Enzymatic biofuel cell based on anode and cathode powered by ethanol

-

Upload

arunas-ramanavicius -

Category

Documents

-

view

232 -

download

4

Transcript of Enzymatic biofuel cell based on anode and cathode powered by ethanol

E

Aa

b

a

ARRAA

KEFBPAAM

1

iateoeaccifodeRbss(a

0d

Biosensors and Bioelectronics 24 (2008) 761–766

Contents lists available at ScienceDirect

Biosensors and Bioelectronics

journa l homepage: www.e lsev ier .com/ locate /b ios

nzymatic biofuel cell based on anode and cathode powered by ethanol

runas Ramanaviciusa,∗, Asta Kausaitea,b, Almira Ramanavicienea,b

Center of Nanotechnology and Material Science, Faculty of Chemistry, Vilnius University, Naugarduko 24, 03225 Vilnius, LithuaniaLaboratory of Immunoanalysis and Nanotechnology, Institute of Immunology of Vilnius University, Moletu pl. 29, 08409 Vilnius, Lithuania

r t i c l e i n f o

rticle history:eceived 1 April 2008eceived in revised form 17 June 2008ccepted 27 June 2008vailable online 9 July 2008

a b s t r a c t

Enzymatic biofuel cell based on enzyme modified anode and cathode electrodes are both powered byethanol and operate at ambient temperature is described. The anode of the presented biofuel cell wasbased on immobilized quino-hemoprotein-alcohol dehydrogenase (QH-ADH), while the cathode on co-immobilized alcohol oxidase (AOx) and microperoxidase (MP-8). Two enzymes AOx and MP-8 acted inthe consecutive mode and were applied in the design of the biofuel cell cathode. The ability of QH-ADH to transfer electrons directly towards the carbon-based electrode and the ability of MP-8 to accept

eywords:nzymatic fuel celluel celliofuel cellQQlcohol dehydrogenase

electrons directly from the same type of electrodes was exploited in this biofuel cell design. Direct electrontransfer (DET) to/from enzymes was the basis for generating an electric potential between the anode andcathode. Application of immobilized enzymes and the harvesting of the same type of fuel at both electrodes(cathode and anode) avoided the compartmentization of enzymatic biofuel cell. The maximal open circuitpotential of the biofuel cell was 240 mV.

euTinbeacsfmaut2oat

lcohol oxidaseicroperoxidase

. Introduction

The production of electrical power from low-cost biofuels is anmportant challenge in the energetics, since biofuels are renew-ble, sustainable, offer lower greenhouse-gas emissions and reducehe demand for common fuel sources, these are of special inter-st of modern-energetics (Pizzariello et al., 2002). As the majorityf organic substrates undergo combustion with the evolution ofnergy, the biocatalyzed oxidation of organic substrates by oxygent electrode interfaces provides a means for the conversion of thehemical energy to an electrical one (Willner et al., 1998a). Signifi-ant concentrations of ethanol and other alcohols are often presentn the various biological substances (Lim and Wang, 2003). Basicermentation processes might be applied to increase concentrationf alcohols in these substances. The chemical energy of abun-ant biological substrates including polyhydroxylic (Arechederrat al., 2007) and monohydroxylic alcohols (Ikeda and Kano, 2001;amanavicius et al., 2005) may be converted into electrical currenty biofuel cells. The advantage of biofuel cells when compared to

tandard fuel cells is that biofuel cells are able to operate at a lowubstrate concentration which can be even at the micromolar levelPizzariello et al., 2002). In the future biofuel cells can be used aslternative energy supply sources for biosensors and for other bio-∗ Corresponding author.E-mail address: [email protected] (A. Ramanavicius).

b

f(olpA

956-5663/$ – see front matter © 2008 Elsevier B.V. All rights reserved.oi:10.1016/j.bios.2008.06.048

© 2008 Elsevier B.V. All rights reserved.

lectronic devices (Willner et al., 2001). These cells may also besed as power sources of implantable devices (Barton et al., 2004).he combination of bioelectronics with nanotechnology allowsntegration of biofuel cells within the operating devices, while theanotechnology offers novel perspectives for the miniaturization ofioelectronic devices and the increase of their efficiency (Willnert al., 2001; Wang et al., 2005). Microorganisms and/or enzymesre catalysts that are able to convert chemical energy to electri-al energy (Katz et al., 1999), for this reason they are importantubjects of biofuel cells (Bullen et al., 2006). The most efficient bio-uel cell designs allow operation’s without compartments dividing

embranes (Chen et al., 2001; Ramanavicius et al., 2005). It allowspplications of biofuel cells as portable power sources. Biofuel cellstilize biocatalysts for the conversion of chemical energy to elec-rical energy (Katz et al., 1999; Chen et al., 2001; Mano et al., 2002,003). The methodology based on the application of purified red-x enzymes for the targeted oxidation and reduction of specific fuelnd oxidizer substrates at the electrode supports and the genera-ion of the electrical current output is used for the development ofiofuel cells (Chen et al., 2001).

There are known several red-ox enzymes able gain electronsrom various alcohols: methanol (Zhang et al., 2006a,b), ethanol

Ramanavicius et al., 2006a), glycerol (Lapenaite et al., 2006) andther alcohols (Ivnitski et al., 2006). Alcohol oxidases (AOxs) uti-izes oxygen as natural electron acceptor thus producing hydrogeneroxide (Ramanavicius et al., 2006b; Malinauskas et al., 2005).lcohol dehydrogenases are using NAD/NADH or artificial red-ox

7 and Bioelectronics 24 (2008) 761–766

mdbaom(

ntte2toeeeteacadD(petcD(wect

tdo

2

2

wLch2(iRt

2

fowad

kt2ogsawCdg

2

pwTpwti

3

tcattamftaQlebvnii

62 A. Ramanavicius et al. / Biosensors

ediators based system for re-oxidation of its active site. It wasemonstrated that both types of alcohol harvesting enzymes coulde applied in the design of biofuel cells, however usually theyre applied for designing of biofuel cell anode. The majority ofxidases and dehydrogenases require the application of red-oxediators to establish direct electron transfer (DET) with electrode

Habermüller et al., 2000; Malinauskas et al., 2004).Among the other types of enzymes, some pyrroloquinoline qui-

ine (PQQ)-dependent red-ox enzymes were also employed forhe construction of biofuel cells (Ikeda and Kano, 2003). Howeverhe majority of PQQ-dependent enzymes are unable to transferlectrons without additional red-ox mediators (Lapenaite et al.,006; Habermüller et al., 2000). The detailed characterization ofhe interfacial electron transfer rates is essential in the constructionf biofuel cells, since the enzyme and electronic conductors are for-ign components in respect of one to the other, that leads to a lack oflectric current between them. The modification of PQQ-dependentnzymes with covalently attached red-ox mediators can be appliedo facilitate electron transfer from active site of enzyme towardslectrode (Laurinavicius et al., 2004). An alternative to this is topply DET-able enzymes (Gorton et al., 1999). The red-ox enzymesontaining heme-c are very promising in this context (Freire etl., 2003; Ramanavicius et al., 2006a). Quino-hemoprotein-alcoholehydrogenase from Gluconobacter sp. 33 (QH-ADH) demonstratesET toward glassy carbon (Ikeda et al., 1993), other forms of carbon

Razumiene et al., 2002), gold (Ikeda et al., 1993) and conductingolymer polypyrrole (Ramanavicius et al., 1999). Another class ofnzymes, heme-c containing peroxidases, are able for direct elec-ron transfer and also are very promising for construction biofuelell cathode (Willner et al., 1998a,b; Ferapontova and Gorton, 2001).irect electrochemistry of microperoxidases with a gold electrode

Willner et al., 1998a), carbon electrodes (Ruzgas et al., 1996), alongith platinum electrodes modified with carbon nanotubes (Wang

t al., 2005), were investigated and exploited in the design of biofuelell cathode. However, DET-based enzymatic biofuel cell utilizinghe same substrate at both electrodes is still a challenge.

The aim of this study was to design basic, non-compartmen-alized, mediator free biofuel cell based on enzymes exhibitingirect bioelectrocatalysis and able to convert the chemical energyf biological substrate – ethanol – at both cathode and anode.

. Experimental

.1. Chemicals

Alcohol dehydrogenase from Gluconobacter sp. 33 (E.C. 1.1.99.8)as isolated and purified at the Institute of Biochemistry (Vilnius,

ithuania). The enzyme had an activity of 171 U/ml and 7.6 mg/mloncentration of proteins. Microperoxidase-8 (MP-8) from horseeart 250 U/mg; AOx from Pichia pastoris (E.C.1.1.3.13), 50 U/ml,5% glutaraldehyde and 96% ethanol were purchased from SigmaBerlin, Germany). Carbon rod electrodes “Ultra F purity” 3 mmn diameter obtained from Ultra Carbon Division of Carbon USA,AVEN-M were used. Carbon rod electrodes were sealed into epoxyo prevent the contact of electrode side surface with the solution.

.2. Preparation of electrodes

Graphite electrodes modified with enzymes were prepared as

ollows: (i) rods of spectroscopic graphite were cut, and polishedn fine emery paper, followed by rinsing the electrode surfaceith ethanol and water. Electrodes were dried at room temper-ture before coating with enzyme; (ii) enzyme solutions wereeposited on the electrode surface and the coated electrodes were

eseae

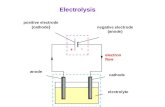

Fig. 1. Configuration of biofuel cell, using ethanol as a fuel for cathode and anode.

ept for 20 h over the 5% solution of glutaraldehyde at 4 ◦C inhe closed vessel as it was previously described (Ramanavicius,007). In preparing the anode, 6 �l of QH-ADH solution was thor-ughly distributed on the surface of the electrode and kept overlutaraldehyde solution. In preparing the cathode, 3 �l of MP-8olution (10 mg/ml) was thoroughly distributed over the electrodend dried for 30 min. Afterwards, 3 �l of AOx solution (10 mg/ml)as deposited and the electrode was kept over glutaraldehyde.ontrol carbon electrode modified with MP-8 was prepared byeposition of 3 �l of MP-8 solution (10 mg/ml) and cross-linked bylutaraldehyde using the same cross-linking protocol.

.3. Electrochemical measurements

All electrochemical measurements were performed byotentiostat–galvanostat PGSTAT 30 using specialized soft-are GPES3 v3,2 Echochemie/Autolab (Utrech, Netherlands).

wo-electrode circuit was applied for registration of electricalotential between electrodes. Some potentiometric measurementsere performed at open circuit; during some other experiments

he resistors were switched into the external circuit (Fig. 1) tomitate circuit-load on biofuel cell.

. Results and discussion

Current developments in nanotechnology enables serioushoughts about nano-devices and even nano-robots, but in manyases such systems require miniature power sources (Chen etl., 2001) otherwise such devices will be very limited in func-ion and application. Major idea of the work presented here waso apply environmentally friendly and/or biodegradable materi-ls. This concept does not allow us to apply any soluble red-oxediators or hazardous red-ox polymers. Direct electron trans-

er exhibiting hemoproteins (Gorton et al., 1999) were selected forhis study to avoid application of any additional environmentallynd/or biologically hazardous red-ox materials. Enzymes MP-8 andH-ADH were selected for the design of biofuel cell as the cata-

ysts. These enzymes are able to transduce chemical energy intolectrical one and to transfer electrical current directly to the car-on electrodes. Carbon is selected as a matrix-material, becausearious carbon forms are very often applied in various nanotech-ological applications (Malinauskas et al., 2005). Moreover carbon

s especially suitable for application in bioelectronic devices sincet supports sufficient electron transfer due to proper enzyme ori-

ntation (Shleev et al., 2005). The QH-ADH is comprised of threeubunits (Fre’bortova et al., 1998). The ability of QH-ADH to transferlectrons directly towards the electrodes was employed for gener-tion of anodic current in amperometric biosensors (Ramanaviciust al., 1999) and later this process was applied in biofuel cell har-

A. Ramanavicius et al. / Biosensors and B

Fig. 2. Open circuit potentials of: (1) QH-ADH functionalized anode as a function ofethanol concentration; (2) MP-8/AOx functionalized cathode as a function of ethanolcicp

vTiTpdbewTcbao

w

E

otttp1acsl

o(atrmiHdtmaototmfebtptcmhebatotoc

E

H

dsp1gthotib

eT24tbi

oncentration; (3) MP-8/AOx functionalized cathode as function of hydrogen perox-de concentration; (4) QH-ADH functionalized anode and MP-8/AOx functionalizedathode-based biofuel cell as a function of ethanol concentration. Investigationserformed in 50 mM Na acetate solution, pH 6.0, with 100 mM KCl at open circuit.

esting ethanol and glucose as biofuels (Ramanavicius et al., 2005).he anode of the constructed enzymatic fuel cell was based onmmobilized QH-ADH, which oxidized ethanol as the anode fuel.he cooperative action of the enzyme-integrated prosthetic groupsyrroloquinoline quinone and hemes-c were assumed to allowirect electron-transfer from the enzyme’s catalytic site to the car-on electrode. The electrical contact between QH-ADH and carbonlectrode was efficient and the electrons extracted from ethanol (1)ere directly transferred to carbon surface (Fig. 1, anode reaction).

his phenomenon has been exploited in anodes of other biofuelells (Ramanavicius et al., 2005; Treu et al., 2006). This enzymeecomes attractive because of the possible improvements whenpplying other carbon-based nanomaterials, including carbon nan-tubes (Treu et al., in press).

The open circuit potential of here studied QH-ADH-based anodeas approximately −125 mV (Fig. 2, curve 1).

Anode reaction:

thanolQH-ADH−→ Ethanal+2H+ + 2e− (1)

The cathode reaction is also very important during the creationf biofuel cells since it can significantly increase electric poten-ial and current of biofuel cell. Various strategies were appliedo maximize the performance of cathodes in biofuel cells andhe application of laccases seems the most popular for this pur-ose (Barton et al., 2001; Tarasevich et al., 1979; Tayhas et al.,

999), it was demonstrated that some carbon-based nanomateri-ls may significantly improve the current of laccase-based biofuelell cathode (Gallaway et al., 2008) and negative influence ofome halide ions could be eliminated by proper orientation ofaccases (Vaz-Dominguez et al., 2008). Advantageous properties(1rms

ioelectronics 24 (2008) 761–766 763

f laccases including major DET aspects were in details reviewedShleev et al., 2005), however some alternative ways includingpplication of heme-c-dependent enzymes could be also appliedo design cathodes of biofuel cells (Bullen et al., 2006). In thisespect, previously we have demonstrated that glucose oxidaseight be principally applied in the design of biofuel cell cathode

f combined with microperoxidase-8 (Ramanavicius et al., 2005).ydrogen peroxide, which is produced by oxidase, is a strong oxi-izer. However electrochemical reduction of hydrogen peroxide athe carbon electrode occurs with very high over-potential, which

ay be reduced if the carbon surface is modified by peroxidasectivity exhibiting enzymes (Ruzgas et al., 1996). From the varietyf peroxidases we have selected the smallest one, MP-8, becausehis enzyme is very stable what is determined by basic structuref this microperoxidases. Although, this biocatalyst was expectedo have the most efficient carbon surface covering due to lowest

olecular weight (Adams, 1991). The influence of an efficient sur-ace covering was demonstrated by investigation of several carbonlectrode-covering strategies. The layered design of the cathodeased on two separated layers of MP-8 and AOx was selected forhis study, because the investigations showed that in the case whenure MP-8 layer was deposited as first layer on these carbon elec-rodes, then higher potential and higher current density of theathode are achieved in comparison with the cathode based onixed MP-8 and AOx. This type of a layered design guaranties a

igher surface-density of MP-8, which is directly deposited on thelectrode. Hydrogen peroxide was formed in the reaction catalyzedy Aox. Then hydrogen peroxide was used as a substrate for MP-8,nd electrons from this reaction were transferred from the elec-rode to the active site of MP-8, which was acting as a reducerf hydrogen peroxide (Fig. 1, cathode interface reaction). Due tohe consecutive action of AOx and MP-8 immobilized on the cath-de, chemical energy of ethanol oxidation by dissolved oxygen wasonverted into electrical current.

Cathode interface reactions:

thanol + O2 + H2OAOx−→Ethanal+H2O2 (2)

2O2 + 2H+MP-8−→2H2O − 2e− (3)

The potential generated by MP-8/AOx cathode in the presence ofifferent ethanol concentrations was examined (Fig. 2, curve 2). Thelope of the second curve (Fig. 2, curve 2) seems much lower if com-ared with that achieved by QH-ADH-based anode (Fig. 2, curve). This effect might be based on diffusion of ethanol and hydro-en peroxide, which was formed during the action of AOx. Fromhe potential values of MP-8/AOx modified electrode at 2 mM andigher hydrogen peroxide concentrations (Fig. 2, curve 3), the the-retical limit of the MP-8 modified electrode potential is estimatedo be 150 mV. The maximal voltage generated by MP-8/AOx mod-fied cathode was close to that generated by biofuel cell cathodeased on MP-11 modified gold cathode (Willner et al., 1998a).

The cathode potential exceeded 125 mV if 5 mM and higherthanol concentrations were added into the cell (Fig. 2, curve 1).he maximal open circuit potential of the complete biofuel cell was40 mV at ethanol concentrations of 20 mM and higher (Fig. 2, curve). Experimental results indicates, that the open circuit potential inhis type of measurements is dependent on substrate concentrationecause of some limitations in measurement: (i) the “open circuit”

s not ideal, despite of very high resistance of measuring device

300 M�), the resistance of circuit cathode/solution/anode was just± 0.2 M�, because of conductivity of used buffer solution, for thiseason the measured potential at least partially depends on enzy-atic reaction rate, which is highly influenced by concentration of

ubstrate—ethanol.

764 A. Ramanavicius et al. / Biosensors and Bioelectronics 24 (2008) 761–766

Fig. 3. The pH dependence of open circuit potential for: (1) MP-8 functionalizedcathode in presence 20 mM of hydrogen peroxide; (2) QH-ADH functionalized anodein presence 20 mM of ethanol; (3) MP-8/AOx functionalized cathode in presence2app

beMdedr(ig2pdisomt

p

FQpo

Fig. 5. Current–voltage behavior of: (1) complete biofuel cell based on both MP-8em

abbpMbccitoewsA

motQ

0 mM of ethanol and (4) biofuel cell based on MP-8/AOx functionalized cathodend QH-ADH functionalized anode in the presence 20 mM of ethanol. Investigationserformed at an open circuit in 50 mM of sodium acetate with accordingly adjustedH, 100 mM of potassium chloride.

The MP-8 modified electrode may be effectively applied in aroad pH diapason: between pH 3 and pH 7 (Fig. 3, curve 1). How-ver, the QH-ADH modified anode (Fig. 3, curve 2) and layeredP-8/AOx modified cathode (Fig. 3, curve 3) are much more depen-

ent on pH level. The result of this is a “sharp” dependence oflectric potential on pH (Fig. 3, curve 4). On the other hand theeveloped biofuel cell is able to operate in the physiological pHange. It is important for possible application of biofuel cell in vivoTsujimura et al., 2001). To enable better operation of biofuel celln vivo, some enzymes might be exchanged into ones harvestinglucose (Malinauskas et al., 2004) and/or glycerol (Lapenaite et al.,006). There are many reasons why pH is affecting open circuitotentials, e.g.: (i) there are significant differences in thermo-ynamics of enzymatic red-ox reactions and in thermodynamics

ntrinsic/extrinsic electron transfer reactions at different pH; (ii)ignificant differences in enzymatic activity, because conformationf enzyme is pH dependent and protonated/deportonated groups

ight be crucial in catalytic site of enzyme; (iii) extrinsic electronransfer might be dependent on enzyme conformation, etc.The stability of biofuel cell was examined at working state in

resence of 2 mM of ethanol at the loading resistance of 1 M� as

ig. 4. Open circuit potentials for: (1) MP-8/AOx functionalized cathode and (2)H-ADH functionalized anode as a function of glucose concentration. Investigationserformed at an open circuit in 50 mM of sodium acetate, pH 6.0, containing 100 mMf potassium chloride and 75 mM of ethanol.

T2msab

F

/AOx cathode and QH-ADH anode; (2) QH-ADH anode vs. unmodified carbonlectrode; (3) MP-8/AOx cathode vs. unmodified carbon electrode. All measure-ents were performed in 25 mM of ethanol.

function of time in the presence of ethanol. The half-life of theiofuel cell was found to be 26 h. Significant improvement in sta-ility of biofuel cell was detected if it is compared with the resultsublished (Willner et al., 1998a) where the cathode was based onP-11 while the anode on GOx “wired” by PQQ derivatives assem-

led on the gold electrode. The “increased” stability of the biofuelell might be based on application of unmodified enzymes whenompared with enzymes treated under harsh conditions due tommobilization via self-assembled monolayers or enzyme “wiring”echniques applied in other studies (Willner et al., 1998a). On thether hand, the structure of MP-8 is very basic, which makes thisnzyme more stable if comparing it with the higher moleculareight enzyme—MP-11 used in previous studies. However in this

tudy used AOx was found to be relatively unstable; for this reasonOx negatively influenced stability of biofuel cell cathode.

The lease expensive alcohol sources, for example natural fer-entation products, typically contain a lot of various sugars. In

rder to study performance of biofuel cells in an environment con-aining sugars the effectiveness of MP-8/AOx (Fig. 4, curve 1) andH-ADH (Fig. 4, curve 2) cathode in presence of glucose was tested.he results demonstrate that higher concentrations of glucose (over00 mM) decrease generated potential by 7–15% (Fig. 4). This effectay be based on significant increase in viscosity. High viscosity of

olution can cause a negative influence in the diffusion of substratend reaction products as it was demonstrated in other studies ofiofuel cells (Arechederra et al., 2007).

ig. 6. Biofuel cell power vs. registered current in presence of 25 mM of ethanol.

and B

ospp

iflb2

4

waaibetiaataametdepphpaetenbse

fticeaGom

dtbmtpem

thot2t

A

LTnL

R

A

AB

BB

CC

D

FF

FG

G

H

III

I

KL

L

L

LLM

M

MMPRR

R

R

R

A. Ramanavicius et al. / Biosensors

Current–voltage behavior of biofuel cell represents how voltagef complete biofuel cell (Fig. 5, curve 1) and anode and cathodeeparately (Fig. 5, curves 2 and 3) depends on load of circuit. Theower density vs. current of the cell (Fig. 6) illustrates that maximalower for completed biofuel cell was 1.5 �W/cm2.

Here described biofuel cell anodes and cathodes might be usedn separated biofuel cells, e.g. the QH-ADH-based anode of the bio-uel cell might be combined with any other type of biocathodes, e.g.accase based, that are also very promising in this for application iniofuel cells including microfluidic biofuel cells (Lim and Palmore,007).

. Conclusions and future developments

An enzymatic biofuel cell based on QH-ADH and MP-8/AOxas designed. The cell was operating at ambient conditions in

bsence of any red-ox mediators. Substrates of QH-ADH and AOxre aliphatic alcohols that are often found in high concentrationsn fermenting biological samples. The development of this type ofiofuel cell does not require any sophisticated procedures; basicnzyme-immobilization method is applied for the construction ofhis cell. The biofuel cell is able to produce an electrical currentn the presence of very common biological substances containinglcohols. The biofuel cell is non-compartmentalized; this designllows the application of this biofuel cell directly in a vessel con-aining alcohol solution (e.g. barrel of wine fermentation). Thepplication of DET-able enzymes ensures that the current gener-ted by such biofuel cells do not depend on leakage of an red-oxediator from the modified electrode. Despite the relatively low

lectrical potential (240 mV) there are some assumptions that thisype of biofuel cell may be exploited in self-powered bioelectronicalevices, because current developments in microelectronics, nano-lectronics and molecular electronics allows to reduce requestedotentials for new electronic devices. Both enzymes used in theresent study exhibit higher red-ox potentials as it was reportedere, e.g. the QH-ADH is able to generate +190 mV vs. Ag/AgCl inresence of a soluble red-ox mediator (Ramanavicius et al., 2006a)nd MP-8 −150 mV vs. Ag/AgCl. This enables the search for morefficient way to apply these enzymes. In this respect, the applica-ion of carbon nanomaterials including carbon nanotubes seemsspecially promising since even glucose oxidase from Aspergillusiger was reported being able for direct electron transfer promotedy carbon nanotubes (Cai and Chen, 2004). Recent works demon-trates that carbon nanotubes can be employed in the design ofnzymatic fuel cells (Ivnitski et al., 2006; Treu et al., in press).

However the stability of the biofuel cell was not steady enoughor long-term operation, but in this respect the future investiga-ions might be encouraged by such facts that significant extensionn life time of biofuel cell function can be achieved if geneti-ally engineered FAD-based (Zhu et al., 2006) and/or PQQ-basednzymes (Yuhashi et al., 2005) will be applied for this purpose. Incontinuance of the operational period of biofuel cells the livingluconobacter cells containing membrane-bound QH-ADH and/orthers PQQ–heme-dependent enzymes present in Gluconobacteright be adopted.Previous investigations showed that almost the same current

ensity of QH-ADH modified electrodes might be produced inhe presence of the same concentrations of ethanol, propanol orutanol (Laurinavicius et al., 2002), and such versatility of QH-ADH

akes proposed biofuel cell especially attractive for the applica-ion in mixture of alcohols. Other PQQ-dependent enzymes that areresent in Gluconobacter (e.g. glycerol dehydrogenase (Arechederrat al., 2007) and lactate dehydrogenase (Treu and Minteer, in press)ight be combined in this type of biofuel cells in order to enhance

R

R

S

ioelectronics 24 (2008) 761–766 765

he variety of combusted fuels. For extension of current density ofere presented biofuel cell some strategies: (i) of proper orientationf enzymes could be applied, as it was reported in case of applica-ion laccase in recent designs of biofuel cells (Vaz-Dominguez et al.,008); (ii) multilayered 3DOM gold based enzyme/(gold nanopar-icles) structures (Deng et al., 2008).

cknowledgements

We are grateful to Dr. R. Meskys, Dr. I. Bachmatova and Dr.. Marcinkeviciene for purification and preparation of QH-ADH.his work was partially financially supported by Agency for Inter-ational Science and Technology Development Programmes inithuania COST program action D40.

eferences

dams, P.A., 1991. In: Everse, J., Everse, K.E., Grisham, M.B. (Eds.), Peroxidases inChemistry and Biology, vol. 2. CRC Press, Boca Raton, pp. 171–200 (Chapter 7).

rechederra, R.L., Treu, B.L., Minteer, S.D., 2007. J. Power Sources 173, 156–161.arton, S.C., Kim, H.H., Binyamin, G., Zhang, Y., Heller, A., 2001. J. Am. Chem. Soc. 123,

5802–5803.arton, S.C., Gallaway, J., Atanasov, P., 2004. Chem. Rev. 104, 4867–4886.ullen, R.A., Arnot, T.C., Lakeman, J.B., Walsh, F.C., 2006. Biosens. Bioelectron. 21,

2015–2045.ai, C., Chen, J., 2004. Anal. Biochem. 332, 75–83.hen, T., Barton, S.C., Binyamin, G., Gao, Z.Q., Zhang, Y.C., Kim, H.H., Heller, A., 2001.

J. Am. Chem. Soc. 123, 8630–8631.eng, L., Wang, F., Chen, H., Shang, L., Wang, L., Wang, T., Dong, S., 2008. Biosens.

Bioelectron. 24, 329–333.erapontova, E., Gorton, L., 2001. Electrochem. Commun. 3, 767–774.re’bortova, J., Matsushita, K., Arata, H., Adachi, O., 1998. Biochim. Biophys. Acta 1363,

24–34.reire, R.S., Pessoa, C.A., Mello, L.D., Kubota, L.D., 2003. J. Braz. Chem. Soc. 14, 230–243.allaway, J., Wheeldon, R., Rincon, I., Atanassov, P., Banta, S., Barton, S.C., 2008.

Biosens. Bioelectron. 23, 1229–1235.orton, L., Lindgren, A., Larsson, T., Munteanu, F.D., Ruzgas, T., Gazaryan, I., 1999.

Anal. Chim. Acta 400, 91–108.abermüller, K., Ramanavicius, A., Laurinavicius, V., Schuhmann, W., 2000. Electro-

analysis 12, 1383–1389.keda, T., Kano, K., 2001. Rev. J. Biosci. Bioeng. 92, 9–18.keda, T., Kano, K., 2003. Biochim. Biophys. Acta 1647, 121–126.keda, T., Kobayashi, D., Matsuma, F., Sagara, T., Niki, K., 1993. J. Electroanal. Chem.

361, 221–228.vnitski, D., Branch, B., Atanassov, P., Apblett, Ch., 2006. Electrochem. Commun. 8,

1204–1210.atz, E., Willner, I., Kotlyar, A.B., 1999. J. Electroanal. Chem. 479, 64–68.apenaite, I., Ramanaviciene, A., Ramanavicius, A., 2006. Crit. Rev. Anal. Chem. 36,

13–25.aurinavicius, V., Razumiene, J., Kurtinaitiene, B., Lapenaite, I., Bachmatova, I.,

Marcinkeviciene, L., Meskys, R., Ramanavicius, A., 2002. Bioelectrochemistry 55,29–32.

aurinavicius, V., Razumiene, J., Ramanavicius, A., Ryabov, D., 2004. Biosens. Bioelec-tron. 20, 1217–1222.

im, K.G., Palmore, G.T.R., 2007. Biosens. Bioelectron. 22, 941–947.im, C., Wang, C.Y., 2003. J. Power Sources 113, 145–150.alinauskas, A., Kuzmarskyte, J., Meskys, R., Ramanavicius, A., 2004. Sens. Actuator

B 100, 387–394.alinauskas, A., Malinauskiene, J., Ramanavicius, A., 2005. Nanotechnology 16,

51–63.ano, N., Mao, F., Heller, A., 2002. J. Am. Chem. Soc. 124, 12962–12963.ano, N., Mao, F., Heller, A., 2003. J. Am. Chem. Soc. 125, 6588–6594.

izzariello, A., Stred’ansky, M., Miertus, S., 2002. Bioelectrochemistry 56, 99–105.amanavicius, A., 2007. Anal. Bional. Chem. 387, 1899–1906.amanavicius, A., Habermuller, K., Csoregi, E., Laurinavicius, V., Schuhmann, W.,

1999. Anal. Chem. 71, 3581–3586.amanavicius, A., Kausaite, A., Ramanaviciene, A., 2005. Biosens. Bioelectron. 20,

1962–1967.amanavicius, A., Kausaite, A., Ramanaviciene, A., 2006a. Sens. Actuator B 113,

435–444.amanavicius, A., Ramanaviciene, A., Malinauskas, A., 2006b. Electrochim. Acta 51,

6025–6037.

azumiene, J., Niculescu, M., Ramanavicius, A., Laurinavicius, V., Csoregi, E., 2002.Electroanalysis 14, 1–7.uzgas, T., Csoregi, E., Emneus, J., Gorton, L., Marko-Varga, G., 1996. Anal. Chim. Acta

330, 123–138.hleev, S., Tkac, J., Christenson, A., Ruzgas, T., Yaropolov, A., Whittaker, J., Gorton, L.,

2005. Biosens. Bioelectron. 20, 2157–2554.

7 and B

T

TT

T

TT

V

W

WW

W

Y

66 A. Ramanavicius et al. / Biosensors

arasevich, M.R., Yaropolov, A.I., Bogdanovskaya, V.A., Varfolomeev, S.D., 1979. Bio-electrochem. Bioenerg. 6, 393–403.

ayhas, G., Palmore, R., Kim, H.H., 1999. J. Electroanal. Chem. 464, 110–117.reu, B.L., Minteer, S.D., in press. Bioelectrochemistry. doi:10.1016/j.bioelectrochem.

2008.07.005.reu, B.L., Anderson, D., Behrmann, A., Minteer, S.D., 2006. Abstracts Papers of The

American Chemical Society. pp. 231.

reu, B.L., Arechederra R., Minteer, S.D., in press. J. Nanosci. Nanotechnol.sujimura, S., Fujita, M., Tatsumi, H., Kano, K., Ikeda, T., 2001. Phys. Chem. Chem.Phys. 3, 1331–1335.az-Dominguez, C., Campuzano, S., Rüdiger, O., Pita, M., Gorbacheva, M., Shleev, S.,

Fernandez, V.M., De Lacey, A.L., 2008. Biosens. Bioelectron. 24, 531–537.ang, M., Zhao, F., Liu, Y., Dong, S., 2005. Biosens. Bioelectron. 21, 159–166.

Z

Z

Z

ioelectronics 24 (2008) 761–766

illner, I., Arad, G., Katz, E., 1998a. Bioelectrochem. Bioenerg. 44, 209–214.illner, I., Katz, E., Patolsky, F., Buckmann, A.F., 1998b. J. Chem. Soc., Perkin Trans. 2,

1817–1822.illner, I., Katz, E., Buckmann, A.F., 2001. J. Am. Chem. Soc. 123, 10752–

10753.uhashi, N., Tomiyama, M., Okuda, J., Igarashi, S., Ikebukuro, K., Sode, K., 2005.

Biosens. Bioelectron. 20, 2145–2150.

hang, E., Xu, W., Diao, G., Shuang, C., 2006a. J. Power Sources 161, 820–825.hang, X.C., Ranta, A., Halme, A., 2006b. Biosens. Bioelectron. 21, 2052–

2057.hu, Z., Momeu, C., Zakhartsev, M., Schwaneberg, U., 2006. Biosens. Bioelectron. 21,

2046–2051.