Battery-Powered Electric and Hybrid Electric Vehicle Projects to

Electric Battery Actual and future Battery Technology · PDF fileElectric Battery Actual and...

-

Upload

trinhquynh -

Category

Documents

-

view

228 -

download

2

Transcript of Electric Battery Actual and future Battery Technology · PDF fileElectric Battery Actual and...

Electric Battery

Actual and future Battery

Technology Trends

Division PowertrainBU Hybrid and Electric Vehicle

1 / Peter Birke / May 2010 © Continental AG

Peter BirkeSenior Technical Expert Battery SystemsBusiness Unit Hybrid Electric VehiclesDivision PowertrainContinental AGCo-authors: Michael Keller, Michael Schiemann

Prague, May 6th, 2010

1789 - Luigi Galvani

1801 - Alessandro Volta

Introduction and short historical overviewBatteries first steps

1802 - Johann Wilhelm Ritter

Division PowertrainBU Hybrid and Electric Vehicle

2 / Peter Birke / May 2010 © Continental AG

Experiments with frogs‘ legs

Battery with alternating one upon the other stacked Copper and Zinc plates (Cu/Zn). The plates were separated by cloths, which

Introduction and short historical overview

The plates were separated by cloths, which have been soaked by acid.

Ritter‘s column (first secondary battery)In 1802 he built the first accumulator with 50 copper discs separated by cardboard disks moistened by a salt solution.

Introduction and short historical overviewBatteries “Walk Of Fame”

1991 Introduction of Lithium – Ion batteries (Sony): Cobalt based

1996 Manganese based Lithium-

1930 Nickel Zinc battery

1950er serial production of sealed Nickel Cadmium production

1972 Development of NaS (Sodium-Sulphur batteries) high temperature batteries

1991 Introduction of Lithium – Ion batteries (Sony): Cobalt based

Ene

rgy

dens

ity E

[Wh/

kg]

Division PowertrainBU Hybrid and Electric Vehicle

3 / Peter Birke / May 2010 © Continental AG

1859 Gaston Planté – first lead acid battery

1899 Waldemar Jungner

1901 Thomas Alva Edison

1930 Nickel Zinc battery

Introduction and short historical overview

Ion batteries (Sony): Cobalt based

Ion batteries – cost optimized

1999 Lithium ion polymer

2004 Introduction LiFePO4 cathode material

2002 Introduction of NMC cathode material

1930 Nickel Zinc battery - Drumm

1950er serial production of sealed Nickel Cadmium production

Begin of 80er CSIR Laboratory development of NaNiCl (Sodium-Nickelchloride) ZEBRA battery

1983 Lithium metal rechargeable - Moli

1990 Introduction of NiMH batteries (Sanyo) with higher energy density and banned Cadmium

Ion batteries (Sony): Cobalt based

first lead acid battery

1899 Waldemar Jungner - first Nickel Cadmium battery (pocket plates)

1901 Thomas Alva Edison – Nickel Iron battery

1930 Nickel Zinc battery - Drumm

Battery types - historical overview Comparison of energy densities

Theoretical energy density

Practical energy density

High temperature battery

40 W

h/kg

161

Wh/

kg

240

Wh/

kg

45 W

h/kg

320

Wh/

kg

80 W

h/kg

300

Wh/

kg

80 W

h/kg

Division PowertrainBU Hybrid and Electric Vehicle

4 / Peter Birke / May 2010 © Continental AG

Pb NiCd NiZn NiMH

20 –

40 W

h/kg

161

Wh/

kg

25 –

45 W

h/kg

45 –

80 W

h/kg

45 –

80 W

h/kg

historical overview

720

Wh/

kg

795

Wh/

kg

kg

435

Wh/

kg

90 W

h/kg

110

Wh/

kg

90 –

140

Wh/

kg

450

Wh/

kg

70 –

200

Wh/

kg

720

Wh/

kg

ZnBr NaNiCl NaS Li-Ion

50 –

90 W

h/kg

80 – 90

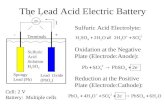

The active material of the lead acid system reacts with the electrolyte (the sulphur of sulphuric acid is inside the plates after discharge reaction).As a result the active material electrode structure becomes disoriented due to active mass displacement resulting in decreased cycle life time.

Introduction short historical overviewElectrode reaction principle of different battery types

resulting in decreased cycle life time.

Modern battery systems like Li-Ion and NiMH cells base on principle of intercalation (both electrodes), NiCd was the first system showing up one intercalation electrode (Ni(OH)2).

Division PowertrainBU Hybrid and Electric Vehicle

5 / Peter Birke / May 2010 © Continental AG

The active material is intercalated inside the grid structure and back (swing principle), the electrolyte is not a part of chemical reaction(thus a high cycle life time results).

The active material of the lead acid system reacts with the electrolyte (the sulphur of sulphuric acid is inside the plates after discharge reaction).As a result the active material electrode structure becomes disoriented due to active mass displacement

Introduction short historical overviewElectrode reaction principle of different battery types

breakthrough

Batteries for hybrid and electric vehiclesFuture development trends powered by vehicle requirements

Hybrid vehicle

Pow

er d

ensi

ty [W

hkg]

Division PowertrainBU Hybrid and Electric Vehicle

6 / Peter Birke / May 2010 © Continental AG

Energy density [Wh/kg]

Batteries for hybrid and electric vehiclesFuture development trends powered by vehicle requirements

Hybrid vehicle

Electric vehicle

Energy density [Wh/kg]

Lithium-Ion batteries trendsElectric Battery 20xx, quo vadis?

Higher energy density (EV, Consumer-Market, especially

portable devices)

Higher currentdensities (e.g. HEV, PHEV, densities (e.g. HEV, PHEV,

power tools)

Alternative active materials, which require less

supervising hardware (e.g. less sophisticated voltage

control)

Division PowertrainBU Hybrid and Electric Vehicle

7 / Peter Birke / May 2010 © Continental AG

Due to increasing different demands there will be a larger variety in cell types and also different electrochemistries.

Higher energy density (EV, Market, especially

portable devices)

Lower costs for „Low end“ products

Low cost active materials for applications with reduced

demands (e. g. less capacity, power)

products

Due to increasing different demands there will be a larger variety in cell types and also different electrochemistries.

Lithium-Ion batteries … the challenges are also on system level

2020

2030

Ene

rgy

dens

ity [W

h/kg

]

Division PowertrainBU Hybrid and Electric Vehicle

8 / Peter Birke / May 2010 © Continental AG

Cell level System level

… the challenges are also on system level

2030 High integrated electronics, new electro-mechanical components and

2015

components and new package design give potentials for future energy increase on system level

System level

*@ 100 % SOC @ 1h @ 20°C 50 Ah cell

Energy Storage Systems - ComponentsElectromechanical components and electronic components

Fuses and current sensingProtection against electrical overload

Switches and Service disconnectHV disconnect in service case Support emergency shut-off

Protection against electrical overload

Division PowertrainBU Hybrid and Electric Vehicle

9 / Peter Birke / May 2010 © Continental AG

HV Connectors and wiringVehicle power interface

Modular Li-Ion Energy Storage System Concept

ComponentsElectromechanical components and electronic components

Software

+

BMCCalculation general condition of batteryInput of max. charge / discharge currentMonitoring of isolation Control of main relay, pre-charge deviceIsolation of control voltage and battery voltage

CSCActive balancing of Li-Ion cells Measuring of temperature

Ion Energy Storage System Concept

Lithium-Ion batteries Challenges on cell and on system level

100%

Weight distribution Mild hybrid battery (H7 packaging)

C 1

0 se

c)Packaging13 %

7 %Electronics & Electromechanical components (fuses, HV connectors, wiring)

80%

60%

40%Cell pack

Wei

ght [

%]

HE

V b

atte

ry (

20 k

W @

25°C

10

sec)

70 %

10 % Cooling

Packaging13 %

Division PowertrainBU Hybrid and Electric Vehicle

10 / Peter Birke / May 2010 © Continental AG

0%

20%

HE

V b

atte

ry (

20 k

W @

25

Challenges on cell and on system level

Electronics & Electromechanical components (fuses, HV connectors, wiring)

Hig

h in

tegr

atio

nH

igh

inte

grat

ion

Cus

tom

ized

ModularCustomized

Cus

tom

ized

100%

Successful weight reduction on system levelJump from first to second generation

-2% -4%Improved housing

High integrated Electronics

20%

80%

60%

40%Wei

ght

[%]

Division PowertrainBU Hybrid and Electric Vehicle

11 / Peter Birke / May 2010 © Continental AG

0%

20%

2009

Successful weight reduction on system level

-2%-10% optimized cell design

Reduced sealing

Improved housing Optimized internal accomplishment

Reduced sealing compound

Outlook

2012 2015

Li-Ion battery systemPower density and energy density development is necessary but ….

[W/l]

Power density

2008

2012

2016

2030

20082030

HEV cells

EV cells

0 5,000 10,0000

10,000

Division PowertrainBU Hybrid and Electric Vehicle

12 / Peter Birke / May 2010 © Continental AG

- @ 100 % SOC @ 10s @ 20°C(typical SOC HEV 50 % - 60 %)

- Cell volume without tabs

[W/kg]0 5,000 10,000

Power density and energy density development is necessary but ….

[Wh/l]

Energy density

2012

2016

2008

2030

2008

2012

20162030

HEV cells

EV cells

0 100 200 300

200

400

0

[Wh/kg]

- Cell volume without tabs

0 100 200 300

Lithium-Ion batteries Cathode materials – future potential of Phosphates for Li

LiNiPO4

LiCoPO4

LiMnPO 4,1VLiMnPO4

LiFePO4

LiAl0,05Co0,15Ni0,8O2

LiCoO2

LiNi1/3Co1/3Mn1/3O2

4,1V

3,2V

3,6V

3,6 V

Division PowertrainBU Hybrid and Electric Vehicle

13 / Peter Birke / May 2010 © Continental AG

0 100 200 300 400

Source: Dr. Wohlfahrt

LiCoO2

LiMn2O4

Theoretical spec. energy [Wh/kg]

3,9V

future potential of Phosphates for Li-technology

tom

orro

w

5,1V

4,8V

4,1V tom

orro

w

toda

y

High energy and high intrinsic safety

4,1V

3,6 V

400 500 600 700

Source: Dr. Wohlfahrt-Mehrens, ZSW

Theoretical spec. energy [Wh/kg]

Future cell systemsDevelopment of energy

Future development directionTheoretical energy density

Practical energy density

Ene

rgy

dens

ity [W

h/kg

] Laboratory samples

Future evelopment of energy

80 W

h/kg

130

–…

Wh/

kg

70 -

250

Wh/

kg

320

Wh/

kg

450

Wh/

kg

Division PowertrainBU Hybrid and Electric Vehicle

14 / Peter Birke / May 2010 © Continental AG

Li/S

45 –

80 W

h/kg

NiZn Li-Ion

320

Wh/

kg

3500

Wh/

kg

650

Wh/

kg … 3

500

Wh/

kgFuture development direction

1160

0 W

h/kg

… 2

000

Wh/

kg

3500

Wh/

kg

650

Wh/

kg … 3

500

Wh/

kg

… 2

000

Wh/

kgLi/Sx

Li/MeOzLi/MeFy Li/F2 Li/O2

New Battery trendsLithium + … Sulfur

Negative Electrode: Lithium metal (electrodeposited and sandwiched between current collector and stabilization layers

Electrolyte: Organic based

Positive Electrode: Sulphur with carbonPositive Electrode: Sulphur with carbon

Division PowertrainBU Hybrid and Electric Vehicle

15 / Peter Birke / May 2010 © Continental AG

Challenges: Safety and life time (especially over cycles)

Negative Electrode: Lithium metal (electrodeposited and sandwiched between current collector and stabilization layers

Negative conductor

Separator

Negative electrode

Positive conductor

Challenges: Safety and life time (especially over cycles)

Separator

Positive electrode

New Battery trendsLithium + … Fluorine

Negative Electrode: Lithium metal (electrodeposited and sandwiched between current collector and stabilization layers

Electrolyte: Solid State, Polymer

Positive Electrode: MexFy (Me: Metal) in Matrix

Challenges:

Division PowertrainBU Hybrid and Electric Vehicle

16 / Peter Birke / May 2010 © Continental AG

Challenges: High temperature requiredExcellent material distribution within the matrix

Negative Electrode: Lithium metal (electrodeposited and sandwiched between current collector and

(Me: Metal) in Matrix

Excellent material distribution within the matrix

New Battery trendsLithium + … Air

Air

Division PowertrainBU Hybrid and Electric Vehicle

17 / Peter Birke / May 2010 © Continental AG

Challenges: Safety and life time (especially over cycles)

Oxygen permable membrane

Composite carbon electrode onNi current collector (Cathode)

Solid polymer electrolyte

Li on Ni current collector (Anode)

Metallized plastic envelope

Challenges: Safety and life time (especially over cycles)

Outlook cell technologiesCell technologies in dependence on applications

Mic

ro H

EV

2010 2020

VRLA & FLA VRLA / Li

VRLA & DLC VRLA & ECCAP

Mild

HE

VP

lug

In H

EV

Li-Ion / NiMH Li

Li-Ion / NiMH

Division PowertrainBU Hybrid and Electric Vehicle

18 / Peter Birke / May 2010 © Continental AG

EV Li-Ion

VRLA – sealed lead acid batteries with immobilized electrolyte (absorbed glass mat batteries AGM))FLA – vented lead acid batteries with fluid electrolyteUCAP – double layer capacitor, ECCAP – double layer capacitor with extended capacityLi-Ion – Lithium-Ion battery, Li – e.g. Lithium-air , other – e. g. Nickel tin battery

Cell technologies in dependence on applications

2020 2030

DLC

FLA

VRLA / Li -Ion VRLA & Li-Ion / other

ECCAP / Li-Ion VR

LA

VRLA & Li-Ion / ECCAP / other

NiM

HH

EV

Cell

PH

EV

Cell

Li-Ion

Li-Ion / other

Li-Ion

Li -Ion

Li-Ion / Li

VR

LA

ECCAP / other

PH

EV

Cell

EV

Cell

Li-Ion

Li-Ion

Li-Ion

Li-Ion / Li

sealed lead acid batteries with immobilized electrolyte (absorbed glass mat batteries AGM)),

double layer capacitor with extended capacity, NiMH – Nickel-metal hydride batterye. g. Nickel tin battery

Li-Air

System ComparisonVision of electrical energy storage systems and operating range

Operating range [km] per weight of energy carrier [kg]

EV has weight advantage…

Gasoline

Li-Ion

Li-Fluorine

Division PowertrainBU Hybrid and Electric Vehicle

19 / Peter Birke / May 2010 © Continental AG

0% 25% 50% 75% 100%

1) Basis for comparison: Weight of powertrain + weight of energy carrier/storageICE: Vehicle with Internal Combustion Engine, EV: Electric Vehicle

km/kgkm/kg[ ]

Vision of electrical energy storage systems and operating range

Operating range [km] per weight of energy carrier [kg]

EV has weight advantage… 1)

… for almost all driving scenarios

… up to 120 kmoperating range

… up to 1,500 kmoperating range

driving scenarios

km/kgkm/kg[ ]

System ComparisonVision of electrical energy storage systems and operating range

Division PowertrainBU Hybrid and Electric Vehicle

20 / Peter Birke / May 2010 © Continental AG

Vision of electrical energy storage systems and operating range

Summary

The Li-Ion technology will become more and more the dominant technology forelectro mobility.

The Li-Ion technology has not yet reached its full potential, further improvements are still possible.

For high end applications Li (metal) technology may be the follower of Li

For low-end applications also electrochemistries such as Lead acid or Nickelwill still be interesting options.

Parallel to the evolutions on cell level, the development on system level such as electronics, electromechanical components, software, battery algorithms, thermal

Division PowertrainBU Hybrid and Electric Vehicle

21 / Peter Birke / May 2010 © Continental AG

electronics, electromechanical components, software, battery algorithms, thermal management, housing will lead to decrease in volume, weight and system costs.

Ion technology will become more and more the dominant technology for

Ion technology has not yet reached its full potential,

For high end applications Li (metal) technology may be the follower of Li-Ion

end applications also electrochemistries such as Lead acid or Nickel-Zinc

Parallel to the evolutions on cell level, the development on system level such as electronics, electromechanical components, software, battery algorithms, thermal electronics, electromechanical components, software, battery algorithms, thermal management, housing will lead to decrease in volume, weight and system costs.

Thank you for your Attention

Division PowertrainBU Hybrid and Electric Vehicle

22 / Peter Birke / May 2010 © Continental AG

Thank you for your Attention