.The relationship between ethanol concentration and specific growth rate suggested a strong inhibitory effect of ethanol on the specific culturegrowth rate.© 2005 Published by Elsevier B.V.

K

1

m(ouaiKffo[mc

msim

n of

ma--

nol.ished

-

asnsive

zed)45%

1d

eywords: Fermentation; Whey; Ethanol; Batch kinetics; Biomass

. Introduction

Cheese whey represents an important source of environ-ental pollution due to its enormous global production rate

to make 1 kg of cheese, 9 kg whey is generated) and highrganic matter content, exhibiting the BOD and COD val-es of 50 and 80 g L−1, respectively[9]. One of the mostttractive options to check the proliferation of whey pollution

s its bioconversion to ethanol employing yeast, especiallyluyveromycesspecies. The presence of lactose as the only

ermentable carbohydrate in whey confines its use to selectiveermentations involving microorganisms which are capablef breaking down lactose with the enzyme,�-galactosidase

2–4]. Apart from lactose, whey also contains vitamins andinerals which may improve the physiological activity of the

ells.Ethanol has tremendous applications in chemical, phar-

aceutical and food industries in the form of raw material,olvent and fuel. The annual production of industrial ethanols about four million tonnes, 80% of which is produced by fer-

entation. It is very important to choose a strain with suitable

physiological characteristics to achieve a good utilizatiolactose from whey.

The main aspect of this investigation is to study the fortion of ethanol from crude whey withKluyveromyces marxianus leading to maximum lactose utilization and ethaAlthough a great deal of research has been accomplwith the cultures of the yeast strains, such asK. marxianus,Kluyveromyces lactis,Kluyveromyces fragilis,Candidapseudotropicalis, Candida intermediaand Torula cremorisondeproteinized whey[1,2,4,7,8], the use of crude wheya culture media has not been explored in a comprehemanner.

2. Materials and methods

2.1. Culture medium

Crude (non-deproteinized, non-diluted and non-steriliwhey was used as a culture medium. It contained 3.

∗ Corresponding author. Tel.: +91 571 2404025; fax: +91 571 2721776.E-mail address:owais [email protected] (M. Owais).

lactose and was fortified with 0.45% (NH4)3SO4, 0.1% yeastextract, 0.1% malt extract and with a trace element solutioncontaining: CuSO4·5H2O, 0.3 mL L−1; MnSO4·H2O,0.8 mL L−1; MoO4·2H2O, 0.4 mL L−1; ZnSO4·7H2O,

4

369-703X/$ – see front matter © 2005 Published by Elsevier B.V.oi:10.1016/j.bej.2005.05.009

BEJ-4101; No. of Pages

296 S. Zafar, M. Owais / Biochemical Engineering Journal 27 (2005) 295–298

3.0 mL L−1 and FeCl3·6H2O, 4.0 mL L−1 made up withdistilled water to 1 L.

2.2. Microorganism and maintenance

K. marxianusstrain MTCC 1288 was procured from theculture collection of the Institute of Microbial Technology(MTCC), Chandigarh (India). The strain was maintainedon agar slant having the following composition: lactose,20 g L−1; bactopeptone, 10 g L−1; yeast extract, 5 g L−1;agar, 20 g L−1. A 24-h growth of the yeast was preservedat 4◦C.

2.3. Analytical methods

Biomass was measured in terms of dry weight. Yeast cellswere harvested by centrifugation for 10 min at 10,000 rpmand then washed twice with distilled water and weighed after24 h at 100◦C. Lactose concentration was determined byemploying the DNS method for reducing sugars[10]. Ethanolwas estimated by the dichromate colorimetric method, whichis based on the complete oxidation of ethanol by dichromatein the presence of sulphuric acid to form acetic acid[11].

2.4. Fermentation

sksi tem-p eda erec e at5 geda 4f

3

heyw o-ct stw .T

hd n-s bea dingt

waso ani po-n tiona uenceo cing

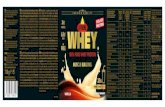

Fig. 1. Experimental kinetics of batch culture of crude whey byKluyveromyces marxianusat temperature 34◦C and pH 4.5.

the uptake of the substrate.qS exhibited an increase betweenthe fermentation time of 18 and 20 h apparently due to theincreased metabolic activity of the cells before their death.

qP attained the peak value of 0.046 h−1 during the batchfermentation time of 6 and 8 h (Fig. 4), i.e., during theexponential phase of the process. The increased lactose con-sumption by the yeast cells during this period may have beenresponsible for the early upsurge in the production of ethanol.

F udew

Batch fermentation was performed in Erlenmeyer flan an anaerobic shaker at an agitation of 500 rpm. Theerature was controlled at 34◦C and the pH was maintaint 4.5 by frequent addition of sterile 6N NaOH. Samples wollected at an interval of 2 h. After recording absorbanc80 nm, the remaining volume of the sample was centrifut 4800 rpm for 15 min. The supernatant was stored at◦C

or lactose and ethanol estimation.

. Results and discussions

The batch kinetics of ethanol production from crude was studied in detail.Fig. 1shows the batch kinetics of bionversion of whey to ethanol byK. marxianus. Most ofhe initial lactose (35 g L−1) was metabolized by the yeaithin 22 h resulting in the formation of 2.10 g L−1 ethanolhe biomass produced was about 8.9 g L−1.

The growth rate reached a maximum value of 0.157−1

uring the exponential phase (Fig. 2) but it decreased coiderably after the fermentation time of 12 h. This mayttributed to the accumulation of ethanol in the broth lea

o product inhibition.The peak specific substrate consumption rate

bserved within the fermentation time of 10 h, which isndication of maximum substrate utilization during the exential phase (Fig. 3). The decrease in lactose consumpt 6 and 8 h of fermentation may have been the conseqf accumulation of lactose into the cell, thereby redu

ig. 2. Variation of specific growth rate with time for batch culture of crhey byKluyveromyces marxianus.

S. Zafar, M. Owais / Biochemical Engineering Journal 27 (2005) 295–298 297

Fig. 3. Variation of specific substrate consumption rate with time for batchculture of crude whey byKluyveromyces marxianus.

Fig. 5 shows the relationship betweenP and µ whichreflects a strong inhibitory effect of ethanol on the specificgrowth rate[6]. But it is important to realize that the plottedrelationship is based on an actual observed behaviour anddoes not represent the effect of ethanol alone (organic com-pounds like glycerol, lactic acid, etc. are also produced duringfermentation of whey).

The relationship betweenqS and S has been shown inFig. 6. The overall lactose consumption represents a com-bination of sugar consumed for different cellular functionsincluding growth and for the production of ethanol and other

F cul-t

Fig. 5. Relationship between specific growth rate and ethanol formation forbatch fermentation of whey byKluyveromyces marxianus.

Fig. 6. Relationship between substrate utilization rate and lactose consump-tion for batch fermentation of whey byKluyveromyces marxianus.

products. The scatter of the points inFig. 6 suggest thatthe lactose consumption relationship can be mathematicallydescribed by a combination of rate equation for linear rela-tionship and hyperbolic relationship between sub-processrates and substrate concentration as described by the follow-ing equation.

dS

dt= k1SX + k2

S

KS + SX (1)

4. Conclusions

The relationship betweenPandµas measured after the lagphase in batch cultures suggested a strong inhibitory effect

ig. 4. Variation of specific product formation rate with time for batchure of whey byKluyveromyces marxianus.

298 S. Zafar, M. Owais / Biochemical Engineering Journal 27 (2005) 295–298

of ethanol on the specific growth rate of yeast cells. Furtherimprovement in ethanol yield may be obtained by employingsuitable nutrient feeding strategy and studying the influenceof initial lactose concentration on selective ethanol produc-tion.

The cellular growth rate and product formation ratereached a maximum value of 0.157 and 0.046 h−1, respec-tively, during the exponential phase which is an indicationof maximum substrate consumption within this period. Theresults obtained in this investigation have a great importancein processes based on batch mode of operation since the rateof lactose fermentation byK. marxianusis reduced by sugarconcentrations above 2% and by the accumulation of ethanolin the fermentation broth[5]. This raises new perspectives foralcoholic fermentation of whey byKluyveromycessp. sincefinancially viable strategy for disposal of whey continues tobe a big challenge for the cheese industry.

Acknowledgements

We wish to express thanks to Prof. M. Idrees, Chairman,Department of Chemical Engineering (A.M.U., Aligarh)and Prof. M. Saleemuddin, Coordinator, InterdisciplinaryBiotechnology Unit (A.M.U., Aligarh) for the material andfinancial help for the completion of this study.

A

kkKP

qP specific product formation rateqS specific substrate consumption rateS lactose concentrationX biomass concentration

Greek letterµ specific growth rate

References

[1] D. Barba, F. Beolchini, G.D. Re, G.D. Giacomo, F. Veglio, Kineticanalysis ofKluyveromyces lactisfermentation of whey: batch andfed-batch operations, Process Biochem. 36 (2001) 531–536.

[2] C. Compagno, B.M. Ranzi, A. Tura, E. Martegani, Bioconversionof lactose/whey to fructose diphosphate with recombinantSaccha-romyces cerevisiaecells, Biotechnol. Bioeng. 42 (1993) 393–400.

[3] L. Dominguez, L. Nelson, J.A. Teixiera, Alcohol production fromcheese whey permeate using genetically modified flocculent yeastcells, Biotechnol. Bioeng. 72 (2000) 507–514.

[4] S. Grba, T. Vesna, D. Stanzer, Selection of yeast strainKluyveromyces marxianusfor alcohol and biomass production onwhey, J. Chem. Biochem. Eng. 45 (1998) 24–32.

[5] W.V. Guimaraes, Fermentation of sweet whey by ethanologenicEscherichia coli, Biotechnol. Bioeng. 40 (1999) 41–45.

[6] G.H.T. Luong, Kinetic of ethanol inhibition in alcohol fermentation,Biotechnol. Bioeng. 27 (1985) 280–285.

[7] A. Michel, F. Jacob, J. Perrier, S. Poncet, Yeast production fromcrude sweet whey, Biotechnol. Bioeng. 30 (1987) 780–783.

hey

eyIRS

[ thod,

[ ol,

ppendix A. Nomenclature

1 constant2 constantS saturation constant

ethanol concentration

[8] D. Porro, E. Martegani, B.M. Ranzi, L. Alberghina, Lactose/wutilization and ethanol production by transformedS. cerevisiaecells,Biotechnol. Bioeng. 39 (1992) 799–805.

[9] U. von Stocker, I.W. Marison, Unconventional utilization of whin Switzerland, in: T.K. Ghose (Ed.), Bioprocess Engineering,Press, Oxford, United Kingdom, 1993, pp. 330–364.

10] K. Tasun, P. Ghose, K. Ghen, Sugar determination of DNS meBiotechnol. Bioeng. 12 (1970) 921.

11] M.B. William, D. Reese, Colorimetric determination of ethyl alcohAnal. Chem. 22 (1950) 1556.