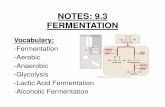

ES Fermentation

-

Upload

maria-cecille-sarmiento-garcia -

Category

Documents

-

view

223 -

download

2

description

Transcript of ES Fermentation

Pamantasan ng Lungsod ng MaynilaCollege of Engineering and Technology

Chemical Engineering Department

Fermentation

Submitted by:

Baldo, Jerlyn Mae B.

De Guzman, Khaye Anne F.

Dizon, Glyzel G.

Macasil, Renzo C.

Percil, Queenie Rose I.

Submitted to:

Engr. Milagros C. Cabangon

July 4, 2014

Objectives

Fermentation

Pamantasan ng Lungsod ng MaynilaCollege of Engineering and Technology

Chemical Engineering Department

General Objective:

To identify and enumerate the raw materials, unit operations and equipment involved in manufacturing of products of fermentation

Specific Objectives:

To discuss the chemical reaction that takes place in beer fermentation

To discuss the process of brewing

To identify the step by step process involved in the fermentation of wine

To differentiate white wine production from red wine production

To identify and enumerate the raw materials, equipment and unit operation involved in

manufacturing cheese

To identify and enumerate the raw materials needed in production of cheddar cheese

To identify and enumerate the unit operations and the corresponding equipment involved in the

manufacturing of cheddar cheese

To determine the different types of distilled spirits

To understand the process of manufacturing distilled spirits.

To identify the different raw materials in manufacturing distilled spirits

Fermentation

Pamantasan ng Lungsod ng MaynilaCollege of Engineering and Technology

Chemical Engineering Department

Fermentation of Wine

Manufacturing companies of Wine in the Philippines:

1. Destileria Limtuaco & Co., IncThe Philippine market has always enjoyed the world-class quality that Destileria

Limtuaco products have been known for. The distillery is proud of its wide range of distilledspirits andalcoholic beverages expertly blended and produced with the highest degree ofmanufacturing excellence, being the finest liquormakers in the Philippines.

For over 160 years, Destileria Limtuaco's excellent brand portfolio consists of distilledspirits, whiskies, brandies, gins, rums, vodkas, tequilas, cocktails, herbal and sweet wines, andthe original medicinal wines. These products are produced strictly followingspecial manufacturing processes and well-guarded formula developed by the master blenders,creating exceptional products of superior taste and quality that satisfies the impeccable taste ofFilipinos and connoisseurs the world over. Destileria Limtuaco is known as "The Oldest Distilleryin the Philippines".

2. Barcino CorporationBarcino Corporation is a company engaged in the importation and distribution of wines

and the best Spanish beer in the Philippines. We also seek to venture into importing otherSpanish products like olive oil, cold cuts, cheeses, and other canned and bottled food as aresponse to the market’s growing need. Barcino Corporation was established in 2006 with themain purpose of distributing wines and food in a small deli shop.

The company offers a wide selection of wine which boasts of 250 labels from Spain,South Africa, Chile, Argentina, and Italy. Some of its most notable brands are multi-awardedwines from Beronia, Martin Codax, Vallformosa, Ponte da Boga, Emilio Moro, etc. And to makeour wine range even more expanse, Barcino Corporation will also start importing from France,Australia, and New Zealand.

3. The Straits Wine CompanyStarted in 2006, The Straits Wine Company is now Southeast Asia’s leading wine

importer, retailer and distributor, with operations in Singapore, Malaysia and Philippines. It has acomprehensive range of services that caters to any and all wine needs. From private wineparties to cellar planning, a trusted bottle shop to private client concierge, the Straits teamof wine professionals is at your disposal.

Our 12 retail wine bars across Singapore showcase a wide range of wines from aroundthe world including Australia, New Zealand, France, Spain, Italy, Argentina, Portugal, India,USA, Lebanon, Japan, Switzerland and many, many more.

Straits Wine is also proud to offer a bespoke events planning service. Specializing inpersonal, boutique wine experiences, our events team plans every aspect to the last detail.

Fermentation

Pamantasan ng Lungsod ng MaynilaCollege of Engineering and Technology

Chemical Engineering Department

From customized tastings, to incredible cheese boards or full themed events and parties, yourguests walk away with a very special memory and experience of a truly one-of-a-kind event.Whether its buying wine for your house party, a girls night in or ordering for your restaurant,Straits Wine is a one stop solution to your wine needs. The Straits Wine Company is currentlythe largest wine retailer in the Southeast Asia region.

Uses of Wine:

Can prevent diseases

Wine is used for preventing diseases of the heart and circulatory system, includingcoronary heart disease, “hardening of the arteries” (atherosclerosis), heart failure, heart attack,and stroke. Wine contains ethanol (alcohol), which blocks various nerve pathways in the brain. Italso contains chemicals that might have beneficial effects on the heart and blood circulationsuch as antioxidant effects, and preventing blood platelets from forming clots.

Marinate the cancer away

Marinating steak in wine for six hours can cut the cancer causing compounds formedduring frying or grilling by up to 90 percent. It can also make your meat more flavorful and juicy.

Grease Remover

If you have grease stains on your driveway or the floor of your garage, try pouring a littlewhite wine on the stain. The acidity will help remove some of the stain. Mix in some baking sodafor an added.

Disinfectant

Leftover white wine makes a great disinfectant for your kitchen. The alcohol combinedwith the acidity can remove stains and kill germs without all the harsh chemicals of standardcleaners. Just be careful as the acidity can damage some countertops like granite.

Soften your skin

The antioxidants that give red wine its glory in health circles are equally as beneficial foryour skin. Use leftover wine as a toner or dump it into your bath water and soak the night away.You may not get a buzz, but you'll be left with baby soft skin. If we find out it can get rid ofwrinkles, we may never actually drink wine again.

History and Background Information

Enology, a word that comes from the Greek words for wine and study, is the term that is used todescribe the science of winemaking. This science has its roots in prehistoric times, as the effects ofalcohol were probably discovered when rotten fruit was consumed and found to have an intoxicatingeffect, which was viewed as pleasant. Fermented liquid could be stored for a long time without fear ofdecomposition, and a reliable drinking source was obtained (Wade, 1999).

The process of fermentation is described by the reaction:

Fermentation

Pamantasan ng Lungsod ng MaynilaCollege of Engineering and Technology

Chemical Engineering Department

C6H12O6 + yeast -> 2C2H5OH + 2CO2

glucose (sugar) -> ethanol carbon dioxide

Yeast is added to a solution containing glucose, and the yeast cells convert the simple sugars toethanol and carbon dioxide. The alcoholic solution that results from fermentation contains about 12-15% ethanol, as yeast cells cannot survive in higher concentrations of ethanol (Wade, 1999). High sugar content is necessary for fermentation to proceed in a desirable manner. Because ofthis, the sugar-rich species of grape Vitis vinifera is used for the majority of the wines produced aroundthe world. As many as 4000 varieties of Vitis Vinefera have been developed and are used in theproduction of wines. Although the specifics of winemaking can vary from location to location and theindividual fermenting techniques, the basic steps involved in winemaking are similar for most wineries. There are three main categories of wine: table wines, sparkling wines, and fortified wines. Tablewines can be red, white, or rose, are allowed to ferment naturally, and account for the bulk of theworld’s wine production. Sparkling and fortified wines are made by processes similar to the tablewines, but extra steps are added to give the carbonation or extra alcohol desired.

Well documented in numerous Biblical references, evidence of wine can be traced back toEgypt as far as 5,000 B.C. Tomb wall paintings showing the use of wine as well as actual wine jarsfound in Egyptian tombs provide evidence of this fact. Because more northern climates and soilproduce better wine, the growth of the wine industry can be traced from its emergence along the NileRiver in Egypt and Persia northward into Europe and, eventually, to North America.

The colonists brought wine production to the east coast of the New World by the mid-1600s.The earliest account of wine used in the New World may be when the Pilgrims fermented grapes tocelebrate their first Thanksgiving in 1623. Settlers tried to grow imported grape cuttings they broughtfrom Europe, but unfortunately the European cuttings had not developed immunities to the NorthAmerican plant diseases that eventually killed them. By the middle of the nineteenth century winerieswere established in Pennsylvania, Virginia, Ohio, Indiana, Alabama, Mississippi, and North Carolina.

In 1697, European cuttings of Vitis vinifera grapes were successfully introduced to California byFranciscan priests at the Mission San Francisco Xavier. They soon became the dominant grapespecies in California wine making. A great boost to California wine making came from Colonel AgostonHaraszthy, a Hungarian nobleman, who introduced more high-quality European cuttings during the1850s. His knowledge made him the founder of California's modern wine industry.

Today, California and New York state are by far the largest American producers of wine, andCalifornia is one of the largest wine producers in the world. Though many of its table wines are knownfor their quality, the enormous wineries of central and southern California produce gigantic quantities ofneutral, bulk wines that they ship elsewhere to make specific wines, such as dessert wines, or to blendwith other wines. They also make grape concentrates to fortify weaker wines and brandies that uselarge quantities of grapes.

Raw Materials in Wine Fermentation:

Fruit

The grape itself contains all the necessary ingredients for wine: pulp, juice, sugars,acids, tannins, and minerals; and these ingredients contain vitamins, seed, etc that are basicallyfound in wines.

Fermentation

Pamantasan ng Lungsod ng MaynilaCollege of Engineering and Technology

Chemical Engineering Department

Yeast

Yeast converts sugar into alcohol. Therefore, it is responsible for the alcoholic content ofwine.

Additives: Cane or Beet Sugar

It is also responsible for the increase the wine’s alcoholic content. Sulfur Dioxide

It is usually added during fermentation to control the growth of wild yeasts.

Manufacturing Process:

A. Red Wine Process1. Harvesting

Wine makers inspect sample clusters of wine grapes with a refractometer to determine ifthe grapes are ready to be picked. The refractometer is a small, hand-held device (the size of aminiature telescope) that allows the wine makers to accurately check the amount of sugar in thegrapes.If the grapes are ready for picking, a mechanical harvester (usually a suction picker)gathers and funnels the grapes into a field hopper, or mobile storage container.

2. Crushing The old way was to tread the grapes: the modern way is to crush and then destem themwith mechanical crusher-destemmers. The aim of crushing is to split the skins and release thejuice, enabling yeast activity and fermentation to begin. Destemming is not always necessaryand bunches may be crushed whole, but stems and stalks are usually removed if the winemakerwishes to avoid high tannin levels in the wine. The object of destemming and crushing is toremove the stem and gently break the berry skin. Care is taken to avoid excessive skinmaceration and breaking of seeds. The crushed fruit consisting of pulp, skin, and seed, calledmust, is transferred to a container and about 30 mg/L of free SO2 is added. The purpose of SO2addition is to prevent the development of unwanted microbes such as indigenous yeast andharmful bacteria.

3. Maceration or Cold Soak In the practice of cold soak or cold maceration, the must is cooled to about 15 to 20 ºC

(41 to 68 ºF) to slow down the onset of fermentation by indigenous yeast, and contact betweenskins and juice is promoted. The purpose of cold soaking is to encourage extraction of pigmentsand other phenolic compounds from skins in the absence of ethanol. The skins are soaked forone to two days and the must is pumped over or mixed to facilitate the phenolic extraction. Thecold maceration is thought to improve color, body, and mouth feel of the resulting wine. Theeffectiveness of this approach will depend on variety, fruit composition and the condition of thefruit.

Fermentation

Pamantasan ng Lungsod ng MaynilaCollege of Engineering and Technology

Chemical Engineering Department

4. Must AdjustmentGrapes are generally harvested at 22 to 24 ºBrix for red wine production. Some varieties

may not have sufficient amount of sugar at harvest. For these varieties (e.g., Concord), sugaraddition to the must would be necessary. Sugar addition can be done to the must at thebeginning of fermentation. However, one needs to make an allowance for the volume of seedsand skins when calculating the amount of sugar needed. To circumvent this problem, somewinemakers prefer to add sugar to the fermenting must after pressing and removing seeds andskins. In low sugar, high acid American grapes such as Concord, sugar syrup in place of drysugar can be used. This process is also called amelioration. The advantage of this process isthat while sugar content increases, the acid level decreases due to dilution. To ensure thequality of the resulting wine, the extent of amelioration within legal limits should be carefullyevaluated.

5. Must TreatmentThe issue of SO2 addition needs some consideration. Some winemakers do not add free

SO2 to red must prior to fermentation. The rationale is to minimize SO2 levels in wine, facilitatemalolactic fermentation, and maybe to achieve flavor complexity by allowing indigenous yeast toparticipate in alcoholic fermentation. The problem with this approach is that no SO2 addition canleave must unprotected from the activity of undesirable microorganisms such as wild yeast andspoilage-causing bacteria. We recommend the addition of a small amount (20 to 30 mg/L freeSO2) of SO2 to the clean must; must with rot will need higher (75 to 100 ppm) doses. This level(20 to 30 ppm) is sufficiently high to discourage spoilage organisms but not too high to suppressmalolactic fermentation, if it is so desired.

6. FermentationAfter making all the necessary adjustments (sugar, acid, etc.) and additions, the red

must, consisting of juice, skin, and seeds is ready for fermentation. The must can be fermentedin open top containers. This allows for ease in must handling, cap management, andtemperature control. However, some provision should be made to keep the fruit flies away fromthe fermenting must. Some winemakers prefer to use fermenters with closed tops or somecover to keep fruit flies away. Smaller lots can be fermented in tubs, tanks, bins, or othercontainers made of plastic or stainless steel. For larger must volumes, specially designedstainless steel fermenters should be used. The fermentation should be conducted in a well-ventilated area, and provisions should be made to remove excess CO2 generated duringfermentation.

A wide selection of yeast strains is available for conducting red wine fermentation. Thewinemaker should choose the strain that will ferment the must efficiently and completely withvery little (below sensory threshold) amounts of undesirable compounds such as acetic acid,ethyl acetate, and hydrogen sulfide. To obtain a clean and rapid fermentation, commerciallyproduced strains of active wine yeast in dry form should be used. Dry yeast must be properlyrehydrated before inoculating the must. We suggest that winemakers experiment with various

Fermentation

Pamantasan ng Lungsod ng MaynilaCollege of Engineering and Technology

Chemical Engineering Department

strains to make proper selection. Some winemakers use indigenous yeast strains. This practicecan sometimes give good results; however, it is risky and requires a lot more skill and attention.

7. Cap ManagementWith the onset of active fermentation the skins rise to the top of the fermenting liquid and

form a cap. Thus the skins and juice in a fermenter are somewhat separated. In order tomaximize the extraction of color and flavor from skin it is important to keep skins in closecontact with the juice during fermentation. To achieve this, the cap is punched and skins andjuice are mixed.

8. Skin ExtractionThe color and tannins are the two major components that are extracted from skins

during fermentation. The purplish-red color of red grapes is due to the pigments known asanthocyanins. The pigments are located mostly in the outer layers of the skins. In grapes, manykinds of anthocyanins are present. They occur in both color and colorless forms. The amount ofpigment in colored or colorless form is strongly influenced by the pH of the wine and also by thepresence of free sulfur dioxide. Lowering the pH shifts the equilibrium towards the colored formand SO2 has a bleaching effect on the (monomeric) anthocyanins.

Tannins are complex polymeric phenols. They react with proteins, and it is this propertythat is used in tanning hides to make leather. They are bitter and astringent compounds with awide range of molecular sizes. Condensation and polymerization of smaller tannin moleculesleads to the formation of bigger tannin molecules such as condensed and highly condensedtannins. These large tannin polymers are less astringent and assume yellow-red to yellow-brown color. When the tannins become too large, they precipitate.

Tannins also play an important role by forming complexes with pigments, whichcontributes to color stability. These polymeric pigments (pigment and tannin complexes) are lesssensitive to changes in pH and SO2 levels in wine. During alcoholic fermentation, both thepigments and tannins are extracted from the skin, but their pattern of extraction is slightlydifferent.

The extraction of color is rapid at the beginning of fermentation. It reaches a peak in thefirst two to three days; and, then slightly declines during the remainder of fermentation. Thismeans a short maceration time of about two to three days is sufficient to obtain good color.Tannins and other phenolic substances are also extracted quickly at the beginning but their rateof extraction slows down as the fermentation proceeds. However, the concentration of totalphenols (this includes tannins) continues to increase towards the end of fermentation.

9. Carbonic MacerationCarbonic maceration is an alternative fermentation process in which the fruit is allowed

to ferment spontaneously under a protective layer of CO2. This weight of the grapes is sufficientto crush the fruit and release the juice, known as free-run, without mechanical pressure. Theresulting wines tend to be softer and less astringent than those fermented in the traditional way,so this method is well suited to grapes which normally give hard, acidic wines. Wines made by

Fermentation

Pamantasan ng Lungsod ng MaynilaCollege of Engineering and Technology

Chemical Engineering Department

carbonic maceration are usually for drinking young and do not respond well to aging.

10. Pressing Pressing the grape mass, or pomace, occurs after the free-run wine has been removed fromthe fermentation vat. This process is not for white, and in fact is not always carried out at all.'Press wine' is high in tannin and colouring pigments. At the discretion of the winemaker apercentage of it may be blended with the free-run wine to add tannins, character and longetivity.

11. Malolactic FermentationThis process is almost always encouraged in red winemaking. It is a secondary

fermentation in which malic acid is converted into lactic acid and CO2. It softens the acidity ofthe wine and, once completes, adds to its complexity and stability. In many European cellars thewines will mature for six months before the malolactic fermentation commences.

12. Maturing

- Maturing in OakHigh quality red wines today are almost always matured in oak. Oak contributes vanilla

and wood tannin flavours. For how long the winemaker ages the wine in barrel is one of thecrucial decisions, arrived at by regular tasting.

- RackingThe wine is racked every few months by transferring it to a clean sterile barrel, gently

aerating it and leaving any sediment in the bottom of the old barrel.

- FiningThe object of fining is to clarify the wine. The fining agent (usually egg white or bentonite

clay) is poured onto the surface. As it sinks through the wine it carries any solids to the bottomof the vat.

- FiltrationThe final option before bottling is whether or not to filter. Passing the wine through a fine

filter guarantees (or should guarantee) its stability and 'brightness' even under fairly adverseconditions. But some winemakers believe it strips the wine of its character.

13. StabilizationThe practice of stabilization refers to the treatment of wine to prevent cloudiness and

formation of sediment in the bottle. Red wines are rich in tannin contents, which carry a negativecharge. The tannins interact with positively charged proteins which lead to agglomeration andsettling of the tannin-protein complex. Due to the removal of proteins in this manner, theproblem of proteinaceous haze in red wines is not a serious one. Some winemakers use a small

Fermentation

Pamantasan ng Lungsod ng MaynilaCollege of Engineering and Technology

Chemical Engineering Department

dose of bentonite to clarify the wine, which also helps in protein stability. However, winemakersgenerally do not treat wine for protein instability unless a test warrants it.

14. AgingThe process of maturation and aging involves a series of changes that lead to the

improvement in the appearance, color, taste, and flavor of a wine. Red wine color is due to thepresence of anthocyanin pigments, which occur in monomeric and polymeric forms. Youngwines have higher levels of monomeric anthocyanin pigments in various colored and colorlessforms. The proportion of colored and colorless types is pH dependent. In the range of wine pH,the lower the pH, the greater the concentration of pigments in red form. Therefore, to produceyoung red wines of attractive color, the winemaker should strive for a lower wine pH. Themonomeric pigments are also susceptible to sulfur dioxide, which causes bleaching. Thisreaction, however, is reversible and loss of SO2 can restore original color. This point isimportant to remember when sulfating young red wines. As the wine matures, the monomericpigments are polymerized and the color becomes more stable. It is then less responsive tochanges in pH and SO2 levels.

15. Finishing or BottlingBefore bottling the wine should be completely stable. It remains vulnerable to oxidation

and contamination until the cork goes in. Mechanical bottling lines account for 95 percent ofmodern bottling. It is important to fill the bottles to exactly the right level to allow adequate roomfor the cork.

B. White Wine Process

1. CrushingThe first stage of controlled vinification is to crush the grapes and release the pulp and

juice, making them easier to press. A Key decision at this stage is whether or not to remove thestems. Left with the grape stems allow juice to drain more freely during pressing. For somewines, where white wines are being made from red grapes, crushing of any kind is avoided(because it would colour the wine): grapes go whole into the press.

2. Pressing

- CoolingDelaying fermentation until after pressing is essential. Where the ambient must

temperatures are high the juice is cooled by pumping it through 'must chillers'.

- PressingWhite wine grapes are always pressed. Better quality juice results when pressing is

gentle. If too aggressive the pips and stems break and bitter astringent flavours, whichoverpower those natural in the grapes, are released. Good results are achieved with pneumaticpresses, which are now replacing traditional vertical wooden ones. Both types yield juice of thehighest quality and also enable the separation of different quality pressings.

Fermentation

Pamantasan ng Lungsod ng MaynilaCollege of Engineering and Technology

Chemical Engineering Department

- SettlingThe juice is drained from the press into settling vats where the skin, pip and stem

fragments remaining in suspension after pressing will settle to the bottom of the vat. The cleanjuice is then racked into separate vats ready for fermentation to begin. Centrifuging can also becarried out at this stage to clarify the wine, but it is an aggressive process, removing all thelarger particles in the must, even yeast cells. It is often carried out when cultured yeasts are toreplace natural ones for fermentation.

3. FermentationTraditionally in oak casks (increasingly favoured for many high quality wines) white wine

is now more often fermented in stainless steel vats which enable easier regulation of yeastactivity through temperature control. Prolonged fermentation at cool temperatures protectsprimary fruit characteristics and ensures the conversion of all the sugar to alcohol. Afterfermentation some winemakers chose to leave their wine in contact with its lees (yeastsediment) which adds both flavour and freshness to the wine, retained by bottling it withoutdelay.

4. Malolactic FermentationTo soften astringent acidic flavours and to add complexity, a second or malolactic

fermentation can be encouraged (it may occur quite naturally or be brought about artificially).This converts harsher malic acids to softer lactic ones. Where retaining acidic qualities in thewine is important (e.g. in warmer climates where the grapes gain greater sugar and fruit flavoursat the expense of their natural acidity) this second fermentation is prevented by removing theyeasts and proteins needed to initiate it.

5. Maturing- Clarification

Filtration, centrifuging or fining with bentonite clay (which 'collects' remaining yeasts,proteins, grape skin particles etc, and precipitates them to the bottom of the vat) are used toprevent unwanted malolactic fermentation and any further yeast activity once all the sugar in thewine has been converted to alcohol It also removes substances leading to 'off tastes'. Withclarification the wine gains stability: the processes used for this stabilization, however are quiteaggressive and many believe they lead to flavour loss. Clarification is completed by removingtartrates from the wine. Modern wineries now use thickly insulated stainless steel vats for coldstabilization. By cooling the wine to around - 4C, tartrate crystals, which may otherwise form inthe bottle, precipitate and fall to the bottom of the vat. In Germany this process traditionallyoccurred in large oak Fuders situated in cellars cool enough for tartrates to precipitate out atambient temperatures. After stabilization the wine may be bottled immediately or matured first inoak barrels.

- Maturing in OakMaturing white wine in new oak imparts flavours which can overpower wines of more

subtle character, but add depth and complexity to others. Older barrels give more moderate

Fermentation

Pamantasan ng Lungsod ng MaynilaCollege of Engineering and Technology

Chemical Engineering Department

flavours and are an option often favoured in Burgundy.

6. Finishing - Bottling

During bottling cleanliness is essential: any bacterial activity, which may be encouragedby warm temperatures- especially when the wine is later transported or shipped for sale- isprevented by passing the wine through a fine filter. Some producers bottle the wine straight fromits lees after fermentation to retain yeast character and freshness (even a slight spritz). Others,particularly in the New World, inject CO2 at the bottling stage for the same effect.

INDUSTRIAL PROCESS FLOWCHART

EQUIPMENT FLOWCHART

Fermentation

Pamantasan ng Lungsod ng MaynilaCollege of Engineering and Technology

Chemical Engineering Department

FERMENTATION OF BEER

DEFINITION OF BEERA fermented beverage made by the extraction and partial conversion, through malting, mashing

of cereal starch, most often Barley into fermentable sugars. Hops are usually added fermentation, isperformed primarily with yeast, primarily with part of the resulting carbon dioxide retained in thebeverage.

BRIEF HISTORY OF BEERAle is one of the oldest beverages humans have produced, dating back to at least the 5th

millennium BC and recorded in the written history of Ancient Egypt and Mesopotamia. As almost anycereal containing certain sugars can undergo spontaneous fermentation due to wild yeasts in the air, itis possible that beer-like beverages were independently developed throughout the world soon after atribe or culture had domesticated cereal. Chemical tests of ancient pottery jars reveal that beer wasproduced about 7,000 years ago in what is today Iran, and is one of the first-known biologicalengineering tasks to utilize the process of fermentation. In Mesopotamia, the oldest evidence of beer isbelieved to be a 6,000-year-old Sumerian tablet depicting people drinking a beverage through reedstraws from a communal bowl. A 3900-year-old Sumerian poem honouring Ninkasi, the patron goddessof brewing, contains the oldest surviving beer recipe, describing the production of beer from barley viabread.The invention of bread and/or beer has been argued to be responsible for humanity's ability todevelop technology and build civilization. The earliest chemically confirmed barley beer to date wasdiscovered at Godin Tepe in the central Zagros Mountains of Iran, where fragments of a jug, at least5000 years old was found to be coated with beerstone, a by-product of the brewing process. Beer mayhave been known in Neolithic Europe as far back as 5000 years ago, and was mainly brewed on adomestic scale. Ale produced before the Industrial Revolution continued to be made and sold on adomestic scale, although by the 7th century AD beer was also being produced and sold byEuropean monasteries. During the Industrial Revolution, the production of beer movedfrom artisanal manufacture to industrial manufacture, and domestic manufacture ceased to besignificant by the end of the 19th century. The development of hydrometers and thermometers changedbrewing by allowing the brewer more control of the process, and greater knowledge of theresults.Today, the brewing industry is a global business, consisting of several dominant multinationalcompanies and many thousands of smaller producers ranging frombrewpubs to regional breweries.

Fermentation

Pamantasan ng Lungsod ng MaynilaCollege of Engineering and Technology

Chemical Engineering Department

[9] More than 133 billion liters (35 billion gallons) are sold per year—producing total global revenues of$294.5 billion (£147.7 billion) in 2006.

RAW MATERIALS FOR BREWING

MALT

Malt is a grain product that contributes flavor and color to the beer. Barley is the most commonly usedgrain for malting and beer making, but some malts are also made from wheat, rye, and dinkel (speltwheat). Malted barley gives beer its color, malty sweet flavor, dextrins to give the beer body, protein toform a good head, and perhaps most important, the natural sugars needed for fermentation. Malt alsocontains small amounts of other sugars, such as sucrose and fructose, which are not products of starchmodification but were already in the grain.

A. BARLEY Barley a member of the grass family, it is a major cereal grain. It was one of the first

cultivated grains and is now grown widely. It is also the world’s most nutritional crop and isrecommended for beer brewing. This is because barley contains many elements that are richsources of health and energy for brewing yeast. The composition of barley, including thepercentage of minerals, gives a general idea about its uses in brewing industry. Barley containsabout

STARCH 62-66%SUGARS `1-2%B-GLUCANS 3-5%PENTOSANS 4-7%LIPIDS 2-3%PROTEIN 8-13%Amino acids and peptides 0.5 %Nucleic acids 0.2 – 0.3Minerals 2 %

HOPSHops are the female flowers of the hop plant, Humulus lupulus. It Contains 0.3–1% volatile oil;

3–12% resinous bitter principles composed of α-bitter acids other resins, some of which are oxidationproducts of the α- and β-acids.They are used primarily as a flavoring and stability agent in beer, towhich they impart a bitter, tangy flavor, though hops are also used for various purposes in otherbeverages.

YEAST Yeast, a single-cell organism, is the sole agent of beer fermentation. During fermentation, yeastconverts sugars in the unfermented beer into alcohol and carbon dioxide.

A. Ale Yeast

Fermentation

Pamantasan ng Lungsod ng MaynilaCollege of Engineering and Technology

Chemical Engineering Department

This is a top-fermenting yeast strain that is used to makeales. This yeast rises to the top of thefermentation tank during fermentation, thus the name "top-fermenting." These work best at relativelywarm temperatures - between 59 and 77°F (15 and 25°C).

B. Lager Yeast This is a bottom-fermenting yeast strain that is used to makelagers. This yeast sinks to

the bottom of the fermentation tank during fermentation, thus the name "bottom-fermenting." Thesework best at relatively cold temperatures - between 41 and 50°F (5 and 10°C).

WATERFinished beer is more than 90% water. The quality and characteristics of the water used for

brewing greatly affects the taste of the finished beer. The amount and composition of dissolvedminerals, such as calcium and magnesium, play a large part the taste of the beer. Brewing water must,therefore, be clean, healthy, and of the right composition. Of the ions required for brewing, calcium is byfar the most important. This is because of the acidifying effect that calcium has on the wort.

MANUFACTURING OF BEERRAW MATERIALS CONDITIONINGMALTING

Malting is the process where barley grain is made ready for brewing Malting is broken down intothree steps in order to help to release the starches in the barley. First, during steeping, the grain isadded to a vat with water and allowed to soak for approximately 40 hours, this is done because yourtarget is to awaken the embryo of the barley, The objective of steeping is to achieve a moisture contentof 46% with a strong uniform growth so when water is added with barley it breaks the wall of theembryo then as the barley absorbs water it begins to respire, taking in oxygen and exhausting carbondioxide (CO2). In order to maintain optimum malting conditions for the barley kernels, the CO2 is drawnoff and replaced with fresh oxygen.. During germination, the grain is spread out on the floor of thegermination room for around 5 days, during this days germination converts the grain’s starch into sugarand certain enzymes are formed. It is vital to preserve the enzymes, released through germination,which enable the final conversion of starch to soluble, fermentable sugar, to be completed duringmashing. The final part of malting is kilning when the malt goes through a very high temperature drying in a kiln;The kiln operates much like a conventional oven. Hot air is forced through the green malt, drying androasting it so that all biochemical activity stops, and flavor develops, .The drying rate is dependent onthe air-on temperature and air flow, which varies between 45 – 75 deg. When kilning is complete, thegrains are now termed malt, the temperature the grain is exposed to determines the color and flavor ofthe sugar found within the grain. final flavour and colour of the malt is established and the final moisturecontent will be below 4.5%.Finally, malted barley contains more endosperm degrading enzymes thanbarley, more soluble proteins, amino acids and more colour compounds. This enables greater hot waterextraction of malt sugars and amino acids during mashing, thus producing a greater yield of ethanolduring fermentation

ENZYMES THAT ARE FORMED DURING MALTING

Fermentation

Pamantasan ng Lungsod ng MaynilaCollege of Engineering and Technology

Chemical Engineering Department

Alpha Amylase

Alpha amylase is an endo acting enzyme that catalyses the hydrolysis of alpha-glucido-(1,4)-glucose linkage at random within starch chains. It’s not present in the barley but the amount of enzymewill be produced mainly during second and fourth days of germination and increases throughout thegermination period.

Beta AmylaseBeta amylase is concentrated in the sub-aleurone layer of the barley grain and decline in amounttowards the central endosperm. It’s present already in the barley in a bound form. The amount will beincreases considerably on the second and third days of germination and in the later phase will beslowly decreases. The enzyme formation directly related to the respiration (requires proteolysis). So,adequate aeration in the first germination phase is very important for malting production.

Limit dextrinase

Because of the alpha-(1,6) bound in amylopectin are not hydrolysed by alpha and beta amylase,another enzyme is required to hydrolyse these bonds and allow complete conversion of starch to lowmolecular weight is limit dextrinase enzyme. For the applications of this enzyme is to increase degreeof fermentability.

MASHINGIn brewing mashing is the process of combining a mix of milled grain and water, known as

"liquor", and heating this mixture. Mashing allows the enzymes in the malt to break down the starch inthe grain into sugars, typically maltose to create a malty liquid called wort. There are two main methods—infusion mashing, in which the grains are heated in one vessel; and decoction mashing, in which aproportion of the grains are boiled and then returned to the mash, raising the temperature. Mashinginvolves pauses at certain temperatures (notably 45 °C, 62 °C and 73 °C) [113°F, 144°F, and 163°F],and takes place in a "mash tun"—an insulated brewing vessel with a false bottom. The end product ofmashing is called a “wort", In large breweries, in which optimal utilization of the brewery equipment iseconomically necessary, there is at least one dedicated vessel for mashing. In decoction processes,there must be at least two. They practice decoction because of the unique malty flavor it lends to thebeer; boiling part of the grain results in Maillard reactions, The Maillard reaction is a chemicalreaction between amino acids and reducing sugars that gives browned foods their desirable flavorwhich create melanoidins that lead to rich, malty flavors.

Fermentation

Pamantasan ng Lungsod ng MaynilaCollege of Engineering and Technology

Chemical Engineering Department

FUNCTIONS OF ENZYMES

B-Glucanase is Beta Glucanase enzyme, which can catalyze Beta Glucan in barley plant orgrain sample efficiently into glucose and other low molecular material to reduce the viscosity of themalt.Diastatic enzymes

The diastatic brewing enzymes break down and convert starch (the endosperm of the grain)into fermentable sugars and unfermentable dextrins. We are interested in the two diastatic enzymesthat become active during the mash. These are alpha-amylase and beta-amylase. They work togetherto break down long complex chains of soluble (or gelatinized) starch molecules into sugars ordextrins. Starch molecules are basically just long chains of glucose molecules. But due to the bondsbetween them, they are not fermentable. Maltose has two glucose molecules bonded together and isfermentable. Dextrins have long chains with four or more glucose molecules and are by products ofstarch conversion. Dextrins are not fermentable and have no taste. They do however add body andmouthfeel to beer.Alpha-amylase chops up starch molecules randomly into chunks that beta-amylasecan then work on. Until these molecules are chopped up, they are unfermentable and called dextrins.What alpha-amylase does is called liquefication. It physically liquefies the starches, making them readyfor further enzymatic activity. Mash schedules that target the alpha-amylase enzymatic action (optimumat 158°F/50°C) yield a wort with a high percentage of unfermentable sugars, or dextrins. The beerproduced is very rich, with a thicker body and mouthfeel.Beta-amylase breaks down starch and dextrinsinto glucose (one molecule), maltose (two molecules) and maltotriose (three molecules). After beta-amylase is through working, the starch has been broken down into fermentable sugar. Mash schedulesthat target the beta-amylase enzymatic action (optimum at 140°-149°F/60°-65°C) yield a wort that ishighly fermentable. The beer produced will be drier tasting and contain more alcohol.It is important tounderstand that although mash enzymes have an optimum temperature, they will work over a widerange, and most of the time, the activity of enzymes overlap within that range. Both alpha-amylase and

Fermentation

Temp °C Temp °F Enzyme Breaks down

40-45 °C 104.0-113.0 °F β-Glucanase β-Glucan

50-54 °C 122.0-129.2 °F Protease Protein

62-67 °C 143.6-152.6 °F β-Amylase Starch

71-72 °C 159.8-161.6 °F α-Amylase Starch

Pamantasan ng Lungsod ng MaynilaCollege of Engineering and Technology

Chemical Engineering Department

beta-amylase will work well together within the range of 145° to 158°F (63°-70°C). So in general, if youwant a thinner, drier, more alcoholic beer you can rest your mash in the lower portion of this range, andif you want a richer more dextrinous beer with more mouthfeel and body, you should rest your mash inthe upper portion of this range. A good compromise is made by mashing in the middle, around 152°F(67°C).

Mashing involves protein restThe process of activating the proteolytic enzymes is called the protein rest.Proteolytic Enzymes

Two groups of proteolytic enzymes are important in the brewing process, protease and peptidase. Protease breaks down the very large protein molecules into smaller aminoacid chains, which enhances the head retention of beer and reduces haze. The other enzyme ispeptidase. It breaks down the smaller amino acid chains released by protease, but only works from theends, releasing nutrients used by the yeast. Most proteins in the wort are not soluble until the wortreaches the 113°-131° range of the protein rest. The two enzyme's temperature ranges overlap, but theideal temperature for a protein rest is 122°F (50°C). The enzymes are denatured by temperaturesgreater than 150° F (65°C). Its ideal pH range is a little below the normal mash pH of 5.2-5.8, but itworks well enough at this range that you shouldn't worry about lowering the mash pH to accommodatethem.

LAUTERINGLautering is a process in brewing beer in which the mash is separated into the clear

liquid wort and the residual grain. Lautering usually consists of 3 steps: mashout, recirculation, andsparging.Mashout is the term for raising the temperature of the mash to 77 °C (170 °F). This both stopsthe enzymatic conversion of starches to fermentable sugars, and makes the mash and wort more fluid.Mashout is considered especially necessary if there is less than 3 liters of water per kilogram of grain orif the grain is more than 25% wheat or oats. The mashout step can be done by using external heat, orsimply by adding hot water.Recirculation consists of drawing off wort from the bottom of the mash, andadding it to the top. Lauter tuns typically have slotted bottoms to assist in the filtration process.Sparging is trickling water through sugars.

BOILING

After mashing, the beer wort is boiled with hops (and other flavourings if used) in a large tank known asbrew kettle – though historically the mash vessel was used and is still in some small breweries Theboiling process is where chemical and technical reactions take place, including sterilization of the wortto remove unwanted bacteria, releasing of hop flavours, bitterness and aroma compoundsthrough isomerization, stopping of enzymatic processes, precipitation of proteins, and concentration ofthe wort. . Hops lupulin glands produced alpha acids in which the bitter taste of the beer comes from,the longer the boiling the bitter the beer.

WHIRPOOLINGAt the End of the Boil, the wort is set into a whirlpool. The so called teacup effect forces the

more dense solids into a cone in the whirpool tank, simply in this process the hops are separated fromthe wort.

Fermentation

Pamantasan ng Lungsod ng MaynilaCollege of Engineering and Technology

Chemical Engineering Department

WORT COOLINGAfter the whirlpool, the wort must be brought down to fermentation temperatures (20–

26°Celsius) before yeast is added. After cooling, oxygen is often dissolved into the wort to revitalize theyeast and aid its reproduction.

FERMENTATIONAfter the wort is cooled and aerated – usually with sterile air – yeast is added to it, and it begins

to ferment. It is during this stage that sugars won from the malt are metabolized into alcohol and carbondioxide, and the product can be called beer for the first time. Fermentation happens in tanks whichcome in all sorts of forms, from enormous cylindro-conical vessels, through open stone vessels, towooden vats.

AGINGAfter an initial or primary fermentation, beer is conditioned, matured or aged, in one of several

ways, which can take from 2 to 4 weeks, several months, or several years, depending on the brewer'sintention for the beer. The beer is usually transferred into a second container, so that it is no longerexposed to the dead yeast and other debris (also known as "trub") that have settled to the bottom of theprimary fermenter. This prevents the formation of unwanted flavours and harmful compounds suchas acetylaldehydes.

KrauseningKräusening is a conditioning method in which fermenting wort is added to the finished beer. The

active yeast will restart fermentation in the finished beer, and so introduce fresh carbon dioxide; theconditioning tank will be then sealed so that the carbon dioxide is dissolved into the beer producing alively "condition" or level of carbonation. The kräusening method may also be used to condition bottledbeer.

Lagering

Lagers are stored at near freezing temperatures for 1–6 months while still on the yeast. Theprocess of storing, or conditioning, or maturing, or aging a beer at a low temperate for a long period iscalled "lagering", and while it is associated with lagers, the process may also be done with ales, withthe same results – that of cleaning up various chemicals, acids and compounds.

Secondary fermentation

During secondary fermentation, most of the remaining yeast will settle to the bottom of thesecond fermenter, yielding a less hazy product.

Bottle fermentation

Fermentation

Pamantasan ng Lungsod ng MaynilaCollege of Engineering and Technology

Chemical Engineering Department

Some beers undergo a fermentation in the bottle, giving natural carbonation. This may be a second orthird fermentation. They are bottled with a viable yeast population in suspension. If there is no residualfermentable sugar left, sugar and/or wort may be added in a process known as priming. The resultingfermentation generates CO2 that is trapped in the bottle, remaining in solution and providing naturalcarbonation. Bottle-conditioned beers may be either filled unfiltered direct from the fermentation orconditioning tank, or filtered and then reseeded with yeast.

FILTERINGFiltering the beer stabilizes the flavour, and gives beer its polished shine and brilliance. Not all

beer is filtered. Filters come in many types. Many are in the form of sheets or "candles". Others use afine powder such as diatomaceous earth, also called kieselguhr. The powder is added to the beer andrecirculated past screens to form a filtration bed.Filters range from rough filters that remove much of theyeast and any solids (e.g., hops, grain particles) left in the beer, to filters tight enough to strain colourand body from the beer. Filtration ratings are divided into rough, fine, and sterile. Rough filtration leavessome cloudiness in the beer, but it is noticeably clearer than unfiltered beer. Fine filtration removesalmost all cloudiness. Sterile filtration removes almost all microorganismPACKAGINGPACKAGINGPackaging is putting the beer into the containers in which it will leave the brewery. Typically, this meansputting the beer into bottles, aluminium cans and kegs/casks, but it may include putting the beer intobulk tanks for high-volume customers.

I. History of Distilled Spirits

The first clear evidence of distilled alcoholic beverages are found in Asia dating to around 800 BC. The

Japanese distilled Shochu from sake (rice wine), Arrack was made in India from a mix of rice and

molasses, and in the Caucasus mountains (modern day Georgia) Skhou was distilled from mare’s milk.

There are some records pointing to a type of distillation used by the Egyptians to create perfumes, but

the evidence is not conclusive.

Greek alchemists in Alexandria in the first century AD began to improve on just basic steam collecting

devices and developed the first stills. As Europe descended into the Dark Ages it was ironically (Islam

forbids alcohol consumption) the medieval Arabs who continued the distillation research. It would

appear that their research was directed towards perfumes and purifying water rather than creating

alcoholic beverages.In the Middle Ages of Europe the earliest evidence of alcoholic distillation comes

from Salerno in southern Italy in the 12th century. It was not until 1437 however that the production of

brandy (using wine as a base for distillation) is first noted. In the 14th Century the popularity of distilled

Fermentation

Pamantasan ng Lungsod ng MaynilaCollege of Engineering and Technology

Chemical Engineering Department

spirits rose and were commonly used as medicinal remedies for the Black Death. The basic process of

distillation today has not changed very much since the 9th Century. Many distillers actually prefer

traditional methods to the modern techniques that can also be used. The traditional French alembic

copper pot stills are widespread across Europe and America, the personal touch each of these stills

provides is highly touted and coveted.

II. Companies

Emperador Distillers, Inc.

IBM Plaza

8 Eastwood Ave

Quezon City 1110

Tanduay Distillers

J Nepomuceno

Maynila

San Miguel Brewery Inc.

United Mandaluyong Fire Emergency and Rescue Volunteer Inc.

Pinatubo

Mandaluyong 1550

Ginebra San Miguel Inc.

433 St. Francis Street St. Francis Avenue Ortigas, Metro Manila

III Types of Distilled Spirits

Types of Distilled Spirit Raw Material Picture

Fermentation

Pamantasan ng Lungsod ng MaynilaCollege of Engineering and Technology

Chemical Engineering Department

Brandy Grapes

Tequila Blue Agave

Rum Sugar Cane

Vodka Potatoes

Fermentation

Pamantasan ng Lungsod ng MaynilaCollege of Engineering and Technology

Chemical Engineering Department

Gin Juniper Berries

Whiskey Grains

IV. Raw Materials

Sugar

In making distilled spirits choosing the appropriate sugar source is first thing to do because your sugar

source will clearly tell what type of distilled spirits you will have when you have done all process needed

to have a certain spirits. Whiskeys, for example, start with a sugar sourced from the starch in cereal

grains (refer to step 3 to learn how starch becomes sugar). The style of whiskey is also largely

dependent on which grains, or combination of grains, are chosen; for instance, Bourbon is a mixed-

grain whiskey dominated by corn, while malt whiskeys are produced exclusively from malted barley.

Other spirits such as Brandies are produced from grapes and fruit, Rum is made from sugar cane or

sorghum molasses, and Tequila is made from the sweet nectar of the agave cactus.

Water

Fermentation

Pamantasan ng Lungsod ng MaynilaCollege of Engineering and Technology

Chemical Engineering Department

The second fundamental raw material, is water. Spirits are commonly 60% by volume, water, as such a

good spirit cannot be made from bad water. At CAS the water used in making our spirits is ultra-purified

using a sophisticated 7 stage treatment process. This level of treatment creates nearly pure H2O, to

which natural minerals are added, carefully adjusting the amount of each mineral to suit the spirit being

distilled.

Yeast

The third fundamental raw material, is the yeast. Yeast, not only creates the alcohol in spirits, but also

contribute in large part to the flavors associated with each spirit. Proprietary yeast strains are carefully

selected, to create unique flavor profiles for each spirit.

V. Unit ProcessingA. Preparation of Raw MaterialsHARVESTINGHarvesting is the most critical stage in producing distilled spirits because here in harvesting we need tochoose the raw material that will let us have our desired product also in harvesting we need to test thesugar content of each source of sugar because we don’t want a fruit to have small amount of sugarbecause that will not make the taste of the spirit good.

B. Conditioning of Raw MaterialsCOOKINGThere are types of distilled spirits that uses cooking to condition the raw material like in tequila and rum.In tequila the blue agave was burned for 40-72 hours so that the starch content of the blue agavebecome a simple sugar, In Rum making they commonly cook the juice they get from the sugar cane toconvert this to molasses

MILLING Raw materials are typically milled or crushed to make the starches in the grains, or the sugars in the

fruit,readily available for the mashing process and/or fermentation.

Juicing

They commonly do this conditioning with the distilled spirits that uses fruit as the sugar source. Like in

Tequila after they turn the cooked blue agave to fibers they juice it with the use of tahona. In some type

of brandy they also juice the product before they star the fermentation

Fermentation

Pamantasan ng Lungsod ng MaynilaCollege of Engineering and Technology

Chemical Engineering Department

MASHING

The Mashing Process has two primary functions: first it breaks up and dissolves starches and sugars

into water, secondly it converts any available starch into sugars. Starches are, simply put, long chains

of sugar molecules linked together, like a string of pearls. The Mashing Process breaks the starch into

individual sugars, similar to cutting up a string of pearls. The Mashing Process starts by heating water

to a specified temperature, and then adding milled grains. The mixture continues to heat until, small

crystals of starch in the grains begin to swell, burst and eventually dissolve into the water. Once all of

the starch has been dissolved, it is converted to sugar using natural enzymes (chemicals that act like

scissors) found in malted grains. The final product of mashing is a sweet liquid called called wort.

C. Heart Of The Process

FERMENTATION

The fermentation process varies by distillery, and there's a great deal of variation involved. At one

extreme is "natural fermentation," where yeasts inherent in the environment are relied upon to ferment

the sugars in open vats. At the other extreme, fermentation is tightly controlled under laboratory-like

conditions. For efficiency and predictability, most commercial rum fermentation processes fall between

these two extremes; distilleries purchase and add the specific yeast cultures they want and take basic

precautions appropriate to their environment. Time is also factor for fermentation; some ferments last

only several hours while others can take up to two weeks.

DISTILLATION

Distillation is the name of the process that allows us to separate the alcohol we’ve made through

fermentation from the rest of the non-alcoholic liquid. This increases the ABV (from say 15% alcohol to

something like 45% alcohol), while also changing the taste, flavour and removing the colour. Continuing

with the wine example – if we distil fermented grape juice (wine around 10-15% abv) then we end up

Fermentation

Pamantasan ng Lungsod ng MaynilaCollege of Engineering and Technology

Chemical Engineering Department

with Brandy (at around 40% abv). The more we distil, or the closer we get to pure ethanol, or 100%

alcohol, the less of the original flavours from the fermentation remain – we end up with what we

call neutral spirit, as it is relatively odourless and flavourless.

.

D. Refining ProcessMATURINGDuring maturation, spirits like Whiskey, Brandy, and others, undergo a transformation from a clear spirit,heavy in grain flavor, to a golden brown spirit complex in flavor. A majority of the flavor, and all of thecolor found in aged spirits comes from chemical compounds found in the wooden barrels used to storethe spirits. The most important flavor compounds are created when the barrel is charred. These flavorsinclude vanilla, caramel, smoke, and spices like cinnamon and cloves. Spirits are sampled regularly tomonitor the maturation process. Once a spirit has been deemed to have reached it’s peak maturation itis removed from the barrel and diluted to the appropriate alcohol content for bottling.

BLENDINGThe spirits produced by the distillation process are typically too high in alcohol to bottle directly, so thespirit is transferred to mixing tanks where it is combined with carefully crafted, ultra-pure water. Themixture is “proofed” or checked for alcohol content, and adjusted until the alcohol content is suitable forbottling, or transferring into barrels for maturation. Every batch undergoes a final quality check, basedon it's organoleptic profile (fancy term for taste and smell), before it is approved for bottling.

E. PackagingBOTTLINGOnce the spirits have been blended and proofed to the final alcohol content. They are ready for bottling.Each bottle is filled and labeled by hand, before being boxed, and sold to one of several retailestablishments ready to be enjoyed in your favorite cocktail.

VII. Process Flow Chart

Fermentation

Pamantasan ng Lungsod ng MaynilaCollege of Engineering and Technology

Chemical Engineering Department

VIII Flowchart A. Tequila Process Flowchart

Fermentation

Pamantasan ng Lungsod ng MaynilaCollege of Engineering and Technology

Chemical Engineering Department

Rum Making

Fermentation

Pamantasan ng Lungsod ng MaynilaCollege of Engineering and Technology

Chemical Engineering Department

Brandy Making

IX.Equipments:

Coa

Fermentation

Pamantasan ng Lungsod ng MaynilaCollege of Engineering and Technology

Chemical Engineering Department

A sharp edged blade that is commonly used by farmers to remove the nectar from the leaf so that the nectar can be processed

Tahona

A Big Rotating wheel that is used to juice the fibers of blueagave that will be fermented and turned the juice into an alocoholic beverages after the fermentation.

Juicer

A machine that extracts the juice from the fiber by addingwater while pressing down the fibers.

Distillery

Fermentation

Pamantasan ng Lungsod ng MaynilaCollege of Engineering and Technology

Chemical Engineering Department

Used to increase the alcoholic content of the fermented juice by boiling the mash then when the alcoholbecome a vapor the vapor will turn into a liquid because of a condenser.

Fermentation Tank

Fermentation tanks, also called bioreactors, used forindustrial fermentation processes are glass, metal orplastic tanks, equipped with gages and settings to controlaeration, stir rate, temperature, pH and other parametersof interest. Units can be small enough for bench-topapplications (5-10 L) or up to 10,000 L in capacity forlarge-scale industrial applications. Fermentation unitssuch as these are used in the pharmaceutical industry forthe growth of specialized pure cultures of bacteria, fungiand yeast, and the production of enzymes and drugs.

FERMENTATION OF CHEESE

Introduction

A dairy product is food produced from the milk of mammals. Dairy products are usually highenergy-yielding food products. Dairy product, milk and any of the foods made from milk, includingbutter, cheese, ice cream, yogurt, and condensed and dried milk. A production plant for the processingof milk is called a dairy or a dairy factory. Apart from breastfed infants, the human consumption of dairyproducts is sourced primarily from the milk of cows, yet goats, sheep, yaks, camels, and othermammals are other sources of dairy products consumed by humans. Dairy products are commonlyfound in European, Middle Eastern, and Indian cuisine, whereas aside from Mongolian cuisine they arelittle-known in traditional East Asian cuisine.

Fermentation

Pamantasan ng Lungsod ng MaynilaCollege of Engineering and Technology

Chemical Engineering Department

Milk has been a part of our nutrition since time immemorial. Around 10 000 BC, the “agriculturalrevolution” occurred changing societies from nomadic tribes to those who settled in communities. Withthis came domesticated animals and the ingenuity for people to use by-products such as milk. Inancient Egypt, milk and other dairy products were reserved for royalty, priests and the very wealthy. Bythe 5th century AD, cows and sheep in Europe were prized for their milk.

By the 14th century, cow’s milk became more popular than sheep’s milk. European dairy cowswere brought to North America in the early 1600s. Louis Pasteur, a French microbiologist, conductedthe first pasteurization tests in 1862. Pasteur is credited with revolutionizing the safety of milk and, inturn, the ability to store and distribute milk well beyond the farm. Commercial pasteurization machineswere introduced in 1895.

In 1884, the first milk bottle was invented in New York state. In the 1930s, milk cans werereplaced with large on-farm storage tanks, and plastic coated paper milk cartons were invented, whichallowed for wider distribution of fresh milk.

Definition of Terms

Fermentation is the decomposition of carbohydrates by bacteria and microorganisms to produce newproducts.

Pasteurization is the process of heating a food, which is usually a liquid, to a specific temperature for apredefined length of time and then immediately cooling it after it is removed from the heat. This processslows spoilage caused by microbial growth in the food.

Rennet is an enzyme that was traditionally collected from the stomach of a milk-fed calf (naturalrennet). This enzyme is responsible for the coagulation of the milk proteins to produce curds.

Brief History

CHEESE MANUFACTURING

Cheese is an ancient food whose origins predate recorded history. There is no conclusiveevidence indicating where cheese making was originated, either in Europe, Central Asia or the MiddleEast, but the practice had spread within Europe prior to Roman times and, according to Pliny the Elder,had become a sophisticated enterprise by the time the Roman Empire came into being.

The earliest evidence of cheese-making in the archaeological record dates back to 5,500 BCE,in what is now Kujawy, Poland, where strainers with milk fats molecules have been found. Earliestproposed dates for the origin of cheesemaking range from around 8000 BCE, when sheep were firstdomesticated. Since animal skins and inflated internal organs have, since ancient times, providedstorage vessels for a range of foodstuffs, it is probable that the process of cheese making wasdiscovered accidentally by storing milk in a container made from the stomach of an animal, resulting in

Fermentation

Pamantasan ng Lungsod ng MaynilaCollege of Engineering and Technology

Chemical Engineering Department

the milk being turned to curd and whey by the rennet from the stomach. There is a legend – withvariations – about the discovery of cheese by an Arab trader who used this method of storing milk.

Cheesemaking may have begun independently of this by the pressing and salting of curdledmilk to preserve it. Observation that the effect of making milk in an animal stomach gave more solid andbetter-textured curds may have led to the deliberate addition of rennet.

Early archeological evidence of Egyptian cheese has been found in Egyptian tomb murals,dating to about 2000 BCE. The earliest cheeses were likely to have been quite sour and salty, similar intexture to rustic cottage cheese or feta, a crumbly, flavorful Greek cheese.

Cheese produced in Europe, where climates are cooler than the Middle East, required less saltfor preservation. With less salt and acidity, the cheese became a suitable environment for usefulmicrobes and molds, giving aged cheeses their respective flavors.

Cheese Producing Companies

Companies Brief InformationEden Cheese is a product of MondelēzInternational, a new Company comprised ofthe global snacking and food brands of theformer Kraft Foods

Magnolia has been making every meal adelight for 30 years since it started in 1981 asa business unit of San Miguel Corporation'sMagnolia Ice Cream Division.Magnolia entered into a joint venture with NewZealand Dairy Board (NZDB) in 1987; namedas Philippine Dairy Products Corporation(PDPC); SMC owning 70% until in July 2002buying out NZDB share and became MagnoliaIncorporated, a subsidiary of San Miguel PureFoods Company.

Alaminos Goat Farm is known in the industryas the home of the most pampered boer goatsin the Philippines, Managed by Art Almeda, heimported his first batch of 30 heads of full-blood boer does and two award-winning full-

Fermentation

Pamantasan ng Lungsod ng MaynilaCollege of Engineering and Technology

Chemical Engineering Department

blood Boer bucks from Southern Australis inyear 2005.

CHEESE MANUFACTURING

Introduction

Cheese is a food derived from milk,produced in a wide range of flavors, textures, and forms. It comprises proteins and fat from milk, usuallythe milk of cows, buffalo, goats, or sheep. It is produced by coagulation of the milk protein casein.Typically, the milk is acidified and addition of the enzyme rennet causes coagulation. The solids areseparated and pressed into final form. Some cheeses have molds on the rind or throughout. Mostcheeses melt at cooking temperature.

Etymology

The word cheese comes from Latin caseus, from which the modern word casein is closelyderived. The earliest source is from the proto-Indo-European root kwat-, which means "to ferment,become sour”.

Classification of Cheese according to Moisture

1. Soft Cheese - examples are Brie, Comembre, Cottage and Cream

Fermentation

DIFFERENT KINDS OF CHEESE

Pamantasan ng Lungsod ng MaynilaCollege of Engineering and Technology

Chemical Engineering Department

2. Semisoft Cheese – examples are Limburger, Munster, Port du Salut and Roquefort

3. Hard Cheese – examples are Cheddar, Edem, Gruyere and Swiss

Fermentation

Pamantasan ng Lungsod ng MaynilaCollege of Engineering and Technology

Chemical Engineering Department

4. Very Hard Cheese – examples are Asiago, Parmesan, Romano and Sapsago

Cheddar Cheese

Cheddar cheese is a relatively hard, pale yellow to off-white (unless artificially coloured), andsometimes sharp-tasting, cheese. Originating in the English village of Cheddar in Somerset, cheeses ofthis style are produced beyond this region and in several countries around the world.

Raw Materials

Fermentation

Pamantasan ng Lungsod ng MaynilaCollege of Engineering and Technology

Chemical Engineering Department

1. Milk

The quality of cheese is influenced by the composition and quality of the raw milk. Onthe average, , cow milk consists of 3.7% fat, 3.4% protein, 4.8% lactose and 0.7% ash andhas a pH of (6.6). Milk is raw milk (whole or 3.3%). The milk must be "ripened" before addingin the rennet. The term ripening means allowing the Lactic acid bacteria (LAB) to turnlactose into lactic acid which lowers the pH of the solution, greatly aiding in the coagulationof the milk. This is vital for the production of cheese curds that are later formed intoCheddar. The milk of the cow is used in the production of cheddar cheese.

2. Rennet/chymosin/pepsin

Rennet is an enzyme that was traditionally collected from the stomach of a milk-fed calf(natural rennet). Animal based rennet typically contains 90% chymosin and 10% pepsin inpurified form and is considered by many cheese makers to be the preferred rennet. Differentratios are available such as 92-85% chymosin and 8-15% pepsin. This enzyme isresponsible for the coagulation of the milk proteins to produce curds. Cheese produced thisway is neither vegetarian nor Kosher. Coagulation can also be achieved using acids, butyields lower-quality Cheddar. The two key components of natural rennet are chymosin andbovine pepsin. Extracts from plants such as nettles were found to produce similar effects,and have been used in some types of cheese-making (vegetable rennet).

When calf-rennet grew scarce in the 1960s, scientists developed a synthesized type ofChymosin by fermenting certain bacteria or fungi (microbial rennet), but this also wasn'tuseful for all types of cheese-making.[clarification needed] A solution using recombinant-gene (GMO microbial rennet) technology was developed and approved by the U.S. Foodand Drug Administration in 1990. This splices the calf-gene for producing chymosin into thegenes of certain bacteria, yeasts or fungi, producing pure chymosin. Rennet is used in themanufacture of most ripened cheeses to hydrolyze the peptide bond and cause aggregationof casein micelles.

Cheese Making Reaction

Fermentation

Pamantasan ng Lungsod ng MaynilaCollege of Engineering and Technology

Chemical Engineering Department

Lactose is the major sugar in human and cow’s milk (4-8%). Lactose is a disaccharide of twomonosaccharides: galactose and glucose. The term saccharide comes from the Latin (saccharum,sugar) and refers to the sweet taste of some simple carbohydrates. Monosaccharides (or simplesugars, as they are sometimes called) are carbohydrates that cannot be hydrolysed to simplercompounds. Monosaccharides are classified according to the number of carbon atoms present.Galactose and glucose are both examples of a hexose as they both contain six carbon atoms. Glucoseis the most abundant natural monosaccharide. In lactose, C1 of the galactose unit is linked to thehydroxyl group at C4 of the glucose unit. During the ripening process (four weeks for ModernCamembert) a series of chemical and biological changes take place, including: proteolysis, lipolysis andglycolysis. One of the major products from the glycolytic biochemical pathway is lactic acid. The IUPACname of lactic acid is 2-hydroxypropanoic acid. Unlike lactose and its monosaccharide constituents,lactic acid has a chain structure. The structures of the four organic compounds discussed above aredisplayed in the figure below.

Key Idea: In compounds containingcarbon-hydrogen bonds (known asorganic compounds), the carbonatoms bind to one another throughsingle, double or triple covalentbonds to form chains or rings.

Process Flowchart

Fermentation

Pamantasan ng Lungsod ng MaynilaCollege of Engineering and Technology

Chemical Engineering Department

Unit Operation

Pasteurization

The raw milk is heated from about 10°C to at least 72°C is held for 15 s, and then isusually cooled to the separation temperature of about 55°C. Pasteurization is carried out to killbacteria in the milk. The mass of bacteria in milk is so small that it will be consideredinsignificant in this analysis.

Equipment Mechanism Reagent Usedand Feed

Product /Outcome

Pasteurizer The pasteurizerheats the raw milkfrom about 10°C toat least 72°C isheld for 15seconds, and thencooled to theseparationtemperature ofabout 55°C.

-there is noreagent used inpasteurization

-Pasteurized milkis the product ofthis process

Separation

Fermentation

Pamantasan ng Lungsod ng MaynilaCollege of Engineering and Technology

Chemical Engineering Department

Centrifugal separators are used to remove fat from whole milk. Practically all the fat inmilk is contained within fat globules which are surrounded by a protein-based fat globulemembrane. It is more accurate to consider that separators remove fat globules, rather than fat,from whole milk. The entire fat globule is less dense than the remainder of the milk. Within theseparation process skim milk can be considered as the heavy component and fat globules asthe light component. The heavy stream contains only about 0.06% of the light component whilethe light stream (cream) contains a mixture of light and heavy components.

Equipment Mechanism Reagent Used andFeed

Product /Outcome

Centrifugal Separator -The fat globulesare separated fromthe whole milkusing centrifugalforces. The heavymilk is tossed tothe side of theseparator and thecream is siphonedto be subjected todifferent processesto produce cheese.

-there is noreagent used inmilk separation.

-Fat globules andskim milk is theproduct of thisprocess.

Coagulation

Generally 3 to 4 oz. (85 to 110 g) of rennet are added per 1,000 lb. (450 kg) of mix. Therennet will serve to coagulate the milk protein and form curds. The vat must be mixedthoroughly after the addition of the rennet to ensure equal mixing, and it also helps to dilute therennet to make it easier to spread around.

Pure water is used when diluting the rennet as any pH that is not near 7 will rapidlydecrease the effectiveness of the rennet, as will chlorine. Thus, water with impurities will resultin a vastly decreased yield of cheese.

Fermentation

Pamantasan ng Lungsod ng MaynilaCollege of Engineering and Technology

Chemical Engineering Department

Equipment Mechanism Reagent Used andFeed

Product / Outcome

Cheese Vat The rennet willserve to coagulatethe milk protein andform curds. The vatmust be mixedthoroughly after theaddition of therennet to ensureequal mixing, and italso helps to dilutethe rennet to makeit easier to spreadaround.

3 to 4 oz. (85 to110 g) of rennet isadded per 1,000lb. (450 kg) of mix.

Pure water is usedwhen diluting therennet as any pHthat is not near 7will rapidlydecrease theeffectiveness ofthe rennet, as willchlorine.

Coagulated milk isthe product.

Setting the curd

Once the rennet is added, the mixture must be allowed to set and form curds. Themixture is kept at around 29 to 31 °C (84 to 88 °F). Generally temperature is controlled byflowing warm water through the jacket of the vat. Setting time varies, and allowing a properamount of time is vital. It commonly takes anywhere from 30 to 40 minutes to set the curd.

The most common way to determine when the curd is set is by inserting a flat blade at a45 degree angle into the curd and raising it slowly. If the curd breaks cleanly leaving a glassyfracture, it is ready for cutting. In a large Cheddar manufacturing facility, this may also be testedusing a viscometer.

Equipment Mechanism Reagent Usedand Feed

Product / Outcome

Cheese Vat The temperature -there is no The curd texture is the

Fermentation

Pamantasan ng Lungsod ng MaynilaCollege of Engineering and Technology

Chemical Engineering Department

is controlled byflowing warmwater through thejacket of the vat. Itcommonly takesanywhere from 30to 40 minutes toset the curd.

reagent used insetting of curd.

product .

Cutting the curd

The curd is cut into 0.63-to-1.59-centimetre (0.25 to 0.63 in) cubes using stainless steelwire knives. A smaller cube size means the cheese will be lower moisture whereas a larger cubesize will result in a high moisture cheese.

It is important that cutting time is minimized and that the cuts be clean. The best way todetermine how efficient the cutting job was is to determine the fat content of the whey. Theoptimal level of fat content of whey is 0.3% fat or less.

The curds are handled gently after cutting to prevent fat and protein loss to the whey.The curd is prevented from sticking to the sides of the vat, but minimal agitation is desired. Thecurds are allowed to set again for 10 to 15 minutes. Fat and protein loss may affect the ability ofthe cheese to be considered Cheddar cheese, depending on the region where it is created.

Equipment Mechanism Reagent Used andFeed

Product / Outcome

Stainless Steel Knives Stainless steelknives are used touniformly cut thecurds at variouspoints during theprocess. The deviceis basically a

-there is no reagentused in cutting ofcurds.

0.63 to 1.59centimeter cubes ofcurd is the product.

Fermentation

Pamantasan ng Lungsod ng MaynilaCollege of Engineering and Technology

Chemical Engineering Department

stainless steel framewith stainless steelwires, which cutsthe curd cleanly

Cooking the curd

The curd is cooked by adding hot water to the jacket of the vat (up to 39 °C (102 °F)).The curd is stirred constantly during this step to avoid uneven cooking or overcooking, and thecooking will only take 20–60 minutes. The whey's pH will be around 6.1 to 6.4 by the end of thecooking.

Equipment Mechanism Reagent Used andFeed

Product / Outcome