EQUIPMENT CATALOGUEeng.aospg.ru/media/1570/promintech-catalog.pdf · PN 1,6-25,0 MPa (Class 150 –...

Transcript of EQUIPMENT CATALOGUEeng.aospg.ru/media/1570/promintech-catalog.pdf · PN 1,6-25,0 MPa (Class 150 –...

THE PRODUCTION OF OIL AND GAS EQUIPMENT

EQUIPMENT CATALOGUE of ProEnTech Plant . 2017

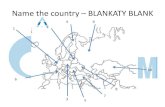

Siberian Industrial Group JSC is an industrial group of companies which includes the following divisions: management, production, engineering-Innovational and trading.

www.aospg.ru

PromInTech Plant is a machine-building enterprise which manufacturing a wide range of shut-off and control valves, including increased operational reliability.

www.proentech.ru

Izhevsk Isolation Plant is a manufacturer of pipes with internal and external corrosion-resistant coating for the oil and gas industry.

www.izitech.ru

TVEL-Tobolsk is one of the oldest, largest, and most advanced manufacturers of insulated pipes and pipeline fittings in Russia.

www.tvel-tobolsk.com

The trading house Siberian Industrial Holding is an authorized and exclusive agent that sales pipe products and metal structures on the territory of the Russian Federation and abroad.

www.sp-holding.ru

ProEnTech Plant — is the main enterprise of the mechanical-

engineering division of Siberian Industrial Group JSC.

STRUCTURE OF THE HOLDING:

The trading house Siberian Industrial Group - is a company that engages the supply of shut-off and control valves and pipe products.

Содержание

About the company ..................................................................................................................................................................................... 2

Why ProEnTech Plant .................................................................................................................................................................................. 3

Certificates of ProEnTech Plant ............................................................................................................................................................ 4

Our capabilities ............................................................................................................................................................................................... 6

Ball Valves of ProEnTech Plant ............................................................................................................................................................ 7

Technical specifications ............................................................................................................................................................................ 9

PIT-R demountable corps ..................................................................................................................................................................... 10

PIT-T corps with upper access ........................................................................................................................................................... 14

PIT-C all-welded corps ............................................................................................................................................................................ 18

Special applications ................................................................................................................................................................................... 22

Quality control and testing ................................................................................................................................................................... 23

Contact details ............................................................................................................................................................................................. 24

CONTACT DETAILS

Address: Nauchnii Proezd, 14A, building 1, office 2.2, Moscow, Russia, 117246

Tel/Fax: +7 (499) 272-33-20

PLANT

Address: Severnaya Street, 13, Podolsk, Russia, 142103

Tel/Fax: +7 (499) 272-33-20

2

About the company ProEnTech Plant — production, engineering company, offering

complex solutions in the production, total overhaul, testing,

service and warranty service of oil and gas equipment. The

company specializes in the production of heavy industrial

valves - ball valves for operation under high pressure up

to 25 MPa, at high temperatures up to 625˚C, as well

as at ultra-low temperatures down to -196˚C, and for

operation with media with high concentration of methanol,

hydrogen sulfide, carbon dioxide and abrasive particles.

Our plant is equipped with all necessary

equipment, which allows assemble and test ball

valves without involving of third parties.

EQUIPMENT AND SERVICES:

Side-entry ball valves, top-entry ball

valves, fully-welded ball valves

Pneumatic, pneumohydraulic, electric

and electro-hydraulic actuators

Control ball valves

Rerair of ball valves

INDUSTRIES:

Oil&Gas

Oil refining

Gas refining

Electric-power industry

Transmission of hydrocarbon

Chemical industry

Nuclear Industry

LNG

MAIN APPLICATIONS:

Offshore platforms

Subsurface gas storages

Group of gas wells

Group of oil wells

Petroleum processing plants

Gas processing plants

Mainline pipeline

Pump/compression stations

Gas treating systems

LNG processing systems

ProEnTech Plant

production, engineering company, offering engineering

solutions for applications in various fields of industry.

3

Why ProEnTech Plant

IMPORT SUBSTITUTION

Using the advanced technologies of European

manufacturers of valves, we use exclusively

Russian components in the main assemblies

for the production of ball valves.

INNOVATION

We are always in search of new engineering

solutions for our Customers.

FLEXIBILITY

In the production of ball valves we follow

all Customer requirements for the design

and material design of ball valves.

SERVICE & REPAIR

Highly qualified employees and plant modern

equipment allows us to produce repair of

ball valves using own production facilities.

4

Certificates of ProEnTech Plant

5

6

Our capabilities

DESIGN DOCUMENTS

The design center of the ProEnTech Plant comprises highly

qualified employees, has own developments in the production

of ball valves. When designing and assembling we use upgraded

technologies and developments of the European and domestic

manufacturers to ensure the highest quality of ball valves since

the beginning stages of design:

• solid modeling

• finite element analyses

• fluid dynamic analyses

• stress analyses

Our researches in the field of manufacturing of

valves and constant testing of new materials for

using in different ball valve’s units help us to satisfy

the most stringent Customer requirements.

MANUFACTURING

Our plant is equipped with all necessary equipment,

which allows assemble and test ball valves

without involving of third parties.

Our factory produces following operations:

• mechanical restoration

• сassembling

• welding

• non-destructive testing

• hydraulic and pneumatic testing

• dyeing and and covering

with protective coatings

7

Ball Valves of ProEnTech PlantOur ball valves are produced in accordance with the technical specifications

of LLC ProEnTech Plant «TC 3742-002-17871972-2014 BALL VALVES DN 50 – 1000 (NPS 2” - 40”)

PN 1,6-25,0 MPa (Class 150 – 1500)», «STO Gazprom 2-4.1-212-2008 General technical requirements

for valves supplied to JSC Gazprom»; «ST CKBA 052-2008 Pipeline fittings. Requirements

for the materials of valves used in hydrogen sulfide-containing media»; «API 6D Specification

for Pipeline Valves»; «GOST 21345-2005 Ball, lifting-plug and cylindrical cocks for nominal pressure

at most PN250. General specifications» and other Russian and international standards.

TECHNICAL SPECIFICATIONS:

OUR PRODUCT:

PIT R PIT T PIT C

ANSI 150(1,6 MPа)

ANSI 300(5,0 MPа)

ANSI 600(10,0 MPа)

ANSI 900(15,0 MPа)

ANSI 1500(25,0 MPа)

PIT R 2” до 40”(50-1000mm)

2” до 40”(50-1000mm)

2” до 40”(50-1000mm)

2” до 40”(50-1000mm)

2” до 36”(50-900mm)

PIT Т2” до 40”

(50-1000mm)2” до 40”

(50-1000mm)2” до 40”

(50-1000mm)2” до 40”

(50-1000mm)2” до 36”

(50-900mm)

PIT C2” до 40”

(50-1000mm)2” до 40”

(50-1000mm)2” до 40”

(50-1000mm)2” до 40”

(50-1000mm)2” до 36”

(50-900mm)

Size ranges&pressure ratings:

* PIT R — side-entry ball valve

* PIT T — top-entry ball valve

* PIT C — fully-welded ball valve

8

9

Technical specifications

TEMPERATURE RANGE

• Low temperature down to - 196˚С;

• High temperature up to 625˚С;

OPERATION

Manual lever, gearbox, actuator

(electric, pneumatic, hydraulic, gas-over-oil actuator)

MATERIAL CONSTRUCTION OF BALL VALVES

BODY BALL/SEATS STEM SEATING SEALS BOLTING

CARBON STEEL

А105WCBLCCLF2LF3

F60 / F65ст20

09Г2С

STAINLESS STEEL

31632134713Сr

13Cr4Ni17-4PH6Mo

12x18H10T

DUPLEX STEELSUPERDUPLEX HC,

NICKEL ALLOYS

Inconel Monel

TITANIUM

CARBON STEEL

А105LF2LF3

F60 / F65ст20

09Г2С

STAINLESS STEEL

31632134713Сr

13Cr4Ni17-4PH6Mo

10X17H13M3T

DUPLEX STEELSUPERDUPLEX HC,

NICKEL ALLOYS

Inconel Incoloy Monel Stellite

TITANIUM

CARBON STEEL

4140LF3

F60 / F6509Г2С

STAINLESS STEEL

31613Сr

13Cr4Ni17-4PH6Mo

12X18H10T

DUPLEX STEELSUPERDUPLEX HC,

NICKEL ALLOYS

Inconel Incoloy Monel Stellite

TITANIUM

SOFT SEATING

RPTFENYLONPEEKPCTFE

METAL SEATING

TCCENPCCC

Ni-SiC

SOFT SEATING

RPTFEFKMHNBRFFKM

Graphite

УГЛЕРОДИСТАЯ СТАЛЬ

B7/2HL7/7

B7M / 2HML7M / 7ML43 / 720XH3A

STAINLESS STEEL

B8/8B8M/8M

660

SUPERDUPLEX HC

NICKEL ALLOYS

Inconel

TITANIUM

Material selection:

10

PIT-R demountable corps The body is made of two or three parts and the ball is supported by trunnion or no

retainers held by end adaptors. In such a way, the line pressure loads are transferred

to the valve body granting a smooth rotation of the ball with low torque values.

One of the most common and trusted designs used in the Oil&Gas industry.

The bolted body construction grants high field maintainability (easy removal of the valve body from

the pipeline for inspection and one-site maintenance) and allows the use of forged components

in various grades of CS, SS and exotic materials )suitable to severe service conditions).

Competitiveness in terms of costs and delivery deadlines.

Design in accordance with API 6D/6A/6DSS/17D.

Manual or actuated configuration.

008008

012

210

207

006

302004

104

305

306

025

503

212

101

300

050

301

215

215

007

304 213

103502045

013

303

046

209

021

048

011201

204206

044

001 BODY004 CLOSURE006 BODY COVER007 TRUNNION COVER008 BALL011 SEAT RING W/INSERT012 STEM013 TRUNNION021 SPACER RING025 OPERATOR FLANGE044 SEAT SPRING045 ANTI STATIC DEVICE046 DOWEL PIN048 OPERATOR FLANGE PIN050 STEM KEY101 STEM WASHER103 LOW FRICTION BEARING104 LOW FRICTION STEM BEARING201 SEAT SEAL204 BODY SEAL206 BODY FIRE SAFE GASKET207 STEM SEAL209 STEM FIRE SAFE GASKET210 BODY COVER SEAL212 BODY COVER FIRE SAFE GASKET213 TRUNNION COVER SEAL215 TRUNNION COVER FIRE SAFE GASKET300 STEM KEY CAPSCREW

301 BODY STUD302 BODY NUT303 BODY COVER BOLT304 TRUNNION COVER BOLT305 OPERATOR MOUNTING STUD306 OPERATOR MOUNTING NUT501 VENT PLUG502 BLEED VALVE503 STEM GREASE FITTING

201 SEAT SEAL204 BODY SEAL206 BODY FIRE SAFE GASKET207 STEM SEAL209 STEM FIRE SAFE GASKET210 BODY COVER SEAL212 BODY COVER FIRE SAFE GASKET213 TRUNNION COVER SEAL215 TRUNNION COVER FIRE SAFE GASKET

RECOMMENDED SPARE PARTS FOR START-UP AND MAINTENANCE

BILL OF MATERIALS

11

ED

F

L RTJL RF

L BW

DNPS DN

D L BW L RF L RTJ E F Вес, kgmm BW RF, RTJ

2" 50 49 216 178 191 93 118 21 27

3" 80 74 283 203 216 108 133 40 45

4" 100 100 305 229 241 128 210 58 69

6" 150 152 457/403 394 406 231 245 145 170

8" 200 203 521/502 457 470 277 288 245 270

10" 250 254 559/568 533 546 310 331 320 354

12" 300 305 635/648 610 622 344 368 560 610

14" 350 337 762 686 699 370 393 860 925

16" 400 387 838 762 775 415 437 1036 1206

20" 500 489 991 914 927 491 515 1758 1832

28" 700 686 1346/1650 1245 — 675 683 4250 4533

40" 1000 978 1780/2250 1850 — 928 943 10 260 10 872

PIT-R demountable corps

PN 16 — Class 150

L-RF — construction length with flanges according to GOST 54432-2011. Исп. В / ASME B16.5 RF

L-RTJ — construction length with flanges according to GOST 54432-2011 Исп. J / ASME B16.5 RTJ

L-BW — construction length with weld ends

12

ED

F

L RTJL RF

L BW

D

NPS DND L BW L RF L RTJ E F Вес, kg

mm BW RF, RTJ2" 50 49 216 216 232 93 118 21 28

3" 80 74 283 283 298 108 133 41 55

4" 100 100 305 305 321 128 210 78 59

6" 150 152 457/419 403 419 231 245 145 178

8" 200 203 521/502 502 518 277 288 245 293

10" 250 254 559/568 568 584 310 331 320 392

12" 300 305 635/648 648 664 344 368 560 660

14" 350 337 762 762 778 370 393 860 990

16" 400 387 838 838 854 415 437 1036 1286

20" 500 489 991 991 1010 491 515 1758 1928

28" 700 686 1346/1650 1346 1372 675 683 4250 4533

40" 1000 978 1780/2250 1850 — 928 943 10 260 10 872

NPS DND L BW L RF L RTJ E F Вес, kg

mm BW RF, RTJ2" 50 49 292 292 295 93 125 25 31

3" 80 74 356 356 459 113 148 53 78

4" 100 100 432 432 435 130 200 71 100

6" 150 152 559 559 562 237 249 152 208

8" 200 203 660 660 664 277 297 295 378

10" 250 254 787 787 791 314 337 420 560

12" 300 305 838 838 841 355 378 663 824

14" 350 337 889 889 892 381 400 923 1080

16" 400 387 991 991 994 427 448 1434 1714

20" 500 489 1194 1194 1200 500 538 2250 2664

28" 700 686 1549 1549 1562 675 690 5420 5800

40" 1000 978 1900 2000 — 943 955 13 210 14 355

PIT-R demountable corps

PN 40 (50) — Class 300

PN 63 — Class 400 / PN 100 — Class 600

L-RF — construction length with flanges according to GOST 54432-2011. Исп. В / ASME B16.5 RF

L-RTJ — construction length with flanges according to GOST 54432-2011 Исп. J / ASME B16.5 RTJ

L-BW — construction length with weld ends

13

ED

F

L RTJL RF

L BW

D

NPS DND L BW L RF L RTJ E F Вес, kg

mm BW RF, RTJ2" 50 49 368/350 368 371 102 135 40 63

3" 80 74 381/450 381 384 113 148 69 83

4" 100 100 457/520 457 460 130 225 140 157

6" 150 152 610/700 610 613 288 255 230 286

8" 200 203 737/800 737 740 333 295 345 440

10" 250 254 838/900 838 841 376 357 560 720

12" 300 305 965/1050 965 968 419 386 770 990

14" 350 337 1029 1029 1038 453 420 950 1220

16" 400 387 1130 1130 1140 487 471 1150 1610

20" 500 489 1321 1321 1334 565 547 2860 3480

28" 700 686 1600 1600 1682 746 757 6030 7370

40" 1000 978 2100 2180 — 1013 1007 15 240 18 580

NPS DND L BW L RF L RTJ E F Вес, kg

mm BW RF, RTJ2" 50 49 368 368 371 102 135 52 99

3" 80 74 470 470 473 125 158 88 115

4" 100 100 546 546 549 152 203 160 180

6" 150 146 705 705 711 333 300 330 400

8" 200 194 832 832 841 388 350 615 735

10" 250 241 991 991 1000 446 427 925 1120

12" 300 289 1130 1130 1146 503 470 1300 1550

14" 350 318 1257 1257 1276 569 522 1600 1915

16" 400 362 1384 1384 1407 629 598 1950 2350

20" 500 454 1664 1664 1686 725 692 3715 4455

28" 700 635 2198 2198 2251 973 969 8020 9650

PIT-R demountable corps

PN 125/PN 160 — Class 900

PN 250 — Class 1500

L-RF — construction length with flanges according to GOST 54432-2011. Исп. В / ASME B16.5 RF

L-RTJ — construction length with flanges according to GOST 54432-2011 Исп. J / ASME B16.5 RTJ

L-BW — construction length with weld ends

14

PIT-T corps with upper access This configuration featuring a cast or forged body closed by a bolted

bonnet allows to minimize the number of potential leak paths.

Full in-line service and maintenance. Without dismantling the valve from the pipeline,

the removal of the bonnet allows free access to the body cavity, where ball and seats

can be also dislodged, serviced and re-assembled with a set of maintenance tools.

Upon completion of in-line maintenance the integrity of the seat seals

can be easily checked by pressurizing the body cavity.

The body is sized to grant maximum rigidity against pipeline

forces even when the trim is removed for service.

The valve can be welded directly to the pipeline assembly.

Suitable for critical service conditions where on-site field reparability and quick

turnaround are needed or in areas where space is limited, such as platform decks.

A design for installation on vertical pipes with horizontal stem (e.g. platforms risers) is available.

Design in accordance with API 6D/6A/6DSS/17D.

Manual or actuated configuration.

559008

504

505

001

103

102011201076

044342

077

258 253 020

045

300

005

049

506

212

503

207

021

303

025

306

050

048

306

046

209

006

210

302

301

204

101

206

103

012

001 BODY005 BONNET006 BODY COVER008 BALL011 SEAT RING W/INSERT012 STEM020 SPRING HOLDER RING021 SPACER RING025 OPERATOR FLANGE044 SEAT SPRING045 ANTI STATIC DEVICE046 DOWEL PIN048 OPERATOR FLANGE PIN049 BONNET PIN050 STEM KEY076 BACK SEAT SEAL077 SPACER101 STEM WASHER 102 TRNNION WASHER103 LOW FRICTION BEARING201 SEAT SEAL204 BODY SEAL206 BODY FIRE SAFE GASKET207 STEM SEAL209 STEM FIRE SAFE GASKET210 BODY COVER SEAL212 BODY COVER FIRE SAFE GASKET253 PISTON SEAT GREASE INJECTION SEAL258 SPRING HOLDER RING SEAL300 STEM KEY CAPSCREW301 BODY STUD302 BODY NUT303 BODY COVER BOLT

305 OPERATOR FLANGE STUD306 GEAR MOUNTING NUT342 SEAT PLATE BOLT503 STEM GREASE FITTING504 SEAT GREASE FITTING505 CHECK VALVE506 SAFETY RELIEF VALVE 559 SEAT PLATE

076 BACK SEAT SEAL201 SEAT SEAL204 BODY SEAL206 BODY FIRE SAFE GASKET 207 STEM SEAL209 STEM FIRE SAFE GASKET210 BODY COVER SEAL212 BODY COVER FIRE SAFE GASKET253 PISTON SEAT GREASE INJECTION SEAL258 SPRING HOLDER RING SEAL

RECOMMENDED SPARE PARTS FOR START-UP AND MAINTENANCE

BILL OF MATERIALS

15

NPS DND L BW L RF L RTJ E F

Вес, kgmm

2" 50 49 292 292 295 85 207 30

3" 80 74 356 356 359 114 223 57

4" 100 100 432 432 435 140 280 100

6" 150 150 559 559 562 219 275 215

8" 200 201 660 660 664 265 321 470

10" 250 252 787 787 791 315 355 560

12" 300 303 838 838 841 405 470 710

14" 350 334 889 889 892 432 455 760

16" 400 385 991 991 994 451 460 1100

20" 500 487 1194 1194 1200 560 560 1930

28" 700 684 1549 1549 1562 710 730 4600

40" 1000 976 2337 2337 2337 1030 1012 12 790

PN 16 — Class 150

PIT-T corps with upper access

D

L

EF

L-RF — construction length with flanges according to GOST 54432-2011. Исп. В / ASME B16.5 RF

L-RTJ — construction length with flanges according to GOST 54432-2011 Исп. J / ASME B16.5 RTJ

L-BW — construction length with weld ends

16

PIT-T corps with upper access

PN 40 — Class 300

PN 63 — Class 400 / PN 100 — Class 600

NPS DND L BW L RF L RTJ E F

Вес, kgmm

2" 50 49 292 292 295 90 211 36

3" 80 74 356 356 359 119 226 63

4" 100 100 432 432 435 145 286 106

6" 150 150 559 559 562 224 282 221

8" 200 201 660 660 664 270 325 412

10" 250 252 787 787 791 320 360 566

12" 300 303 838 838 841 410 475 715

14" 350 334 889 889 892 437 460 766

16" 400 385 991 991 994 456 465 1106

20" 500 487 1194 1194 1200 565 565 1936

28" 700 684 1549 1549 1562 715 738 4607

40" 1000 976 2337 2337 2337 1036 1020 12 798

NPS DND L BW L RF L RTJ E F

Вес, kgmm

2" 50 49 292 292 295 85 240 41

3" 80 74 356 356 359 116 305 67

4" 100 100 432 432 435 140 275 230

6" 150 150 559 559 562 180 296 420

8" 200 201 660 660 664 275 324 417

10" 250 252 787 787 791 325 365 570

12" 300 303 838 838 841 415 480 720

14" 350 334 889 889 892 442 465 770

16" 400 385 991 991 994 461 470 1112

20" 500 487 1194 1194 1200 570 570 1940

28" 700 684 1549 1549 1562 722 742 4612

40" 1000 976 2169 2169 2169 1041 1025 12 850

D

L

EF

L-RF — construction length with flanges according to GOST 54432-2011. Исп. В / ASME B16.5 RF

L-RTJ — construction length with flanges according to GOST 54432-2011 Исп. J / ASME B16.5 RTJ

L-BW — construction length with weld ends

17

PIT-T corps with upper access

PN 125, PN 160

PN 250

NPS DND L BW L RF L RTJ E F

Вес, kgmm

2" 50 49 368 368 371 110 295 52

3" 80 74 381 381 384 122 230 110

4" 100 100 457 457 460 154 283 200

6" 150 150 610 610 613 203 329 430

8" 200 201 737 737 740 245 375 800

10" 250 252 838 838 841 275 431 1000

12" 300 303 965 965 968 322 511 1300

14" 350 322 1029 1029 1038 443 520 1695

16" 400 373 1130 1130 1140 390 582 2560

20" 500 471 1321 1321 1334 605 625 4400

28" 700 665 1753 1753 1775 723 820 10 400

40" 1000 956 - - - - - -

NPS DND L BW L RF L RTJ E F

Вес, kgmm

2" 50 49 368 368 371 100 201 56

3" 80 74 470 470 473 122 230 153

4" 100 100 546 546 549 164 293 278

6" 150 144 705 705 711 416 245 600

8" 200 192 832 832 841 273 465 1100

10" 250 239 991 991 1000 330 574 1438

12" 300 287 1130 1130 1146 427 520 2017

14" 350 315 1257 1257 1276 456 550 2612

16" 400 360 1384 1384 1407 487 565 3890

20" 500 454 1664 1664 1686 630 650 6678

28" 700 546 1945 1945 1972 640 660 11 700

D

L

EF

L-RF — construction length with flanges according to GOST 54432-2011. Исп. В / ASME B16.5 RF

L-RTJ — construction length with flanges according to GOST 54432-2011 Исп. J / ASME B16.5 RTJ

L-BW — construction length with weld ends

18

PIT-C all-welded corps 3-piece design with no bolted bonnet or body joints, which reduces the quantity of potential leak paths.

Typically used for applications where maintenance is not required, like

gas transmission pipelines, underground/remote installations, subsea lines.

The split body design arrangement allows for the use of forged materials in various grades

(CS, SS, exotic materials) complying with the most severe service condition.

The forged design is typically used for high-pressure valves and critical applications where the

integrity of the pressure envelope is of paramount importance. It allows to save valve weight

in applications where the weight of the equipment significantly impact on the installation.

Design in accordance with API 6D/6A/6DSS/17D.

Manual or actuated configuration.

051004

047

001

502

052

501

045

050

212

006

303

046

306025

305

048

503

209

021

101

012

015103

008044

011201

210

207

001 BODY004 CLOSURE006 BODY COVER008 BALL011 SEAT RING W/INSERT012 STEM015 BEARING RETAINER021 SPACER RING025 OPERATOR FLANGE044 SEAT SPRING045 ANTI STATIC DEVICE046 DOWEL PIN047 BEARING RETAINER PIN048 OPERATOR FLANGE PIN050 STEM KEY051 LIFTING LUG052 VALVE SUPPORT101 STEM WASHER102 TRUNNION WASHER103 LOW FRICTION BEARING201 SEAT SEAL207 STEM SEAL

209 STEM FIRE SAFE GASKET210 BODY COVER SEAL212 BODY COVER FIRE SAFE GASKET303 BODY COVER BOLT305 OPERATOR MOUNTING STUD306 GEAR MOUNTING NUT501 VENT PLUG502 DRAIN PLUG503 STEM GREASE FITTING

207 STEM SEAL209 STEM FIRE SAFE GASKET210 BODY COVER SEAL212 BODY COVER FIRE SAFE GASKET

RECOMMENDED SPARE PARTS FOR START-UP AND MAINTENANCE

BILL OF MATERIALS

19

PN 16 — Class 150

PIT-C all-welded corps

ED

F

L RTJL RF

L BW

DNPS DN

D L BW L RF L RTJ E F Вес, kgmm BW RF, RTJ

2" 50 49 216 178 191 93 118 21 27

3" 80 74 283 203 216 108 133 40 45

4" 100 100 305 229 241 128 210 58 69

6" 150 152 457/403 394 406 231 245 145 170

8" 200 203 521/502 457 470 277 288 245 270

10" 250 254 559/568 533 546 310 331 320 354

12" 300 305 635/648 610 622 344 368 560 610

14" 350 337 762 686 699 370 393 860 925

16" 400 387 838 762 775 415 437 1036 1206

20" 500 489 991 914 927 491 515 1758 1832

28" 700 686 1346/1650 1245 — 675 683 4250 4533

40" 1000 978 1780/2250 1850 — 928 943 10 260 10 872

L-RF — construction length with flanges according to GOST 54432-2011. Исп. В / ASME B16.5 RF

L-RTJ — construction length with flanges according to GOST 54432-2011 Исп. J / ASME B16.5 RTJ

L-BW — construction length with weld ends

20

PIT-C all-welded corpss

PN 40 (50) — Class 300

PN 63 — Class 400 / PN 100 — Class 600 E

DF

L RTJL RF

L BW

D

NPS DND L BW L RF L RTJ E F Вес, kg

mm BW RF, RTJ2" 50 49 216 216 232 93 118 21 28

3" 80 74 283 283 298 108 133 41 55

4" 100 100 305 305 321 128 210 78 59

6" 150 152 457/419 403 419 231 245 145 178

8" 200 203 521/502 502 518 277 288 245 293

10" 250 254 559/568 568 584 310 331 320 392

12" 300 305 635/648 648 664 344 368 560 660

14" 350 337 762 762 778 370 393 860 990

16" 400 387 838 838 854 415 437 1036 1286

20" 500 489 991 991 1010 491 515 1758 1928

28" 700 686 1346/1650 1346 1372 675 683 4250 4533

40" 1000 978 1780/2250 1850 — 928 943 10 260 10 872

NPS DND L BW L RF L RTJ E F Вес, kg

mm BW RF, RTJ2" 50 49 292 292 295 93 125 25 31

3" 80 74 356 356 459 113 148 53 78

4" 100 100 432 432 435 130 200 71 100

6" 150 152 559 559 562 237 249 152 208

8" 200 203 660 660 664 277 297 295 378

10" 250 254 787 787 791 314 337 420 560

12" 300 305 838 838 841 355 378 663 824

14" 350 337 889 889 892 381 400 923 1080

16" 400 387 991 991 994 427 448 1434 1714

20" 500 489 1194 1194 1200 500 538 2250 2664

28" 700 686 1549 1549 1562 675 690 5420 5800

40" 1000 978 1900 2000 — 943 955 13 210 14 355

L-RF — construction length with flanges according to GOST 54432-2011. Исп. В / ASME B16.5 RF

L-RTJ — construction length with flanges according to GOST 54432-2011 Исп. J / ASME B16.5 RTJ

L-BW — construction length with weld ends

21

PIT-C all-welded corps

PN 125, PN 160

PN 250E

DF

L RTJL RF

L BW

D

NPS DND L BW L RF L RTJ E F Вес, kg

mm BW RF, RTJ2" 50 49 368/350 368 371 102 135 40 63

3" 80 74 381/450 381 384 113 148 69 83

4" 100 100 457/520 457 460 130 225 140 157

6" 150 152 610/700 610 613 288 255 230 286

8" 200 203 737/800 737 740 333 295 345 440

10" 250 254 838/900 838 841 376 357 560 720

12" 300 305 965/1050 965 968 419 386 770 990

14" 350 337 1029 1029 1038 453 420 950 1220

16" 400 387 1130 1130 1140 487 471 1150 1610

20" 500 489 1321 1321 1334 565 547 2860 3480

28" 700 686 1600 1600 1682 746 757 6030 7370

40" 1000 978 2100 2180 — 1013 1007 15 240 18 580

NPS DND L BW L RF L RTJ E F Вес, kg

mm BW RF, RTJ2" 50 49 368 368 371 102 135 52 99

3" 80 74 470 470 473 125 158 88 115

4" 100 100 546 546 549 152 203 160 180

6" 150 146 705 705 711 333 300 330 400

8" 200 194 832 832 841 388 350 615 735

10" 250 241 991 991 1000 446 427 925 1120

12" 300 289 1130 1130 1146 503 470 1300 1550

14" 350 318 1257 1257 1276 569 522 1600 1915

16" 400 362 1384 1384 1407 629 598 1950 2350

20" 500 454 1664 1664 1686 725 692 3715 4455

28" 700 635 2198 2198 2251 973 969 8020 9650

L-RF — construction length with flanges according to GOST 54432-2011. Исп. В / ASME B16.5 RF

L-RTJ — construction length with flanges according to GOST 54432-2011 Исп. J / ASME B16.5 RTJ

L-BW — construction length with weld ends

22

Special applications

HIGH TEMPERATURE +220˚C TO +625˚C

• Side-entry and top-entry configurations

• Cast or forged construction

• Extended bonnet for insulation allowance

• Metal and graphite seals

• Built-in firesafe design

• Adjustable stem packing with live load which

guarantees performance also under thermal cycles

• Anti-friction coating on seating surfaces

for torque requirements

• Materials compliant with stricter requirements

• Selection of hard facing technologies (ENP, CCC, NiSic)

suitable for any service

LOW TEMPERATURE DOWN TO -196˚C

• Side-entry and top-entry configurations

• Cast or forged construction

• Extended bonnet with vapor space to maintain

the stem packing within the suitable temperature range

• Enhanced seat and seal design to guarantee leak tightness

• Anti-friction coating on seating surfaces

for torque requirements

• Compliance with FE standards - noncontrolled

discharge of pollutants into the atmosphere

• Materials compliant with stricter requirements

• Additional inspection and testing

MEDIUM WITH A HIGH CONTENT OF HYDROGEN SULPHIDE

• Side-entry configurations

• Forged construction

• Body closure with overlaying in the contact areas of seals

• Metal and graphite seals

• Built-in firesafe design

• Anti-friction coating on seating surfaces

for torque requirements

• Materials compatible with the requirements

of CKBA 052-2008; NACE MR0175; ISO 15156

• Selection of hard facing technologies (ENP, CCC, NiSic)

suitable for any service

23

Quality control and testingThe plant has a multistage quality control system, beginning with individual operations, component

parts, assemblies and finishing with the end product. Quality control is carried out by the Quality Control

Department accordance with the requirements of design, regulatory and technical documentation.

We strive to meet the most stringent Customer requirements in verifying our products in accordance

with technical specifications due to comprehensive tests on such parameters as fire resistance,

operation at extremely low temperatures down to -196˚C, uncontrolled atmospheric emissions, durability,

high gas pressure and many others. We carry out entrance control of 100% of the components

and materials supplied to our plant.

PRODUCT STANDARDS AND CUSTOMER SPECIFIC TESTS

STANDARD OPTIONAL

• Stem leakage test

• Hydrostatic Body Test

• Hydrostatic Seat Test

• Low Pressure Air Test

• Pressure Relief from the Cavity Test

• Functional Test

• Anti-static Test

• Torque Test

• Endurance Test (cycling)

• Double Isolation and Bleed Test

• High Pressure Air Test

• Drive Gear Strength Test

• Fugitive Emission Test

• Low Temperature/Cryogenic Test

• High Temperature Test

• Type-approval test to MESC 77/300A

• Firesafe Test

• Hyperbaric Test

• Others

24

Service Professionals of the ProEnTech Plant carry out regular service and post-warranty aintenance of manufactured

ball valves. Also on the basis of the ProEnTech Plant any manufacturer’s ball valves for oil and gas industry

pipeline systems are repaired using components manufactured by both Russian and foreign companies.

OUR FACTORY PRODUCES FOLLOWING TYPES OF REPAIR WORKS

Dismantling/Cutting

Replacement Of Seals

Repair Of Inside Surfaces

Repair Of The Ball

Assembling

Welding

Non-Destructive Testing

Acceptance Test

Coating

Your assistant in the choice of oil and gas equipment

This catalogue contains information about products produced by ProEnTech Plant. All data in the catalog is provided specially for information only and are not exhaustive. For more information contact the company representatives. ProEnTech Plant reserves the right at any time and without notice to update, delete, add and alter the content in all sections of this catalogue. The use of the information contained in this catalogue may be carried out only if the requirements of the copyright and intellectual property laws of the Russian Federation are complied. Property of ProEnTech Plant.

© ProEnTech Plant, 2015

CONTACT DETAILSAddress: Nauchnii Proezd, 14A, building 1, office 2.2, Moscow, Russia, 117246Tel/Fax: +7 (499) 272-33-20E-mail: [email protected]