Engineering Foundation - WordPress.com · Web viewFor cutting threads in steel, normal engine oil...

Transcript of Engineering Foundation - WordPress.com · Web viewFor cutting threads in steel, normal engine oil...

Level 1

Engineering Foundation

1

HAND TOOLS

Spanners

Spanners (or wrenches) are the technician’s ‘bread and butter’ tools. These tools facilitate the removal of the nuts and bolts that secure components to a vehicle to enable repair or access.

There are many different types of spanners available, designed for a multitude of tasks but four of the most commonly used are shown below.

Ring spanners provide more contact between the tool and the nut or bolt and their use is far less likely to result in damage or ‘rounding off’. Open-ended spanners should be used only when a ring spanner is not suitable.

Sockets and Ratchets

Sockets are also designed for aiding the removal of nuts and bolts. Unlike a spanner, they cannot be used on their own but have to be used in conjunction with a secondary tool such as a ratchet or perhaps a knuckle bar or speed brace.

Ratchets

2

Sockets are available in varying sizes and shapes such as shallow, standard, deep, six point and twelve point. Strengthened sockets (impact sockets) must always be used with air tools. Standard sockets do not have sufficient strength and could shatter.

Different types of socket.

The ‘spanner priority’ should be observed when deciding which tool is best suited for the removal of a nut or bolt. Other factors permitting, the choice should be in the following order – socket, ring spanner, open-ended, and finally an adjustable spanner if all else has failed!

Q Name the spanner priority?

A.

Torque WenchA torque wrench is designed to facilitate the accurate and consistent tightening of nuts and bolts. They can also be used for carrying out adjustments where a given amount of resistance to rotation is required on an assembly (pre-load).

Each use requires a different type of torque wrench – a ‘click type’ for tightening nuts and bolts as shown below. It is bad practice to click the wrench several times when tightening a bolt. One click is sufficient.

3

A ‘torque meter’ is used for pre-load as shown below.

Pliers

Pliers can be used for a variety of tasks and there are many different types available. Combination pliers are the most common and can be used to carry out any number of operations where increased grip and leverage are required. Generally speaking, side cutters can do a large number of jobs adequately, but if there is a specific task in mind, it is wise to consider a specialist tool for the job (i.e. electrical pliers for wire cutting and crimping connectors). Electrical pliers provide a limited degree of protection to the user from an electric shock thanks to the use of insulation on the handles. A selection of pliers are shown below.

Files

The file is a form of hand operated milling tool. It can be used for shaping metal objects and dressing rough edges. The body and heel are all cutting faces, whilst the tang is provided for the fitting of a handle. All cutting portions are hardened and tempered, whereas the tang is usually left in a softened condition.

4

Hacksaw

A technician’s role often requires the use of a hand cutting saw, such as a metal hacksaw. It is commonly used to cut off rods, bolts and studs. The replaceable blades are commonly made of alloy steel. This gives excellent cutting properties but also provides a large amount of strengthshould the blade be accidentally twisted.

It is important when replacing a blade to ensure that the cutting teeth face forward. This ensures that the removal of metal occurs on the forward (and most powerful) stroke. (See below)

Drills

Drills are used to form holes in a variety of operations such as number-plate fitting, mud flap fitting and sheared bolt removal. There are many different types of drill, but the most commonly used example is the twist drill The flutes formed by the twist of the drill aid swarf clearance. Most good quality twist drills are made from high speed steel (HSS) and have excellent wearproperties.

Above is a drawing of a twist bit.

5

Taps and Dies

Taps and dies are used to cut internal (taps) and external (dies) threads. (See picture below)

The tap consists of a threaded and fluted member, with a square end for mounting in a tap wrench. The taper tap has the last five or six threads ground away to ease passage of the tap into the drilled or prepared hole. This tap should be screwed in as far as it will go to form the bulk of the thread. The second cut tap is then used to bring the thread out to the correct finished dimensions. In general, a plug tap is used for finishing a thread in a blind hole. When cutting a new thread, it is important that the hole is drilled to the correct size. When cutting the thread, apply a little cutting lubricant to the tap. For cutting threads in steel, normal engine oil is fine. Use paraffin for aluminium alloys.

Dies are designed to cut external threads. The cylindrical material that is to receive the thread should be finished to an appropriate diameter (as with taps) in order to receive the appropriate die. (See picture below.)

6

Length

The S.I (Système Internationale) unit of length is the metre. This unit of length is too large for the majority of automotive applications, so the metre is divided into smaller parts: One metre is divided into 100 equal parts called a centimetre. Each centimetre is divided into 10 equal parts called a millimetre. Each millimetre is divided into 100 equal parts and each is referred to decimally:

0.01mm (1 hundredth of a millimetre). Each 0.01mm can be split down further into 10 equal parts and therefore each

and expressed: 0.001mm (1 thousandth of a millimetre).

If we are looking at much greater distances we can multiply the metre by 1000 and express this as one kilo metre (1 Km).

Other Units Used

Quantity Unit AbbreviationDistance Metre mVolume Litre lPower Watts WMass Kilogramme kg

Velocity Metres per second m/sForce Newton N

Torque Newton per metre Nm

1 metre

1 millimetre

1 centimetre

1 Kilometre

Multiply by 1000

Divide by 100

Divide by 1000

7

Areas and Volumes

To work out an area of a simple square/rectangle all we do is multiply one side by the other side. Example below:

Answer 100cm2

To work out an area of a circle you have to multiply the radius by the radius and by π (3.142). Therefore the formula for an area of a circle is = πr2

Example

πr2 = 3.142 x 10 x 10Answer = 314.2 cm2

To work out the volume of any of the above all we have to do is multiply the area by the height.

Examples.

10cm

10cm

10 cm

10 cm R = 10cm cm

15cm 15cm

R

8

10 cm

Answer for the square = 10 x 10 x 15 = 1500cm3

Answer for the cylinder = 3.142 x 10 x 10 x 15 = 4713cm3

Measuring

Working as a technician you will be called upon to read and take measurements of various equipments using different types of measuring tools, some of these measurements may have to be very precise. Some of the tools we used are listed in the table below.

Tool Purpose

Dividers For marking out circles and transferringmeasurment

Oddleg Calipers For marking out lines parallel to an edge

Bevel Protractor For marking out and measuring angles invarying degrees

Combination Set For marking and measuring a variety ofshapes and sizes

Trammels For marking out circles and transferringmeasurement

Square Checking and marking out a 90 0 angle

Vee Blocks and Clamps To support and grip round objects

Surface Table or Surface Plate To provide a flat surface or datum

Angle Plate and Surface Gauge Used in conjunction with surface plate

Parallels and Parallel Blocks To support components on a surfacetable

A Template To provide a pattern to work from

Although the main precise measurement tools we would use during the day is: The common ruler:

9

The micrometer:The micrometer can be used to measure internal and external measurements associated with engineering and the automotive industry.

1. Measuring faces 2. Spindle 3. Micrometer Screw4. Fixed nut 5. Thimble sleeve 6. Thimble cap7. Ratchet stop 8. Thimble 9.Barrel10. Locking ring 11. Frame 12. Anvil

The vernier gauge:

Can be used to measure external, internal and depths of equipments.

10

The Dial Test Indicator (DTI)

A dial test indicator (DTI) is only capable of direct measurement a few situations - mostly, they provide the user with comparative values.

A DTI is a device that turns lateral movement (straight) into the rotary sweep of a needle on a dial face, using a clockwork mechanism that represents the direct movement of the plunger.

The outer face graduations (Bezel) on most represent 100 th of a millimetre and the inner dial (sweep counter) graduations represent whole millimetres. One full sweep of the outer bezel face is directional proportional to 1mm movement on the plunger. Although it should be noted that some DTIs can come in finer measurements.

Materials

Different materials are required when designing a vehicle, the choice of material is dependent on certain factors to the properties that they have. Some of the factors are listed below:

i) Environment – is it hot, cold, wet, abrasive or corrosive.ii) Strength – what forces will be acting on the material iii) Friction – Does the material have good or bad friction properties?iv) Weight – does the material have to be light or heavy?

11

Metals

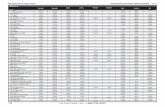

Metals has a rule are categorised into two; these are if they contain Iron (Ferrous) or if they don’t (Non Ferrous). Below is a table of Ferrous and Non Ferrous metals.

Ferrous (Contains Iron)

Metals % Carbon

Wrought Iron 0.01

Mild Steel 0.25

Medium Carbon Steel 0.50

High Carbon Steel 1.20

Cast Iron 3.00

Non Ferrous (Doe’s not contain Iron)

Metal Colour Main Properties

Aluminium White Very light, soft, ductile, good conductor ofheat and electricity

Copper Reddish / brown Soft, ductile, good conductor of heat andelectricity

Tin Silver / white Ductile and malleable

Lead Silver / white Soft, malleable almost non elastic andunaffected by acid

Zinc Whitish / grey Ductile and malleable.Non-corrosive in air

12

Electrics

Everything is made up of atoms. The atom is constructed of a Nucleus containing Protons that have a positive charge and Neutrons that have no charge, surrounding the Nucleus are electrons that have a negative charge. These electrons are attracted to the Nucleus by their charge but are not connected directly to it which means they can be moved by an external force. See below.

Below is a drawing of a two copper atoms you can see from the drawing that a copper atom as 29 protons 35 Neutrons and 29 electrons. From the drawing you can also see that there is only one electron in the outer ring; it is the movement of this outer electron from one atom to another that produces electricity. Materials that readily allow this movement are called conductors and materials that restrict this movement are called insulators.

Electricity Electricity is measurable in three ways. The force of the electrons being pushed around a circuit is measured in Volts(v) and is known has voltage. The quantity of electrons going around a circuit is measured in amps(I) and is known has ampage. The resistance to the flow of electrons is ohms (Ω). Volts, amps and ohms are affected proportionally by each other; this is known has “Ohms Law”

13

Electron movement from one atom to another

This is written as: - :

Power

When electricity is passed around a circuit it provides energy. This electrical energy can be converted into three useful different types:

Thermal energy – by passing electrical charge through a resistance heat is created. This resistance is called a “heating element” on items such as electric fire, electric oven and Kettle.

Radiant energy – when electrons are passed through a light bulb, light is given off this energy is known as radiant energy.

Mechanical Energy – By using a motor, electrical energy can be converted into mechanical movement. This is used on such things as washing machines.

The unit of electrical power is called the Watt and it is directly proportional to the amount of voltage and ampage available. And is written as: - W = amps x volts or

TYPES OF CIRCUIT

The way in which components are connected in a circuit dictates the properties of the circuit (and the performance of the component). The ability to recognise different types of circuit is important.

Series circuit

V

R

I = OR V

I R

W

I V

14

Parallel Circuit

In a series circuit the components follow each other in line in the drawing the components are battery, fuse and resistors. It’s like looking at a row of terraced houses in a street. The advantage of this type of circuit is that its simple and cheap. The disadvantage is that if one of the resistors fail then the othe resistor will not work.

15

How ever a large circuit can contain both a series and parallel type circuit within it.

In a parallel circuit the resistors are next to each other. The advantage of this type of circuit is that if one of the resistors fails the other will still get a feed and work. The disadvantage is you are using more electrical wire and the circuit can get complicated.

16