(English) - bsuh.nhs.uk · logic which indicate the year of manufacture and a . sequential unit...

Transcript of (English) - bsuh.nhs.uk · logic which indicate the year of manufacture and a . sequential unit...

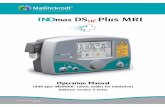

Part No. 20003 Rev - 01 Part No. 20181 Rev-022012-06

Operation and Maintenance Manual(English)

User ResponsibilityThis Product will perform in conformity with the description contained in this operating manual and accompanying labels and/or inserts, when assembled, operated, maintained and repaired in accordance with the instructions provided. This Product must be checked prior to use following the Pre-Use Checkout procedure described in section 3. A defective Product should not be used. Parts that are broken, missing, visibly worn, distorted or contaminated should be replaced immediately.

Should such repair or replacement become necessary, the manufacturer recommends that a telephone request for service advice be made to the local distributor. This Product or any of its parts should not be repaired other than in accordance with written instructions provided by the manufacturer or local distributor. The Product must not be altered. The user of this Product shall have the sole responsibility for any malfunction which results from

improper use, faulty maintenance, improper repair, damage, or alteration by anyone other than Ikaria.

Outside the U.S.A. and Canada, check local laws for any restrictions that may apply. Caution: U.S. Federal and Canadian law restrict this device to sale by or on the order of a licensed medical practitioner.

Inhaled Nitric Oxide mixtures must be handled and stored in compliance with federal, state and local regulations.

Ikaria products have unit serial numbers with coded logic which indicate the year of manufacture and a sequential unit number for identification.

©2012 Ikaria, Inc.INOMAX®, INOmax DSIR

®, and INOblender® are registered trademarks of INO Therapeutics LLC and their respective owners. INO Therapeutics LLC is a wholly-owned subsidiary of Ikaria, Inc.

BL 20051234 The first two digits indicate the product, the next four numeric digits indicate the year of manufacture, and the next four digits are the sequential unit number produced that year.

10026 INOblender (DISS, 800 ppm, English)10004 INOblender (DISS, 800 ppm, English)10021 INOblender (NIST, 400 ppm, English)

Part No. 20181 Rev-022012-06

Part No. 20181 Rev-022012-06

1

1. General Information .............................................................................................................3 Introduction .......................................................................................................................4. DefinitionsandAbbreviations ...........................................................................................4. Theory of Operation ..........................................................................................................5 EnvironmentalEffects .......................................................................................................6

2. Setup ...................................................................................................................................7

3. Pre-UseCheckout ...............................................................................................................9

4.. Operation ...........................................................................................................................12

5. Maintenance ......................................................................................................................15 ReplacingRegulatorTips................................................................................................16 CylinderLeakCheck.......................................................................................................18 PartsandAccessories ....................................................................................................19

6. Specifications.....................................................................................................................21

Contents

Part No. 20181 Rev-022012-06

2

(Intentionallyleftblank)

Part No. 20003 Rev - 01 Part No. 20181 Rev-022012-06

1/ General Information

General

Information

Part No. 20181 Rev-022012-06

1/ General Information

Gen

eral

Info

rmat

ion

Part No. 20181 Rev-022012-06

3

CautionsandWarningsWARNINGS:•ThepurgeproceduremustbefollowedtohelpensureNO2ispurgedfromthepressureregulator,INOblenderandhosesbeforethemanualresuscitatorbagornasalcannulaisconnectedtothepatient.ThemanualbagshouldbesqueezedcontinuouslyduringusetoavoidNO2buildingupinthebag.IfthebagisnotsqueezedcontinuouslywhiledeliveringINOMAXthebagshouldberemovedfromthepatientandthepurgeprocedureperformedbeforecontinuing.

• TheINOblendershouldonlybeusedinaccordancewiththeindications,usage,contraindications,warningsandprecautionsdescribedintheINOMAXdrugpackageinsertandlabeling.Refertothismaterialpriortouse.

• PersonsusingthisdeviceshouldbetrainedonandexperiencedintheuseofthisdevicetoassureeffectiveadministrationofINOMAXandtoavoidinjurytothepatientorothersresultingfrominhalationofexcessINOMAX,nitrogendioxideorotherreactionproducts.

• TheNationalInstituteforOccupationalSafetyandHealth(NIOSH)intheU.S.hasarecommendedtime-weighted(8hours)averageconcentrationof25ppmforNOandalimitof1ppmforNO2.PersonsusingtheINOblenderwhomaybeparticularlysensitivetoNOorNO2,orwhomaybeexposedtotheseagentsforprolongedperiodsasaresultoftheuseofthisdevice,shouldbeawarethattheINOblenderdoesnotscavengetheexhaustdrug,andthatthisisventedattheresuscitatorbag.AmbientconcentrationsofNOorNO2areexpectedtobelessthan0.2ppmwhenusingtheINOblender,seeSection1EnvironmentalEffects.

Cautions:•OutsidetheU.S.andCanada,checklocallawsforanyrestrictionsthatmayapply. U.S.federallawandCanadianlawrestrictthisdevicetosalebyorontheorderofalicensedmedical practitioner.

•Properuseofthisproductdependsoncarefulreadingandunderstandingoflabelingandinstructions.

•Tohelpensureproperoperationofthisproduct,completethepre-usecheckoutpriortoeachuse.

•Whennotinuse,theO2flowmeterandtheINOMAXcylindervalveshouldbeturnedoff.

•Whencleaning,donotsubmergeinliquid.

•Donotautoclave.

•Refertothemanufacturer’sproceduresforusingtheresuscitationbag.

WARNING:Warningstellyouaboutdangerousconditionsthatcancauseinjurytotheoperatororthepatientifyoudonotobeyalloftheinstructionsinthismanual.

Caution:Cautionstellyouabouthowtoproperlyusetheequipmentandconditionsthatcouldcausedamagetotheequipment.

Readandobeyallwarningsandcautions.

Note:Notesprovideclarificationorsupplementalinformation.

Bluearrowdenotesrequireduseraction.

Part No. 20181 Rev-022012-06

4.

Pneumatic Inlet

Pneumatic Outlet

RxONLY Prescriptionuseonly

Pressure

Productpackagingisabletobe recycled

Protectfromheatandradioactivesources

SN SerialNumber

StorageTemperatureLimitation

StorageHumidityLimitation

ThisproductisincompliancewiththeEuropeanCouncilDirective93/42/EECanditsamendmentsconcerningmedicaldevices

Attention,consultaccompanyingdocuments!

AuthorizedRepresentativeintheEuropeanCommunity

CatalogNumber

Date of Manufacture

Donotuseifpackageisdamaged

Fragile,handlewithcare

Keep Dry

Manufacturer

NO or O2GasInlet

NOGasOutlet

IntroductionTheINOblenderallowsuserstoselectaconcentrationofINOMAX,(nitricoxideinabalanceofnitrogen),tobemixedintoausersetflowofoxygenwhichisdeliveredtoapatient.TheintendedusefortheINOblenderisasabackuptoaprimaryINOMAXdeliverysystem;orforshorttermattendedusewhenaprimarydeliverydevicecannotpracticablybeused.Thisintendeduseincludesapplicationswithinamedicalfacilityandtransportoutsideofamedicalfacility.TheINOblenderisnotintendedforuseasaprimaryINOMAXdeliverysystemforlongtermuse.

DefinitionsandabbreviationsN2 NitrogenNO INOMAX(nitricoxide)forinhalationNO2 NitrogendioxideNO/N2 Nitricoxide(NO)andnitrogen(N2)gasmixtureO2 Oxygenppm PartsPerMillionSet NO ThedoseofINOMAXsetbytheuserv/v Volume to volume

Note:ThismanualshowstheSetNOdisplaysassociatedwiththe0-80ppmrange.

SymbolsusedinthismanualoronthesystemSymbolsreplacewordsontheequipmentand/orinthismanual.Thesesymbolsinclude:

Part No. 20181 Rev-022012-06

5

INOblenderSchematicDiagram

Theory of Operation1. TheINOblenderconnectstoa3-5bar(45-75psig)oxygensupply.Theoxygenflowisthen

controlledbyanintegratedoxygenflowmeter(2-14lpm).Thereisafixedrestrictorintheoxygenflowpathwhichcreatesapressureproportionaltotheoxygenflowrate.

2. TheINOblenderisalsoconnectedtoa2bar(30psig)INOMAX(800ppmor400ppm)supply.

•TheINOMAXflowiscontrolledbyabalanceregulatorinproportiontotheoxygenpressurecausedbythefixedrestrictorandtheINOblendersetting.

•ThebalanceregulatormaintainsaconstantINOMAXdoseforvaryingoxygenflowrates.

3. TheflowsofO2 and INOMAXaremixedpriortoexitingtheINOblenderoutlet.

INOMAXCylinder

INOMAXRegulator

OxygenSource

BalanceRegulator

DoseKnob

INOMAXandO2Outlet

FixedLaminarRestrictor

INOMAXOxygenOxygen/INOMAX

Part No. 20181 Rev-022012-06

6

EnvironmentalEffectsTheNationalInstituteforOccupationalSafetyandHealth(NIOSH)hasrecommendedexposurelimitsasfollows(ref1).

NO time-weighted(8hours)average concentration limit of 25 ppm

NO2 ceiling limit of 1 ppm.

Theenvironmentalbuildupofnitricoxide in a well ventilatedICUroomcanbeevaluatedusingthefollowingcalculation:

Roomsize 10ftsquare(approx.3meters)

Roomvolume 27,000L of air

Roomventilation 2,700L/min at 6 room changes/hr

NOflowintoroom 14L/minat80ppm

Averageroom 80x14/2,700=0.4ppmofNO concentration of NO

ThistheoreticcalculationcanbesupplementedbymeasurementsasperformedbyHessetal.TheNO and NO2concentrationsweremeasuredusingachemiluminescenceanalyzerwhen100ppmofNOat8L/minwasdeliveredintoaroomwithnoscavengingbeingused.ThemaximumNO and NO2 concentrationsmeasuredoveraone-hourperiodwere 0.12 ppm of NO and 0.03 ppm of NO2.

Bothmethodsshowthattheexposurelevelsaresignificantlylessthanthelevelsrecommended byNIOSH.

IfthelocationforusingNOhasuncertainventilation,thenthelocationshouldbeevaluatedforNO and NO2builduppriortouse.

Ref. 1 Centers for Disease Control, Atlanta, GA 30333 USA. NIOSH Recommendations for Occupational Safety and Health Standards 1988. August 26, 1988 / vol. 37 /No. 9.

Ref. 2 Hess et al, Use of Inhaled Nitric Oxide in patients with Acute Respiratory Distress Syndrome, Respiratory Care, 1996, vol. 41, No 5, pg. 424-446.

Part No. 20003 Rev - 01 Part No. 20181 Rev-022012-06

2/ Setup

Setup

Part No. 20181 Rev-022012-06

2/ Setup

Setu

p

Part No. 20181 Rev-022012-06

7

SetupChecktheINOMAXgascylinderforthecorrectproductidentitylabels,cylinderconcentration(800or400ppm)andexpirationdate.EnsuretheINOMAXgascylinderhas>14bar(200psig).

1.Connectahigh-pressureregulatortoan INOMAXcylinderandhandtightenthefitting totheINOMAXcylinder.

2.ConnecttheINOMAXregulatorhosetothe INOblenderinlethoseusingthequick connectfittings.

3.ConnecttheoxygensupplytotheO2 inlet fitting.(seepartlistforcorrectoxygenhose) Note:3.5bar(50psig)nominal

1.MakesuretheNOdosesettingdialis turnedtozero.

2.Attachamanualresuscitationbagtothe INOblenderoutletfitting.

Tooxygensource

TheINOblenderisnowsetup.ProceedtoSection3/Pre-useCheckout.

1

23

1

2

Note: •FortheCGA-typeINOMAXregulatorconnector,ensurethewhiteplastictipisnotchippedorcracked.Removeandreplaceasnecessary.(seeReplacingthetipontheINOMAXregulator,Page16).

•FortheISO-typeregulatorconnector,checkthattheO-ringispresentandisnotdamaged(seeReplacingthetipontheINOMAXregulator,Page17).

Part No. 20181 Rev-022012-06

8

(Intentionallyleftblank)

Part No. 20003 Rev - 01 Part No. 20181 Rev-022012-06

3/ Pre-Use Checkout

Pre-U

se Checkout

Part No. 20181 Rev-022012-06

3/ Pre-Use Checkout

Pre

-Use

Che

ckou

t

Part No. 20181 Rev-022012-06

9

Pre-useCheckout

High-PressureLeakTest

1.MakesureNOdosesettingdialisturnedtozeroandflowmeterisOFF.

2.Openandthenclosethecylindervalve.3.Pressuregaugeshouldindicate>14bar (200psig).

4.Monitorpressuregaugefor30secondsforanysignsofpressuredecrease.Ifnopressuredecreaseisobserved,high-pressureleaktestsuccessful,proceedtoDeliveryConfirmationand Purge.

5.Ifobservedpressuredecreasecontinues,seeSection5/Maintenance;CylinderLeakCheck.

6.Ifleakcannotbetraced,replacetheINOblender.

DeliveryConfirmationandPurge

1.SettheINOblenderto40ppmwhenusingan 800ppmcylinder(20ppmwhenusinga400 ppmcylinder).

2.SettheoxygenflowontheINOblenderflow meterto10L/mintobeginpurge.

3.Ensurethepressuregaugedecreases approximately14bar(200psig)in10seconds (+2sec.).

4.Continuepurginguntilpressuregauge readszero.

Caution: Tohelpensureproperoperation,completethepre-usecheckoutpriortoeachuse.

Set-uptheINOblenderasdescribedinSection2/Setup

TheINOblenderisnowreadyforuse.ProceedtoSection4/Operation.

1

2

3

1

2

4. Note: Ifthepressuredoesnotdecrease,then

theINOblenderisnotdeliveringNOandtheINOblendershouldbereplaced.

Part No. 20181 Rev-022012-06

10

(Intentionallyleftblank)

Part No. 20003 Rev - 01 Part No. 20181 Rev-022012-06

4/ Operation

Operation

Part No. 20181 Rev-022012-06

4/ Operation

Ope

ration

Part No. 20181 Rev-022012-06

11

(Intentionallyleftblank)

Part No. 20181 Rev-022012-06

12

Operation

Cautions:• Whennotinuse,theoxygenflowmeterandtheINOMAXcylindervalveshouldbeturnedoff.

• WhentheINOblenderisusedwithanoxygen/airblender:

- ThespecificationforINOMAXdeliverywhenusingtheINOblenderwith100%oxygenis+/-20%ofsettingor2ppm(whicheverisgreater).Theuseof100%oxygenat3.4bar(50psig)isthelabeledspecificationfortheINOblender.

- Ausermaydeterminethatsomeclinicalconditionsmaynecessitatetheuseofanoxygen/airblenderwiththeINOblendertoachieveFiO2levelslessthan100%.

- Usingoxygen/airmixtures(21%to95%v/v)willreducethedeliveredNOconcentrationbyupto10%ofsettingor1ppm(whicheverisgreater)comparedtousing100%oxygenalone,resultinginacumulativeerrorupto+/-30%ofsettingor3ppm(whicheverisgreater).

• Refertothemanufacturer’sprocedureswhenusingthemanualresuscitatorbag.• Whenfinished,turntheNOcylindervalveOFFandallowtheoxygentoflowuntiltheNOpressuregaugereadszero,thenturntheoxygenflowOFF.

WARNINGS:• ThepurgeproceduremustbefollowedtohelpensureNO2ispurgedfromthesystembeforethemanualresuscitatorbagisconnectedtothepatient.

• ThemanualbagshouldbesqueezedrepeatedlyduringusetoavoidNO2frombuildingupinthebag.

• IfthebagisnotsqueezedrepeatedlywhiledeliveringINOMAX,thebagshouldberemovedfromthepatientandthebagpurgeprocedureperformedbeforecontinuing.

• TheINOblendershouldbeuprightwhensettingtheoxygenflowrateforaccuratesetting.

• DonotusepneumaticallypowerednebulizerswiththeINOblender.ThiswillresultinsignificantoverdeliveryofINOMAX(nitricoxide)forinhalationinexcessof80ppm(40ppmwitha400ppmcylinder).

- TheINOblenderoutletpressurehasbeenvalidatedforuseupto400millibar(5.8psig)pressure.Theamountofback-pressuregeneratedbypneumaticnebulizersissignificantlygreater[1.4-2.0bar(20-30psig)]andwillresultinoverdeliveryofINOMAXinexcessof80ppmwithan800ppmcylinder(40ppmwitha400ppmcylinder).TheuseradjusteddosesettingontheINOblenderwillnotcorrelatewith,orhaveaneffecton,theactualdelivereddose.

- Inaddition,theINOblenderflowmeterisnotback-pressurecompensatedandwilldisplayalowerthanactualflowratewhenpressureisappliedtotheoutlet.

Part No. 20181 Rev-022012-06

13

ThepurgeprocedurecontainedinthePre-useCheckouthelpsensureanyNO2ispurgedfromthepressureregulator,INOblenderandhosesbeforethemanualresuscitatorbagisconnectedtothepatient.

1.OpentheINOMAXcylindervalve.

2.Checkforsupplypressureof>14bar (200psig).

1

2

AdjustSettings

1.TurntheINOblendersettingdialtothe desiredconcentration(5to80ppmforan 800 ppm cylinder and 2.5 to 4.0 ppm for a 400ppmcylinder).

2. Turn the O2flowmetertothedesiredflowrate (5to14L/min).

3.Squeezethemanualresuscitator3-4times to purge the NO2fromthesystem.

TheINOblenderisnowreadyforpatientuse.

1

2

3

Priortooperation,completethePre-UseCheckoutinSection3.

Note: DepressurizetheINOMAXregulatorbyusingthepurgeportonthebackoftheINOmaxDSIR prior to removing from the cylinder valve.

Part No. 20181 Rev-022012-06

14.

(Intentionallyleftblank)

Part No. 20003 Rev - 01 Part No. 20181 Rev-022012-06

5/ Maintenance

Maintenance

Part No. 20181 Rev-022012-06

5/ Maintenance

Mai

nten

ance

Part No. 20181 Rev-022012-06

15

Cautions: • Whencleaning,donotsubmergeinliquid.• Donotautoclave.

CleaningProcedure

Maintenance

CleaningAgent ActiveIngredientsPreciseHospitalFoamCleanerDisinfectantbyCaltechIndustries

o-Phenylphenol<0.37%Otheringredients99.63%

PureGreen24byPureGreen,LLC SDC–silverions0.003%Citricacid4.84%Otheringredients95.157%

PDISuperSaniClothbyPDI n-Alkyl(68%C12,32%C14)dimethylethylbenzylammoniumchlorides0.25%n-Alkyl(60%C14,30%C16,5%C12,5%C18)dimethylbenzylammoniumchlorides0.25%Isopropylalcohol55%Inertingredients44.50%

SaniClothHBbyPDI n-Alkyl(60%C14,30%C16,5%C12,5%C18)dimethylbenzylammoniumchlorides0.07%n-Alkyl(68%C12,32%C14)dimethylethylbenzylammoniumchlorides0.07%Inertingredients99.86%

Asepti-HBbyEcolabInc. n-Alkyl(60%C14,30%C16,5%C12,5%C18)dimethylbenzylammoniumchlorides0.07%n-Alkyl(68%C12,32%C14)dimethylethylbenzylammoniumchlorides0.07%Inertingredients99.86%

CavicideandCaviWipesbyMetrex Diisobutylphenooxyethoxyethyldimethylbenzylammoniumchloride0.28%Isopropylalcohol17.2%Inertingredients82.52%

Caution:• Applycleaningagenttoaclothbeforeapplication;donotspraycleaningagentdirectlyonthedevice. Itisimportanttopreventpoolinganddirectcontactwithopenconnectionswhichcancausedamage over time.- CleantheoutersurfaceoftheINOblenderwithasoftclothdampenedinamildsoapandwatersolution(Example:PalmoliveUltraantibacterial,4dropsper50mLofwarmwater),isopropylalcohol(70%),orwithoneofthefollowingcleaningagentswhilefollowingthemanufacturer’srecommendations.

Note: TheINOblenderdoesnotcontainanyuserrepairableparts.

BioquellHydrogenPeroxideSterilantBioquellHydrogenPeroxideSterilantandhydrogenperoxidevaporgeneratorsareregulatedbytheUSEnvironmentalProtectionAgency(EPA)aspesticidechemicalsinaccordancewithFederalInsecticide,Fungicide,andRodenticideAct(FIFRA).Useoftheseproductsincleaning/disinfectionprocesseshavenotbeenvalidatedwiththeINOblender.DonotusetheseproductstodecontaminatetheINOblenderoranyancillaryproductsusedwiththeINOblender.

Part No. 20181 Rev-022012-06

16

ReplacingtheCGA626tipontheINOMAXregulator

YearlyCalibrationTheINOblendercalibrationshouldbecheckedevery12monthsusingtheNOmonitoroftheprimaryNOdeliverysystem.Thetestpointsshouldincludeallthecontrolsettingsatoxygengasflowsof5and14L/min.IftheINOblenderisoutsideoftheaccuracyspecification,itshouldnotbeused.

ContactCustomerSupportatthenumberonthebackcoverofthismanualforrepair.

Figure 5-1

1.DisconnecttheregulatorfromtheINOMAX gascylinder.

2.RemovetheoldCGA626tip(forISOsee Figure5-2)bypullingonthetip(a)andturning itcounterclockwise(b)(seeFigure5-1).

3.Ensurethethreadsarecleanonthe regulatortip(ifrequired,usealintfreecloth).

4.Installthenewtip: Flexthefourprongsbysqueezingtwoprongs atatimeusingonlyyourfingers.Thiswillhelp startthenewtipintothethreads.Turnthetip clockwisewhenthreadingthetip.Whenthe tipisfullyinserted,itshouldturnfreely.

a

b

Note: •DepressurizetheINOMAXregulatorbyusingthepurgeportonthebackoftheINOmaxDSIR prior to removing from the cylinder valve.

•ChecktheINOblenderandconnectionhosesforsignsofwearanddamage. •FortheCGA-typeregulatorconnector,ensurethewhiteplastictipisnotchippedorcracked.Remove

andreplaceasnecessary.(seeFigure5-1). •FortheISO-typeregulatorconnector,checkthattheO-ringispresentandisnotdamaged

(seeFigure5-2).

Part No. 20181 Rev-022012-06

17

Figure 5-2

1.DisconnecttheregulatorfromtheINOMAXtherapygascylinder.

2.RemovetheoldISOO-ringbyrollingitoffitsgroove(seeFigure5-2).

3.Cleantheconnectortip(ifrequired,usealintfreecloth).

4.RollthenewO-ringintoitsgroove.Whencorrectlyinstalled,itshouldnotberemovablebyturningit.

Caution: DonotusehardobjectstoremovetheO-ringastheymaydamagethemetalglandand causealeak.

O-ring

Gland

ReplacingtheO-ringontheISO5145INOMAXregulatorfitting

Note: DepressurizetheINOMAXregulatorbyusingthepurgeportonthebackoftheINOmaxDSIR prior to removing from the cylinder valve.

Part No. 20181 Rev-022012-06

18

CylinderLeakCheckIfaleakissuspectedduringthehigh-pressureleaktest(seeSection3/Pre-UseCheckout;HighPressureLeakTest),thefollowingstepscanbetakentocheckforleaks(seeFigure5-3forpossiblecylindergasleaklocations)intheINOMAXregulatororINOMAXcylinder.

Figure 5-3

1. CylinderValveRegulatorConnection2. INOMAXRegulatorHandWheelConnection3. RegulatorEndCapConnection4.. Tamper Evident Tape5. Valve Nut6. SafetyPressureReleaseDevice

1. EnsurethatINOMAXregulatorisconnectedtocylindervalveoutlet(hand-tightenonly),thatthecylindervalveisopen,andthatthecylinderhasmorethan14bar(200psig).

2. Applysoapywatertopoints1,2,3,5and6(seeFigure5-3);ifbubblesform,thereisaleak.

3. Iftherearenobubbles,leakmaybeinsideINOblenderorINOmaxDSIRandcannotberepaired.ReplaceINOblenderorINOmaxDSIR andcontactCustomerSupport.

Recommendedactionsshouldaleakbedetected:

1. Aleakdetectedatpoints1and2(seeFigure5-3)maybecorrectedbytighteningtheINOMAXregulator hand wheel.a. Ifcylindervalveisopen,closecylindervalve

andtightenINOMAXregulatorhandwheel.b.Opencylindervalveandreapplysoapywater

topoints1and2.c.Ifbubblesform,thereisaleak.d.RemoveINOMAXregulatorandcheckwhite

plastictiponINOMAXregulatorforchipsorcracks.Replaceifnecessary(seereplacingthetipontheINOMAXregulator,page16).FortheISOtyperegulatorconnector,checkthattheO-ringispresentandisnotdamaged.Replaceifnecessary(seereplacingtheO-ringontheINOMAXregulator,page17).Repeatstepb(note:Ifleakremains,replaceINOMAXregulator).

2. Ifaleakisdetectedbetweentheregulatorbodyandregulatorendcap(seepoint3),replaceINOMAXregulatorandcontactCustomerSupport.

3. Aleakdetectedatcylindervalvenutconnection(seepoint5)maynotberepaired. ReplaceINOMAXcylinderandcontactCustomerSupport.

4. Aleakdetectedatsafetypressurereleasedevice(seepoint6)maynotberepaired.ReplaceINOMAXcylinderandcontactCustomerSupport.

6

5

1

2 3

4

Note: Refertohospitalpoliciesandprocedures fordealingwithleakinggascylinders. Additionalinformationregarding environmentaleffectscanbefoundin thesection1/GeneralInformation.

Part No. 20181 Rev-022012-06

19

PartsandAccessories

WARNING: Useonlyparts/accessoriesdesignatedforusewiththissystem.

Parts/Accessories PartNumberClampAssembly 10008HoseAssembly,OxygenGreen,DISStoDISS,15Feet 8034.4.HoseAssembly,OxygenWhite,DISStoDISS,15Feet 8034.5HoseAssembly,OxygenWhite,DISStoSIS,15Feet 80353HoseAssembly,OxygenWhite,NISTtoNIST,15Feet 804.81INOMAXRegulator,CGA626 10006INOMAXRegulator,ISO5145 10020INOMAXRegulatorExtensionHose 10014.Operation and Maintenance Manual 20181O-ring,ISO5145INOMAXRegulator 804.70Tip,CGA626INOMAXRegulator 1605-314.9-000TransportMountingBracketAssembly/Spacer 5004.1

OperationandMaintenanceManual PartNumberEnglish 20181Czech 20308Danish 20309Dutch 20310Finnish 20311French 20312German 20313Hungarian 20314.Italian 20315Korean 20316Norwegian 20317Polish 20318Portuguese 20319Spanish 20305Swedish 20320

Part No. 20181 Rev-022012-06

20

(Intentionallyleftblank)

Part No. 20003 Rev - 01 Part No. 20181 Rev-022012-06

6/ Product Specifications

Part No. 20181 Rev-022012-06

6/ Product Specifications

Part No. 20181 Rev-022012-06

21

Specifications

INOblender

Ü NOSetRange 5to80ppm(800ppmcylinder) 2.5to40ppm(400ppmcylinder) Settingaccuracy +/-20%indicatedor2ppm,whicheverisgreater Gasflowrange 5to14L/minofO2 O2inletconnection DISS(male),3.4bar(50psig,nominal) NO/N2inletpressure 1.7to2.4bar(25to35psig) NOinlet Quickdisconnectwithshut-off(Female) NO/O2outlet Barbfittingforoxygensupplytubing Max.Dimensions 200mm(W)X120mm(H)X110mm(D)DISS 200mm(W)X120mm(H)X131mm(D)NIST Max.weight 1.5kg

OperatingandStorageConditions

OperatingTemperature 10to40°C OperatingHumidity 15%to95%non-condensing OperatingBarometricPressure 57to110kPa StorageTemperature -40to+70°C StorageHumidity 15%to98%noncondensing StorageBarometricPressure 57to110kPa

INOMAXPressureRegulator

CylinderValveConnector CGA626orISO5145valve InletPressure 14to155bar(200to2,248psig) NOOutletPressure 1.7to2.4bar(25to35psig)

ManualResuscitatorsThe INOblender is compatible with most types of manual resuscitation bags when used within the specifications of this device. The INOblender has been validated against the following manual resuscitation bags.*

*AirlifeAdultManualResuscitatorwithreservoirtubing *Allegiance½LPediatricManualResuscitatorwithreservoirtubing

Part No. 20181 Rev-022012-06

22

(Intentionallyleftblank)

17Part No. 20181 Rev-02

2012-06

23

(Intentionally left blank)

EuropeEuropean Authorized Representative

MDSS GmbHSchiffgraben 41

30175 Hannover, Germany

AustraliaAustralia RepresentativeIkaria Australia Pty Ltd.

+61 3 9882 4855

Europe

Part No. 20181 Rev-022012-06

ManufacturerNorth America

INO Therapeutics LLC d/b/a Ikaria, Inc.Perryville III Corporate Park

53 Frontage Road, Third Floor Hampton, NJ 08827-9001, USA

1-877-566-9466www.ikaria.com