Emission Inventory Report

Transcript of Emission Inventory Report

WEST RAND DISTRICT MUNICIPALITY: EMISSION INVENTORY FOR 2011

Report No. uMN014-12 i

EMISSION INVENTORY FOR

THE WEST RAND DISTRICT

MUNICIPALITY

Issued by: Issued to:

uMoya-NILU Consulting (Pty) Ltd

P O Box 20622

Durban North, 4016

South Africa

MD Mokoena

Air Quality Officer

West Rand District Municipality

Corner Park and 6th Streets

Randfontein

2000

May 2012

WEST RAND DISTRICT MUNICIPALITY: EMISSION INVENTORY FOR 2011

Report No. uMN014-12 ii

This report has been produced for the West Rand District Municipality by uMoya-NILU Consulting (Pty) Ltd. The intellectual property contained in this report

remains vested in uMoya-NILU Consulting (Pty) Ltd. No part of the report may be reproduced in any manner without written permission from the West Rand District Municipality and uMoya-NILU Consulting (Pty) Ltd.

When used as a reference this report should be cited as follows:

uMoya-NILU (2012): Emission Inventory for the West Rand District Municipality, report

for the West Rand District Municipality, uMoya-NILU Consulting (Pty) Ltd, Report No.

uMN014-12.

WEST RAND DISTRICT MUNICIPALITY: EMISSION INVENTORY FOR 2011

Report No. uMN014-12 iii

EXECUTIVE SUMMARY

Introduction:

Substances released into the air can affect the health of the environment, residents,

animals and plants. Air emissions are the quantity of a substance, measured as mass of

substance per time unit, released into the atmosphere from a source. Sources of air

emissions include industrial facilities, transportation, home heating, agriculture, forest

fires and many others.

The West Rand District Municipality (WRDM) comprises four local municipalities, namely

Mogale City, Randfontein, Merafong and Westonaria. The WRDM is undertaking its first

air emissions inventory, which will then have to be updated on a regular basis to account

for emission changes. The results of the emission inventory will be used to shape the

way air quality is improved in the WRDM. The emission inventory is fundamental to the

development, implementation, monitoring and evaluation of the WRDM’s air quality

strategy. The emission inventory is also used as a major input to atmospheric dispersion

models.

The base year relevant to the emission inventory is 2011, which means that all emission

estimates will be based on 2011 activity data. The primary focus of the emission

inventory will be on the following criteria pollutants:

Sulphur dioxide (SO2)

Nitrogen oxides (NOx)

Carbon monoxide (CO)

Particulate matter (PM, PM10)

Lead (Pb)

The United States Environmental Protection Agency (USEPA) regulates these pollutants

by developing health-based air quality standards. In addition to these pollutants,

emissions will also be estimated for VOC and benzene. Emissions will be reported as

emission rates, of which the most common units are ton/day or kg/year. Pollutant

emission rates will be estimated by a combination of approaches, including the emission

factor approach and emissions monitoring.

Categorisation of Source in WRDM:

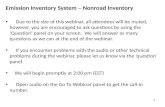

The emission sources in the WRDM are grouped into three main emission types (Figure

A) based on their characteristics, namely, point, mobile and area sources.

Point sources are sub-divided into the two categories of listed activities, i.e., large

industries regulated by Section of the National Environmental Management: Air Quality

Act (Act 39 of 2004) (AQA), and smaller industrial processes with boilers. Mobile

WEST RAND DISTRICT MUNICIPALITY: EMISSION INVENTORY FOR 2011

Report No. uMN014-12 iv

sources include on-road motor vehicles, ships, aircraft and locomotives. Only on-road

motor vehicles will be considered in this study as there are no harbours or airports in the

WRDM.

Figure A: Categorisation of emission sources in the WRDM

Due to the absence of credible information on agricultural activities in the WRDM, this

source is excluded from the study. However, the prescribed burning of crops is covered

as part of biomass burning.

Listed activities and small industrial processes:

Combustion devices found in industries are key emitters of criteria pollutants (SO2, NOx,

CO and PM10) and toxic air pollutants such as benzene, toluene and xylene. Data to

estimate emissions from industries was gathered with the aid of questionnaires. This

was supplemented by personal interviews with industry representatives and site visits.

The methods used to estimate industrial emissions were the emission factor approach

and calculations based on emission testing undertaken by the industries. The key types

of data required for the emission factor approach include the types of fuel (coal, fuel-oil,

diesel and gas) used and the consumption rates of the fuels. Questionnaires were issued

to 66 industries in the WRDM. It was discovered that several industries were not

sources of atmospheric emissions. The general response from industries was mixed,

with some being very cooperative and others not at all. A breakdown of emissions from

WRDM Atmospheric Emission Inventory

Point Mobile Area

Listed Activities Motor Vehicles

Small Industrial Processes

Domestic Burning

Agricultural

Biomass Burning

Tailings Dams

WEST RAND DISTRICT MUNICIPALITY: EMISSION INVENTORY FOR 2011

Report No. uMN014-12 v

the individual industries is contained in Section 4 of this report. The following table

provides a summary per local municipality:

Table A: Breakdown of industrial emission rates per local municipality in

WRDM, ton/day

Local

Municipality

Emission Rate (ton/day)

SO2 NOx CO PM10 VOC Benzene Lead

Mogale City 3.111 2.449 383.680 2.190 0.013 0.001 0.030

Randfontein 1.184 0.297 0.194 0.530 1.492 0.017 0

Westonaria 0.626 0.119 0.078 11.577 0.001 0 0

Merafong 0 0 0 0.004 0 0 0

Total 4.921 2.864 383.952 14.297 1.506 0.017 0.030

The largest industrial source of SO2 emissions is Mogale Alloys at 2.27 ton/day. Its

contribution to total SO2 emissions exceeds 46%, implying that significant reductions in

industrial SO2 emissions in the WRDM could be achieved by focussing reduction efforts

solely on Mogale Alloys. The other industries that have recorded notable SO2 emissions

are the Foodcorp Grocery Division and West End Clay Brick. Emissions of NOx from

industries in the WRDM are also low at 2.86 ton/day.

The local municipality that produces the largest quantity of industrial emissions is Mogale

City. However, it is interesting to note that the highest emissions of PM10 are from

Westonaria. This is primarily due to the many mining operations taking place there.

Motor vehicles:

A motor vehicle is defined as an on-road vehicle that derives its power for propulsion

from the combustion of fossil fuel. The most common types of motor vehicles that

operate in the WRDM are cars, vans (light-duty vehicles), buses and trucks (heavy-duty

vehicles). Cars are fuelled by both diesel and petrol (gasoline), whereas trucks are only

fuelled by diesel. Pollution from vehicles arises from the by-products of the combustion

process (emitted via the exhaust system), from evaporation of the fuel itself from the

fuel tank and from brakes and tyre wear. The pollutants produced include SO2, NOx, CO,

PM10, VOC and lead.

Motor vehicle emissions were estimated by using the Tier 1 approach proposed by the

European Environmental Agency (EEA). The key types of data required for this approach

are fuel sales data and emission factors. Fuel sales data was sourced from the

Department of Energy, which collates fuel sales data for the oil companies. Data was

available for all the local municipalities with the exception of Merafong. Emission factors

were sourced from the EEA.

The total emissions estimated from motor vehicles are presented below in Table B.

WEST RAND DISTRICT MUNICIPALITY: EMISSION INVENTORY FOR 2011

Report No. uMN014-12 vi

Table B: Breakdown of motor vehicle emission rates per local municipality in

WRDM, ton/day

Local

Municipality

Emission Rates (ton/day)

SO2 NOx CO PM10 VOC Lead

Mogale City 0.143 5.329 27.278 0.341 2.977 0.000

Randfontein 0.046 1.911 11.228 0.099 1.215 0.000

Westonaria 0.042 1.742 10.243 0.090 1.108 0.000

Total 0.231 8.982 48.749 0.530 5.300 0.000

The largest quantity of motor vehicle emissions are from Mogale City, followed by

Randfontein and Westonaria. Motor vehicle emissions in Mogale City, on average, make

up approximately 60% of total motor vehicle emissions in the WRDM. With respect to

individual pollutants, the pollutant emitted in the greatest quantity from motor vehicles

in the WRDM is CO at 48.749 ton/day. This is followed by NOx at 8.982 ton/day and

VOC at 5.3 ton/day. The largest source of VOC is gasoline-fuelled passenger cars. PM10

from diesel engines is considered to be one of the most dangerous pollutants from motor

vehicles with regard to human health. PM10 emissions from motor vehicles in the WRDM

are estimated to be 0.53 ton/day or 193 558 kg/year. The largest source of PM10

emissions is high-sulphur diesel and consequently light-duty trucks and heavy-duty

vehicles (trucks and buses). Due to the phase-out of lead from fuels, total lead

emissions from motor vehicles in the WRDM are low at 5 kg/year.

Tailings dams:

Tailings are the residue of the milling process used to extract valuable metals from

mined ores. There are currently approximately 52 active and inactive tailings dams in

the West Rand District Municipalities owned by the various gold mines located in the

areas. A total of 14 tailings dams were identified in Mogale City, 2 in Randfontein, 11 in

Westonaria and 23 in Merafong.

Tailings dams are examples of open areas that provide substantially large un-vegetated

areas that are exposed to wind erosion. They are a major source of dust and particulate

emissions. The estimation of particulate emissions is based on the USEPA methodology

for wind erosion of open aggregate storage piles and exposed areas in industrial facilities

provided in Chapter 13 of the USEPA 42 (USEPA, 2006). The total estimated emissions

from tailings dams are presented in Table C.

Table C: Breakdown of tailings dams emission rates per local municipality

Local Municipality PM Emission Rate

(kg/year)

PM Emission Rate

(ton/day)

% of

Total

Mogale City 1 797 629 4.92 10.95

Randfontein 1 925 291 5.28 11.75

Westonaria 3 956 869 10.83 24.10

WEST RAND DISTRICT MUNICIPALITY: EMISSION INVENTORY FOR 2011

Report No. uMN014-12 vii

Merafong 7 734 055 21.21 47.21

Total 16 467 289 42.24

The local municipality that emits the largest quantity of PM emissions from tailings dams

is Merafong at 21.21 ton/day, which is also the municipality with the greatest number of

tailings dams. More than 47% of all PM emissions from tailings dams are emitted from

Merafong. Significant quantities of emissions also originate from Westonaria, where

many tailings dams are also located. Since there is no information on what proportion of

the PM consists of PM10, it is assumed that all PM is PM10 which is representative of a

worst-case scenario.

Domestic burning:

The three primary application categories relating to domestic fuel burning are cooking,

lighting and space heating. The primary fuels used in South Africa for domestic

purposes are coal, paraffin, liquefied petroleum gas (LPG) and wood. Domestic use of

fuels is restricted largely to informal, low-income and densely populated settlements.

The combustion of these fuels is a significant source of air pollution, especially during

winter. The impact on air quality from residential fire emissions is fairly significant,

considering that the release of pollutants occurs close to ground level at relatively low

temperatures.

Domestic coal burning contributes to the emission of PM10, SO2, NOx, CO and benzene.

The emission factor approach was used to estimate emissions from domestic burning.

Data was sourced on the number of households in the WRDM, the consumption of fuels

by these households and emission factors for the various fuels burned in households.

The estimated emissions from domestic burning are presented in the table below.

Table D: Breakdown of domestic burning emission rates per local municipality

in WRDM, ton/day

Local

Municipalities

Emission Rate (ton/day)

SO2 NOx CO PM10 VOC Benzene

Mogale City 0.087 0.011 0.781 0.019 0.023 0.000

Randfontein 0.040 0.005 0.339 0.007 0.008 0.000

Westonaria 0.068 0.009 0.536 0.010 0.012 0.000

Merafong 0.001 0.000 0.009 0.000 0.000 0.000

Total 0.196 0.025 1.665 0.036 0.044 0.000

Emissions of all pollutants, with the exception of benzene, can be described as

significant. The combustion of coal and paraffin results in high emissions of SO2 due to

the high sulphur content in these fuels. The local municipality that produces the largest

quantity of emissions from domestic burning is Mogale City. This is directly attributable

to the high number of households in Mogale City that use coal for cooking and space

heating. Westonaria is the municipality that produces the second highest quantity of

WEST RAND DISTRICT MUNICIPALITY: EMISSION INVENTORY FOR 2011

Report No. uMN014-12 viii

emissions. Westonaria is the local municipality where the consumption of paraffin is the

greatest. A high number of households use paraffin in Mogale City for cooking, lighting

and space heating.

Biomass burning:

Biomass burning is generally categorised into wildfires and prescribed (controlled)

burning. A wildfire is a large-scale natural combustion process that consumes various

ages, sizes, and types of flora growing outdoors in a geographical area. Consequently,

wildfires are potential sources of large amounts of air pollutants. Prescribed burning

activities include fires that are intentionally started for a variety of reasons such as fuel

reduction for wildfire prevention, regeneration after logging operations, ecosystem

maintenance, land clearing, and agricultural land management. Emissions of PM, CO,

NOx and VOC from wildfires are estimated by using the emission factor approach.

Emissions of SO2 from biomass burning are considered to be negligible.

The emission factor method requires data on the area burned (in hectares) by a fire and

fuel loading (mass of forest fuel/unit land area burned). Data on area burned was

sourced from the Meraka Institute that uses satellite remote sensing techniques to

identify burned areas. For this study, their analyses of burned area consisted of a spatial

overlay with aggregation, performed in a spatial relational database.

The total burned area for 2011 was 782.6 km2, compared to a total estimated area of

the WRDM of 4 087 km2. The burned area represents 20% of the total area of the

WRDM. This does not however imply that 20% of the total surface area of the

municipality was burned as a single location could be burned several times in a year.

A total of 3 651 fires occurred in 2011, meaning that there were approximately 10 fires

in a day in the WRDM. The highest number of fires for both 2010 and 2011 (average of

4.4 a day) occurred in Merafong, by a significant margin. The lowest number of fires

occurred in Randfontein. The results of the estimation of emissions from biomass

burning are presented below in Tables E.

Table E: Breakdown of biomass burning emission rates per local municipality in

WRDM, ton/day

Local

Municipality

Emission Rate (ton/day)

NOx CO PM10 VOC

Mogale City 3.638 127.802 10.856 21.923

Merafong City 7.740 271.913 23.097 46.643

Randfontein 1.763 61.941 5.261 10.625

Westonaria 3.156 110.866 9.417 19.018

Total 16.297 572.522 48.632 98.208

The total emissions from biomass burning can be described as significant. This is

primarily due to the high number of fires that occur in the district municipality.

WEST RAND DISTRICT MUNICIPALITY: EMISSION INVENTORY FOR 2011

Report No. uMN014-12 ix

Significant quantities of all pollutants are emitted into the atmosphere from biomass

burning. The pollutant emitted in the highest quantity if CO at 572.522 ton/day. There

are also significant quantities of VOC and PM emitted at 98.208 ton/day and 48.632

ton/day, respectively. In line with the highest number of fires there, the highest

quantity of emissions as a result of biomass burning are from Merafong.

Total emissions:

Total emissions of all pollutants from all sources in the WRDM are presented below in

Table F.

Table F: Total emissions from all sources in the WRDM, ton/day

Source Emission Rate (ton/day)

SO2 NOx CO PM10 VOC Benzene Lead

Industries 4.921 2.864 383.952 14.297 1.506 0.017 0.030

Motor vehicles 0.231 8.982 48.749 0.530 5.300

0.000

Domestic burning 0.196 0.025 1.665 0.036 0.044

Tailings dams

42.24

Biomass burning

16.297 572.522 48.632 98.208

Total 5.348 28.167 1 006.889 105.736 105.058 0.017 0.030

The emission rates contained in the above tables provide useful information on which

sources to focus when developing emission reduction initiatives. A total of 5.348

ton/day of SO2 are emitted in the WRDM. Industries are the most significant contributor

to this total (>92.0%), due mainly to the combustion of coal.

A total of 28.167 ton/day of NOx emissions are produced in the WRDM, approximately 5

times more than SO2. The largest producer of NOx emissions is from biomass burning.

Wildfires and prescribed burning activities cause nitrogen to be oxidised to NOx. It is

estimated that a total of 16.297 ton/day of NOx emissions are produced in this way. The

other notable sources of NOx emissions are motor vehicles at 8.982 ton/day and

industries at 2.864 ton/day.

A total of 1 006.889 ton/day of CO emissions are produced, greater than both SO2 and

NOx. However, this does not necessarily mean that CO will pose a greater danger to the

health and well-being of residents in the WDM. CO normally causes negative health

impacts at high concentrations, whereas SO2 and NOx cause negative health impacts at

much lower concentrations. The two most significant sources of CO emissions are

biomass burning and industries at 572.522 ton/day and 383.952 ton/day, respectively.

As expected, the tailings dams produce no CO emissions, while motor vehicles produce

48.749 ton/day.

PM10 emissions are produced by all sources identified in this study. The quantity of PM10

emissions produced in the WRDM are greater than both SO2 and NOx. PM10 is recognised

WEST RAND DISTRICT MUNICIPALITY: EMISSION INVENTORY FOR 2011

Report No. uMN014-12 x

as a pollutant of great concern across the world due to its high prevalence and negative

health impacts. The total quantity of PM10 emitted in the WRDM was estimated at

105.736 ton/day. Biomass burning (48.632 ton/day) and the tailings dams (42.24

ton/day) have been identified as the major sources of PM10 emissions in the WRDM.

Industries are also responsible for a significant PM10 emissions rate of 14.297 ton/day.

VOCs consist of a range of organic pollutants that react photo-chemically with NOx in the

presence of sunlight to form ozone (O3), one of the 6 criteria pollutants and known to

have negative health impacts. The most notable source of VOCs is biomass burning at

98.208 ton/day. Emissions of one of the compounds classified as a VOC, namely,

benzene, was estimated separately in the study. Benzene emissions from the

petrochemical storage depot in Tarlton have been estimated at 6 306 kg/year.

Lead emissions originate from Castle Lead Works (11 031 kg/year) and motor vehicles

(5 kg/year). The low quantity of lead emissions from motor vehicles is primarily due to

the phase-out of lead in fuels.

WEST RAND DISTRICT MUNICIPALITY: EMISSION INVENTORY FOR 2011

Report No. uMN014-12 xi

TABLE OF CONTENTS

1. INTRODUCTION ............................................................................................... 1 1.1 Background ........................................................................................................................... 1 1.2 Base Year ............................................................................................................................. 2 1.3 Pollutants .............................................................................................................................. 2 1.4 Source Types ........................................................................................................................ 3 1.5 Time Interval ......................................................................................................................... 4 1.6 General Emission Estimation Methodology .......................................................................... 4

2. TERMS OF REFERENCE ...................................................................................... 5

3. EMISSIONS INVENTORIES................................................................................. 6 3.1 Background ........................................................................................................................... 6 3.2 Emission Estimation Methodologies ..................................................................................... 8

3.2.1 Continuous Emissions Monitoring (CEM) ............................................................... 8 3.2.2 Source Testing ........................................................................................................ 9 3.2.3 Mass Balance .......................................................................................................... 9 3.2.4 Emission Models and Factors ................................................................................. 9

4. CATEGORISATION OF SOURCES IN THE WRDM .................................................. 11

5. LISTED ACTIVITIES AND SMALL INDUSTRIAL PROCESSES .................................. 14 5.1 Description of Emissions .................................................................................................... 14 5.2 Methodology ....................................................................................................................... 15

5.2.1 Data Gathering ...................................................................................................... 15 5.2.1 Estimation of Emissions ........................................................................................ 17

5.3 Results of Emissions Estimations ....................................................................................... 19 6. MOTOR VEHICLES .......................................................................................... 31

6.1 Description of Emissions .................................................................................................... 31 6.2 Methodology ....................................................................................................................... 32 6.3 Results of Emission Estimations ........................................................................................ 35

7. TAILINGS DAMS ............................................................................................. 40 7.1 Description of Emissions .................................................................................................... 40 7.2 Methodology ....................................................................................................................... 41 7.2.1 Data Gathering ................................................................................................................... 41 7.2.2 Estimation of Emissions ..................................................................................................... 41 7.3 Results of Emission Estimates ........................................................................................... 43

8. DOMESTIC BURNING ...................................................................................... 46 8.1 Description of Emissions .................................................................................................... 46 8.2 Methodology ....................................................................................................................... 46

8.2.1 Data Gathering ...................................................................................................... 46 8.2.2 Estimation of Emissions ........................................................................................ 48

8.3 Results of Emission Estimates ........................................................................................... 48 9. BIOMASS BURNING ........................................................................................ 50

9.1 Description of Emissions .................................................................................................... 50 9.2 Methodology for Estimating Emissions............................................................................... 51 9.3 Results of Emissions Estimation ........................................................................................ 53

10. EMISSIONS SUMMARY .................................................................................... 55

11. CONCLUSIONS AND RECOMMENDATIONS ......................................................... 60

12. REFERENCES ................................................................................................. 63

APPENDIX A – STAKEHOLDER WORKSHOP ............................................................. 64

APPENDIX B – DESCRIPTIONS OF POLLUTANTS AND THEIR HEALTH EFFECTS ............ 68

APPENDIX C – EMISSION INVENTORY QUESTIONNAIRE ........................................... 70

APPENDIX D - GUIDELINE DOCUMENT ................................................................... 77

APPENDIX E – STORAGE TANK EMISSIONS ............................................................ 92

APPENDIX F – LOADING GANTRY EMISSIONS ......................................................... 94

APPENDIX G – FUGITIVE EMISSIONS..................................................................... 96

WEST RAND DISTRICT MUNICIPALITY: EMISSION INVENTORY FOR 2011

Report No. uMN014-12 xii

GLOSSARY OF ACRONYMS, TERMS AND UNITS

AEL Atmospheric emission license

API American Petroleum Industry

AQA The National Environmental Management: Air Quality Act (No. 39 of

2005)

AQMP Air quality management plan

BAT Best Available Technology

BTEX Benzene, toluene, ethyl benzene and xylene

CALPUFF The Californian Puff Model, a USEPA approved Gaussian-Lagrangian

air dispersion model

C Degrees Celsius

CEM Continuous emissions monitoring

CO Carbon monoxide

CONCAWE Oil Companies European Association for Environment, Health and

Safety in Refining

DEA The Department of Environmental Affairs

EF Emission factor

EFRT External floating roof tank

EIA Environmental Impact Assessment

Emission

The direct or indirect release of substances, vibrations, heat or noise

from individual or diffuse sources in an installation into the air, water

or land.

FRT Fixed roof tank

g/s Grams per second

HFO Heavy fuel oil

LDAR Leak detection and repair

LPG Liquefied petroleum gas

m/s Meters per second

mg/m3 Milligrams per cubic meter

NEMA National Environmental Management Act (Act No. 107 of 1998)

Nm3/h Normal cubic meters per hour

NOx Oxides of nitrogen, collectively groups nitrogen oxide and nitrous

oxide

NPI National Pollutant Inventory of Australia

O3 Ozone

Pb Lead

PM10 Particulate matter with aerodynamic diameter < 10 microns

PM Particulate matter

ppb Parts per billion

SAWS South African Weather Service

SO2 Sulphur dioxide

TANKS US EPA model to calculate emissions from fuel storage tanks

WEST RAND DISTRICT MUNICIPALITY: EMISSION INVENTORY FOR 2011

Report No. uMN014-12 xiii

TOC Total organic compounds

USEPA The United States Environmental Protection Agency

µg/m3 Micrograms of gaseous substance in one cubic metre of total gas

VKT Vehicle kilometres travelled

VOC Volatile organic compounds

WHO The World Health Organisation

WRDM West Rand District Municipality

WEST RAND DISTRICT MUNICIPALITY: EMISSION INVENTORY FOR 2011

Report No. uMN014-12 1

1. INTRODUCTION

1.1 Background

Substances released into the air can affect the health of the environment, residents,

animals and plants. Air emissions are the quantity of a substance released to the

atmosphere from a source. There are a variety of sources that are responsible for air

emissions, these include both naturally occurring and man-made. Sources of air

emissions include industrial facilities, transportation, home heating, agriculture, forest

fires and many others.

Air pollution comes from many sources, so it is important to know the contribution each

one makes in order to develop the best approaches for improving air quality. The West

Rand District Municipality (WRDM) is undertaking its first air emissions inventory, which

will then have to be updated on a regular basis to account for emission changes. The

results of the emission inventory will be used to shape the way air quality is improved in

the WRDM. The emission inventory is fundamental to the development, implementation,

monitoring and evaluation of the WRDM’s air quality strategy. The emission inventory is

also used as the major input to atmospheric dispersion models.

The WRDM is located in the province of Gauteng and comprises four local municipalities,

namely Mogale City, Randfontein, Merafong and Westonaria (see Figures 1.1 and 1.2).

The North West province is located to the north, west and south of the municipality.

Figure 1.1: Map showing location of WRDM in Gauteng Province

WEST RAND DISTRICT MUNICIPALITY: EMISSION INVENTORY FOR 2011

Report No. uMN014-12 2

Figure 1.2: Map showing local municipalities in WRDM

The economic profile of the West Rand is characterised by agriculture, industrial and

mining activities, of which the latter two contribute largely to pollution and air quality

related problems in the region. In order to address and manage air pollution challenges,

a comprehensive air emission inventory is required for each local municipality.

The WRDM developed an Air Quality Management Plan (AQMP) in 2010 and one of the

gaps identified was the lack of a comprehensive emission inventory. The emission

inventory is intended to provide WRDM with essential information required to combat air

pollution and improve the quality of air within the region. This study was commissioned

in response to this response to the gap identified in the AQMP.

1.2 Base Year

The base year relevant to the emission inventory is 2011, which means that all emission

estimates will be based on 2011 activity data (fuel consumption rates, cleaning devices

efficiencies, traffic counts, etc.). No consideration will be given to proposed changes

intended to improve future air quality performance that have not been implemented by

2011. However, there will be instances where 2011 data will not be available. In such

cases, the year relating to the data will be explicitly stated.

1.3 Pollutants

The primary focus of the emission inventory will be on criteria pollutants, although

hazardous air pollutants (HAPs) will be estimated where permitted by the availability of

the necessary emission factors. The USEPA makes a clear distinction between criteria

WEST RAND DISTRICT MUNICIPALITY: EMISSION INVENTORY FOR 2011

Report No. uMN014-12 3

pollutants and HAPs. Criteria pollutants are the six most commonly found air pollutants

that can harm human health or the environment. They include:

Sulphur dioxide (SO2)

Nitrogen oxides (NOx)

Carbon monoxide (CO)

Particulate matter (PM, PM10)

Ozone (O3)

Lead (Pb)

The USEPA regulates these pollutants by developing health-based air quality standards.

Emissions for five of the six criteria pollutants will be estimated as part of this project.

Ozone will be excluded as it is, strictly speaking, not an emission but is formed by the

photochemical reaction of nitrogen oxides with non-methane volatile organic compounds

(NMVOC).

HAPs, on the other hand, are pollutants that cause or may cause cancer or other serious

health effects. However, these effects normally occur at high concentrations not

commonly found in the ambient environment, but in occupational environments such as

in the vicinity of chemical plants or chemical storage facilities. The standards developed

for HAPs are therefore occupational standards and are applied to workers working in

facilities that produce or store these pollutants. Examples are toluene (found in

gasoline), methylene chloride (found in paint stripper) and perchlorethylene (emitted

from dry cleaners). The USEPA has compiled a list of 187 HAPs, the majority of which

are organic in nature. However, certain non-organic HAPs such as hydrogen sulphide

(H2S), hydrogen fluoride (HF) and mercury also do exist. The full list of HAPs can be

accessed on the following link:

http://www.epa.gov/ttn/atw/188polls.html

1.4 Source Types

The project scope will include the following three primary source categories:

Point sources

Non-point sources

Mobile sources

Point sources are generally large industries with high stacks and high emission loads.

The USEPA defines a point source as any industry emitting >10 ton/annum of a criteria

pollutant or a combination of criteria pollutants. South Africa has not yet adopted a

formal definition for point sources. The following are typical examples of industries

classified as point sources:

Oil refineries

Power plants

WEST RAND DISTRICT MUNICIPALITY: EMISSION INVENTORY FOR 2011

Report No. uMN014-12 4

Pulp and paper mills

Metallurgical industries

Non-point or area sources are smaller sources of similar activity that are grouped

together, which when taken collectively, produce a significant amount of air pollution.

There are several categories of area sources including biogenic sources, small industrial

sources (tank farms, landfills, waste water treatment plants, etc.), agricultural sources,

domestic burning sources and minor road sources.

Mobile sources are classified as on-road or non-road sources. As the name suggests,

on-road sources include all motor vehicles that travel on road such as cars, vans, trucks

and buses. Non-road sources refer to vehicles that are not confined to a road such as

ships, boats, aeroplanes, construction equipment and farming equipment.

1.5 Time Interval

Emissions will be reported as emission rates (versus emission concentrations), that is,

the mass of pollutants emitted in a time unit interval. The most common emission rate

units are ton/day or kg/annum. Reporting in daily averaging units such as ton/day is

important as it allows seasonal variations during the course of the year to be accounted

for. Seasonal variations occur when industries operate for certain months of the year

and not for others. This results in the uneven distribution of emissions during the year.

Variations in emissions also occur for motor vehicle emissions such that emissions rates

are higher during weekdays and lower during weekends. This variation can only be

demonstrated if emission rates are reported on a daily basis.

The unit of ton/day will be reported to two decimal places, whereas the unit of kg/year

will be reported to zero decimal places.

1.6 General Emission Estimation Methodology

Activity data will be obtained from industry groups, government departments and other

service providers. Pollutants emission rates will then be estimated by combining activity

data with emission factors. Where available, source emission test data will be used in

preference to emission factors for industrial and commercial sources. The emissions will

be assigned to the four local municipalities for all sources. Emissions will then be

calculated for days and years using emissions factors derived from various

internationally recognised sources. Emission estimation techniques for all source types

have been based on either published United States Environmental Protection Agency

(USEPA) or Australian (i.e. NPI) methodologies.

WEST RAND DISTRICT MUNICIPALITY: EMISSION INVENTORY FOR 2011

Report No. uMN014-12 5

2. TERMS OF REFERENCE

The following items broadly define the scope of work for the project:

A. Estimation of emissions from the following biogenic and anthropogenic sources:

Veld fires, windblown dust, etc.

Area sources (human settlements)

Point sources:

Industrial (including mining)

Commercial

Agricultural activities:

Crop related

Animal Breading

Mobile sources:

On- road mobile

Off- road mobile

B. Inclusion of the following pollutants in the inventory:

Criteria pollutants

Organic air toxins

C. Inclusion of the Mogale, Randfontein, Merafong and Westonaria local municipal areas

in the inventory.

WEST RAND DISTRICT MUNICIPALITY: EMISSION INVENTORY FOR 2011

Report No. uMN014-12 6

3. EMISSIONS INVENTORIES

3.1 Background

An air emissions inventory is an accounting of air pollutant emissions released over a

given time for a given political or geographic area. It can include point (e.g. industrial

stacks), area (e.g. domestic burning) and mobile (e.g. cars, trucks, and rail) sources. Air

emissions inventories can include emissions from both anthropogenic (man-made) and

natural (e.g. biomass burning, vegetation, soil, etc.) sources.

Air emission inventories are fundamental components of air quality management

systems. Air emissions must be measured before they can be managed and reduced.

Other components of an air quality management system include goals, policies, ambient

objectives, source emission standards, dispersion modelling, ambient air and source

emission monitoring, environmental reporting, approvals, inspections, enforcement and

research. Air emissions inventories are needed to provide regulators, industry and the

public with easy access to the best possible data to make informed decisions. They are

also needed in order to develop and evaluate emission reduction scenarios. Examples of

emission sources are shown in Figure 3.1.

Figure 3.1: Illustration showing typical emission sources

In an emission inventory, all sources of pollution within an area are listed, and details

are provided of the locations and masses of pollutants emitted. Sources of pollution are

divided into the following categories:

Point sources - Emissions from single activities of considerable size, like industrial

plants, power plants and incinerators are characterised by emissions from

individual stacks. It is important to identify the stacks, and to collect information

about their height, physical parameters and the exact location so that it is

spatially resolved.

WEST RAND DISTRICT MUNICIPALITY: EMISSION INVENTORY FOR 2011

Report No. uMN014-12 7

Mobile sources - Emissions from road traffic, streets and highways, and railways.

Emissions are usually estimated based on transportation data (e.g. traffic

counts).

Area sources - Area sources are smaller or more diffuse sources of pollution (e.g.

home heating, public services, veld fires, agricultural activities). Input data for

estimating emissions from these sources are provided on an area basis either for

administrative areas, such as counties, municipalities or for regular grids.

There are several widely used categories to characterise pollutants. These categories

depend on the level of prevalence of the pollutants and the severity of their impacts on

human beings. The three categories that relate particularly to the petroleum industry

are criteria pollutants, toxic (hazardous) air pollutants and nuisance pollutants.

Criteria pollutants:

The USEPA lists criteria pollutants as the six most commonly found air pollutants that

can harm human health or the environment. They include sulphur dioxide (SO2),

nitrogen oxides (NOx), carbon monoxide (CO), particulate matter (PM), ozone (O3), and

lead (Pb). The USEPA regulates these pollutants by developing health-based air quality

standards.

Toxic air pollutants:

Toxic air pollutants are pollutants that cause or may cause cancer or other serious health

effects. However, their effects normally occur at high concentrations or concentrations

not commonly found in the ambient environment. The impacts of toxic air pollutants are

generally occupational in nature and occur at the point of production. The standards

developed for toxic air pollutants are therefore primarily occupational in nature and

applied to the work place. There are various types of toxic air pollutants that originate

from petrochemical refineries, most of which are organic in nature (collectively referred

to as total organic compounds or TOCs) and formed by the volatilization of organic

compounds. For petrochemical facilities, the following have been identified as the key

toxic air pollutants:

Benzene

Toluene

Ethyl benzene

Xylene

They are collectively referred to as the BTEX group of compounds.

Nuisance pollutants:

In addition to criteria and toxic air pollutants, which are associated with negative health

impacts, there are also pollutants that do not affect one’s health but rather quality of

life. These are the so-called nuisance pollutants and included in this category are

WEST RAND DISTRICT MUNICIPALITY: EMISSION INVENTORY FOR 2011

Report No. uMN014-12 8

pollutants such as hydrogen sulphide (H2S) (odour impact), mercaptans (odour impact)

and dust fallout (nuisance impact).

The emissions inventory starts with identifying all relevant sources in the industry. For

each source that may emit air pollution and contribute to exposure, data must be

collected on the:

Type of source (e.g. point, line, and area source)

Location of source

Amount of emission

Variation of the emissions with time (hour of the day, day of the week and year).

When developing an emission inventory, it is imperative that a base year is selected.

This will serve as a reference for future emissions inventories. Emissions inventories are

typically updated every three to five years.

Emissions data serves as the primary input for air dispersion modelling in providing

spatially referenced emission rates from sources such as industries. Emission

inventories are the starting point in the development of air quality management systems

and provide data for:

Establishing a baseline for future planning.

Setting emission limits and reduction targets for industries through permitting.

Tracking environmental performance of industries (and regulators).

Identifying sources and problem areas.

Generating public interest in air quality.

3.2 Emission Estimation Methodologies

The methodologies most commonly used by petroleum refineries to estimate emissions

to the atmosphere are direct measurement methods: continuous emissions monitoring

(CEM), source testing; and indirect methods: mass balance calculations, emission

models and factors, and engineering estimates.

3.2.1 Continuous Emissions Monitoring (CEM)

CEMs are proven technologies for monitoring emissions directly and continuously. CEMs

are used to determine flue gas flow rates, analyse the gas, measure the contaminant

concentrations, and log the data. They can be the most accurate method of quantifying

emissions but are the most costly option. In several countries, regulations require CEMs

to monitor SO2 and NOx emissions from sulphur recovery unit (SRU) incinerators,

fluidised catalytic crackers (FCCs) and boilers. SO2 and NOx emissions are perceived to

be the most significant pollutants, and these three sources are generally the largest at

refineries under normal operating conditions. Most CEMs require certification and

verification of quality assurance/control (QA/QC) activities, as well as routine

maintenance. Continuous monitoring can be done using either an ‘extractive CEM,’ in

which case the sample gas is extracted from the emission stream and transported to a

WEST RAND DISTRICT MUNICIPALITY: EMISSION INVENTORY FOR 2011

Report No. uMN014-12 9

gas analyser for the measurement and recording of the contaminant concentration, or an

‘in-situ CEM,’ which measures and analyses the emissions directly in a stack. The main

benefits of an extractive CEM is that the instruments are not subject to heat, vibration,

and corrosive conditions. Maintenance is easier at ground level and analysers for

extractive CEMs are generally less expensive than those for in-situ systems. The

disadvantages are that sample lines can leak, freeze, or clog, and pollutants can be lost

to adsorption, scrubbing effects, or condensation. The main benefits of an in-situ CEMs

are minimisation of sample loss and elimination of the costly sampling and conditioning

system. However, maintenance and replacement inside the stack are more difficult and

calibration gas must be taken to the analyser location.

3.2.2 Source Testing

Source testing, also known as stack testing or stack sampling, is the regulatory standard

in South Africa. Undertaken by trained and experienced staff during normal operating

conditions, using accredited methods, and at appropriate intervals, source testing can

provide accurate annual emission estimates. It is required to determine compliance with

a country’s emission standards or permit discharge limits. They are also required for

certification of CEMs, and emission factors are often a collection of source tests at

various operating rates.

3.2.3 Mass Balance

A mass balance calculation applies the law of conservation that the mass of material

entering and leaving a process unit remains unchanged provided there is no

accumulation in the unit. The cost depends on the availability of accurate data and staff

time. The general equation for the mass (M) balance calculation is:

Min=Mout + Maccumulated/depleted

A typical refinery example is the combustion of fuel oil containing sulphur. If it is

assumed that all the sulphur in oxidised to SO2, then the following equation could be

used to estimate SO2 emissions:

SO2 Emissions (kg) = Consumption Rate of fuel (m3/day) x S Content (mg/m3) x (No. of

Days Units Operates) x (MW of SO2/S) x 1(kg)/106 (mg)

3.2.4 Emission Models and Factors

Emission models and factors are widely used to measure air emissions from refineries.

If default data are not applicable to local conditions or type of facility, emission models

require detailed input of data, such as meteorological data or equipment specifications.

WEST RAND DISTRICT MUNICIPALITY: EMISSION INVENTORY FOR 2011

Report No. uMN014-12 10

Examples of emission models used in the petroleum refining sector include the USEPA’s

TANKS and WATER9 models, both of which can be used to calculate VOCs and other air

contaminants. An emission factor is a simplified emission model that relates emissions

from a source to some activity associated with the source. A large number of published

emission factors are available for many processes, and they are generally the least

costly method and the easiest to apply. The USEPA provides ratings of reliability with its

AP-42 emission factors.

WEST RAND DISTRICT MUNICIPALITY: EMISSION INVENTORY FOR 2011

Report No. uMN014-12 11

4. CATEGORISATION OF SOURCES IN THE WRDM

The emission sources in the WRDM are grouped into three main emission types (Figure

4.1), based on their characteristics, namely, point, mobile and area sources. Each of the

main emission sources are further categorised into various key emission source

categories, based on the nature of the emission sources.

The point emission source category includes stationary emission sources identified

individually due to the quantity or nature of their atmospheric emissions. This category

is sub-divided into two key emission source categories:

Listed activities, i.e., large industries regulated by Section of the National

Environmental Management: Air Quality Act (Act 39 of 2004) (AQA)

Smaller industrial processes with boilers.

Figure 4.1: Categorisation of emission sources in the WRDM

The mobile emission source category includes emission sources along a defined line. It

includes all on-road mobile sources (these are vehicles operated on the streets and

highways, such as motorcycles and cars) and non-road mobile sources (consisting of all

vehicles and equipment not routinely operated on streets and highways, such as trains,

ships and aircrafts). Since there are no ports or harbours in the WRDM, the only mobile

source in the district municipality is road traffic or on-road motor vehicles.

WRDM Atmospheric Emission Inventory

Point Mobile Area

Listed Activities Motor Vehicles

Small Industrial Processes

Domestic Burning

Agricultural

Biomass Burning

Tailings Dams

WEST RAND DISTRICT MUNICIPALITY: EMISSION INVENTORY FOR 2011

Report No. uMN014-12 12

The area emission source category encompasses a large number of diverse emission

sources and it includes facilities whose individual emissions do not qualify them as point

sources (individually they emit smaller quantities of pollutants but, collectively, they can

release significant quantities of pollutants) and those emissions sources for which

datasets do not exist to locate the emissions any more specifically. This category is sub-

divided into six key emission source categories:

Domestic burning (for cooking, lighting and space heating)

Agricultural activities

Biomass burning

Tailings dams

Due to the absence of credible information on agricultural activities in the WRDM, this

source is excluded from the study. However, the prescribed burning of crops will be

covered as part of biomass burning.

A brief summary of the main pollutants emitted in the WRDM and their primary sources

are contained in Table 4.2.

Table 4.1: Pollutants and sources at petroleum refineries

Air Pollutant Main Sources

Sulphur dioxide Listed activities

Small industrial processes

Motor vehicles

Domestic burning

Biomass burning

Nitrogen oxides Listed activities

Small industrial processes

Motor vehicles

Domestic burning

Biomass burning

Particulate matter Listed activities

Small industrial processes

Motor vehicles

Domestic burning

Biomass burning

Tailings dams

Carbon monoxide Listed activities

Small industrial processes

Motor vehicles

Domestic burning

Biomass burning

Volatile organic

compounds

Listed activities

Small industrial processes

WEST RAND DISTRICT MUNICIPALITY: EMISSION INVENTORY FOR 2011

Report No. uMN014-12 13

Motor vehicles

Domestic burning

Biomass burning

There are many small industrial processes in the WRDM that are sources of criteria

pollutants and HAPs due to the use of boilers in those facilities. There are several listed

activities, but none of these could be classified as major industries in the league of

power stations, crude oil refineries and pulp and paper mills. These listed activities are

regulated and operate in accordance with conditions specified in their atmospheric

emission licenses (AELs).

Many listed activities and small industrial processes in the WRDM have boilers for the

production of steam, which is used for the purpose of heating. The boilers are primarily

small to medium in size with a heat input rating of less than 50 MW, the threshold for

classification as a listed activity. The combustion of fossil fuels such as coal, diesel, gas

and heavy fuel oil (HFO) in these boilers results in emissions of SO2, NOx, CO, PM10 and

VOC.

There are also several gold mines located across the WRDM, owned and operated by the

major gold mining conglomerates in South Africa. Some of these mines are classified as

listed activities while others are not. Those that are not are exclusively involved in the

extraction of precious metals, and not the refining of the metals. Refining entails

combustion, which is a key source of air pollutants, whereas extraction is not. Extraction

type mining processes are primarily a source of dust and PM10.

Interspersed across the WRDM are also numerous tailings dams, which are major

sources of dust and PM10. The burning of biomass such as agricultural crops and bushes

is a source of PM10 and VOCs. Motor vehicles burn petrol and diesel, which are classified

as fossil fuels due to their origin from crude oil. The burning of petrol and diesel in

motor vehicles produces emissions such as SO2, NOx, CO, PM10 and VOC.

WEST RAND DISTRICT MUNICIPALITY: EMISSION INVENTORY FOR 2011

Report No. uMN014-12 14

5. LISTED ACTIVITIES AND SMALL INDUSTRIAL PROCESSES

5.1 Description of Emissions

There are several listed activities and small industrial processes in the WRDM that

operate boilers, the most common type of combustion device in the municipality. The

primary purpose of these boilers is to produce steam for heating. S.21 of the National

Environmental Management: Air Quality Act, 2004 (AQA) defines listed activities and

legislates the need for these activities to operate in compliance with an AEL. None of the

boilers in the WRDM is classified as listed activities as their heat input ratings do not

exceed 50 MW (threshold for being classified as a listed activity). Many of these boilers

will however be classified as controlled emitters in the proposed regulation for boilers

with heat input ratings exceeding 10 MW but less than 50 MW.

Combustion devices are key emitters of criteria pollutants (SO2, NOx, CO and PM10) and

toxic air pollutants such as benzene, toluene and xylene. The greenhouse gases, CO2,

CH4, and nitrous oxide (N2O), are also produced during gas combustion.

Figure 5.1: Picture of an industrial boiler process

According to CONCAWE, combustion processes comprise boilers, furnaces, gas turbines,

gas engines, diesel engines, incinerators and flares. A large number of industrial

processes and facilities make use of industrial boilers for steam generation. Industrial

boilers use a range of fuels depending on boiler size and design characteristics, and on

the availability/proximity of fuel. In many cases, the fuel is a by-product or waste

product from other processes. The volume and nature of the emissions from combustion

WEST RAND DISTRICT MUNICIPALITY: EMISSION INVENTORY FOR 2011

Report No. uMN014-12 15

in boilers differs depending on the fuel composition, fuel consumption, boiler design and

operation, and the emission and pollution control devices in use.

When fuels burn, they produce various pollutants. The non-combustible portion of the

fuel remains as solid waste. The coarser, heavier waste is called “bottom ash” and is

extracted from the burner, and the lighter, finer portion is “fly ash” and is usually

emitted as particulates through the stack. Products of incomplete combustion include

CO, SOx, NOx, acid gases and VOCs. Metals and their compounds may also be entrained

(i.e. carried forward by a stream of gas or vapour of fine liquid droplets).

Process heaters such as furnaces are used extensively in refineries to supply the heat

necessary to increase the temperature of feed materials to reaction or distillation level.

The fuel burned may be refinery fuel gas, natural gas, residual fuel oils, or combinations,

depending on economics, operating conditions, and emission requirements. Process

heaters may also use CO-rich regenerator flue gas as fuel.

In the WRDM, the most commonly used fuels are coal, followed by gas, diesel and heavy

fuel oil (HFO). A total of 25 industries have been identified with either one or multiple

combustion units.

5.2 Methodology

5.2.1 Data Gathering

The steps in gathering information from industries are illustrated with the aid of the flow

charts below in Figures 4.1. The following points regarding the information gathering

process are highlighted:

Emissions inventory questionnaires serves as the principle information gathering

documents for industries.

Guideline documents were developed to assist industries in completing the

questionnaires.

The questionnaires were accompanied by the official letter from the WRDM.

The questionnaires, once completed by the industry, were signed off by the

authorised company representative to certify the correctness of the information

submitted.

Industries were allowed one month for completing the questionnaires.

Industries could use consultants to assist if in-house capabilities do not exist.

Questionnaires with missing data were referred back to the industries. Once the

questionnaires were adequately completed, the previous incomplete versions

were disposed of.

Data was subjected to quality control before final input into the database. This

involved tasks such as reality checks, sample calculations, etc.

WEST RAND DISTRICT MUNICIPALITY: EMISSION INVENTORY FOR 2011

Report No. uMN014-12 16

Figure 5.1: Flowchart showing steps in gathering information

The emissions inventory questionnaires were developed in Microsoft Word format to

allow for ease of completion by the industries. The questionnaires were received from

industries in hard copy or electronic formats. The hard copies were signed by the senior

company official. The hard copies were stored in a Master File and stores in a safe

location until hand-over to the WRDM. Only the most updated questionnaires or latest

revisions were kept on file. Revisions that were found to be incompletely filled were

disposed of once the corrected versions were received.

The electronic copies were saved in an emissions inventory folder called ‘WRDM

Emissions Inventory_2010’. Write-access to the folder was only assigned to emission

inventory team members.

Industries were identified by initially reviewing existing databases such as those

compiled by the team that developed the WRDM’s air quality management plan. This

was complemented by a drive-around with Musa Zwane of the WRDM to identify

industries that did not appear on the databases. The drive around was based on the

Determine list of industries to be

inventoried

Issue notification to industries on legal

requirement to complete

questionnaire

Follow - up with non - respondents

Contact facility to resolve outstanding

issues

Review and code facility

data

Problems?

Inventory database

uMoya-NILU

Yes

No

To Facility

Distribute questionnaires

To facility

From facility

Calculate emission rates using

emission factors

Receive completed questionnaires

Compare emission rates with

questionnaire

Problems?

Yes

No

WEST RAND DISTRICT MUNICIPALITY: EMISSION INVENTORY FOR 2011

Report No. uMN014-12 17

identification of industries with stacks, which pointed to the existence of combustion

devices such as boilers and furnaces on those premises.

Industries that experienced difficulties in completing the questionnaires were assisted in

two ways. Firstly, industries were invited to visit the offices of the WRDM, where

consultants from the emission inventory development team provided basic training in

completing the questionnaires. Secondly, personal visits were made by Benton Pillay

and Musa Zwane to companies to assist them in gathering the required data and

completing the questionnaires. These two measures yielded very positive results.

5.2.1 Estimation of Emissions

The methods used to estimate emissions from listed activities and small industrial

processes using emission factors are briefly described in this section. These methods

apply mostly to boilers. However, in some instances, emission rates were provided by

the industries. Several industries had also undertaken stack sampling, albeit with

service providers not competent to provide this service. The results of these stack

sampling campaigns have also been used to estimate emissions from the industries

concerned.

Sulphur dioxide:

The quantity of SO2 emitted from combustion processes depends on the mass fraction of

sulphur in the fuel burnt. According to CONCAWE, the following equation can be used to

estimate SO2 emissions from combustion processes (Concawe, 2009):

Emission rate (kg/year) = 2000 × A × MFS (1)

Where,

A = mass of fuel consumed (ton/year)

MFS = mass fraction of sulphur in fuel

This equation assumes complete combustion of sulphur to SO2. The composition of

sulphur in coal generally varies between 0.5 and 1.3%. A conservative estimate of 1%

(or mass fraction of 0.01) was however used in cases where the sulphur content was not

known.

The composition of sulphur in HFO is generally high at 3.5% or 0.035 (m/m). HFO is

therefore the fuel that produces the highest emissions of sulphur per unit mass of fuel

burnt when compared with coal, diesel and gas. Sasol gas has the lowest sulphur

content of 0.001875%, thus making it the cleanest burning fuel. This value was

estimated from information provided by Sasol that the sulphur content of its gas is < 15

mg/m3. Using the density of Sasol gas of 0.80 kg/m3, it was possible to estimate the

maximum sulphur content as a mass percentage of 0.001875%, which represents a

WEST RAND DISTRICT MUNICIPALITY: EMISSION INVENTORY FOR 2011

Report No. uMN014-12 18

conservative estimate. The composition of sulphur in diesel is 500 ppm (m/m), which is

commercially available from most suppliers, including the oil companies. In terms of

mass fraction, this equates to a value of 0.0005.

Nitrogen oxides:

Environment Australia has developed a set of emission estimation guidelines entitled

“Emission Estimation Technique Manual” for a range of industrial sector sources

(Environment Australia, 2008). The contents of these manuals are based on

internationally recognised sources such as the USEPA’s AP-42 and the European Union’s

CORINAIR. The major advantage of using the Environment Australia guidelines is the

reporting of numbers in metric units. For instance, NOx emission factors are reported in

units of kg/m3. The other important advantage is the availability of emission factors for

refinery fuel gas. Most other sources only provide emission factors for natural gas and

suggest that this be used as a surrogate for fuel gas.

According to Environment Australia, the following equation can be used to estimate

emissions from combustion processes using emission factors:

Emission rate (kg/year) = A × EF × CE (2)

Where,

A = mass of fuel consumed (ton/year)

EF = uncontrolled emission factor (kg pollutant/ton fuel burnt)

CE = control efficiency of the emission from the use of a control device

The NOx emission factor for the uncontrolled combustion of coal is 3.8 kg/ton. This

implies that for every ton of coal combusted, an average of 3.8 kg of NOx is emitted.

The use of an emission control device will result in a reduction of the emission factor,

based on the efficiency of the control device. For instance, a reduction efficiency of 50%

will result in the emission facto being reduced by half to 1.9 kg/ton. The boilers in use in

the WRDM are generally not equipped with emission control devices such as low NOx

burners for reduction of NOx emissions. The emission factor of 3.8 kg/ton will therefore

stay unchanged for this study.

The NOx emission factor for the uncontrolled combustion of natural gas (similar to Sasol

gas) from boilers of <30 MW is 2.16 kg/ton. The relevant emission factor for the

uncontrolled combustion of residual oil (similar to HFO) is 7.32 kg/ton and for diesel it is

2.72 kg/ton. As with SO2, emissions of NOx are the highest when residual oil is burnt.

Carbon monoxide:

Equation (2) above is also used for the estimation of CO emissions from combustion

processes. The CO emission factor for uncontrolled combustion of coal in boilers is 2.5

kg/ton. There are currently no emission control devices available for small boilers to

WEST RAND DISTRICT MUNICIPALITY: EMISSION INVENTORY FOR 2011

Report No. uMN014-12 19

reduce CO emissions. The emission factor of 2.5 kg/ton is therefore considered

acceptable.

For residual oil combustion, a CO emission factor 0.67 kg/ton is specified by

Environment Australia. This value is almost three times higher for gas combustion at

1.82 kg/ton. The CO emission factor drops to 0.68 kg/ton for diesel, a value similar to

that for residual oil.

Particulate matter:

As with all other pollutants, PM10 emissions vary with the type of fuel combusted and the

duty of the combustion device. An additional factor that has an influence on PM10

emissions is the ash content of the coal when combustion takes place in wall-fired,

tangentially-fired or wet bottom boilers or in cyclone furnaces. The greater the ash

content, the greater the emissions of PM10. For the conventional spreader stoker type

boiler, which is the type primarily used in the WRDM, ash content does not have a

significant influence on PM10 emissions.

The USEPA (2005) provides emission factors of 33 kg/ton for PM and 6.6 kg/ton for PM10

for coal combustion from boilers with a spreader stoker feed configuration. For natural

gas, Environment Australia provides an emission factor of 0.16 kg/ton for boilers rated <

30 MW. For residual oil, the emission factor for PM10 is even less at 0.0542 kg/ton, while

it is 0.14 kg/ton for diesel.

Volatile organic compounds (VOCs):

VOC emissions by definition include all emissions of volatile organics with the exception

of methane. These are the compounds that participate in the photochemical reactions

that lead to the generation of ground-level ozone. Methane is a greenhouse gas (GHG)

and is not involved in photochemical reactions. Emissions of VOCs from combustion

processes are estimated by using the emission factor method and equation (2), as

presented by Environment Australia. In line with the USEPA, Environment Australia

provides an emission factor of 0.03 kg/ton of VOC emissions from the uncontrolled

combustion of coal.

With respect to natural gas, the VOC emission factor increases to 0.119 kg/ton. For

residual oil and boilers rated < 30 MW, the VOC emission factor is low at 0.04 kg/ton,

and decreases further to 0.0272 kg/ton for diesel. VOC emission factors are generally

higher for fuels that are more volatile, such as natural gas.

5.3 Results of Emissions Estimations

The industry databases referenced in this study were found not to be comprehensive.

Several of the industries contained in the databases no longer existed and several others

WEST RAND DISTRICT MUNICIPALITY: EMISSION INVENTORY FOR 2011

Report No. uMN014-12 20

were not sources of atmospheric emissions. Many industries were also very small and

could not be considered as significant sources of air pollutants. During the drive-around

referred to in the methodology section, several industries were identified that were

inexplicably absent from the industry databases. The following is the final list of

industries included in the emission inventory:

Table 5.1: Industries in the WRDM

Local

Municipality Industry

Source of

Emissions

Listed

Activity

Mogale City

Goud Saad/Krugersdorp Mill Unconfirmed No

Krugersdorp Crematorium Yes Yes

Majesty oil Mills Yes No

Boltonia Meats Yes No

Pace Oils (The Old Oil Man) No No

Rely Metpro Yes No

Foodcorp Piemans Pantry Yes No

Mogale Alloys Yes Yes

African Brick Yes Yes

Castle Lead Works Yes Yes

Chemiphos SA Yes Yes

Exol Oil Refinery Yes No

Advance Seed No No

Auto Commodities Unconfirmed

Avima No No

Blancom International Products No No

William Tell Yes Yes

Clariant Southern Africa No No

Sima Yes No

Fima Films SA No No

The Energy Company No No

Duys Roto Moulders No No

Ceramic Industries Limited Yes Yes

AARD Mining No No

Perlite Mining Unconfirmed

SAB Yes No

Lafarge Ready Mix Yes Yes

Yusuf Dadoo Hospital Yes No

Plascon Yes Yes

Cam Chem Unconfirmed

Pace Oils Yes No

Drift Supersand No No

Janho Quarries and Crushing Yes No

Executive Bricks and Paving Yes No

Krugersdorp Abattoir Yes No

Sasko Mills Yes No

Chemico SA Unconfirmed

Leratong Hospital Yes No

Geratech Zirconium Beneficiation Unconfirmed

Nimag Yes No

Transnet Pipelines Yes No

Sachi Chemicals No No

WEST RAND DISTRICT MUNICIPALITY: EMISSION INVENTORY FOR 2011

Report No. uMN014-12 21

Transvaal Rubber Yes No

Isover No No

Galvaglo Yes No

Cobra Watertech Yes No

Bull Brand Foods Yes No

Randfontein

Aranda Textile Mills Yes No

B&S Steel Fabrication Non-existent

Blitz Engineering Non-existent

Wilma Continental Oil Yes No

Cosmos Dairy Yes No

Gemtex Textile Mill Yes No

Meadow (Astral Foods) Yes No

Foodcorp Grocery Division Yes No

Randfontein Hospital No No

Supreme Petfood/ V-Oils Yes No

Tiger Brands Yes No

Ultimate Feeds Unconfirmed No

Vesuvius Rand Steel Non-existent No

Gold One No No

Armco Superlite Yes Yes

SA Oil Yes No

Transnet Pipelines Yes Yes

Cremos Crematorium Yes

Westonaria

BASF Construction Chemicals Yes No

Goldfields South Deep Gold Mine Yes Yes

Goldfields Kloof Gold Mine Yes Yes

Goldfields Driefontein Mine Yes Yes

West End Clay Brick Yes Yes

Merafong

Corobrick Driefontein Yes Yes

Carletonville Transport and Plant Hire No No

Fochville Hospital No No

Western Deep Levels Hospital No No

Leslie Williams Private Hospital (on

property of Goldfields)

No No

Khutsong Medical Centre No No

Fochville Abattoir Non-existent

Durban Roodepoort Deep Gold Mine

(Blyvoor)

Unconfirmed Yes

Harmony Elandsrand Gold Mine Unconfirmed Yes

AngloGold Ashanti Mponeng Mine Unconfirmed Yes

AngloGold Ashanti Tau Tona Mine Cannot locate Yes

AngoGold Ashanti Savuka Mine Unconfirmed Yes

DRD Gold (Blyvooruitchzit Mine) Cannot locate Yes

A total of 37 emission inventory questionnaires were submitted to industries in Mogale

City. Of these, 15 industries returned their questionnaires either completely or partially

completed. A further 12 were determined not to be a source of emissions during the

WEST RAND DISTRICT MUNICIPALITY: EMISSION INVENTORY FOR 2011

Report No. uMN014-12 22

course of telephonic discussions with their representatives (see Table 5.1). The

following 4 industries in Mogale City that did not submit questionnaires were contacted

telephonically to source fuel data (type, consumption rate, sulphur content, etc.) needed

to estimate their pollutant emission rates:

Foodcorp Piemans Pantry

SIMA

Yusuf Dadoo Hospital

Leratong Hospital

The following industries expressed their desire not to participate in the study with

responses that were generally rude and uncooperative:

Goud Saad/Krugersdorp Mill

Cam Chem

The other industries in Mogale City such as Boltonia Meats, Rely Metpro, Perlite Mining,

Lafarge Cement, Krugersdorp Abbatoir and John Turner and Sons have generally been

evasive and uncooperative.

Exol Oil Refinery would like to be included in the study, but the company was in the

process of conducting an air quality study and wished to submit information at a later

stage.

Of the 19 industries listed in Randfontein, a total of 9 returned their questionnaires.

Personal visits had to be paid to several of these industries after they initially failed to

submit their questionnaires on time. During these visits, the emission inventory

questionnaires were completed. A total of 2 industries were confirmed as not being

sources of emissions, a further 2 remain unconfirmed (due to a lack of response) and a

further 3 were found to no longer exist in the Randfontein Municipality. Gemtex Textile

Mill did not submit their questionnaire, but the company was contacted telephonically to

obtain their boiler fuel data. Aranda Textile Mill remains evasive and difficult to source

information from.

A total of 5 industries were contacted in Westonaria. BASF Construction Chemicals and

West End Bricks submitted their emission inventory questionnaires, whereas the 3

Goldfields Mines provided copies of their draft AEL application forms. Most of the

information required to estimate their emission was contained in the AEL application

forms.

Industries in the Merafong Municipality, of which a total of 13 were identified, generally

proved to be the most uncooperative. Emission inventory questionnaires were issued to

the following industries:

Corobrik

Leslie Williams Private Hospital

Harmony Elandsrand Gold Mine

WEST RAND DISTRICT MUNICIPALITY: EMISSION INVENTORY FOR 2011

Report No. uMN014-12 23

AngloGold Ashanti Mponeng Mine

AngoGold Ashanti Savuka Mine

A total of 4 industries were found not to be a source of emissions through telephonic

discussions and 2 could not be located. From Table 5.1, it is clear that the majority of

industries are located in Mogale City, followed by Randfontein, Merafong and Westonaria.

The largest type of industries are the precious metal mines, but smelting operations are

absent from the majority of mines in the WRDM. These mines primarily extract ore,

which is transported to other areas where ore beneficiation in the form of smelting takes

place. Smelting operations result in emissions of combustion pollutants such as SO2,

NOx, CO and PM10. Since smelting operations are absent, the primary pollutant produced

is dust from ore extraction. The estimation of these dust emissions, primarily from the

handling and storage of ore, is a complex task that mines should estimate with the aid of

air quality consultants. However, since the extraction takes place underground, dust

emissions are not expected to be significant. Dust is classified as a nuisance pollutant

that has no health impacts but affect one’s quality of life. Dust is the cause of many

complaints and results in the soiling, contamination, structural corrosion and damage to

precision equipment, machinery and computers. Although highly dependent upon local

sources, dust typically comprises of windblown dust, fine sand, mist, fly ash, pulverised

coal and ore. Transport distances range typically from <1 m to <2 km. South Africa

currently has dust fallout standards in place. The Department of Environmental Affairs