Enabling 10 mol/kg swing capacity via heat integrated sub ... Library/Events/2017/co2...

Transcript of Enabling 10 mol/kg swing capacity via heat integrated sub ... Library/Events/2017/co2...

Enabling 10 mol/kg swing capacity via heat

integrated sub-ambient pressure swing adsorption

Ryan P. Lively

Principal Investigator

Yoshiaki Kawajiri, Matthew J. Realff, David S. Sholl, Krista S. Walton

Co-Principal Investigators

Georgia Institute of Technology

School of Chemical & Biomolecular Engineering

Atlanta, GA 30332

DOE-NETL CO2 Capture Technology Project review Meeting

Thursday, August 24th , 2017

Key Idea:

Combine:

(i) Sub-ambient gas processing and

energy recovery with

(ii) ultra-porous metal-organic

frameworks and

(iii) space- and energy-efficient fiber

sorbent contactors

to yield a game-changing process

strategy 2

Project scope—Re-thinking general assumptions about

post-combustion CO2 capture

• Rapid pressure swing adsorption is

more straightforward than rapid

temperature swing adsorption (the

former has been commercialized)

• Immense pore volume and surface

area of MOFs are advantageous at

sub-ambient conditions and moderate

CO2 partial pressures (~1-2 bar)

• Sub-ambient conditions increase

adsorption selectivity and working

capacity—even without adsorbent

structural changes

• Weaknesses of MOFs addressed

through contactor (hollow fiber

sorbents) and through process

strategy

RCPSA

Sub-ambient membrane system

3

Background: Metal-organic frameworks—State-of-the-art

[1] TM McDonald, JR Long et al., Nature, 2015, 519, 303-308

[2] JM Simmons, T Yildirim et al., Energ. Env. Sci., 2011, 4(6), 2177-2185

4

Mmen-Co2(dobpdc)

Pressure (torr)

25°C

75°C

5

A wide variety of MOFs can hit >10 mol/kg swing capacities at sub-ambient conditions

[1] J Park, RP Lively, DS Sholl, J. Mater. Chem. A. 2017, 5, 12258-12265

0.0 0.5 1.0 1.5 2.0 2.50

10

20

30

40

50

CO

2 U

pta

ke (

mol/kg)

Pressure (bar)

213 K

228 K

243 K

258 K

273 K

Pressure Swing Adsorption

ΔP = 1.9 bar

Sub-Ambient ΔNCO2

~ 40 mol/kg

210 220 230 240 250 260 270 2800

5

10

15

20

25

30

35

40

45

N

CO

2 (

mol/kg)

Temperature (K)

Pads = 2.0 bar

Pdes = 0.1 bar

Pdes = 0.2 bar

Pdes = 0.3 bar

Pdes = 0.5 bar

Pdes = 1.0 bar

6

A wide variety of MOFs can hit >10 mol/kg swing capacities at sub-ambient conditions

𝑝𝐶𝑂2𝑎𝑑𝑠 = 2 𝑏𝑎𝑟

𝑝𝐶𝑂2𝑑𝑒𝑠 = 0.1 𝑏𝑎𝑟

[1] J Park, RP Lively, DS Sholl, J. Mater. Chem. A. 2017, 5, 12258-12265

2nd generation process flow diagram

43.5°C

Gas conditioning

RCPSA CO2 liquefaction and pumping

Sub-ambient heat

exchange

Flue Gas

Liquid CO2

7

2nd generation process flow diagram

Dry

er

be

d

Dryer

bed

Flue Gas

Liquid CO2

Regeneration

N2 effluent

Gas conditioning Sub-ambient

HEX20°C,

60 barBF

W

RCPSA

CycleDesorption Adsorption

DCC

CO2 liquefaction

& pumping

PSA Unit

Vac

CW

1

CW to

cooling tower

1

Cold

Box

Liq. CO2 pump

Comp 1Comp 2

Exp. 2 Exp. 1

Comp

3

Comp 4

Liquefaction

column

4 bar

16 bar

1 bar4 bar

47°C, 1 bar16 bar

4 bar

4 bar

1 bar

0.052% H2O

BF

6 bar

6 bar

0% H2O

BF

W

2°C

1 bar

16 bar

43.5°C

8

9

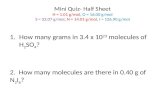

Preliminary technoeconomic analysis

0.00 5.00 10.00 15.00 20.00 25.00 30.00 35.00

80

85

90

32.07

27.77

24.58

30.04

25.84

22.65

28.63

24.53

21.33

27.20

23.20

19.81

25.72

21.51

17.67

Parasitic Load %

Co

mp

resso

r/E

xp

an

de

r e

ffic

ien

cy

Parasitic load (NETL Base Case 550 MW power plant)

95% purity post-PSA 86.7% Purity post-PSA 79.3% Purity post-PSA

72.7% Purity post-PSA 64.4% Purity post-PSA

Task 14 (process flow sheet optimization)

10

Preliminary technoeconomic analysis

Task 14 (process flow sheet optimization)

Equipment Cost (MM$)

compressors &

expanders74

HX 38

PSA 38

DCC & cooling tower 2

Liquid CO2 pump < 0.1

silica bed < 0.1

Total ~155

Background: Hollow fiber sorbents, a mass producible structured sorbent

inspired by hollow fiber membrane spinning

Ideal temperature swing adsorption

1000 µm

[1] RP Lively, WJ Koros et al., Ind. Eng. Chem. Res., 2009, 48(15), 7314-7324

11

Bundle of 40 fibers in a

1.5’ module at GT

Background: Fiber sorbents for PSA applications

2 µm

H2/CO2 separations

12

[1] RP Lively, WJ Koros et al., Int. J. Hydrogen Energ., 2012, 37(20), 15227-15240

Post-synthesis formation of MOFs in fiber sorbents

13

[1] BR Pimentel, RP Lively et al., Ind. Eng. Chem. Res. 2017, 56(17), 5070-5077

Load metal oxide

fibers into

adsorption module

Task 7 (synthesize MOFs and spin fibers)

Post-synthesis formation of MOFs in fiber sorbents

14

Peristaltic Pump

Swagelok®

Module

w/ fibers

Liquid Reservoir

Cu(NO3)2 BTC + Cu(NO3)2

ZnO (Zn, Cu)

HDSHKUST-1

[1] BR Pimentel, RP Lively et al., Ind. Eng. Chem. Res. 2017, 56(17), 5070-5077

Task 7 (synthesize MOFs and spin fibers)

Post-synthesis formation of MOFs in fiber sorbents

15

Peristaltic Pump

Swagelok®

Module

w/ fibers

Liquid Reservoir

Cu(NO3)2 BTC + Cu(NO3)2

ZnO (Zn, Cu)

HDSHKUST-1

[1] BR Pimentel, RP Lively et al., Ind. Eng. Chem. Res. 2017, 56(17), 5070-5077

Task 7 (synthesize MOFs and spin fibers)

MIL-101(Cr) emerged as a promising candidate

16

220 230 240 250 260 270 280

CO2/N

2 0.14/0.86 mixture

Temperature (K)

PCO2,ads

= 2.0 bar

PCO2,des

= 0.1 bar

PCO2,des

= 0.2 bar

PCO2,des

= 0.3 bar

PCO2,des

= 0.5 bar

PCO2,des

= 1.0 bar

220 230 240 250 260 270 2800

5

10

15

20

CO2 single component

N

CO

2 (

mol/kg)

Temperature (K)

Pads = 2.0 bar

Pdes = 0.1 bar

Pdes = 0.2 bar

Pdes = 0.3 bar

Pdes = 0.5 bar

Pdes = 1.0 bar

Low cost ligands (benzene dicarboxylate)

Relatively low cost metal centers (chromium nitrate)

Scale-up is straight forward (70% yield on large batches)

Water stable

[1] J Park, RP Lively, DS Sholl, J. Mater. Chem. A. 2017, 5, 12258-12265[2] L Hamon, GD Weireld et al., J. Am. Chem. Soc. 2009, 131, 8775-8777

MIL-101(Cr) emerged as a promising candidate

17

[1] J Park, RP Lively, DS Sholl, J. Mater. Chem. A. 2017, 5, 12258-12265[2] L Hamon, GD Weireld et al., J. Am. Chem. Soc. 2009, 131, 8775-8777

0 1 2 3 4 50

5

10

15

20

25

30

Upta

ke

(m

mo

l CO

2/g

)

Pressure (Bar)

223 K

233 K

243 K

253 K

263 K

273 K

MIL-101(Cr) CO2 Subambient Isotherm

Low cost ligands (benzene dicarboxylate)

Relatively low cost metal centers (chromium nitrate)

Scale-up is straight forward (70% yield on large batches)

Water stable

18

MIL-101(Cr) fiber sorbents

BET Specific Surface Area (m2/g)

As-synthesized 2740

Post-humid SO2 2790

Task 8 (moisture and acid gas stability—also completed for UiO-66)

Solvent stability

Water stability

Installing thermal modulation into fiber sorbent contactors

19

Hybrid uPCM-UiO-66 Fibers

20μm

MOF-loaded

porous polymer

matrix

Barrier layer

PCM

3 steps: spinning, barrier

layer installation, PCM

installation 1 step: spinning

MOF-loaded

porous polymer

matrix

µPCM

Task 11 (integrate PCM into modules)

0 100 200 300 400 500 600

0.0

0.2

0.4

0.6

0.8

1.0

C/C

0

Time (seconds)

Helium - No PCM Fibers

CO2 - No PCM Fibers

Helium - PCM Fibers

CO2 - PCM Fibers

Effect of PCM incorporation on CO2

Breakthrough of UiO-66 Fibers

Performance of thermally modulated MOF fiber sorbents

20

Performance of thermally modulated MOF fiber sorbents

21

-50 -40 -30 -20 -10 0-1.0

-0.8

-0.6

-0.4

-0.2

0.0

0.2

0.4

0.6

0.8

1.0

Hmelting

= 52.0 J/g

Hfreezing

= 51.2 J/g

Hea

t F

low

(m

W)

Temperature (Degree C)

PCM-UiO-66 Hybrid Fibers

DSC Profile of Modulated Fibers

Operating

Temperature

0 100 200 300 400 500 600 700 800 9000.0

0.2

0.4

0.6

0.8

1.0

1.2

1.4

1.6

1.8

2.0

2.2

2.4

qsorb

en

t @ 5

% L

ea

ka

ge

(m

mo

l CO

2/g

UiO

-66)

Flow Rate (sccm)

No PCM Fibers

PCM Fibers

Sorbent Performace at Different Flow Rates

228 K (uPCM inactive)

Task 10 (experimental PSA cycles)

0 100 200 300 400 500 600 700 800 9000.0

0.2

0.4

0.6

0.8

1.0

1.2

1.4

1.6

1.8

qsorb

en

t @ 5

% L

ea

ka

ge

(m

mo

l CO

2/g

UiO

-66)

Flow Rate (sccm)

No PCM Fibers

PCM Fibers

Sorbent Performance at Different Flow Rates

238 K (uPCM Partially Active)

Performance of thermally modulated MOF fiber sorbents

22

-50 -40 -30 -20 -10 0-1.0

-0.8

-0.6

-0.4

-0.2

0.0

0.2

0.4

0.6

0.8

1.0

Hmelting

= 52.0 J/g

Hfreezing

= 51.2 J/g

Hea

t F

low

(m

W)

Temperature (Degree C)

PCM-UiO-66 Hybrid Fibers

DSC Profile of Modulated Fibers

Operating

Temperature

$ (µPCM) << $ (MOF)

Task 10 (experimental PSA cycles)

Cyclic PSA modeling clearly shows the benefit of thermal modulation

23

Task 12 & 13 (model development)

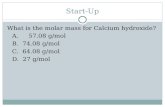

Process Scope—Key Topics, BP2

Seven major activity areas for BP2:

Task 7.0: Generate >250 g/quarter of UiO-66, sub-ambient

sorption isotherms, and simple fiber sorbents—Complete

Task 8.0: Moisture and acid gas stability—Complete

Task 9.0: Lumen layer synthesis—Obsolete via micro PCM

Task 10.0: Cyclic RCPSA using clean gas—Ongoing, 80%

complete

Task 11.0: PCM integration into modules—Complete

Task 12.0 & 13.0: Model development—Complete

Task 14.0: Flowsheet optimization—Complete24

220 230 240 250 260 270 2800

5

10

15

20

CO2 single component

N

CO

2 (

mol/kg)

Temperature (K)

Pads = 2.0 bar

Pdes = 0.1 bar

Pdes = 0.2 bar

Pdes = 0.3 bar

Pdes = 0.5 bar

Pdes = 1.0 bar

Summary25

• Novel polymer/MOF sorbent composite

hollow fibers will be used in new sub-

ambient RPSA process for post-

combustion CO2 capture

• 50% experimental demonstration

• 50% prediction, modeling,

optimization, and economic feasibility

analysis

• Viability of concept is being demonstrated

• Potential for game-changing swing

capacities by utilizing MOFs in sub-

ambient conditions

• Georgia Tech and Inmondo Tech are

partners on this project

• Annual reports, annual review meetings

and conferences presentations and

quarterly reports have been used to

update DOE on team activities

• DOE contribution: ~$2.0M

Georgia Tech contribution: ~$0.5M