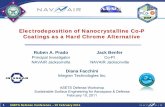

Electrodeposition of Composite Coatings Containing Nanoparticles in a Metal Deposit

Transcript of Electrodeposition of Composite Coatings Containing Nanoparticles in a Metal Deposit

-

poa

. W

vers

tede 24

ing

graphitecopper composite coating for self-lubricating surfaces

variety of new nanomaterials. These include nanocrystallinedeposits, nanowires, nanotubes, nanomultilayers and nanocom-

composite coatings where nanosized particles are suspended in

2. The mechanism of codeposition of particles into a metaldeposit

Two common processes involved in the incorporation of

y 2posites. Strengthened composite coatings, enhanced electricalresistance in printed circuit boards, improved giant magnetore-in car engines [1]. In the early 1950s and late 1960s, thedevelopment of electrodeposited composite coatings developedprogressively [2]. During the 1970s and 1980s, investigationswere focused on the need to produce coatings with enhancedmechanical, corrosion and tribological properties.

The advanced physical properties of composite coatingsquickly became clear and during the 1990s, new areas such aselectrocatalysts and photoelectrocatalysts were considered [3].With the emergence of nanostructured materials over the lastdecade, electrodeposition techniques have provided a route to a

the electrolyte and codeposited with the metal. The effect of ope-rating parameters that influence the quantity of nanosized particlesincorporated into the metallic deposit is discussed and theoreticalmodels used to describe the codeposition phenomenon are high-lighted. Table 1 shows the categories of nanostructured materialsalong with various electrodeposition manufacturing techniques.Readers are directed to a number of earlier reviews [220] for adetailed background to composite electrodeposition of largerparticles which typically have sizes in the range 180 m.(v) pulsed current techniques. Compositional gradient coatings are possible having a controlled distribution of particles in the metal deposit and thetheoretical models used to describe the phenomenon of particle codeposition within a metal deposit are critically considered. 2005 Elsevier B.V. All rights reserved.

Keywords: Electrodeposition techniques (direct current, pulsed direct current, pulsed reverse current); Nanosized particles; Compositional gradient coatings;Codeposition of particles; Composite coatings; Modelling codeposition; Rotating cylinder electrode

1. Introduction

The electrodeposition of metallic coatings containing inertparticles can be traced back to studies which produced a

sistance in memory storage systems and increased microhard-ness for microdevices in micro-electro-mechanical systemshave been the focus of numerous studies.

This paper surveys recent techniques used to produce nano-in the electrolyte solution, (ii) smaller sized nanoparticles; (iii) a low concthe electrolyte by agitation and/or use of surfactants, can be codeposited with the metal. The inclusion of nanosized particles can give (i) an increasedmicrohardness and corrosion resistance, (ii) modified growth to form a nanocrystalline metal deposit and (iii) a shift in the reduction potential of ametal ion.Many operating parameters influence the quantity of incorporated particles, including current density, bath agitation (or movement of workpiece) and electrolyte composition. High incorporation rates of the dispersed particles have been achieved using (i) a high nanoparticle concentration

entration of electroactive species, (iv) ultrasonication during deposition andElectrodeposition of comnanoparticles in

C.T.J. Low, R.G.A

Electrochemical Engineering Group, School of Engineering Sciences, Uni

Received 19 September 2005; accepAvailable onlin

Abstract

Recent literature on the electrodeposition of metallic coatings contain

Surface & Coatings Technolog Corresponding author.E-mail address: [email protected] (F.C. Walsh).

0257-8972/$ - see front matter 2005 Elsevier B.V. All rights reserved.doi:10.1016/j.surfcoat.2005.11.123site coatings containingmetal deposit

ills, F.C. Walsh

ity of Southampton, Highfield, Southampton, SO17 1BJ, United Kingdom

in revised form 24 November 2005January 2006

nanosized particles is surveyed. The nanosized particles, suspended in

01 (2006) 371383www.elsevier.com/locate/surfcoatparticles into metallic coatings can be recognised, namelyphysical dispersion of particles in the electrolyte and electro-phoretic migration of particles [15].

-

Table 2Examples of theoretical models used to describe the behaviour of metal electrodeposition containing particles

Model Characteristics and assumptions Deposit and process conditions

Reaction Particlessizes, m

Current density j,mA cm2

Rotationspeed , rpm

Ref.

Guglielmi, 1972 Describes both adsorption and electrophoresis.The particles are covered by adsorbed metal ions.Particle characteristics and electrolyte conditionsare accounted semi-empirically. The effect of flowis not considered.

Ni/TiO2 Ni/SiC 12 20100 NG [21]

Celis et al., 1987 Uses probability concept to describe the amountof particles that can be incorporated at a givencurrent density. Mass transport of particles isproportional to the mass transport of ions to theworking electrode. Volume ratio of particles inthe metal deposit will: (1) increase under chargetransfer control; (2) decrease under masstransport control.

Cu/Al2O3 Au/Al2O3 0.05 090 400600 [23]

Fransaer et al., 1992 Uses trajectory to describe the codeposition ofnon-Brownian particles. Involves two steps:(1) reduction of metal ions (described byButler-Volmer expression); (2) codeposition ofparticle (described by trajectory expression).

Cu/PS 11 080 0700 [24]Ni/SiC 0.0110 0200 02000 [25]

Hwang et al., 1993 An improvement of Guglielmi's model. Uses threemodes of current density (low, intermediate, high)to distinguish the reduction of adsorbed ion onparticles. Involves three steps: (1) forcedconvective of particles to surface; (2) looseadsorption on the surface; (3) irreversibleincorporation of particles by reductionof adsorbed ions.

Co/SiC 3 160 400 [26]

Vereecken et al., 2000 The transport of particles to the surface is controlledby convective-diffusion. The influence of particlegravitational force and hydrodynamics isaccounted for at various current densities. Validonly when the particle size is smaller than thediffusion layer thickness.

Ni/Al2O3 0.3 540 5002000 [27]

Bercot et al., 2002 An improvement of Guglielmi's model, whichincorporates a corrective factor (a 3rd orderpolynomial equation) to account for the effectsof adsorption and hydrodynamic conditions.

Ni/PTFE 0.5 1070 4001000 [28]

More details on the accuracy of each model are available elsewhere [11,18,37].NG: not given.

Table 1Various types of nanostructured materials which may be produced byelectrodeposition techniquesMethods of electrodeposition Types of nanostructure materials

Nanoparticles in a metal deposit Nanomultilayers Nanotubes/nanowires Nanocrystalline materials

Direct current (DC)Single metal deposit

Nanoparticles

Metal type 1e.g. Ni layer

Metal type 2

Nanotubes Single metal

Pulsed direct current (PDC)

Pulsed reverse current (PRC) Alloy deposit Nanowires

Fe Co

Alloy

Multilayer deposit Tree-likenanowires

Potentiostatic (P)

Pulsed potentiostatic (PP)e.g. Cu layer

Table 1Various types of nanostructured materials which may be produced by electrodeposition techniques

372 C.T.J. Low et al. / Surface & Coatings Technology 201 (2006) 371383

-

Codeposition mechanisms for the dispersion of inertparticles into metallic coatings have been developed frominvestigations of micron sized particles. Many theories havebeen suggested including the transport of particles due to (1)electrophoresis, (2) mechanical entrapment, (3) adsorption and(4) convective-diffusion. Table 2 [2128] provides an overviewof the existing models and their main assumptions. Themechanism proposed by Guglielmi [21] has been adopted byvarious authors. This model enables a quantitative treatment ofthe influence of particle concentration and current density on theincorporation rate of particles into a metal deposit but excludeshydrodynamic effects and particle characteristics. A correctivefactor (3rd order polynomial equation) has been included intoGuglielmi's model to account for the effects of adsorption andhydrodynamics on the incorporation of 500 nm PTFEnanoparticles into a nickel deposit [28]. However, the validityof this function may only lie within a narrow range ofexperimental parameters and its ability to accurately predictother systems requires study.

Fig. 1 shows the common processes involved in thecodeposition of particles into growing metallic layers. Five

Cathode

C.T.J. Low et al. / Surface & CoatingsElectricaldoublelayer

Diffusion layer

Convection layer

Deposit Bulkelectrolyte

Particles (conductive or non conductive)Surfactant (ionic, non-ionic or organic)

Clouding of particles by surfactants

Deposited metal

Clouding of particles by cations

Fig. 1. Mechanisms of particle codeposition into a metal deposit [7]. The regionsinclude: formation of ionic clouds around the particles (bulk electrolyte, typicallength in cm); convective movement toward the cathode (convection layer,

typical length b1 mm); diffusion through a concentration boundary layer(diffusion layer, typical dimensions of hundreds of m); electrical double layer(typical dimensions of nm) followed by adsorption and entrapment of particles.consecutive steps during the codeposition process can beidentified [7]: (1) formation of ionic clouds on the particles,(2) convection towards the cathode, (3) diffusion through ahydrodynamic boundary layer, (4) diffusion through aconcentration boundary layer and finally, (5) adsorption atthe cathode where particles are entrapped within the metaldeposit. Other models include a statistical approach [710,24]which predicts the probability of a particle being incorporatedinto a deposit and particle trajectory models [24,25] whichdescribe non-Brownian particles. The relationships betweenthe quantity of particles in the metal deposit and currentdensity or hydrodynamics have been the focus of manyexperimental studies.

Although many theoretical models have been proposed, theflexibility and reliability of each to describe the behaviour ofa wide range of metallic coatings and particle types stillrequires validation. Often, the existing models involvemathematical relationships that are interrelated to an extensiveset of parameters and, in all the models available so far, theeffects of particle inclusion on deposit electrocrystallisationhave not been considered. This aspect is important since theinclusion of particles into a metal deposit may cause (1)reduction of the cathode surface area if the particles are non-conductive, (2) enlargement of the cathode surface area if theparticles are conductive or (3) modification of the depositmorphology.

Presently, the models used to describe the inclusion ofmicron sized particles are restricted to specific conditions andempirical laboratory trials remain important. Future modelsdescribing the codeposition process will require adequateattention to interactive variables such as the particle character-istics (type, dimensions and concentration), the operatingparameters (temperature, current density, pH and hydrody-namics) and the electrolyte composition (concentrations,presence of surfactants and additives).

3. Experimental parameters

A variety of nanosized particles (typically with sphericaldimensions), ranging from 4 nm to 800 nm diameters, havebeen successfully incorporated into metal electrodeposits.These include aluminium dioxide (Al2O3), chromium (Cr),diamond (C), silicon carbide (SiC), gold (Au), silicon dioxide(SiO2), zirconium dioxide (ZrO2), titanium dioxide (TiO2),polystyrene (PS) and silicon nitride (Si3N4). Amongst manymetals used, copper and nickel have featured strongly.Alumina particles have been the subject of many investigationscompared to other nanoparticles. Table 3 [23,2942] shows therecent examinations of the codeposition of alumina particleswhile Table 4 [22,25,4357] considers other particulateinclusions.

The inclusion of nanosized particles into metal deposits isdependent on many process parameters, including particlecharacteristics (particle concentration, surface charge, type,

373Technology 201 (2006) 371383shape, size), electrolyte composition (electrolyte concentra-tion, additives, temperature, pH, surfactant type andconcentration), current density (direct current, pulsed current,

-

pulse time, duty cycle, potentiostatic control) and hydro-dynamics (laminar, mixed, turbulent regimes) of together

be identified as influencing the codeposition processes,namely (1) the applied current density, (2) the particle type

Table 3Investigations of the inclusion of Al2O3 particles into metal deposits by electrodeposition techniques

Nanoparticles Metaldeposit

Nanoparticle concentration Experimental characteristics

In solution,g dm3

In deposit Method Current density j,mA cm2

Rotationspeed , rpm

Temp. T,K

pH Substrate Ref.

10 nm -Al2O3 Ni 220 030 wt.% DC 250 2001600 NG 3 Cr, Au [29]25 nm -Al2O3 Ni 10, 150 NG DC, PC 0.15, 0.77, 1 NG 298 3.5, 4 Cu [30]32 nm -Al2O3 Cu 060 135 wt.% DC 0 to100 9003600 NG 0.22 Au [31]32 nm -Al2O3 Ni 10, 25 07.5 wt.% DC, PRC 92.8 to 26.5 225, 1600 NG 3, 4, 4.5 Au [32]32 nm Al2O3 Cu 12.5, 25 2.912.7 wt.% PRC 5, 10 800, 1600 NG 4 Au [33]32 nm Al2O3 Ni, Cu 3.125, 12.5 16 wt.% PC 10, 15 1000 299 8 Au [34]37 nm Al2O3 Cu 12.550 317 wt.% DC, PRC 0.6 to 0.15 C/cm2 800 NG 4 Au [35]37 nm Al2O3 Cu 12.5 317 wt.% DC, PRC 5, 10 800 298 4 Au [36]50 nm -Al2O3 Cu 3.9158 NG NG NG 5001500 NG 0.3 Cu [37]50 nm -Al2O3 Cu, Au 090 023.5 wt.% DC 20 400 293 0.3 NG [23]50 nm Al2O3 Ni 0.1, 2 vol.% 020 vol.% DC 5, 20, 40 5001000 NG 3 Cu [38]80 nm Al2O3 Ni 50 NG PC 15 600 313 4.2 SS [39]80 nm Al2O3 Ni 5 1.426.8 vol.% NG 30, 60 200 318 4 CS [40]300 nm Al2O3 Ni 2 vol.% 925 vol.% DC 540 500, 2000 297 3 Cu [41]50, 300 nm Al2O3 Ni 2 vol.% 1025 vol.% DC 540 500, 2000 297 3 Cu [42]

DC, direct current; PC, pulsed current; PRC, Pulsed reverse current; NG, not given.

374 C.T.J. Low et al. / Surface & Coatings Technology 201 (2006) 371383with electrode geometry (rotating disk electrode, rotatingcylinder electrode, plate-in-tanks, parallel plate electrodesand many variations).

Electrolyte composition is known to be a significantfactor affecting the codeposition process. However, a clearpicture of the exact effect of the experimental parametersis often difficult to obtain. The majority of recentinvestigations have suggested that three global factors canTable 4Inclusion of other types of particles into metal deposits by electrodeposition techniq

Nanoparticles Metaldeposit

Nanoparticle concentration Experimenta

In solution,g dm3

In deposit Method Cm

20 nm SiC Ni 1050 025 vol.% NG 520 nm SiC Ni 20 NG PC 520 nm SiC Ni 20, 50 925 vol.% DC 4100 nm SiC Ni 0100 06 wt.% DC 1400 nm SiC Ni 20, 100 03 wt.% PC 9400 nm SiC Ni 20, 100 0.310.5 vol.% PC 9310 nm Au Ni 10 N.G NG 1Au Ni 20 N.G NG N50 nm SiO2 Zn 0.3 N.G DC 14, 10 nm ZrO2 Ni 10, 50 04 wt.% DC 110 nm diamond Ni 10 N.G NG N25 nm diamond Ni 340 N.G DC 230 nm Si3N4 Ni, Fe 50300 23 vol.% NG 939 nm Cr Ni NG 9.6 DC 312 nm TiO2 Ni 0200 011 wt.% DC 620 nm TiO2 Ni 10 to120 020 wt.% DC 24 nm diamond32 nm Al2O3

Au 0.110 NG DC 5

30 nm Al2O3 60 nmZrO2 62 nm SiC

Ni 1.5 vol.% NG NG 1

DC, Direct current; PC, pulsed current; PRC, pulsed reverse current; NG, not givenand concentration and (3) bath agitation or electrodemovement.

3.1. Current density

A variety of galvanostatic techniques can be utilised,including direct current, pulsed direct current and pulsedreverse current techniques. Galvanostatic control, as shownues

l characteristics

urrent density j,A cm2

Rotationspeed , rpm

Temp. T,K

pH Substrate Ref.

80 100, 200 318 4 Ni [43]0 200 323 4.4 Brass [44]0 0250 5.7 CS [44]0200 02000 323 4.5 Ti, Ni [25]00 750 313 4.5 Ti [45]00 750 313 4.5 Ti [46]050 100, 500 318 3, 5 SS [47]G NG NG NG NG [48]00 798 323 2 CS [49]0, 100 NG 333 2.5 Ti [50]G NG? 318 34.5 S [51]550 45450 303 NG Cu [52]

NG 298 4.8 Cu [53]0 NG 308 5.5, 6 Ni [54]6.7 NG NG NG Cu [55]0 NG NG 3 Cu [56], 10 NG 335 5.8, 6 Cu [57]

.580 0 298323 2, 6 Cu [22]

.

-

in Fig. 2, can also be employed however direct current has mostcommonly been used to obtain nanoparticle composites. Thistechnique is based on the concept that the incorporation ofnanoparticles occurs simultaneously with the reduction reactionof an ionic species to form the metal surface.

The application of a pulsed current has enabled theincorporation of higher concentrations of nanoparticles aswell as producing a wider range of deposit compositions andproperties. The pulsed direct current technique is based onalternating two or more direct cathodic currents for variousdeposition times. While the pulsed reverse current technique hassimilar characteristics but imposes a cathodic current during theon time and an anodic current during the off time. This methodhas been the most successful for embedding higher concentra-tions of nanoparticles because it helps to eliminate a fraction ofthe electrodeposited metal during the off time.

Various authors have compared direct current and pulsedcurrent deposition. For example, during the electrodepositednanocrystalline nickel it is reported that under direct current, thenanoparticles (25 nm alumina) are the main inhibiting factor forthe growth of nickel nuclei (average grain diameter of 30 nm).Under pulsed direct current, however, the pulse length is the

Current

Current

Time0

(a)

(b)+

C.T.J. Low et al. / Surface & CoatingsCurrent

Current

Time0

Time0

(c)

(d)

+

+

Time0

+

Fig. 2. Various modes of current density vs. time control during electrodeposi-tion; (a) pulsed direct current with zero current during off-time, (b)

superimposed pulsed direct current with cathodic current during off-time, (c)pulsed reverse current with anodic current during off-time, and (d) pulsedreverse current with combination of zero and anodic current during off-time.limiting factor (average grain diameter of 20 nm) [30]. This isbecause selective entrapment of nanoparticles occurs with thelarger particles being preferentially removed during the reversepulse period, producing a finer deposit with less agglomerationof nanoparticles.

The pulsed reverse current technique has been used toproduce a copper deposit containing high concentrations of 30nm alumina nanoparticles [3336]. By using a steady statepulsed reverse current and long pulse times, three mainadvantageous can be achieved compared to the direct currentmethod: (1) the amount of nanoparticles in a metal deposit canbe enhanced, (2) a lower concentration of nanoparticles in theelectrolyte solution can be used and (3) selective entrapment ofsimilar sizes of nanoparticles can be achieved. All threeadvantages can be associated with the partial dissolution ofthe metal deposit during the anodic period where larger sizes ofnanoparticles tend to be lost from the deposit while smallernanoparticles continue to be entrapped.

Uniform and well-dispersed nanoparticle (80 nm alumina)dispersions in a nickel deposit were achieved by the combina-tion of pulsed current and ultrasound [39]. The introduction ofultrasound reduced the quantity of alumina whiskers in thenickel deposit and only large pyramidal grains were observed athigh frequency (50 Hz) with no alumina whiskers. At lowfrequency (5.6 Hz) an increase in the amount of aluminawhiskers in the nickel deposit was observed with significantagglomeration of nanoparticles. The employment of ultrasoundduring electrodeposition can reduce nanoparticle agglomerationas well as removing the absorbed nanoparticles from the metaldeposit at high frequency.

Direct current combined with ultrasound has also beenstudied as a function of concentration of the electroactivespecies and it has been shown that agglomeration of aluminananoparticles can be reduced by using a lower concentration ofmetal ions. For example, in a 1.27 M Ni2+ electrolyte, theaverage nanoparticle size is approximately 280 nm; in a 0.20 MNi2+ electrolyte, the average nanoparticle size is 178 nm [40].Although a lower concentration of electroactive species tends tofavour well-dispersed and less agglomerated nanoparticles, theoccurrence of hydrogen evolution must considered to avoid areduction in the current efficiency as well as hindering theadsorption of nanoparticles to the metal surface.

The current density is also found to influence the amount ofalumina nanoparticles incorporated into electrodeposited nickel.Using a sulfamate bath containing 600800 nm -Al2O3nanoparticles, an increase in current density resulted in a roughsurface microstructure and lead to less nanoparticles beingincorporated in the metal deposit (Fig. 3) [58]. Another study of32 nm alumina nanoparticle, however, has demonstrated thatthe degree of nanoparticle incorporation was dependent on theelectrolyte type [32]. In a chloride electrolyte, a highernanoparticle content in the deposit was established at lowcurrent density but in a citrate electrolyte, higher nanoparticlecontents were found at elevated current density. It was also

375Technology 201 (2006) 371383found that the current efficiency increased at higher currentdensities in both electrolytes but the amount of nanoparticles inthe nickel deposit was higher in the presence of citrate ions. This

-

nanoparticles (50 nm and 300 nm) into a nickel deposit hasbeen studied. Using similar operating parameters (1000 rpm,20 mA cm2 and 73 C cm2), it was found that thepercentage volume fraction of the 300 nm Al2O3 in the nickel

20

30

40um

e of

par

ticle

s in

dep

osit

10 20 30 40 50 600

2

4

6

8

10

6

8

10

12

(a)

(b)Pe

rcen

tage

vol

ume

of C

in C

u/Sn

allo

y de

posit

Amount of graphite in solution / g dm-3e

of p

artic

les

in d

epos

it

376 C.T.J. Low et al. / Surface & Coatings Technology 201 (2006) 371383suggests that the influence of current density can vary withelectrolyte compositions.

3.2. Effects of nanosized particles on deposit characteristics

The effect of nanoparticle concentration in the electrolyte ontheir concentration in the metal deposit has been predicted tofollow a Langmuir isotherm adsorption phenomenon

0 5 10 15 20 25 300

10

Current density / A dm-2

Perc

enta

ge v

ol

Fig. 3. Influence of current density on the percentage volume of 600 to 800 nm-Al2O3 particles in a nickel deposit [58]. 75 g dm

3, 150 g dm3 and 225 g dm3. Electrolyte composition: 400 g dm3 Ni(NH2SO3)24H2O, 30 gdm3, H3BO3, 5 g dm

3 NiCl26H2O, 0.5 g dm3 CH3(CH2)10CH2OSO3Na, 0.1

g dm3 C6H4OCOCHCH, 50 C and pH 4.[22,42,5962]. Fig. 4 shows the relationship found by variousinvestigators. The amount of nanoparticles in the solution hassignificant effect on the percentage volume fraction of thenanoparticles incorporated into the metal deposits. Two generalobservations can be made: (1) the volume fraction ofnanoparticles in the metal deposit increases substantiallywhen the amount of nanoparticles concentration in the solutionincreases and (2) a saturation state of particles in the deposit isreached at high nanoparticle concentration in the solution.

The size of particles will affect the rate of incorporationinto the metal deposit. Findings have suggested that as thesize of nanoparticles becomes smaller, more can be incorpo-rated into a metal deposit per unit volume. For example, therate of incorporation of two different sizes of Al2O3

0.10

0.15

0.20

0.25

0 30 60 90 120 1500

2

4

(c)

Perc

enta

ge v

olum

Concentration of particles in solution / g dm-3

le v

olum

e to

dep

osit

volu

me

Fig. 4. Langmuir isotherm showing the relationship between the quantity ofparticles in the metal deposit and their concentration in the electrolyte. (a) CuSnalloy deposit with 10mgraphite [62], showing the effect of rotation rate. Speed ofmagnetic stirrer: 50 rpm, 100 rpm and 200 rpm. Electrolyte compositions:29 g l1 CuCN, 35 g l1 K2SnO3, 64 g l

1 KCN, 10 g l1 KOH, 45 g l1 Rochellesalt, pH 12 and 40 C. (b) NiCo alloy deposit with 500 nm-Al2O3 [61], showingthe effect of temperature. Bath temperature: 50 C and 60 C. Electrolytecompositions: 300 g l1 Co(NH2SO3)24H2O, 300 g l

1 Ni(NH2SO3)24H2O, 20ml l1 CH3NO and pH 4.5. (c) Ni deposit with Al2O3 [38,42], showing the effect ofparticle sizes. 300 nm and 50 nm -Al2O3. Electrolyte compositions: 1.24mol l1 Ni(NH2SO3)2, 0.5 mol l

1 H3BO3, 0.02 mol l1 NiCl2, 0.5 g l

1 CH3(CH2)11OSO3Na, 0.1 g l

1 C9H6O2, pH 3 and 25 C.0.05

Rat

io o

f par

tic0.0 0.5 1.0 1.5 2.00.00

Percentage volume of particle in solution

-

the electrolyte, the suspension stability of particles at long timesand the use of electrolyte additives, particularly surfactants.

3.3. Influence of bath agitation and cathode movement

Bath agitation serves two purposes, namely to keep theparticles suspended in the electrolyte and to transport theparticles to the cathode surface. Many investigations have foundthat increased agitation generally enhances the amount ofparticles in the metal deposit. However, excessive agitation maylead to a lower quantity of particles in the metal deposit. Thismay be explained by vigorous hydrodynamic forces in theelectrolyte removing the particles from the cathode surfacebefore they can be entrapped in the metal deposit.

Fig. 5 shows the relationship between electrode rotation rateand particle inclusion for a nickel deposit containing 500 nmPTFE particles [28]. An optimum incorporation rate is seenwhichdepends on both particle concentration and rotation speed. At afixed applied current density of 3 A dm2, the maximum rotationspeed observed before any fall off in volume percentage ofparticles varies with loading of particles in the electrolyte. Thiseffect is also seen during the codeposition of 32 nm -Al2O3

377tings Technology 201 (2006) 371383deposit was much higher compared to the 50 nm Al2O3.However, the quantity of 50 nm Al2O3 particles in the nickeldeposit was much larger than the quantity of 300 nm Al2O3particles [38,42].

In the case of electrodeposition of nickel containing titaniumdioxide particles, the weight percentage of 12 nm anatase in thenickel deposit was higher than for 1 m rutile particles in thenickel deposit. The deposit incorporating 12 nm anatase displayedsuperior corrosion resistance in acidic solution (pH 3.13.3glacial acetic acid, 5.0% NaCl, 1.0 g dm3 CuCl22H2O, 50 Cand 1 week) but showed only a slight increase in Vickersmicrohardness compared to the 1-m rutile containing deposit.Nanoparticle concentration in the deposit has been found toaffect both surface roughness and deposit microstructure. Forexample, the surface microstructure of a nickel depositcontaining 32 nm -Al2O3 nanoparticles changed from roughto smooth as the concentration of particles in the solutionincreased from 0 g dm3 to 60 g dm3 [31].

The presence of nanosized particles in a metal deposit mayinduce changes in the crystalline structure of the metalliccoating. It has been shown that 20 nm SiC nanoparticlesinfluence the competitive formation of nickel nuclei andcrystal growth [63]. The presence of 20 nm SiC nanoparticlesshifted the reduction potential of nickel ions to more positivepotentials and increased the current density. This can beassociated with an increase in surface area of the cathode dueto the adsorbed nanoparticles. By increasing the surface area,more nucleation sites are available for the nickel ions andcrystalline growth is suppressed during electrodeposition.Consequently, a smaller crystal grain size can be obtainedgiving an enhanced microhardness.

Other investigations have demonstrated that 20 nm SiCnanoparticles can lead to a more uniform dispersion in a nickeldeposit than 1 m SiC microparticles [40]. Besides theincorporation of nanoparticles at the borders and edges of thenickel crystals, the authors showed that the nanoparticles couldalso be embedded in the nickel crystal itself [44]. Theseobservations are echoed in other investigations [45,54,55,63]and lead to the conclusion that the presence of nanoparticles willperturb the crystalline growth of a metal deposit, resulting in anincreased number of defects in the crystal structure, facilitatinga nanocrystalline structure with increased microhardness.

During the incorporation of 39 nm Cr particles into a nickeldeposit, the average nickel grain size was reduced from 42 nmto 31 nm in the presence of Cr nanoparticles [54]. The authorsused X-ray diffraction to show that the codeposited nanopar-ticles suppressed the preferred growth direction of the nickel,producing a more homogeneous surface. Enhanced surfaceproperties depend not only on the quantity of nanoparticles inthe metal deposit but also on the crystal structure anddistribution of nanoparticles in the coating.

There appear to be no investigations on structurally differentnanosized particles in a single metal deposit. The type of particles(conducting or non-conducting) and their shape (e.g. nanotubes,

C.T.J. Low et al. / Surface & Coananorods or nanopellets) may have different effects during theincorporation process. Other factors that may affect depositionprocesses include the ageing of nanosized particles suspended inparticles in a copper deposit [31]. In the latter case, the influence ofelectrode rotation rate on the polarization curves did not show adependence on particle concentration. The authors showed that, ata 12.5 g dm3 alumina nanoparticle concentration in the bath, thecharge transfer region did not alter with rotation rate; at 39 g dm3

of alumina nanoparticles, the reduction of copper ions is inhibitedat all rotation rates and at 60 g dm3 of alumina nanoparticles,both the inhibition and enhancement of the copper ion reductionoccurred at different rotation rates. This complex, non-linearrelationship as observed on the polarization curves, suggests that a

400 600 800 10000

2

4

6

8

10

Magnetic follower rotation rate / rev min-1

Perc

enta

ge vo

lum

e of

par

ticle

s in

the

depo

sit

Fig. 5. Influence of rotation speed (of a magnetic stirrer) on the amount of 500 nmPTFE particles incorporated into a nickel deposit [28]. 10 g dm3, 20 gdm3; and 30 g dm3 of PTFE particles in the solution. An optimum

incorporation rate can be observed as a function of both the particle concentrationand rotation speed. Electrolyte composition: 300 g l1 Ni(NH2SO3)2, 10 g l

1

NiCl2, 30 g1 H3BO3, pH 4 and 55 C.

-

simple mechanism based on the adsorption and electrophoreticeffects cannot sufficiently be explained by a simple model.

Two common techniques have been used to keep particlessuspended in the electrolyte, namely (1) physical dispersion ofparticles by bath agitation and (2) chemical dispersion ofparticles by surfactants. A combination of cationic, anionic andnon-ionic surfactants can be used to achieve control of surfacecharge on the particles and the degree of suspension in theelectrolyte [15]. The strategies for bath agitation can becontrolled in many ways depending on the dimensions of theelectroplating bath, as shown in Fig. 6. For industrialapplications, the popular methods used in open tanks includethe overhead blade stirrer, the reciprocating plate plunger or apumped recycle loop of the electrolyte [15]. For laboratoryinvestigations, magnetic stirrers, rotating disk or cylinderelectrodes and parallel plate channel flow can be employed.In contrast, the commonly used plate-in-tank geometry providespoorly defined fluid flow conditions.

Object to be plated Particles in solution

(a) (b) (c)

(d) (e) (f)

378 C.T.J. Low et al. / Surface & CoatingsMagnetic bar Surface to be plated

Particles Surface to be plated

(g) (h) (i)

Fig. 6. Strategies for bath agitation. For industrial applications, the popularmethods used in open tanks include: (a) overhead blade stirrer, (b) reciprocatingplate plunger, and (c) pumped electrolyte [15]. For laboratory investigations,methods include: (d) magnetic stirrer, (e) rotating disk, (f) rotating cylinderelectrodes, and (g) flow between parallel plates. The black area is the cathode

surface where electrodeposition occurs and the white areas are insulatingsurfaces. The particles can also be suspended in the solution by (h) use of acationic surfactant and (i) a combination of ionic and non-ionic surfactants.The rotating disk electrode, rotating cylinder electrode andparallel plates channel flow provide controllable hydrody-namics for quantitative characterisation of electrolytes con-taining particle suspensions. Three different flow regimes canbe distinguished: laminar, transition (laminar to turbulent) andturbulent. For micron-sized particles, there is generally nosignificant influence of electrolyte flow on particle content inthe laminar region; in the transition regime, the particlecontent increased at higher flow rates; and in the turbulentregime, the particle content tended to decrease at higher rates[11].

The presence of micron-sized particles can provide anenhancement of mass transport to the cathode. As anexample, the expression for mass transport dimensionlesscorrelation for a solution containing 1030 vol.% of 2546m microparticles [64]:

Sh aRe0:43Sc0:33 1

a 0:14U0:64 2where a is a constant and is the volume fraction ofmicroparticles in the solution, Sh is the Sherwood numberdescribing the mass transport due to forced convection, Re is theReynolds number describing the fluid flow and Sc is the Schmidtnumber describing the electrolyte transport properties. Theinfluence of nanosized particles on mass transport enhancementhas yet to be studied systematically. It was suggested that theamount of 32 nm alumina nanoparticles in a nickel deposit isstrongly influenced by hydrodynamics but an increasednanoparticle concentration at low rotation rates did not followa 0.7 power relation for a mass transport controlled rotatingcylinder electrode [32]. This can be attributed to the shearing andadsorption forces being the rate controlling steps at high rotationspeeds, resulting in a lower particle concentration in the nickeldeposit.

Rotating cylinder electrodes (RCEs) have been used inmany investigations to obtain controlled mass transport duringthe deposition of single metal, alloy, composite and multilayerdeposits (Table 5). Further details concerning hydrodynamics,mass transport and fundamental characteristics of RCEs areavailable elsewhere [20,6567]. Pulsed reverse current regimeshave been used at RCE cathodes for the incorporation of 3237 nm -Al2O3 nanoparticles into a copper deposit [32,34,36].The authors have shown that the pulsed reverse currenttechnique was most beneficial at low nanoparticle concentra-tions in the electrolyte, minimizing agglomeration and assistinghigh nanoparticles level in the metal deposit.

Linear sweep voltammetry has been used to study theinfluence of various bath concentrations on the codeposition of50 nm -Al2O3 nanoparticles and copper at a rotating cylinderelectrode [37]. The nanoparticle concentrations were 3.9, 19.5,39, 120 and 158 g dm3 with electrode rotation speeds of 500,1000 and 1500 rpm. It was found that increasing the alumina

3 3

Technology 201 (2006) 371383content from 3.9 g dm to 158 g dm decreased the effectiveconcentration of copper ions, increased the viscosity andlowered the electrolyte conductivity. The presence of alumina

-

nanoparticles also resulted in a lower current density in thecharge transfer controlled and mixed controlled regions but nosystematic relationships were obtained in the mass transportcontrolled region.

Other investigations using rotating cylinder electrodesinclude: (1) the study of non-ionic, anionic and cationicsurfactants (cetylpyridinium chloride, cetytrimetylammoniumbromide, cetyltrimetylammonium chloride, nonylphenol

Table 5Examples of studies using rotating cylinder electrode cathodes

Materials deposited Rotationspeed ,rpm

PeripheralvelocityU, cm s1

Currentdensity j,mA cm2

RCE characteristics

Diameter d, cm Length l, cm Area A, cm2 Substrate Ref.

800 nm polystyrene, Zn NG NG 01000 NG NG 6.7 Al [11]32 nm -Al2O3, Ni 2251600 11.883.8 140 to 140 1.0 1.2 3.77 Au [32]32 nm -Al2O3, Cu 800 41.9 100 to 100 1.0 1.2 3.77 Au [33]32 nm Al2O3, Ni/Cu 1000 52.4 050 1.0 1.2 3.77 Au [34]37 nm -Al2O3, Cu 800 41.9 100 to 100 1.0 1.2 3.77 Au [36]50 nm Al2O3, Cu 5001500 31.494.3 0100 1.2 0.8 3.02 Stainless steel [37]

NG, not given.

0.0 0.1 0.2 0.3 0.4 0.5 0.616

18

20

22

24

4

6

8

10

12

(a)

(b)

Dep

ositio

n ra

te /

m h

-1

FC-4 surfactant concentration / g dm-3

age

volu

me

of p

artic

les

in th

e de

posit

379C.T.J. Low et al. / Surface & Coatings Technology 201 (2006) 371383(ethoxylate)28(propoxylate)13(NPE1800) and sodium dodecyl-sulphate) on the electrodeposition of zinc containing 800 nmpolystyrene nanoparticles [11], (2) the electrodeposition of anAuCu alloy with B4C particles using a galvanodynamictechnique where the current density was stepped at 1 mA min1

from 4 to 12 mA cm2 [68] and (3) the codeposition of 32 nmalumina nanoparticles into a NiCu and NiCo alloy deposit. Inthe last case, the addition of alumina particles caused nosignificant change in the percentage of copper concentration inthe CuNi deposit over the current density range 0 to 45 mAcm2 although the copper level decreased over the range of 020 mA cm2 [34].

20

25

30

35

te /

m h

-1pH7.0 7.5 8.0 8.5 9.0 9.5 10.00

5

10

15

Dep

ositio

n ra

Fig. 7. Effect of bath temperature and pH on the electroless deposition of NiCuP containing 50500 nm PTFE particles. The rate of deposition increaseswith an increase in the solution pH (this can be associated with an enhancementin the reducing ability of sodium hypophosphite) and increasing temperatureleads to a faster rate of reaction [82]. 70 C, 76 C, 80 C, 85 C and 88 C.

1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.50

2

Perc

ent

Ratio of surfactant to particles / 10-3 mol surfactant per g SiC

Fig. 8. (a) Influence of a cationic fluorocarbon surfactant, FC-4(C20H20F23N2O4I) on the deposition rate of NiCuP containing 50500 nmPTFE particles [82]. The concentration of FC-4 in the solution: 4 ml dm3,8 ml dm3, 10 ml dm3, 14 ml dm3 and 18 ml dm3. Electrolytecompositions: 50 g l1 NiSO4.6H2O, 1 g l

1 CuSO4.5H2O, 60 g l1

Na3C6H5O7.2H2O, 25 g l1 NaH2PO2.H2O, 40 g l

1 NH4CH3COO, pH 7 and85 C. (b) Influence of cetyltrimethylammonium bromide, CTAB surfactant onthe percentage volume of 100400 nm SiC particles incorporated in the nickeldeposit [40]. The concentration of CTAB in the solution is 1 g dm3, 10 gdm3 and 20 g dm3. Electrolyte compositions: 70 g l1 Ni(NH3SO3)2, 10 gl1 NiCl2, 40 g l

1 H3BO3, pH 4 and 50 C.

-

3.4. Other operating parameters

Important operational parameters include pH, bath tempera-ture, additives type and concentration. Some investigationshave shown that further enhancement of surface properties canbe obtained by appropriate selection of deposition conditions.Examples include the addition of cobalt to a nickel depositcontaining 310 nm diamond nanoparticles, which wereclaimed to give (1) an enhancement in the microhardness ofthe deposited coating, (2) an increased quantity of diamondnanoparticles in the nickel deposit, (3) uniform and well-dispersed diamond nanoparticles in the nickel deposit and (4)improved wear resistance [46]. The addition of sodiumdodecylsulfate additive was claimed to improve the dispersion,uniformity and quantity of 20 nm SiC nanoparticles in a nickeldeposit [43].

Bath temperature and pH of an electrolyte can also affectthe rate of deposition at the cathode surface. Fig. 7 shows thepH vs. deposition rate for electroless deposition of NiCuPcontaining 50500 nm PTFE particles. The rate of deposition

increased with small increases in pH (possibly due toenhanced reducing ability of sodium hypophosphite) andincreasing temperature resulting in a faster deposition rate[69].

The influence of cationic fluorocarbon surfactants on the rateof deposition is shown in Fig. 8(a) [69]. Fig. 8(b) shows thevolume fraction of 100400 nm SiC particles in a nickel depositincreased with higher concentrations of cetyltrimethylammo-nium bromide (CTAB) surfactant. This is attributable to moresurfactant molecules being available for adsorption onto theparticles surface, increasing the strength of the surface chargeon the particles leading to stronger attraction to the cathodesurface [40].

4. Gradient distribution of particles in the metal deposit

Careful modulation of the deposition conditions can lead tometal layers with a non-uniform, gradient or a layered distributionof incorporated particles. Examples include a Ni deposit with 15m SiC microparticles [70], 110 m SiC microparticles [71],

% Volume in solution % Volume in deposit

Al Al2O3 Al Al2O3

7.7 0 12 0

2.6 3.5 9 16

2.5 6.8 9 24

Outside surface of deposits

ace00

Reg

its

N

(a)

-par

380 C.T.J. Low et al. / Surface & Coatings Technology 201 (2006) 371383

Distance from surf0 50 1

Kno

op h

ardn

ess /

100

g in

dent

er

100

200

300

400

500

600

700

800

Region 3 Region 2

Growth of depos

30 % vol. -Al2O3

15 % vol. -Al2O3

(b)

Fig. 9. (a) Gradient distribution of 14 m Al conductive particles and 6080 nmLighter regions: Al [66]. Three distinct layers with different compositions of

concentrations of particle in the solution. (b) Knoop hardness profile for a gradiemicrohardness are achievable in a single coating. Region 1 is a pure Ni deposit, Regioin the deposit [60].Substrate 20 m

of deposit / m150 200

ion 1 Ni substrate

i

Al2O3 non-conductive nanoparticles in a nickel deposit. Darker spots: -Al2O3.ticles have been achieved using a current density of 5 A dm2 and various

nt distribution of -Al2O3 nanoparticles in a nickel deposit. Three regions ofn 2 has 15 vol.% of -Al2O3 in the deposit and Region 3 has 30 vol.% of -Al2O3

-

particles in the solution. Fig. 9(b) shows the Knoop hardnessprofile for a gradient distribution of -Al2O3 nanoparticles ina nickel deposit. Three different regions of microhardness canbe seen for 30%, 15% and 0% of -Al2O3 nanoparticles inthe deposit. In all these investigations, many analyticalmethods have been used to quantify the physical propertiesof the deposited metals including gravimetric analysis, X-rayfluorescence, atomic absorption spectrophotometry, opticalmicroscopy, scanning electron microscopy, X-ray diffraction,transmission electron microscopy and wavelength dispersiveX-ray spectroscopy.

5. Physical properties of nanocomposite deposits

Common targets for metallic nanocomposite deposits areincreased corrosion resistance and greater microhardness. Acomparison of Vickers microhardness for a wide range ofnanoparticles in nickel deposits is shown in Fig. 10[38,39,41,42,4448,5157]. Several trends were identified:

381tings Technology 201 (2006) 371383Type of deposit

Vick

ers

mic

roha

rdne

ss /

HV

0

200

400

600

800

1000

Microcrystalline Ni

Ni/Co/Au

Microcrystalline Ni/TiO2

Nanocrystalline Ni/TiO2

Microcrystalline Ni/Au

Coating made from DC

Coating usingPDC

Nanocrystalline coating

After annealing at high temperature

Pure

Ni

Ni/A

u

Ni/T

iO2

Ni/S

iC

Ni/A

l 2O3

Ni/S

i 3N4

Ni/Z

rO2

Coating usingPDC

After annealing at high temperature

High ZrO2content in Ni matrix

Nanocrystalline Ni

NanocrystallineNi/C

Microcrystalline Ni/C

Ni/C

Low ZrO2content in Ni matrix

Fig. 10. Vickers microhardness values for different ranges of particle size in anickel deposit. The values are displayed from minimum to maximum (bottom totop) found in the literature [38,39,41,42,4448,5157]. DC: direct current;PDC: pulsed direct current.

C.T.J. Low et al. / Surface & Coa1.220 m SiC microparticles [72], 3050 nm ZrO2 nanoparti-cles [73], 50 nm -Al2O3 nanoparticles [74], 79 m SiCmicroparticles [69], 600800 nm -Al2O3 nanoparticles [58] and14 m Al microparticles and 6080 nm -Al2O3 nanoparticles[75]. More information related to the development of gradientdistributions of materials is available elsewhere [7679]. Thegradient distribution of particles in the metal deposit can beachieved in a single electrolyte bath by simple alterations of theapplied current density or potential and/or by modulation of thehydrodynamics and concentration of particles in the solution.

For example, by varying the degree of compressed airagitation in the bath, multilayers of nickel containing differentquantities and sizes of SiC particles were achieved [70,71]. Theresulting nickel deposit was shown to contain three differentlayers: (1) under static bath conditions, 0.71.1 vol.% of SiC; (2)under intermediate hydrodynamic conditions, 9.211.8 vol.%finely dispersed SiC; and (3) under intensive hydrodynamicconditions, 12.6 vol.% coarse SiC. A more recent investigationcontrolled the influence of particle concentration (0150 gdm3), current density (2550mA dm2), electrode rotation (01200 rpm) and deposition period (40150 min) to produce acontinuous gradient distribution of SiC (79 m) in a nickeldeposit [69].

Single and mixed particles (14 m Al conductiveparticles and 6080 nm -Al2O3 non-conductive nanoparti-cles) in a nickel deposit were produced by varying the currentdensity and concentration of particles in the solution [58,75].Fig. 9(a) shows an example of a gradient distribution of Aland -Al2O3 particles in a nickel deposit, achieved byconstant current deposition with varied concentration of(1) nanocrystalline structure gave a higher microhardness thana microcrystalline structure, (2) coatings produced by pulsecurrent technique could be superior in microhardness com-pared to a direct current technique and (3) annealing at hightemperature could have a non-uniform affect on themicrohardness.

The corrosion rate of nickel coatings containing TiO2particles was investigated in acidic solution (5.0% NaCl, 1 gdm3 CuCl22H2O, 50 C, 1 week immersion) [55]. Fig. 11shows that the rate of corrosion was dependent on both thesize and quantity of TiO2 particles in the nickel deposit. Thepresence of nanosized particles in the nickel deposit gavebetter corrosion resistance than a pure nickel layer. Anataseparticles (average diameter12 nm) gave lower corrosionrates than the rutile (average diameter1 m) containingcomposites. However, these findings cannot be generalised

0 4 8 10 124

6

8

10

12

14

16

18

Corro

sion

rate

/ gm

-2

h-1

Weight percentage of particles in the nickel deposit62

Fig. 11. Dependence of corrosion rate on the amount of TiO2 particles in the

nickel deposit [55]. anatase (average diameter=12 nm) and rutile (averagediameter=1 m). Electrolyte conditions: 250 g l1 NiSO46H2O, 25 g l

1

H3BO3, 5 g l1 saccharin, pH 3, 30 C. Applied current density: 66.7 mA cm2.

-

ingsfor other systems for example, in nickel coatings containing150 nm Al2O3 and 300 nm TiO2 particles, the corrosion rateswere higher compared to the nickel coatings without particles[80].

The performance of wear resistant nickel coatings(produced by direct current, pulsed current and pulsed reversecurrent techniques) containing 1030 nm ZrO2 has beencompared [81]. The tests were conducted using a ball-on-disctribometer (dry sliding at 160 rpm with 11.3 N loading and1200 cycles). It was found that the hardness of the threecoatings increased in the order direct currentbpulsedcurrentbpulsed reverse current deposition. All the coatingsshowed better wear resistance than a pure nickel coating.

The magnetic properties of a nickel coating containing300 nm Al2O3 particles were found to be similar to a purenickel coating. The coercivity of the nanocomposite coatingsincreased with increasing particle content in the deposit (50nm Al2O3 has higher coercivity than the 300 nm Al2O3) andsaturation magnetization of the nanocomposite coatingsremains similar for a wide range of particle content in thedeposit [42]. In the majority of the investigations, thephysical properties of coatings are fundamentally dependentnot only on the quantity of nanosized particles in the metaldeposit but also on the quality of the particle dispersion inthe coating and the electrodeposition technique.

6. Conclusions

1. Various electrodeposition techniques (direct current, pulseddirect current, pulsed reverse current, potentiostatic, pulsedpotentiostatic) have been employed to incorporate nanosizedparticles into metal deposits. These techniques have enabledthe fabrication of composite coatings possessing a widerange of properties not available with pure metal or alloycoatings.

2. Pulsing the current has, in some cases, shown superioritycompared to direct current deposition for the production ofnanocomposites. Benefits include refined surface micro-structure, increased incorporation rate into the metal depositand size selective entrapment of particles.

3. Applied current density, hydrodynamics and characteristicsof the particles in solution strongly influences theirincorporation rate into metal deposits. High incorporationrates have been achieved by using: (i) high nanoparticleconcentration in the electrolyte solution, (ii) smaller sizednanoparticles, (iii) a low concentration of electroactivespecies, (iv) ultrasonication during deposition and (v) pulsedreverse current techniques.

4. The inclusion of nanosized particles can give: (i) anincreased microhardness and corrosion resistance whichcan be further enhanced with a nanocrystalline metal deposit,(ii) modified crystal growth to form a nanocrystalline metaldeposit and (iii) a shift in the reduction potential of a metalion.

382 C.T.J. Low et al. / Surface & Coat5. Flexibility and validity of various theoretical models todescribe the behaviour of a wide range of metal depositscontaining particles still requires attention. The impor-tance of experimental trials on the current density, masstransport and hydrodynamics to the incorporation rate ofnanoparticles are crucial to produce good theoreticalmodels.

6. A gradient distribution of particles in metal deposits (singlemetal, alloy or multilayers) may lead to the production ofenhanced coatings that have the ability to self-controlchemical or physical properties as a function of coatingthickness.

7. It is important to control fluid flow during the co-depositionof nanosized particles in a metal deposit and geometries suchas the rotating cylinder electrode provide establishedresearch tools.

References

[1] C.G. Fink, J.D. Prince, Trans. Am. Electrochem. Soc. 54 (1928) 315.[2] R.V. Williams, Electroplat. Met. Finish. 19 (3) (1966) 92.[3] M. Musiani, Electrochim. Acta 45 (2000) 3397.[4] E.C. Kedwood, Metallurgia 79 (476) (1969) 225.[5] V.P. Greco, Plating Surf. Finish. 76 (7) (1989) 62.[6] V.P. Greco, Plating Surf. Finish. 76 (10) (1989) 68.[7] J.R. Roos, J.P. Celis, J. Fransaer, C. Buelens, J. Met. 42 (11) (1990) 60.[8] J.P. Celis, J.R. Roos, C. Buelens, J. Fransaer, Trans. Inst. Met. Finish. 69

(4) (1991) 133.[9] C. Buelens, J. Fransaer, J.P. Celis, J.R. Roos, Bull. Electrochem. 8 (8)

(1992) 371.[10] J. Fransaer, J.P. Celis, J.R. Roos, Met. Finish. 91 (6) (1993) 97.[11] A. Hovestad, L.J.J. Janssen, J. Appl. Electrochem. 25 (1995) 519.[12] B. Doudin, J.P. Anserment, Nanostruct. Mater. 6 (1995) 521.[13] U. Erb, Nanostruct. Mater. 6 (1995) 533.[14] D. Clark, D. Wood, U. Erb, Nanostruct. Mater. 9 (1997) 755.[15] K. Helle, F.C. Walsh, Trans. Inst. Met. Finish. 75 (2) (1997) 53.[16] A. Robertson, U. Erb, G. Palumbo, Nanostruct. Mater. 12 (58) (1999)

1035.[17] C. Kerr, D. Barker, F.C. Walsh, J. Archer, Trans. Inst. Met. Finish. 78 (5)

(2000) 171.[18] J.L. Stojak, J. Fransaer, J.B. Talbot, Adv. Electrochem. Sci. Eng. 7 (2001)

193.[19] W. Gao, Z. Li, Mater. Res. 7 (1) (2004) 175.[20] C.T.J. Low, C. Ponce-de-leon, F.C. Walsh, Aust. J. Chem. 58 (2005) 246.[21] N. Guglielmi, J. Electrochem. Soc. 119 (8) (1972) 1009.[22] S. Wang, W.J. Wei, Mater. Chem. Phys. 78 (2003) 574.[23] J.P. Celis, J.R. Ross, C. Buelens, J. Electrochem. Soc. 134 (6) (1987)

1402.[24] J. Fransaer, J.P. Celis, J.R. Ross, J. Electrochem. Soc. 139 (2) (1992) 413.[25] G. Maurin, A. Lavanant, J. Appl. Electrochem. 25 (1995) 1113.[26] B.J. Hwang, C.S. Hwang, J. Electrochem. Soc. 140 (1993) 979.[27] P.M. Vereecken, I. Shao, P.C. Searson, J. Electrochem. Soc. 147 (7) (2002)

2572.[28] P. Bercot, E. Pena-Munoz, J. Pagetti, Surf. Coat. Technol. 157 (2002) 282.[29] P.R. Webb, N.L. Robertson, J. Electrochem. Soc. 141 (3) (1994) 669.[30] J. Steinbach, H. Ferkel, Scr. Mater. 44 (2001) 1813.[31] A. Lozano-Morales, E.J. Podlaha, J. Electrochem. Soc. 151 (7) (2004)

C478.[32] A.B. Vidrine, E.J. Podlaha, J. Appl. Electrochem. 31 (4) (2001) 461.[33] E.J. Podlaha, Nano Lett. 1 (8) (2001) 413.[34] A. Panda, E.J. Podlaha, Electrochem. Solid-State Lett. 6 (11) (2003) C149.[35] E.J. Podlaha, D. Landolt, AESF SUR/FIN Annual Intern. Technical

Conference, 1998.[36] E.J. Podlaha, D. Landolt, J. Electrochem. Soc. 144 (7) (1997) L200.[37] J.L. Stojak, J.B. Talbot, J. Appl. Electrochem. 31 (5) (2001) 559.

Technology 201 (2006) 371383[38] I. Shao, P.M. Vereecken, R.C. Cammarata, P.C. Searson, J. Electrochem.Soc. 149 (11) (2002) C610.

[39] N.S. Qu, K.C. Chan, D. Zhu, Scr. Mater. 50 (2004) 1131.

-

[40] S. Kuo, Y. Chen, M. Ger, W. Hwu, Mater. Chem. Phys. 86 (2004) 5.[41] P.M. Vereecken, I. Shao, P.C. Searson, J. Electrochem. Soc. 147 (7) (2000)

2572.[42] I. Shao, P.M. Vereecken, C.L. Chien, P.C. Searson, R.C. Cammarata,

J. Mater. Res. 17 (6) (2002) 1412.[43] L. Benea, P.L. Bonora, A. Borello, S. Martelli, F. Wenger, P. Ponthiaux,

J. Galland, J. Electrochem. Soc. 148 (7) (2001) C461.[44] P. Gyftou, M. Stoumbouli, E.A. Pavlatou, N. Spyrellis, Trans. Inst. Met.

Finish. 80 (3) (2002) 88.[45] A.F. Zimmerman, D.G. Clark, K.T. Aust, U. Erb, Mater. Lett. 52 (2002)

85.[46] A.F. Zimmerman, G. Palumbo, K.T. Aust, U. Erb, Mater. Sci. Eng., A 328

(2002) 137.[47] L. Wang, Y. Gao, H. Liu, Q. Xue, T. Xu, Surf. Coat. Technol. 191 (2005) 1.[48] V.I. Kurmachev, Y.V. Timoshkov, T.I. Orehovskaja, V.Y. Tomoshkov, Fiz.

Tverd. Tela 46 (4) (2004) 679.[49] K. Kondo, A. Ohgishi, Z. Tanaka, J. Electrochem. Soc. 147 (7) (2000)

2611.[50] A. Moller, H. Hahn, Nanostruct. Mater. 12 (1999) 259.[51] L. Wang, Y. Gao, Q. Xue, H. Liu, T. Xu, Mater. Sci. Eng., A 390 (2005)

313.[52] W.-H. Lee, S.-C. Tang, K.-C. Chung, Surf. Coat. Technol. 120121 (1999)

607.[53] X. Li, Z. Li, Mater. Sci. Eng., A 358 (2003) 107.[54] Y. Zhang, X. Peng, F. Wang, Mater. Lett. 58 (2004) 1134.[55] J. Li, Y. Sun, X. Sun, J. Qiao, Surf. Coat. Technol. 192 (2005) 331.[56] J. Li, J. Liang, H. He, Y. Sun, J. Mater. Sci. Lett. 21 (2002) 939.[57] F. Wunsche, A. Bund, W. Plieth, J. Solid State Electrochem. 8 (2004) 209.

3203.

[62] A. Afshar, M. Ghorbani, M. Mazaheri, Surf. Coat. Technol. 187 (23)(2004) 293.

[63] L. Benea, P.-L. Bonora, A. Borello, S. Martelli, Wear 249 (1011) (2002)995.

[64] D.W. Gibbons, R.H. Muller, C.W. Tobias, J. Electrochem. Soc. 138 (1991)3255.

[65] D.R. Gabe, J. Appl. Electrochem. 4 (1974) 91.[66] D.R. Gabe, F.C. Walsh, J. Appl. Electrochem. 13 (1983) 3.[67] D.R. Gabe, G.D. Wilcox, J. Gonzalez-Garcia, F.C. Walsh, J. Appl.

Electrochem. 28 (1998) 759.[68] B. Bozzini, G. Giovannelli, P.L. Cavallotti, J. Appl. Electrochem. 29 (6)

(1999) 685.[69] H. Wang, S. Yao, S. Matsumura, J. Mater. Process. Technol. 145 (2004)

299.[70] L. Orlovskaja, N. Periene, M. Kurtinaitiene, G. Bikulcius, Surf. Coat.

Technol. 105 (12) (1998) 8.[71] L. Orlovskaja, N. Periene, M. Kurtinaitiene, S. Surviliene, Surf. Coat.

Technol. 111 (23) (1999) 234.[72] S.K. Kim, H.J. Yoo, Surf. Coat. Technol. 108109 (1998) 564.[73] L. Jun, D. Changsong, W. Dianlong, H. Xinguo, Surf. Coat. Technol. 91

(1997) 131.[74] Y.S. Dong, P.H. Lin, H.X. Wang, Surf. Coat. Technol. (2005) (Available

online 15 January 2005).[75] . K. Barmak, S.W. Banovic, C.M. Petronis, D.F. Susan, A.R. Marder,

J. Microsc. 185 (2) (1997) 265.[76] Z.Q. Zheng, S.Q. Liang, Mater. Sci. Eng. 10 (1) (1992) 1.[77] N. Periene, A. Cesuiniene, L. Taicas, Plating Surf. Finish. 80 (10) (1993)

73.[78] B.Y. Chen, Mater. Sci. Eng. 7 (1993) 45.

383C.T.J. Low et al. / Surface & Coatings Technology 201 (2006) 371383[59] J. Fransaer, E. Leunis, T. Hirato, J.P. Celis, J. Appl. Electrochem. 32 (2002)123.

[60] C.F. Malfatti, J. Zoppas-Ferreira, C.B. Santos, B.V. Souza, E.P. Fallavena,S. Vaillant, J.P. Bonino, Corros. Sci. 47 (3) (2005) 567.

[61] G. Wu, N. Li, D. Zhou, K. Mitsuo, Surf. Coat. Technol. 176 (2004) 157.[79] X.S. Lei, N. Ling, H.J. Wang, Mater. Prot. 28 (7) (1995) 12.[80] F. Erler, C. Jakob, H. Romanus, L. Spiess, B. Wielage, T. Lampke, S.

Steinhauser, Electrochim. Acta 48 (2003) 3063.[81] W. Wang, F. Hou, H. Wang, T. Guo, Scr. Mater. 53 (2005) 613.[82] Q. Zhao, Y. Liu, Surf. Coat. Technol. (2004) (Available online 29 July

2004).[58] S.W. Banovic, K. Barmak, A.R. Marder, J. Mater. Sci. 34 (13) (1999)

Electrodeposition of composite coatings containing nanoparticles in a metal depositIntroductionThe mechanism of codeposition of particles into a metal depositExperimental parametersCurrent densityEffects of nanosized particles on deposit characteristicsInfluence of bath agitation and cathode movementOther operating parametersGradient distribution of particles in the metal depositPhysical properties of nanocomposite deposits

ConclusionsReferences

![Surface & Coatings Technology - Cairo Universityscholar.cu.edu.eg/?q=han/files/electrodeposition... · cement, rubber, epoxy or coatings [5]. Generally, various protective methods](https://static.fdocuments.in/doc/165x107/5f1682883d0df5084770ca79/surface-coatings-technology-cairo-cement-rubber-epoxy-or-coatings-5.jpg)