enclosed area and · PDF filecoating,painting and printing technology;pots and pans assembly...

Transcript of enclosed area and · PDF filecoating,painting and printing technology;pots and pans assembly...

Almesan Aluminium, the leader manufacturer in �at products sector, disc and slug production continues its manufacturing operations with superior HAZELETT strip belt casting and hot rolling technology owned since 2009. It keeps on growing with the new investment made in 2015 which is called aluminium continous casting technology.

Almesan Aluminum constructed at a 50.000 m2 enclosed area and 100.000 m2 open area in Kocaeli Arslanbey Organized Industrial Zone is a subsidiary of SELÇUKLU HOLDING. An annual 50.000 ton casting and hot rolled coil manufacturing is made via 2 pieces of 40 ton Melting furnaces, and modern aluminum furnaces with 30 ton holding capacity with Hazelett continuous sheet strip belt casting technology.

It has 30.000 ton aluminum disc, slug, cold rolled coil, strip, plate, aluminum thick plate and thick foil manufacturing capacity with its process equipments with capability for cold rolling, Coil slitting, Sheet cut to length, pan and pot disc manufacturing presses, impact extrusion slug manufacturing presses, rich moulding inventory for broad range manufacturing capacity, sheet roll and slug annealing furnaces, surface sandblasting, vibration and tumbling processes,aluminium disc PTFE coating,painting and printing technology;pots and pans assembly line. Almesan has the capacity to design the moulds with its own workshop and to manufacture orders in di�erent diameter sizes requested by the customers.The alloys 5000, 6000, 4000 series are manufactured by Almesan the �rst time in Turkey. Hazelett technology is solely available within Almesan in Turkey.

- Hot rolling technology, - 12 ton/hour casting capacity, - 6082, 5083, 4006 plate, sheet manufacturing �rst time in Turkey, - 1.000.0000 pieces / year coating and assembly capacity, - 3600 ton and 5000 ton hidrolic forge presses and speci�c mould inventory, - Stainless steel bottomed disc production, - Supplying added value aluminium product in alloy 6082,6060,5754 for automotive,marine,defence,aerospace and transportation industries, - Deep drawable product quality,- Mould production and wide moulding options owing to its own moulding workshop, - Customer speci�c product options.

Almesan starting manufacturing in 2009 pursues its operations in quali�ed aluminum �at product manufacturing at an increasing pace everyday, together with its young, dynamic and highly skilled sta�. Almesan focusing on continuous development oriented to customer satisfaction carries on its investments incrementally and reinforces its strong position in aluminum sector.

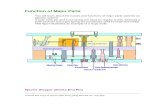

During melting the aluminum raw material and preparing the desired chemical composition in the �nal order, 40 ton-capacity melting and 30 ton-capacity tilting & holding furnaces. The 7 ton-capacity melting furnaces with regenerative burner burning system has an automatic temperature and environment control mechanism. The melting furnace can be recharged quickly with 10 ton-capacity wheel charger. There are equipments capable of performing �uxing and gas re�ning processes required for aluminum re�ning.In addition to this, 35 ton capacity modern melting and 25 ton capacity holding furnace runs in continous casting line with 3,5 ton per hour melting capacity.

The aluminum liquid obtained from melting and holding furnace is manufactured as hot sheet in continuous strip belt casting machine. This sheet manufactured under 500C temperature passes through Hot Roll-1 positioned in the course of the same line and Hot Roll-2 positioned afterwards, and Hot Rolled Coil or plate is manufactured. The alloy desired from the liquid metal, thickness and width is ensured by the continuous casting hot rolled manufacturing and thick plate manufacturing with continuous strip belt casting line and Hot Roll. 300-650 mm wide and 16-50 mm thick 1xxx, 3xxx ,8xxx series and high alloy 5xxx, 6xxx, 4xxx series aluminum alloy manufacturing are made. The solidi�cation of aluminum is realized by its casting technology at lower cooldown temperatures of the aluminum. Thus, excellent metallurgical interior structure, and deep drawing and forming processes can be performed on the manufactured coils and sheets. Daily high volume casting roll manufacturing can be performed with high casting speeds.

The sheet at 500C temperature right out of Hazelett strip belt casting machine is

rolled through hot roll-1 and hot roll-2 at a high reduction rate of 55%, and is manufactured as hot coil or as Aluminum sheet at desired thickness. Special emulsion cooling oils are used as cooling oil. Roll manufacturing at maximum weight of 4 tons, width of 650 mm and diameter of 1800 mm can be made. 650 mm wide, 50 mm thick and 3000 mm long aluminum sheets can be manufactured.

Hot Rolled coils are rolled according to the �nal thickness properties at the cold rolling machine requested by our customers. Cold rolling machine with a cold rolling capacity of 30.000 tons has 4-Hi, the state of the art hardware, electronic automation and thickness measurement system. 1050 mm and 1750 mm width, 1800 mm outside diameter , 5,5 ton and 10 ton weight heavy coils can be rolled down to the thickness from 10 mm to 0,150 mm with cold rolling machine.

CONTINOUS CASTING ( CC Caster )

1700 mm width, 2000 mm outside diameter ,5-12 mm thickness , 1xxx ,3xxx,4xxx,8xxx alloy casting production is made in CC caster.

C-Type Automatic Presses can operate within the diameter range of 160 mm to 600 mm and thickness range of 0,5 to 10 mm. H type zig-zag press can operate within the diameter range of 100- 750 mm .With automatic drive controlled coil opener at 200 ton power and press feeding systems, precision tolerated, high speed disc manufacturing is made. It has monthly 2000 ton manufacturing capacity.

Monthly 500 ton slug production at a diameter from 12,7 to 178 mm, with thickness range of 1 to 50 mm can be made. Materials to work in impact extrusion processes with perforated and non-perforated, �at, concave or tailor made round and rectangular forms can be produced. As an alloy, pure 1xxx series or high alloy 5xxx, 6060, 6061,6063 or 6082 slug production is also made.

To ensure the mechanical properties requested by the customer, the �nal products are annealed and the conditions desired in the order are ensured. 2 units of 30 ton annealing capacity (20.000 tons annually) industrial annealing furnaces are available.

Our mission as Almesan is to provide the highest contribution to every sector where aluminum is used as semi-product.

In aluminum semi-product manufacturing, to be a worldwide exemplary institution with quality, innovative product, e�cient manufacturing, labor safety, esteem for the employees, respect to the idea and modern management understanding.

It has 20.000 ton aluminum disc, slug, cold rolled coil, strip, sheet plate, aluminum thick plate and thick foil manufacturing capacity with its process equipments with capability for cold rolling, Coil slitting, Sheet lengthwise cutting, pan and pot disc manufacturing presses, impact extrusion slug manufacturing presses, rich moulding inventory for broad range manufacturing capacity, sheet roll and slug annealing furnaces, surface sandblasting, vibration and tumbling processes.

750

BRIEF PRODUCT INFO: Aluminum discs are used in cookware manufacturing by coating with Te�on or enamel. Furthermore, tabbed (toothed) discs are used to bring the heat transmission at the underlay perfection in cookware industry such as stainless steel pots and pans. The customers' demands are satis�ed with broad range of mould inventory. By manufacturing our mould inour own moulding workshop, we uniquely provide distinction at price and quality.

50

Aluminum slugs are used extensively as the impact extrusion, deep drawing, forming and shaping material in many sectors such as packaging, automotive, �ltering, cooling, electricity and electronics industries.

Aluminum used in machinery production and particularly in moulding production in the industry by importing it to our country is manufactured in thick sheet plates. Material manufacturing is made at conditions and technical speci�cations to cover the quality expectations of our customers.

PTFE coated disc

COATED DISC

Aluminium discs can be coated by PTFE in rock oven with Roller and Curtain technology according to customer speci�cation.Customer special design request can be carried out by serigraphy technology.

DIAMETER(mm)

0,8 - 5 160 - 450

To perform the process works required to be made in the production of quali�ed aluminum materials, our R&D lab is equipped with chemical analysis device, mechanical tensile test, hardness, heat treatment annealing furnace, optical microscope, metallography polishing device, distillation and chemical test equipments with oil and water analyses with a trained R&D sta�.Owing to the collaboration made with Turkey's prominent universities and research and development centers, various alloy experiments are made.

- Germany- Italy- U.K.- France- Spain- Mexico- Belgium

- Check Republic- Algeria- Ghana- Indıa- Egypt- Portugal- Greece

Factory : Arslanbey Org. San. Bölgesi, 1. Cad.No: 10, Kartepe/ KOCAELİ Phone: +90 262 351 39 43 Fax: +90 262 351 39 46

Headquarter: Akpınar Mah. Kanuni Cad. No:6, 34885, Sancaktepe / İSTANBUL / TURKEY Phone: +90 216 419 76 41 Fax: +90 216 419 71 50

ALMESAN ALÜMİNYUM SAN. ve TİC. A.Ş.

e-mail : [email protected]