EL SEGUNDO UNIFIED SCHOOL DISTRICT€¦ · NFPA 20 Stationary Pumps for Fire Protection ..... (2016...

Transcript of EL SEGUNDO UNIFIED SCHOOL DISTRICT€¦ · NFPA 20 Stationary Pumps for Fire Protection ..... (2016...

ARCHITECT

PBK ARCHITECTSCONTACT: GILBERT BAEZ2855 E GUASTI RD.SUITE 43ONTARIO, CA 91761t: 909-937-9200 EXT. 7034

OWNER/PROJECT MANAGER

EL SEGUNDO UNIFIED SCHOOL DISTRICT CONTACT: DYLAN FARRIS641 SHELDON ST.EL SEGUNDO, CA 90245t: 310-615-2650 EXT. 1510

SHADE STRUCTURE MANUFACTURER

DAVE BANG ASSOCIATESCONTACT: MARC GUTFELD1885 NORTH MAIN STREETORANGE, CA 92865t: 800-669-2585 EXT. 3126

DSA A# 03-120646

CENTER STREET ELEMENTARY SCHOOL SHADESTRUCTURE ADDITIONS

EL SEGUNDO UNIFIED SCHOOL DISTRICT

DSA SUBMITTAL SET03/10/2020

PARTIAL LIST OF APPLICABLE CODES

2019 California Administrative Code (CAC) ...................................................................... (Part 1, Title 24, CCR)

2019 California Building Code (CBC) ................................................................................(Part 2, Title 24, CCR) (2018 International Building Code Volumes 1-2 and 2016 California Amendments)

2019 California Electrical Code (CEC) ............................................................................... (Part 3, Title 24, CCR) (2017 National Electrical Code and 2019 California Amendments)

2019 California Mechanical Code (CMC) ........................................................................... (Part 4, Title 24, CCR) (2018 Uniform Mechanical Code and 2019 California Amendments)

2019 California Plumbing Code (CPC) ............................................................................... (Part 5, Title 24, CCR)

(2018 Uniform Plumbing Code and 2019 California Amendments) 2019 California Energy Code (CEC) ................................................................................... (Part 6, Title 24, CCR)

2019 California Fire Code (CFC) ......................................................................................... (Part 9, Title 24, CCR)

(2018 International Fire Code and 2019 California Amendments) 2019 California Green Building Standards Code .............................................................. (Part 11, Title 24, CCR)

2019 California Referenced Standards Code .................................................................... (Part 12, Title 24, CCR)

Title 19 CCR, Public Safety, State Fire Marshall Regulations

2016 ASME A17.1 Safety Code For Elevators and Escalators

PARTIAL LIST OF APPLICABLE STANDARDS

NFPA 13 Automatic Fire Sprinkler Systems ................................................................................ (2016 Edition)

NFPA 14 Standpipe and Hose Systems ...................................................................................... (2016 Edition)

NFPA 17 Dry Chemical Extinguishing Systems .......................................................................... (2017 Edition)

NFPA 17a Wet Chemical Extinguishing Systems ....................................................................... (2017 Edition)

NFPA 20 Stationary Pumps for Fire Protection ........................................................................... (2016 Edition)

NFPA 22 Water Tanks for Private Fire Protection ...................................................................... (2013 Edition)

NFPA 24 Private Fire Mains & their Appurtenances ................................................................... (2016 Edition)

NFPA 25 Standard for Inspection, Testing and Maintenance of Water-Based Fire Protection Systems ...................................................................................................... (2016 Edition)

NFPA 72 National Fire Alarm & Signaling Code ......................................................................... (2016 Edition)

NFPA 80 Fire Doors and Other Opening Protectives ................................................................. (2016 Edition)

NFPA 92 Standard for Smoke Control Systems ......................................................................... (2016 Edition)

NFPA 253 Critical Radiant Flux of Floor Covering Systems ....................................................... (2015 Edition)

NFPA 2001 Clean Agent Fire Extinguishing Systems ................................................................ (2015 Edition)

ICC 300 ICC Stds on Bleachers, Folding and Telescoping Seating and Grand stands .............. (2012 Edition)

UL 300 Fire Testing of Fire Extinguishing Sys for Protection of Restaurant Cooking Areas......... (2005 Edition)

UL 464 Audible Signal Appliances ............................................................................................... (2003 Edition)

UL 521 Heat Detectors for Fire Protective Signaling Systems .................................................... (1999 Edition)

-Reference Code Section for NFPA Standards - 2019 CBC (SFM) Chapter 35. See Chapter 35 for State of California Admendments to NFPA Standards.

SHEET DISCIPLINE TYPE

DISCIPLINE

A2.01A

0 - GENERAL1 - SITE PLANS & DETAILS2 - FLOOR PLANS (Note: Flip Sheets are Schedules)3 - ROOF4 - ADA & ENLARGED PLANS5 - PLAN DETAILS6 - EXTERIOR/INTERIOR ELEVATIONS7 - PARTITION TYPES & WALL SECTIONS8 - CASEWORK ELEVATIONS9 - WINDOWS, DOORS, FRAME ELEVATIONS & DETAILS10 - REFLECTED CEILING PLANS & DETAILS

SEQUENCE (.01 - .99......etc.)

G - GENERAL (Cover, A0 Sheets)C - CIVILL - LANDSCAPED - DEMOA - ARCHITECTURALS - STRUCTURALI - INTERIORSM - MECHANICALE - ELECTRICALP - PLUMBINGT - TECHNOLOGY

BUILDING AREA

FOR ARCHITECTS/ENGINEERS WHO UTILIZE PLANS, INCLUDING BUT NOT LIMITED TO SHOP DRAWINGS, PREPARED BY OTHER LICENSED DESIGN PROFESSIONALS AND/OR CONSULTANTS

(Application No. ______________________ File No. ______________)

The drawings or sheets listed on the cover or index sheet (see asterisk *)This drawing, page of specifications/calculations

have been prepared by other design professionals or consultants who are licensed and/or authorized to prepare such drawings in this state. It has been examined by me for:

1) design intent and appears to meet the appropriate requirements of Title 24, California Code of Regulations and the project specifications prepared by me, and

The Statement of General Conformance “shall not be construed as relieving me of my rights, duties, and responsibilities under Sections 17302 and 81138 of the Education Code and Sections 4-336, 4-341 and 4-344” of Title 24, Part 1. (Title 24, Part 1, Section 4-317 (b))

I certify that: The drawings or sheets listed on the cover or index sheet

is/are in general conformance and

Signature Date

Architect or Engineer designated to be in general responsible charge

Print Name

License Number Expiration Date

Signature Date

Architect or Engineer deligated responsibility for this portion of the work

Print Name

License Number Expiration Date

2) coordination with my plans and specifications and is acceptable for incorporation into the construction of this project.

This drawing or page

have been coordinated

is/are in general conformance and

have been coordinated

05/31/21C-28195

MARK EACRETT

03/10/20

03-120646 19-34

DIMENSIONS

NOTE: all dimensions to face of wall unlessotherwise noted

COLUMN LINE

FLOOR LINE

MATCH LINE

NORTH SYMBOL

INTERIOR ELEVATION SYMBOL

DOOR DESIGNATION

EXTERIOR ELEVATION SYMBOL

PLAN OR DETAIL ENLARGED

DETAIL SECTIONSAND VERTICAL SECTIONS

PARTITION TYPE

REVISION NUMBER

DETAIL ENLARGED

WINDOW DESIGNATION

EXISTING ELEVATION

FINISH GRADE ELEVATION

AREA DRAIN

PROPERTY LINE

NO.

NO.

A1.01 1

2

3

4

12

1

18'-6"

SPOT COORDINATE

KEY NOTE

BREAK LINE

MATCH LINE

SEE XX/X-XXX

EQUIPMENT DESIGNATION

TOILET ACCESSORY SYMBOL

GRAPHIC SCALE

ROOM NAME AND NUMBER

SPOT ELEVATION

WHICH CONTINUATIONSHEET NUMBER ON

IS FOUND

FHCFHC

FIRE HOSE CABINET

FECFEC

FIRE EXTINGUISHER CABINET

(RECESSED AND SURFACE MOUNTED)

(RECESSED AND SURFACE MOUNTED)

SHOWER HEAD

RTU REFER TO MECHANICAL FOR TYPE

ROOF TOP UNIT

F.D.

FLOOR SINK

FLOOR DRAIN

OVERFLOW DRAIN AND ROOF DRAIN

F.S.

FENCING (WITH POSTS)

NORTHTRUE NORTH

12.34

OVERFLOW DRAIN

ROOF DRAIN

25C

TA1

SCALE: 1" = 4'-0"

0 2' 4' 8'

1

A-100

EXISTING PARTITION

NEW PARTITION

N - 58' 2"E - 150' 11"

1

A-100

SECTION CALLOUT SYMBOL

?

?

?

?

Room name

101

150 SF

4'-0"6'-0"

10'-0"

O

NameElevation

A101

1

A1.01

101

A1t

A101

1

1i

1. CONSTRUCTION DOCUMENTS DESCRIBE THE PRODUCTS, SYSTEMS, QUANTITIES, CONFIGURATION AND PERFORMANCE SPECIFICATIONS THAT DELIVER THE OVERALL DESIGN INTENT OF THE PROJECT.

2. THE CONSTRUCTION DOCUMENT DRAWINGS AND SPECIFICATIONS ARE COMPLIMENTARY, AND WHAT IS REQUIRED BY ONE SHALL BE AS BINDING AS IF REQUIRED BY BOTH.

3. PERFORMANCE BY THE CONSTRUCTION TEAM SHALL BE CONSISTENT WITH THE CONSTRUCTION DRAWINGS AND SPECIFICATIONS AS NECESSARY TO DELIVER THE INDICATED RESULTS OF THE DESIGN INTENT.

4. ALL MATERIALS AND WORKMANSHIP SHALL COMPLY WITH ALL GOVERNING CODES, ORDINANCES, REGULATIONS AND LAWS.

5. THE DESIGN ADEQUACY AND SAFETY OF ERECTION BRACING, SHORING, TEMPORARY SUPPORTS AND SCAFFOLDING IS THE SOLE RESPONSIBILITY OF THE CONTRACTOR.

6. WHERE ANY CONFLICT OCCURS BETWEEN THE REQUIREMENTS OF LAWS, CODES, ORDINANCES, RULES AND REGULATIONS, THE MOST STRINGENT SHALL GOVERN.

7. ENACT ALL MEASURES TO PROTECT AND SAFEGUARD ALL EXISTING ELEMENTS TO REMAIN FROM BEING DAMAGED. REPLACE OR REPAIR EXISTING ELEMENTS DAMAGED BY THE EXECUTION OF THIS CONTRACT TO EQUAL OR BETTER CONDITION.

8. CUTTING, BORING, SAWCUTTING OR DRILLING THROUGH THE EXISTING OR NEW STRUCTURAL ELEMENTS SHALL NOT BE STARTED UNTIL THE DETAILS HAVE BEEN REVIEWED AND APPROVED BY THE ARCHITECT, AND STRUCTURAL ENGINEER OF RECORD.

9. VERIFY DIMENSIONS AND EXISTING CONDITIONS BEFORE COMMENCING WORK. REPORT DISCREPANCIES TO THE ARCHITECT PRIOR TO PROCEEDING WITH AFFECTED WORK.

10. DIMENSIONS NOTED AS "FIELD VERIFY" SHALL BE CHECKED AT THE SITE BY THE CONTRACTOR AND REVIEWED WITH THE ARCHITECT BEFORE INCORPORATING INTO THE WORK.

11. DO NOT SCALE DRAWING. WRITTEN DIMENSIONS TAKE PRECEDENCE. IF CLARIFICATION IS REQUIRED IN ORDER TO DETERMINE THE INTENT OF THE CONTRACT DOCUMENTS, CONTACT THE ARCHITECT.

12. NOTES OR DIMENSIONS LABELED "TYPICAL" SHALL APPLY TO SITUATIONS THAT ARE THE SAME OR SIMILAR.

13. ALL DIMENSIONS ARE TO FACE OF STUD, UNLESS NOTED OTHERWISE.14. ALL SPACES WITH FLOOR DRAINS TO HAVE FINISHED FLOORS SLOPED TO DRAIN NOT TO

EXCEED ONE IN FIFTY.15. ALL FLOORS FINISH CHANGES SHALL OCCUR AT THE CENTERLINE OF DOORS UNLESS

NOTED OTHERWISE. ALL FLOOR FINISH CHANGES SHALL HAVE THRESHOLDS OR REDUCER STRIPS.

16. COORDINATE HOUSEKEEPING PAD DIMENSIONS AND LOCATIONS WITH EQUIPMENT TO BE INSTALLED.

17. ALL DOORS IN INTERIOR GYP. BD STUD WALLS SHALL BE SET 4" OFF THE PERP. ADJ. WALL ON THE HINGE SIDE OF THE DOOR UNLESS OTHERWISE NOTED. THE CONTRACTOR SHALL CONTACT THE ARCHITECT IF ANY CONFLICTS OCCUR.

18. ALUM. THRESHOLDS TO BE SET IN FULL BED OF SEALANT AT ALL EXT. DOORS.19. COORDINATE ROOF DRAIN LEADER LOCATIONS WITH FLOOR PLAN PRIOR TO SLAB

CONSTRUCTION.20. PROVIDE VINYL REDUCER AT ALL DISSIMILAR FLOOR MATERIALS UNLESS OTHERWISE

NOTED.21. UNLESS OTHERWISE NOTED, ALL ELECTRICAL AND MECHANICAL OPERABLE DEVICES

SHALL BE MOUNTED WITH THE HIGHEST OPERABLE CONTROL AT MAX. OF 42" AFF.22. SHOULD ANY EXISTING CONDITIONS SUCH AS DETERIORATION OR NON-COMPLYING

CONSTRUCTION BE DISCOVERED WHICH IS NOT COVERED BY THE DSA APPROVED DOCUMENTS WHEREIN THE FINISHED WORK WILL NOT COMPLY WITH TITLE 24, CALIFORNIA CODE OF REGULATIONS, A CONSTRUCTION CHANGE DOCUMENT, OR A SEPARATE SET OF PLANS AND SPECIFICATIONS, DETAILING AND SPECIFYING THE REQUIRED REPAIR WORK SHALL BE SUBMITTED TO AND APPROVED BY DSA BEFORE PROCEEDING WITH THE REPAIR WORK, PER CAC, 2019, 4-317(c)

E MARIPOSA AVE

E PALM AVE

E MAPLE AVE

E WALNUT AVE

IMPERIAL HWY

PA

CIF

IC C

OA

ST

HW

YCA

LIF

OR

NIA

ST

CE

NT

ER

ST

E PINE AVE

E GRAND AVE

OR

EG

ON

ST

E PALM AVE

IMPERIAL AVE

PROJECT LOCATION

ARCHITECTURALA1.00 RAMP, STAIR & RAILING DETAILS

A4.02 LUNCH SHELTER ENLARGED SITE PLANS

A4.03 SHADE STRUCTURE ENLARGED SITE PLANS

A4.04 RAMP & STAIR ENLARGED SITE PLAN

GENERALG0.00 COVER SHEET

G0.01 SHEET INDEX, DRAWING CONVENTIONS, AND LOCATION MAP

G0.02 ACCESSIBILITY SITE PLAN

G0.03 FIRE ACCESS SITE PLAN

G0.04 ARCHITECTURAL SPECIFICATIONS

G0.05 ARCHITECTURAL SPECIFICATIONS & GEO-TECH LETTER

DRAWING CONVENTIONS DRAWING INDEXSTATEMENT OF GENERAL CONFORMANCE

SHEET NUMBERING

SCOPE OF WORKDSA NOTES

PROJECT DATA

DEFERRED APPROVAL ITEMS

VICINITY MAP

GENERAL NOTES

1. ALL WORK SHALL CONFORM TO 2019 EDITION TITLE 24, CALIFORNIA CODE OF REGULATIONS (CCR)

2. CHANGES TO THE APPROVED DRAWINGS AND SPECIFICATIONS SHALL BE MADE BY A CONSTRUCTION CHANGE DOCUMENT (CCD) APPROVED BY THE DIVISION OF THE STATE ARCHITECT, AS REQUIRED BY SECTION 4-338, PART I, TITLE 24, CCR

3. A PROJECT INSPECTOR EMPLOYED BY THE DISTRICT (OWNER) AND APPROVED BY THE DIVISION OF THE STATE ARCHITECT SHALL PROVIDE CONTINUOUS INSPECTION OF THE WORK. THE DUTIES OF THE INSPECTOR ARE DEFINED IN SECTION 4-32, PART 1, TITLE 24, CCR; CLASS __2__

4. A DSA ACCEPTED TESTING LABORATORY DIRECTLY EMPLOYED BY THE DISTRICT (OWNER) SHALL CONDUCT ALL THE REQUIRED TESTS & INSPECTIONS FOR THE PROJECT.

1. ITEM 1

2. ITEM 2

INSTALLATION OF THE ITEMS ABOVE SHALL NOT BE STARTED UNTIL DETAILED PLANS AND SPECIFICATIONS ARE SUBMITTED AND APPROVED BY THE DIVISION OF THE STATE ARCHITECT (DSA)

ALL CONSTRUCTION AND SERVICES REQUIRED TO PROVIDE...

ADDITION OF TWO (2) SHADE STRUCTURES (PC APPROVED BY DAVE BANG ASSOCIATES) AT TWO (2) LOCATIONS ON THE CAMPUS.

SITE IMPROVEMENTS INCLUDE, BUT ARE NOT LIMITED TO; WALKWAYS AND LANDSCAPING

PROJECT ADDRESS:

700 CENTER ST.EL SEGUNDO, CA 90245

SEISMIC CRITERIA:SDS = 1.235

WIND LOAD:BASIC WIND SPEED = 85 MPHMAXIMUM WIND SPEED = 110 MAX

S.D. SOAP DISPENSER

SCHED SCHEDULE

SCPL SOLID CORE PLASTICLAMINATE

SECT SECTION

SHT SHEET

SIM SIMILAR

SPC SPECIAL COATING SYSTEM

SPEC SPECIFICATION (S)

SQ. SQUARE

SS. SOUND STRIP

SS. STL. STAINLESS STEEL

STD STANDARD

STL STEEL

STRUC STRUCTURAL

SUSP SUSPENDED

SVDF SHEET VINYL DANCEFLOORING

SYS SYSTEM

T.B. TACK BOARD

T.D.R. TOWEL DISPENSER ANDRECEPTACL

T.O. TOP OF

T.O.B. TOP OF (WOOD) BLOCKING

T.O.M. TOP OF MASONRY

T.O.S. TOP OF STEEL

T.T.D. TOILET TISSUE DISPENSER

TCNA TILE COUNCIL OF NORTHAMERICA

TEL TELEPHONE

TERR TERRAZZO

THK THICK (NESS)

TYP TYPICAL

U.N.O. UNLESS NOTED OTHERWISE

UR. URINAL

V VENT

V.C.T. VINYL COMPOSITION TILE

V.I.F. VERIFY IN FIELD

VENT. VENTILATING, VENTILATED

VER. VERIFY

VERT. VERTICAL

VGB (PREFINISHED) VINYL CLADGYPSUM BOARD

VWC VINYL WALL COVERING

W WASHING MACHINE

W.P. WATER PROOFING

W.S. WEATHERSTRIP

W.W. WATER WELL

W.W.F WELDED WIRE FABRIC

W/ WITH

WC WATER CLOSET

WD WOOD

WDW WINDOW

WT WEIGHT

MEP MECHANICAL, ELECTRICALAND PLUMBING

MEZZ. MEZZANINE

MFR. MANUFACTURE (R)

MH. MANHOLE

MIN. MINIMUM

MISC. MISCELLANEOUS

MOD MODULAR

MTL METAL

MTP. METAL TOILET PARTITION

N.D. NAPKIN DISPOSAL

N.I.C. NOT IN CONTRACT

N.R. NOT RATED

N.T.S. NOT TO SCALE

N.V. NAPKIN VENDOR

NO. NUMBER

O.C. ON CENTER (S)

O.C.E.W. ON CENTER EACH WAY

O.D. OUTSIDE DIAMETER

O.F.C.I. OWNER FURNISHED,CONTRACTOR INSTALLED

O.H. OPPOSITE HAND

OPNG. OPENING

OPP. OPPOSITE

P. LAM. PLASTIC LAMINATE

P.C. PRECAST

P.H. PAPER HOLDER

P.L. PROPERTY LINE

P.P. POWER POLE

P.W.B. PREFINISHED WALL BOARD

PL. PLATE

PLUMB. PLUMBING

PLYWD. PLYWOOD

POL. POLISHED

PR. PAIR

PREFIN. PRE-FINISHED

PT. POINT

PTD. PAINTED

Q.T. QUARRY TILE

R / RAD RADIUS

RD ROOF DRAIN

RE. , REF. REFER TO / REFERENCE /SEE

RECP. RECEPTACLE

REINF. REINFORCE (D), (ING)

REQ'D. REQUIRED

RES. RESILIENT

REV. REVISION (S), REVISED

RF RECREATIONAL RESILIENTFLOORING

RPG. RELOCATABLE PAINTEDGYPSUM BOARD

RSS. ROD STOCK AND SEALANT

S.C. SEALED CONCRETE

EQUIP EQUIPMENT

EXIST EXISTING

EXP EXPANSION

EXT EXTERIOR

F.E. FIRE EXTINGUISHER

F.E.C. FIRE EXTINGUISHERCABINET

F.H.C. FIRE HOSE CABINET

FB. FACE BRICK

FD. FLOOR DRAIN

FIN. FINISH (ED)

FIXT. FIXTURE

FLR. FLOOR (ING)

FLSHG. FLASHING

FLUOR FLUORESCENT

G.B. GRAB BAR

G.I. GALVANIZED IRON

GA. GAUGE

GALV. GALVANIZED

GCMU GLAZED CONCRETEMASONRY UNIT

GEN. GENERAL

GEN. GENERAL

GL. GLASS / GLAZING

GL. GLASS

GR. GRADE

GTP. GLAZED TILE PAVER

GYP. GYPSUM DRYWALL

H.W. HOT WATER

HM HOLLOW METAL FRAME

HORIZ. HORIZONTAL

HT. HEIGHT

I.D. INSIDE DIAMETER

I.P.S. IRON PIPE SIZE

INSUL INSULATE (ED), (ION)

INT. INTERIOR

ISA INTERNATIONL SYMBOL OFACCESSIBILITY

JT. JOINT

L.P. LIGHT POLE

LAM. LAMINATE (D)

LAV. LAVATORY

LT. LIGHT

LT. WT. LIGHTWEIGHT

M.O. MASONRY OPENING

MAS. MASONRY

MATL. MATERIAL (S)

MAX. MAXIMUM

MB. MARKER BOARD

MECH. MECHANICAL

MEM MEMBRANE

MEM. WP. MEMBRANEWATERPROOFING

A.D. AREA DRAIN

A.D.A. AMERICANS WITHDISABILITIES ACT

A.F.F. ABOVE FINISH FLOOR

A.F.G. ABOVE FINISH GRADE

A.H.J. ATHORITY HAVINGJURISDICTION

A/C AIR CONDITIONING

ACP. ACOUSTICAL PANEL

ACT. ACOUSTICAL TILE

ADJ. ABADJUSTABLE

ALT. ALTERNATE

ALUM. ALUMINUM

ASPH. ASPHALT

ے ANGLE

B.U.R. BUILT-UP ROOF

BD. BOARD

BLDG. BUILDING

BLK. BLOCK

BM. BEAM

C CHANNEL

C.J. CONTROL JOINT

C.M.U. CONCRETE MASONRY UNIT

C.W. COLD WATER

CAB,CABT

CABINET

CFMF COLD FORMED METALFRAMING

CL CENTERLINE

CLG. CEILING

CLR CLEAR

COL. COLUMN

COMP. COMPRESSIBLE

CONC. CONCRETE

COND. CONDITION

CORR. CORRIDOR

CPT. CARPET (ED)

CT. CERAMIC TILE

CTG CLEAR TEMPERED GLAZING

CTSK. COUNTER SINK

D DRYER

D.F. DRINKING FOUNTAIN

D.P. DAMPPROOFING

D.S. DOWN SPOUT

DIA. DIAMETER

DIM. DIMENSION

DTL. DETAIL

DWG. DRAWING

E.J. EXPANSION JOINT

E.Q. EQUAL

EA. EACH

EDF ELECTRIC DRINKINGFOUNTAIN

EL. ELEVATION (HEIGHT)

ELECT. ELECTRICAL

ELEV ELEVATION (DRAWING)

ABBREVIATIONS

CODES & STANDARDS

NOTE:FIRE SAFETY DURING DEMOLITION AND/OR CONSTRUCTION SHALL COMPLY WITH 2019 CFC CHAPTER 33

TOTAL SHEETS: 20

N

.

te

cEkra

M

A a r

t

3 -1 20 2 1

5.NER

-

A

CT

ET

HCREDSNE

CIL

I

C L F

IN

RFO

E

AT

S

T

A

A

OI

No. C-28195

Engineer

Architect

ARCHITECT PBK Architects, Inc.

KEY PLANTRUE

NORTH

DATE

CLIENT

REVISIONS

PBK.comONTARIO

3110 East Guasti Road, Suite 300Ontario, CA 91761

909-937-9200 P909-937-6161 F

PLAN NORTH

DSA A#03-120646

A

B

C

D

E

F

G

H

J

K

4/9

/2020

10:1

2:0

0 A

M

C:\U

se

rs\m

ca

rrill

o\ D

ocu

men

ts\2

007_C

ente

r S

tree

t E

S_S

had

e S

tru

ct u

re A

ddn_

A19_C

EN

TR

AL

_m

arc

os.c

arr

illo.r

vt

CE

NT

ER

ST

RE

ET

EL

EM

EN

TA

RY

SC

HO

OL

SH

AD

E S

TR

UC

TU

RE

AD

DIT

ION

S

DS

A S

UB

MIT

TA

L S

ET

SHEET INDEX,DRAWING

CONVENTIONS,AND LOCATION

MAP

03/10/2020

Project Number

EL SEGUNDO UNIFIED SCHOOLDISTRICT

DSA SUBMITTAL SET

700

CE

NT

ER

ST

.E

L S

EG

UN

DO

, C

A 9

024

5

G0.01

BUILDING

GROUP

OCCUPANCY

CLASSNO. OF

STORIES

TYPE OF

CONST.

ALLOWANCE

SQ. FOOTAGE

ACTUAL SQ.

FOOTAGE

CODE ANALYSIS

SHADESTRUCTURE

A

A-3

1 V-B 6,000 840

SHADESTRUCTURE

B

A-3

1 V-B 6,000 2,400

*CIVILC001 DEMOLITION PLAN

C002 GRADING PLAN

DEMOLITIOND4.00 ENLARGED DEMOLITION SITE PLAN

*LUNCH SHELTER DSA P.C. 02-115731G.1 AMERICANA SHELTERS DESIGN NOTES, EXAMPLE FORM DSA 103

MT20.0 20' MERAMEC SHELTER DESIGN NOTES, EXAMPLE FORM DSA 103

MT20.1 20' MERAMEC SHELTER PLANS, SECTIONS AND DETAILS

*FABRIC CANOPIES DSA P.C. 04-1179701 COVER SHEET & NOTES

2 CANOPY PLANS & TABLES

3 TYPICAL CANOPY BRACING DETAILS

4 TYPICAL CANOPY DETAILS & T&I GUIDELINE

OCCUPANCY

LOAD

56

160

No. Description Date

⬛

⬛

⬛

⬛

⬛

⬛

⬛

⬛

⬛⬛

⬛

⬛

⬛

⬛

⬛

⬛⬛

⬛

⬛

⬛

⬛

⬛

⬛

⬛

⬛

⬛

⬛⬛

⬛⬛

⬛

⬛

⬛

⬛

⬛

⬛

⬛⬛

⬛

⬛

⬛

⬛

⬛

⬛

X XX X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X

X

X

XX

XX

XXX XXXXXXXXXXXXXXXXXXX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

X

XX XXXXXXXXXXXXXXXXXXX

XX XXXXXXXXXXXX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

X

X XX X X X X X X X

X XX X X

XX

XX

X

X

X

XX XXXXXXXXXX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

X

XX XXXXXXXXXXXXXXXXXXX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

X

X XX X X X X X X X X X X X X X

XX

XX

X

XX XXXXXXXXXXXX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

X

X

X

X

XX XXXXXXXXXXXXXXXXXXXXXXXXXXX

X XX X X X X X X XXX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

X

X

X

XX

XX

X

X XX X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X

XX

XX

X X

X XX X X X X

XX

X

XX X

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

X

XX

XX XXXXXXXXXXXX

X XX X X X X X X X X X X X X X X X X X X

X X

XX XXXXXXX XXXXX

XX

X X X X

X X X X

XX

XX

XX

X

XX

XX

X

X

XX

XX

X

X

X

X

XX

X

X X

XX

X

X

XX

XX

XX

X

X

X

XX

X X X X X X

XXX

XXX

XX

X

XX

X

XXX

XX

X

XX

X

XXX

XX

XX

X

X

XX

XX

X

X

X

XX

XX

X

XX

X

X

X

X

CE

NT

ER

ST

RE

ET

BUILDING A

(A# 03-103586)

MARIPOSA AVE.

CA

LIF

OR

NIA

ST

.

E. PALM AVE.

BUILDING E

BUILDING D

BUILDING C

BUILDING B

(A# 03-103586)

BUILDING K

(A# 03-103586)

BUILDING J

(A# 03-103586)

BUILDING H

(A# 03-103586)

BUILDING G

(A# 03-103586)

BUILDING F

PORTABLE

PO

RT

AB

LE

(A# 0

3-1

03586)

(A# 03-105244)

B

G

GBS

PORTABLE

PORTABLE

PORTABLE

PORTABLE

PARKING LOT #1

PARKING LOT #2

BASEBALL FIELD

BASEBALL FIELD

ASPHALT

OUTSIDE COURT

OUTSIDE COURT

BLACKTOP

CE

NT

ER

ST

RE

ET

A4.02

6

A4.04

6

(A# 03-103586)

(A# 03-103586)

(A# 03-103586)

(A# 03-103586)

(A# 03-109114)

PORTABLE

(A# 03-109114)

PORTABLE

(A# 03-109114)

PORTABLE

(A# 03-109114)

PORTABLE

(A# 03-103586)

A4.03

10

(A# 03-103586)

(A# 03-103586)

(A# 03-117904)

02.2002.20

02.19

1

1819

34

35

39

PLAYAREA

02.24

02.24

02.28

02.23

02.27

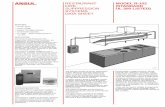

SHADE STRUCTURE A

M / 42' x 20'P.C. 02-115731

SHADE

STRUCTURE BSC / 30' x 40' (2)P.C. 04-117970

60'-0"

40'

-0"

DSA CERTIFICATION LIST

1. RELOCATABLE BUILDING PROJECT: A# 03-105244 - CLOSED WITH DSA CERTIFICATION ON 5/7/2008

2. CAMPUS ALTERATION: A# 03-103586 - CLOSED WITH DSA CERTIFICATION ON 1/23/2009

3. RELOCATION OF PORTABLES: A# 03-105339 - CLOSED WITH DSA CERTIFICATION ON 1/7/2008

4. CAMPUS ALTERATION: A# 03-109114 - CLOSED WITH DSA CERTIFICATION ON 8/4/2009

5. RELOCATABLE BUILDING PROJECT: A# 03-117904 - CLOSED WITH DSA CERTIFICATION ON 6/5/2018

PATH OF TRAVEL

DESIGN PROFESSIONAL IN GENERAL RESPONSIBLE CHARGE STATEMENT:THE POT INDENTIFIED IN THESE CONSTRUCTION DOCUMENTS IS COMPLIANT WITH THE CURRENT APPLICABLE CALIFORNIA BUILDING CODE ACCESSIBILITY PROVISIONS FOR PATH OF TRAVEL

REQUIREMENTS FOR ALTERATIONS, ADDITIONS AND STRUCTURAL REPAIRS. AS PART OF THE DESIGN OF THIS PROJECT, THE POT WAS EXAMINED AND ANY ELEMENTS, COMPONENTS OR PORTIONS OF THE POT THAT WERE DETERMINED TO BE NONCOMPLIANT 1) HAVE BEEN IDENTIFIED AND 2) THE CORRECTIVE WORK NECESSARY TO BRING THEM INTO COMPLIANCE HAS BEEN INCLUDED WITHIN THE SCOPE OF THIS PROJECT'S WORK THROUGH DETAILS, DRAWINGS AND SPECIFICATIONS INCORPORATED INTO THESE CONSTRUCTION DOCUMENTS. ANY NONCOMPLIANT ELEMENTS, COMPONENTS OR PORTIONS OF THE POT THAT WILL NOT BE CORRECTED BY THIS PROJECT BASED ON VALUATION THRESHHOLD LIMITATIONS OR A FINDING OF UNREASONABLE HARDSHIP ARE SO INDICATED IN THESE CONSTRUCTION DOCUMENTS. DURING CONSTRUCTION, IF POT ITEMS WITHIN THE SCOPE OF THE PROJECT REPRESENTED AS CODE COMPLIANT ARE FOUND TO BE NONCONFORMING BEYOND REASONABLE CONSTRUCTION TOLERANCES, THEY SHALL BE BROUGHT INTO COMPLIANCE WITH THE CBC AS A PART OF THIS PROJECT BY MEANS OF A CONSTRUCTION CHANGE DOCUMENT.

ACCESSIBILITY LEGEND

EXISTING BUILDINGS NOT IN SCOPE

SHADE STRUCTURE TO BE PROVIDED AS PART OF THIS CONTRACT, REFERENCE MANUFACTURER DRAWINGSSST / L' x W'

EXISTING ACCESSIBLE TOILET ROOMS PER A# 03-103586 & A# 03-117904GN = GENDER NEUTRALS = STAFFB = BOYSG = GIRLS

PROPERTY LINE

(E) PATH OF TRAVEL PER A#03-104857 & A#03-117904

(N) PATH OF TRAVEL

WIDTH

LENGTH

SHADE STRUCTURE TYPE:M = MERAMEC (METAL) - P.C. 02-115731SC = SHADE CANOPY (FABRIC) - P.C. 04-117970

PARKING CALCULATION(E) PARKING LOT 1:

STANDARD STALLS ......................................... 32VAN ACCESSIBLE STALLS .............................. 1STD ACCESSIBLE STALLS .............................. 1

TOTAL P-LOT 1 STALLS .................................. 34

(E) PARKING LOT 2:STANDARD STALLS ......................................... 5

TOTAL P-LOT 2 STALLS .................................. 5

_____________________________________________________________________

TOTAL STALLS ON SITE ..................................................... 39

N

.

te

cEkra

M

A a r

t

3 -1 20 2 1

5.NER

-

A

CT

ET

HCREDSNE

CIL

I

C L F

IN

RFO

E

AT

S

T

A

A

OI

No. C-28195

Engineer

Architect

ARCHITECT PBK Architects, Inc.

KEY PLANTRUE

NORTH

DATE

CLIENT

REVISIONS

PBK.comONTARIO

3110 East Guasti Road, Suite 300Ontario, CA 91761

909-937-9200 P909-937-6161 F

PLAN NORTH

DSA A#03-120646

A

B

C

D

E

F

G

H

J

K

4/9

/2020

10:1

2:0

3 A

M

C:\U

se

rs\m

ca

rrill

o\ D

ocu

men

ts\2

007_C

ente

r S

tree

t E

S_S

had

e S

tru

ct u

re A

ddn_

A19_C

EN

TR

AL

_m

arc

os.c

arr

illo.r

vt

CE

NT

ER

ST

RE

ET

EL

EM

EN

TA

RY

SC

HO

OL

SH

AD

E S

TR

UC

TU

RE

AD

DIT

ION

S

DS

A S

UB

MIT

TA

L S

ET

ACCESSIBILITYSITE PLAN

03/10/2020

Project Number

EL SEGUNDO UNIFIED SCHOOLDISTRICT

DSA SUBMITTAL SET

700

CE

NT

ER

ST

.E

L S

EG

UN

DO

, C

A 9

024

5

G0.021/32" = 1'-0"6 ARCHITECTURAL SITE PLAN

N

ACCESSIBILITY KEYED NOTES# Description

02.19 (E) ACCESSIBLE HI-LO DRINKING FOUNTAIN PER A# 03-103586

02.20 (E) ACCESSIBLE PARKING PER A# 03-117904

02.23 (E) TOW AWAY SIGN PER A# 03-117904

02.24 (E) ACCESSIBLE PARKING SIGN PER A# 03-117904

02.27 (E) ACCESSIBLE CONNECTION TO PUBLIC RIGHT OF WAY

02.28 (E) ACCESSIBLE PATH OF TRAVEL SIGN PER A# 03-117904

No. Description Date

⬛

⬛

⬛

⬛

⬛

⬛

⬛

⬛

⬛⬛

⬛

⬛

⬛

⬛

⬛

⬛⬛

⬛

⬛

⬛

⬛

⬛

⬛

⬛

⬛

⬛

⬛⬛

⬛⬛

⬛

⬛

⬛

⬛

⬛

⬛

⬛⬛

⬛

⬛

⬛

⬛

⬛

⬛

X XX X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X

X

X

XX

XX

XXX XXXXXXXXXXXXXXXXXXX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

X

XX XXXXXXXXXXXXXXXXXXX

XX XXXXXXXXXXXX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

X

X XX X X X X X X X

X XX X X

XX

XX

X

X

X

XX XXXXXXXXXX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

X

XX XXXXXXXXXXXXXXXXXXX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

X

X XX X X X X X X X X X X X X X

XX

XX

X

XX XXXXXXXXXXXX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

X

X

X

X

XX XXXXXXXXXXXXXXXXXXXXXXXXXXX

X XX X X X X X X XXX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

X

X

X

XX

XX

X

X XX X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X

XX

XX

X X

X XX X X X X

XX

X

XX X

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

XX

X

XX

XX XXXXXXXXXXXX

X XX X X X X X X X X X X X X X X X X X X

X X

XX XXXXXXX XXXXX

XX

X X X X

X X X X

XX

XX

XX

X

XX

XX

X

X

XX

XX

X

X

X

X

XX

X

X X

XX

X

X

XX

XX

XX

X

X

X

XX

X X X X X X

XXX

XXX

XX

X

XX

X

XXX

XX

X

XX

X

XXX

XX

XX

XX

X

X

X

X

FIRE ACCESS LEGEND

(E) BUILDING NOT IN SCOPE

PROPERTY LINE

(E) FIRE ACCESS LANE, 20' MIN CLEAR

PROPOSED SHADE STRUCTURES TO BE PROVIDED AS PART OF THIS CONTRACT

CE

NT

ER

ST

RE

ET

BUILDING A

(A# 103586)

MARIPOSA AVE.

BUILDING E

BUILDING D

BUILDING C

BUILDING B

(A# 103586)

BUILDING K

(A# 103586)

BUILDING J

(A# 103586)

BUILDING H

(A# 103586)

BUILDING G

(A# 103586)

BUILDING F

PORTABLE

(A# 103586)

(A# 105244)

PORTABLE

PORTABLE

PORTABLE

PORTABLE

PORTABLE

PARKING LOT #1

PARKING LOT #2

BASEBALL FIELD

BASEBALL FIELD

ASPHALT

OUTSIDE COURT

OUTSIDE COURT

BLACKTOP

CE

NT

ER

ST

RE

ET

(A# 103586)

(A# 103586)

(A# 103586)

(A# 103586)

(A# 105244)

PORTABLE

(A# 105244)

PORTABLE

(A# 105244)

PORTABLE

(A# 105244)

PORTABLE

(A# 103586)

(A# 103586)

(A# 103586)

(A# 117904)

R 2

50' -

0"

R 150' - 0"

R 250' -

0"

R 1

50' -

0"

(E) FIRE ACCESS LANE

(E) FIRE ACCESS LANE

(E)

FIR

E A

CC

ES

S L

AN

E

20' -

0"

20' - 0"

20

' - 0

"

20

' - 0

"

R 2

5' - 0

"

R 3

0' - 0"

R 25' - 0"

R 25' - 0"

02.05

02.06

02.06

02.06

02.06

02.07

R 36' - 0"

PLAYAREA

SHADE STRUCTURE A

M / 42' x 20'P.C. 02-115731

SHADE

STRUCTURE BSC / 30' x 40' (2)P.C. 04-117970

SAFE DISPERSAL AREAOCCUPANT LOAD (840/15 = 56)REQUIRED AREA (56x5 = 280SF)PROVIDED AREA (28'-0"x10'-0" = 280SF)

SAFE DISPERSAL AREAOCCUPANT LOAD (2,400/15 = 160)REQUIRED AREA (160x5 = 800SF)PROVIDED AREA (30'-0"x30'-0" = 900SF)

11'-6

"11

'-6"

02.32

02.13

02.32

IMAGINARY

PROPERTY LINE

17'-8"

17'-8"

IMA

GIN

AR

Y

PR

OP

ER

TY

LIN

E

N

.

te

cEkra

M

A a r

t

3 -1 20 2 1

5.NER

-

A

CT

ET

HCREDSNE

CIL

I

C L F

IN

RFO

E

AT

S

T

A

A

OI

No. C-28195

Engineer

Architect

ARCHITECT PBK Architects, Inc.

KEY PLANTRUE

NORTH

DATE

CLIENT

REVISIONS

PBK.comONTARIO

3110 East Guasti Road, Suite 300Ontario, CA 91761

909-937-9200 P909-937-6161 F

PLAN NORTH

DSA A#03-120646

A

B

C

D

E

F

G

H

J

K

4/9

/2020

10:1

2:0

6 A

M

C:\U

se

rs\m

ca

rrill

o\ D

ocu

men

ts\2

007_C

ente

r S

tree

t E

S_S

had

e S

tru

ct u

re A

ddn_

A19_C

EN

TR

AL

_m

arc

os.c

arr

illo.r

vt

CE

NT

ER

ST

RE

ET

EL

EM

EN

TA

RY

SC

HO

OL

SH

AD

E S

TR

UC

TU

RE

AD

DIT

ION

S

DS

A S

UB

MIT

TA

L S

ET

FIRE ACCESSSITE PLAN

03/10/2020

Project Number

EL SEGUNDO UNIFIED SCHOOLDISTRICT

DSA SUBMITTAL SET

700

CE

NT

ER

ST

.E

L S

EG

UN

DO

, C

A 9

024

5

G0.03

FIRE ACCESS KEYED NOTES# Description

02.05 (E) 20' FIRE ACCESS GATE EQUIPPED WITH KNOX BOX

02.06 (E) FIRE HYDRANT

02.07 (E) 12' WIDE GATE

02.13 EDGE OF BUILDING K OVERHANG

02.32 (E) FIRE STROBE

1/32" = 1'-0"6 FIRE ACCESS SITE PLAN

EL SEGUNDO UNIFIED SCHOOL DISTRICT

CENTER STREET ES - SHADE STRUCTURE

700 CENTER ST, EL SEGUNDO CA 90245

No. Description Date

N

.

te

cEkra

M

A a r

t

3 -1 20 2 1

5.NER

-

A

CT

ET

HCREDSNE

CIL

I

C L F

IN

RFO

E

AT

S

T

A

A

OI

No. C-28195

Engineer

Architect

ARCHITECT PBK Architects, Inc.

KEY PLANTRUE

NORTH

DATE

CLIENT

REVISIONS

PBK.comONTARIO

3110 East Guasti Road, Suite 300Ontario, CA 91761

909-937-9200 P909-937-6161 F

PLAN NORTH

DSA A#03-120646

A

B

C

D

E

F

G

H

J

K

4/9

/2020

10:1

2:0

8 A

M

C:\U

se

rs\m

ca

rrill

o\ D

ocu

men

ts\2

007_C

ente

r S

tree

t E

S_S

had

e S

tru

ct u

re A

ddn_

A19_C

EN

TR

AL

_m

arc

os.c

arr

illo.r

vt

CE

NT

ER

ST

RE

ET

EL

EM

EN

TA

RY

SC

HO

OL

SH

AD

E S

TR

UC

TU

RE

AD

DIT

ION

S

DS

A S

UB

MIT

TA

L S

ET

ARCHITECTURALSPECIFICATIONS

03/10/2020

Project Number

EL SEGUNDO UNIFIED SCHOOLDISTRICT

DSA SUBMITTAL SET

700

CE

NT

ER

ST

.E

L S

EG

UN

DO

, C

A 9

024

5

G0.04

SECTION 03 11 00 - CONCRETE FORMING

SECTION 03 11 00 - CONCRETE FORMING

PART 1 - GENERAL

1.1 RELATED DOCUMENTSA. Drawings and general provisions of the Contract, including General and Supplementary Conditions and other

Division 01 Specification Sections, apply to this Section.

1.2 SECTION INCLUDESA. Formwork for cast-in place concrete, with shoring, bracing and anchorage.B. Openings for other work.C. Form accessories.D. Form stripping.

1.3 REFERENCE STANDARDSA. CBC 2016 California Building Code (CCR Title 24, Part 2, as adopted and amended by DSA).B. ACI 117 - Standard Specifications for Tolerances for Concrete Construction and Materials; 2010.C. ACI 301 - Specifications for Structural Concrete for Buildings; American Concrete Institute International; 2010.D. ACI 318 - Building Code Requirements for Structural Concrete and Commentary; American Concrete Institute

International; 2010.E. ACI 347 - Guide to Formwork for Concrete; American Concrete Institute International; 2010.F. ASME A17.1 - Safety Code for Elevators and Escalators; The American Society of Mechanical Engineers;

2010.G. PS 1 - Structural Plywood; 2010.

1.4 SUBMITTALSA. See Section 01 33 00 – Submittal Procedures, for submittal procedures.B. Product Data: Provide data on void form materials and installation requirements.C. Shop Drawings: Indicate pertinent dimensions, materials, bracing, and arrangement of joints and ties.

1.5 QUALITY ASSURANCEA. Maintain one copy of each installation standard on site throughout the duration of concrete work.

1.6 DELIVERY, STORAGE, AND HANDLINGA. Deliver void forms and installation instructions in manufacturer's packaging.B. Store void forms off ground in ventilated and protected manner to prevent deterioration from moisture.

PART 2 - PRODUCTS

2.1 FORMWORK - GENERALA. Provide concrete forms, accessories, shoring, and bracing as required to accomplish castin-place concrete

work.B. Design and construct to provide resultant concrete that conforms to design with respect to shape, lines, and

dimensions.C. Comply with applicable State and local codes with respect to design, fabrication, erection, and removal of

formwork.D. Comply with relevant portions of ACI 347, ACI 301, and ACI 318.

2.2 WOOD FORM MATERIALSA. Form Materials: At the discretion of the Contractor, with Architect's approval.

2.3 PREFABRICATED FORMSA. Tubular Column Type: Round, spirally wound laminated fiber material, surface treated with release agent, non-

reusable, of sizes indicated.

2.4 FORMWORK ACCESSORIESA. Form Ties: Removable type, galvanized metal, fixed length, cone type, with waterproofing washer, 1/2 inch

back break dimension, free of defects that could leave holes larger than 1 inch in concrete surface.B. Form Release Agent: Colorless mineral oil that will not stain concrete.C. Corners: Filleted, rigid plastic type; 3/4 x 3/4 inch size; maximum possible lengths.D. Dovetail Anchor Slot: Galvanized steel, 22 gage thick, foam filled, release tape sealed slots, anchors for

securing to concrete formwork.E. Flashing Reglets: Galvanized steel, 22 gage thick, longest possible lengths, with alignment splines for joints,

foam filled, release tape sealed slots, anchors for securing to concrete formwork.F. Nails, Spikes, Lag Bolts, Through Bolts, Anchorages: Sized as required, of sufficient strength and character to

maintain formwork in place while placing concrete.G. Waterstops: Rubber, minimum 1,750 psi tensile strength, minimum 50 degrees F to plus 175 degrees F

working temperature range, 3 inch wide, maximum possible lengths, ribbed profile, preformed corner sections, heat welded jointing.

PART 3 - EXECUTION

3.1 EXAMINATIONA. Verify lines, levels and centers before proceeding with formwork. Ensure that dimensions agree with drawings.

3.2 EARTH FORMSA. Hand trim sides and bottom of earth forms. Remove loose soil prior to placing concrete.

3.3 ERECTION - FORMWORKA. Erect formwork, shoring and bracing to achieve design requirements, in accordance with requirements of ACI

301.B. Provide bracing to ensure stability of formwork. Shore or strengthen formwork subject to overstressing by

construction loads.C. Arrange and assemble formwork to permit dismantling and stripping. Do not damage concrete during stripping.

Permit removal of remaining principal shores.D. Align joints and make watertight. Keep form joints to a minimum.E. Obtain approval before framing openings in structural members that are not indicated on drawings.F. Provide fillet strips on external corners of beams, joists, and columns.G. Install void forms in accordance with manufacturer's recommendations. Protect forms from moisture or

crushing.H. Coordinate this section with other sections of work that require attachment of components to formwork.I. If formwork is placed after reinforcement, resulting in insufficient concrete cover over reinforcement, request

instructions from Architect before proceeding.

3.4 APPLICATION - FORM RELEASE AGENTA. Apply form release agent on formwork in accordance with manufacturer's recommendations.B. Apply prior to placement of reinforcing steel, anchoring devices, and embedded items.C. Do not apply form release agent where concrete surfaces will receive special finishes or applied coverings that

are affected by agent. Soak inside surfaces of untreated forms with clean water. Keep surfaces coated prior to placement of concrete.

3.5 INSERTS, EMBEDDED PARTS, AND OPENINGSA. Provide formed openings where required for items to be embedded in passing through concrete work.B. Locate and set in place items that will be cast directly into concrete.C. Coordinate with work of other sections in forming and placing openings, slots, reglets, recesses, sleeves,

bolts, anchors, other inserts, and components of other work.D. Install accessories in accordance with manufacturer's instructions, so they are straight, level, and plumb.

Ensure items are not disturbed during concrete placement.E. Install waterstops in accordance with manufacturer's instructions, so they are continuous without displacing

reinforcement. Heat seal joints so they are watertight.F. Provide temporary ports or openings in formwork where required to facilitate cleaning and inspection. Locate

openings at bottom of forms to allow flushing water to drain.G. Close temporary openings with tight fitting panels, flush with inside face of forms, and neatly fitted so joints will

not be apparent in exposed concrete surfaces.

3.6 FORM CLEANINGA. Clean forms as erection proceeds, to remove foreign matter within forms.B. Clean formed cavities of debris prior to placing concrete.

1. Flush with water or use compressed air to remove remaining foreign matter. Ensure that water and debris drain to exterior through clean-out ports.

2. During cold weather, remove ice and snow from within forms. Do not use de-icing salts. Do not use water to clean out forms, unless formwork and concrete construction proceed within heated enclosure. Use compressed air or other means to remove foreign matter.

3.7 FORMWORK TOLERANCESA. Construct formwork to maintain tolerances required by ACI 117.B. Construct and align formwork for elevator hoistway in accordance with ASME A17.1.C. Camber slabs and beams 1/4 inch per 10 feet.

3.8 FIELD QUALITY CONTROLA. An independent testing agency will perform field quality control tests.B. Inspect erected formwork, shoring, and bracing to ensure that work is in accordance with formwork design,

and to verify that supports, fastenings, wedges, ties, and items are secure.C. Do not patch formwork.

3.9 FORM REMOVALA. Do not remove forms or bracing until concrete has gained sufficient strength to carry its own weight and

imposed loads.B. Loosen forms carefully. Do not wedge pry bars, hammers, or tools against finish concrete surfaces scheduled

for exposure to view.C. Store removed forms to prevent damage to form materials or to fresh concrete. Discard damaged form.

END OF SECTION 03 11 00

SECTION 03 20 00 - CONCRETE REINFORCEMENT

PART 1 - GENERAL

1.01 RELATED DOCUMENTSA. Drawings and general provisions of the Contract, including General and Supplementary Conditions and other

Division 01 Specification Sections, apply to this Section.

1.02 SUMMARYA. This Section includes the following:

1. Provide all material, labor, equipment and services necessary to completely install all reinforcing materials, accessories and other related items to complete the Project as indicated by the Contract Documents.

1.03 REFERENCES:A. ACI American Concrete InstituteB. ASTM American Society for Testing and MaterialsC. AWS American Welding SocietyD. CRSI Concrete Reinforcing Steel Institute

1.04 SUBMITTALS:A. Submit in accordance with Section 01 33 00 Submittal Procedures, and the Contract General Conditions.

1. Mill test certificates identifying chemical and physical analysis of each load of reinforcing steel delivered. If mill test reports are not available and the quantity of steel for a structure exceeds 5 tons, provide a laboratory test to prove yield strength and bending.

2. Manufacturer’s specification and installation instructions for splice devices.a. Bar supports

3. Drawings and placing diagrams for each grade slab including dowels and corner bars.a. On the placing diagrams, show all openings for pipelines and architectural features. Include additional

reinforcing at openings and corner bar arrangements at intersecting beams, walls, and footings.b. Coordinate placing diagrams with the concrete placing schedule.

1.05 PRODUCT DELIVERY:A. Deliver reinforcement to project site in bundles marked with tags indicating bar size and length.B. Store on wooden supports above ground surface.

PART 2 - PRODUCTS

2.01 BARSA. Bars shall be deformed billet steel conforming to ASTM A 615, Grade 40 for #4 bars and smaller, Grade 60 for

#5 bars and larger. Mixing of steel grades will not be allowed.

2.02 BAR SUPPORTSA. Bar support shall be concrete or metal chairs, spacers or hangers. Reinforcing bars shall not be supported by

forms.

2.03 TIE WIREA. Tie wire shall be annealed steel wire of not less than 16-gauge.

PART 3 - EXECUTION

3.01 PLACEMENTA. Position reinforcement in accordance with the drawings, secure with wire ties or suitable clips at all

intersections, and support by an adequate number of concrete or metal chairs, spacers, or metal hangers such that reinforcing bars do not sag more than one quarter of an inch (1/4”) between supports. Do not place reinforcement or supports in contact with the forms. Bend tie wires away from the forms in order to provide the specified concrete coverage. To secure reinforcement in position, the Contractor may elect to locate bars additional to those shown on the drawings, but at no additional cost to the Owner.

B. Set reinforcing dowels and anchor bolts in place prior to placing concrete. Do not press them into the concrete after the concrete has been placed.

3.02 SPLICESA. Splice bars only at locations shown on the drawings.

3.03 CLEANINGA. Remove dirt, form oil, excessive rust, cement coating from previous pours, and foreign matter that will reduce

bond with concrete.

3.04 PROTECTION DURING CONCRETINGA. Keep reinforcing steel in proper position during concrete placement.

END OF SECTION 03 20 00

SECTION 03 30 00 - CAST-IN-PLACE CONCRETE

PART 1 - GENERAL

1.01 RELATED DOCUMENTSA. Drawings and general provisions of the Contract, including General and Division 01 Specification Sections,

apply to this Section.

1.02 SUMMARYA. Section includes cast-in-place concrete, including formwork, reinforcement, concrete materials, mixture

design, placement procedures, and finishes, for the following:1. Footings and foundation walls.2. Interior Slabs-on-grade.3. Exterior slabs-on-grade.4. Concrete filled floor deck.5. Concrete stairways and elevated landings.

B. Special Coordination Requirements: Coordinate with the work of the following sections to identify the finish flooring manufacturer’s concrete slab requirements. Such requirements may be over and above the requirements of the Contract Documents and may require additional materials, means, or methods, which shall be included as part of the Work.

1.03 DEFINITIONSA. Cementitious Materials: Portland cement alone or in combination with one or more of the following: blended

hydraulic cement, fly ash and other pozzolans, ground granulated blastfurnace slag, and silica fume; subject to compliance with requirements.

1.04 ACTION SUBMITTALSA. Product Data: For each type of product indicated.B. Design Mixtures: For each concrete mixture. Submit alternate design mixtures when characteristics of

materials, Project conditions, weather, test results, or other circumstances warrant adjustments.1. Indicate amounts of mixing water to be withheld for later addition at Project site.

C. Steel Reinforcement Shop Drawings: Placing drawings that detail fabrication, bending, and placement. Include bar sizes, lengths, material, grade, bar schedules, stirrup spacing, bent bar diagrams, bar arrangement, splices and laps, mechanical connections, tie spacing, hoop spacing, and supports for concrete reinforcement.

D. Samples: For vapor retarder.E. Certificates: Weighmaster’s Certificates.

1.05 INFORMATIONAL SUBMITTALSA. Material Certificates: For each of the following, signed by manufacturers:

1. Cementitious materials.2. Admixtures.3. Waterstops.4. Curing compounds.5. Floor and slab treatments.6. Bonding agents.7. Adhesives.8. Vapor retarders.9. Semirigid joint filler.10. Joint-filler strips.11. Repair materials.

B. Material Test Reports: For the following, from a qualified testing agency, indicating compliance with requirements:1. Aggregates. Include service record data indicating absence of deleterious expansion of concrete due to

alkali aggregate reactivity.C. Floor surface flatness and levelness measurements indicating compliance with specified tolerances.

1.06 QUALITY ASSURANCEA. Codes and Standards: Comply with provisions of following codes, specifications and standards, except where

more stringent requirements are shown or specified:1. CBC 2019 California Building Code (CCR Title 24, Part 2, as adopted and amended by DSA).

B. Manufacturer Qualifications: A firm experienced in manufacturing ready-mixed concrete products and that complies with ASTM C 94/C 94M requirements for production facilities and equipment.1. Manufacturer certified according to NRMCA's "Certification of Ready Mixed Concrete Production

Facilities."C. Source Quality Control: Furnish Weighmaster’s Certificates for all concrete.D. Welding Qualifications: Qualify procedures and personnel according to AWS D1.4/D 1.4M, "Structural Welding

Code - Reinforcing Steel."E. ACI Publications: Comply with the following unless modified by requirements in the Contract Documents:

1. ACI 117, "Specifications for Tolerances for Concrete Construction and Materials."2. ACI 301, "Specifications for Structural Concrete,"3. ACI 305R, “Hot Weather Concreting”.4. ACI 306R, “Cold Weather Concreting”.5. ACI 308, “Standard Practice for Curing Concrete”.6. ACI 318-14, “Building Code Requirements for Reinforced Concrete”.7. Concrete Testing Service: Engage a qualified independent testing agency approved by DSA to perform

material evaluation tests and to design concrete mixtures.

1.07 DELIVERY, STORAGE, AND HANDLINGA. Steel Reinforcement: Deliver, store, and handle steel reinforcement to prevent bending and damage.

PART 2 - PRODUCTS

2.01 FORM-FACING MATERIALSA. Smooth-Formed Finished Concrete: Form-facing panels that will provide continuous, true, and smooth

concrete surfaces. Furnish in largest practicable sizes to minimize number of joints.1. Plywood, metal, or other approved panel materials.

B. Chamfer Strips: Wood, metal, PVC, or rubber strips, 3/4 by 3/4 inch, minimum.C. Form-Release Agent: Commercially formulated form-release agent that will not bond with, stain, or adversely

affect concrete surfaces and will not impair subsequent treatments of concrete surfaces.1. Formulate form-release agent with rust inhibitor for steel form-facing materials.

D. Form Ties: Factory-fabricated, removable or snap-off metal or glass-fiber-reinforced plastic form ties designed to resist lateral pressure of fresh concrete on forms and to prevent spalling of concrete on removal.1. Furnish ties with integral water-barrier plates to walls indicated to receive dampproofing or waterproofing.

2.02 STEEL REINFORCEMENTA. Reinforcing Bars: ASTM A 615/A 615M, Grade 40 for #4 bars and smaller, Grade 60 for #5 bars and larger,

using deformed bars for #3 and larger.B. Welded Reinforcing Bars: Low-Alloy-Steel Reinforcing Bars, ASTM A 706/A 706M, deformed.C. Do not use reinforcement having any of the following defects:

1. Bar lengths, depths, or bends exceeding the specified fabricating tolerances.2. Bends or kinks not indicated on the Drawings or required for this Work.3. Bars with cross-section reduced due to excessive rust or other causes.

2.03 REINFORCEMENT ACCESSORIESA. Bar Supports: Bolsters, chairs, spacers, and other devices for spacing, supporting, and fastening reinforcing

bars and welded wire reinforcement in place. Manufacture bar supports from steel wire, plastic, or precast concrete according to CRSI's "Manual of Standard Practice," of greater compressive strength than concrete and as follows:1. For concrete surfaces exposed to view where legs of wire bar supports contact forms, use CRSI Class 1

plastic-protected steel wire or CRSI Class 2 stainlesssteel bar supports.

2.04 CONCRETE MATERIALSA. Cementitious Material: Use the following cementitious materials, of the same type, brand, and source,

throughout Project:1. Portland Cement: ASTM C 150, Type I/II. Supplement with the following:

a. Fly Ash: ASTM C 618, Class F.B. Normal-Weight Aggregates: ASTM C 33.

1. Maximum Coarse-Aggregate Size: 3/4 inch nominal maximum aggregate size.2. Fine Aggregate: Free of materials with deleterious reactivity to alkali in cement.

C. Lightweight Aggregate: ASTM C 330, 3/4-inch nominal maximum aggregate size.D. Water: ASTM C 94 and potable.

2.05 ADMIXTURESA. Air-Entraining Admixture: ASTM C 260.B. Chemical Admixtures: Provide admixtures certified by manufacturer to be compatible with other admixtures

and that will not contribute water-soluble chloride ions exceeding those permitted in hardened concrete. Do not use calcium chloride or admixtures containing calcium chloride.1. Water-Reducing Admixture: ASTM C 494/C 494M, Type A.2. Retarding Admixture: ASTM C 494/C 494M, Type B.3. Water-Reducing and Retarding Admixture: ASTM C 494/C 494M, Type D.4. High-Range, Water-Reducing Admixture: ASTM C 494/C 494M, Type F.5. High-Range, Water-Reducing and Retarding Admixture: ASTM C 494/C 494M, Type G.6. Plasticizing and Retarding Admixture: ASTM C 1017/C 1017M, Type II.

2.06 VAPOR RETARDERSA. Sheet Vapor Retarder: ASTM E 1745, Class A. Include manufacturer's recommended adhesive or pressure-

sensitive tape.1. Products: Subject to compliance with requirements, acceptable products:

a. Carlisle Coatings & Waterproofing, Inc.; Blackline 400.b. Fortifiber Building Systems Group; Moistop Ultra 15.c. Grace Construction Products, W. R. Grace & Co.; Florprufe 120.d. Insulation Solutions, Inc.; Viper VaporCheck 16.e. Meadows, W. R., Inc.; Perminator 15 mil.f. Raven Industries Inc.; Vapor Block 15.g. Reef Industries, Inc.; Griffolyn 15 mil Greenh. Stego Industries, LLC; Stego Wrap 15 mil Class A.

B. Granular Fill: Clean mixture of crushed stone or crushed or uncrushed gravel; ASTM D 448, Size 57, with 100 percent passing a 1-1/2-inch sieve and 0 to 5 percent passing a No. 8 sieve.

2.07 CURING MATERIALSA. Absorptive Cover: AASHTO M 182, Class 2, burlap cloth made from jute or kenaf, weighing approximately 9

oz. /sq. yd. when dry.B. Moisture-Retaining Cover: ASTM C 171, polyethylene film or white burlap-polyethylene sheet.C. Water: Potable.D. Clear, Waterborne, Membrane-Forming Curing Compound: ASTM C 309.

1. Shall not discolor concrete or other materials, shall not leave an oily residue upon evaporation of solvent.2. Shall afford moisture loss not greater than 0.055 grams/cm2 at minimum average of 300 square feet.3. Meet State of California Air Regulation Board Solvent Emission Standards.

2.08 RELATED MATERIALSA. Non-shrink Grout:

1. Factory premixed grout; ASTM C1107.2. Compressive strength: 5,000 psi at 28 days.3. Exterior Concrete Walks: Provide a capillary break consisting of 2” of clean dry sand, ASTM C33, evenly

spread on top of the compacted subgrade.

2.09 CONCRETE MIXTURES, GENERALA. Prepare design mixtures for each type and strength of concrete, proportioned on the basis of laboratory trial

mixture or field test data, or both, according to ACI 301.1. Use a qualified independent testing agency for preparing and reporting proposed mixture designs based

on laboratory trial mixtures.2. All concrete mix designs shall be prepared and stamped by a California registered Civil Engineer.

B. Cementitious Materials: Limit percentage, by weight, of cementitious materials other than portland cement in concrete as follows:1. Fly Ash: 15 to 25 percent.

C. Admixtures: Use admixtures according to manufacturer's written instructions.1. Use water-reducing admixture in concrete, as required, for placement and workability.2. Use water-reducing and retarding admixture when required by high temperatures, low humidity, or other

adverse placement conditions.3. Use water-reducing admixture in pumped concrete, concrete required to be watertight, and concrete with

a water-cementitious materials ratio below 0.50.

2.10 CONCRETE MIXTURES FOR BUILDING ELEMENTSA. Footings and Foundation Walls, Concrete Stairs, Concrete Walls, and Elevated Concrete Slabs: Proportion

normal-weight concrete mixture as follows:1. Minimum Compressive Strength: 4000 psi at 28 days unless otherwise noted.2. Maximum Water-Cementitious Materials Ratio: 0.55.3. Minimum Cementitious Materials Content: 5.5 sacks of cement per cubic yard.4. Slump Limit: 4 inches, plus or minus 1 inch.

B. Interior Slabs-on-Grade: Proportion normal-weight concrete mixture as follows:1. Minimum Compressive Strength: 4000 psi at 28 days.2. Maximum Water-Cementitious Materials Ratio: 0.45.3. Minimum Cementitious Materials Content: 6.0 sacks of cement per cubic yard.4. Slump Limit: 4 inches, plus or minus 1 inch.

C. Exterior Slabs-on-Grade: Proportion normal-weight concrete mixture as follows:1. Minimum Compressive Strength: 4000 psi at 28 days.2. Maximum Water-Cementitious Materials Ratio: 0.55.3. Minimum Cementitious Materials Content: 5.5 sacks of cement per cubic yard.4. Slump Limit: 4 inches, plus or minus 1 inch.

D. Concrete on Metal Deck: Proportion light-weight concrete mixture as follows:1. Minimum Compressive Strength: 4000 psi at 28 days.2. Maximum Water-Cementitious Materials Ratio: 0.55.3. Minimum Cementitious Materials Content: 5.5 sacks of cement per cubic yard.4. Slump Limit: 4 inches, plus or minus 1 inch.5. Light Weight concrete shall weigh 110 pcf

2.11 FABRICATING REINFORCEMENTA. Fabricate steel reinforcement according to CRSI's "Manual of Standard Practice."

2.12 CONCRETE MIXINGA. Ready-Mixed Concrete: Measure, batch, mix, and deliver concrete according to ASTM C 94/C 94M, and

furnish batch ticket information.1. When air temperature is between 85 and 90 deg F, reduce mixing and delivery time from 1-1/2 hours to

75 minutes; when air temperature is above 90 deg F, reduce mixing and delivery time to 60 minutes.

PART 3 - EXECUTION

3.01 FORMWORKA. Design, erect, shore, brace, and maintain formwork, according to ACI 301, to support vertical, lateral, static,

and dynamic loads, and construction loads that might be applied, until structure can support such loads.B. Construct formwork so concrete members and structures are of size, shape, alignment, elevation, and position

indicated, within tolerance limits of ACI 117C. Construct forms tight enough to prevent loss of concrete mortar.D. Retighten forms and bracing before placing concrete, as required, to prevent mortar leaks and maintain proper

alignment.E. Coat contact surfaces of forms with form-release agent, according to manufacturer's written instructions,

before placing reinforcement.

3.02 EMBEDDED ITEMSA. Place and secure anchorage devices and other embedded items required for adjoining work that is attached to

or supported by cast-in-place concrete. Use setting drawings, templates, diagrams, instructions, and directions furnished with items to be embedded. In no case shall any bolt or anchor be stabbed in place while or after the concrete is poured.1. Install anchor rods, accurately located, to elevations required and complying with tolerances in Section 7.5

of AISC's "Code of Standard Practice for Steel Buildings and Bridges."

3.03 REMOVING AND REUSING FORMSA. General: Formwork for sides of beams, walls, columns, and similar parts of the Work that does not support

weight of concrete may be removed after cumulatively curing at not less than 50 deg F for 24 hours after placing concrete. Concrete has to be hard enough to not be damaged by form-removal operations and curing and protection operations need to be maintained.1. Leave formwork for beam soffits, joists, slabs, and other structural elements that supports weight of

concrete in place until concrete has achieved at least 70 percent of its 28-day design compressive strength.

2. Do not strip vertical concrete in less than 7 days.3. Remove forms only if shores have been arranged to permit removal of forms without loosening or

disturbing shores.B. Clean and repair surfaces of forms to be reused in the Work. Split, frayed, delaminated or otherwise damaged

form-facing material will not be acceptable for exposed surfaces. Apply new form-release agent.C. When forms are reused, clean surfaces, remove fins and laitance, and tighten to close joints. Align and secure

joints to avoid offsets. Do not use patched forms for exposed concrete surfaces unless approved by Architect.

3.04 SHORES AND RESHORESA. Comply with ACI 318 and ACI 301 for design, installation, and removal of shoring and reshoring.

1. Do not remove shoring or reshoring until measurement of slab tolerances is complete.B. Plan sequence of removal of shores and reshore to avoid damage to concrete. Locate and provide adequate

reshoring to support construction without excessive stress or deflection.

3.05 VAPOR RETARDERSA. Sheet Vapor Retarders: Place, protect, and repair sheet vapor retarder according to ASTM E 1643 and

manufacturer's written instructions.1. Lap joints 6 inches and seal with manufacturer's recommended tape.2. Seal all penetrations (including pipes) per manufacturer’s tape.3. No penetration of the vapor barrier is allowed except for reinforcing and permanent utilities.4. Repair damaged areas by cutting patches of vapor barrier, overlapping damaged area 6 inches and taping

all four sides with tape.5. Do not saturate the sand cushion.6. If sand is saturated prior to placement of concrete, remove the sand and replace.7. Protect all installed moisture barrier construction from precipitation and water penetration by covering and

providing positive drainage away from the moisture barrier.8. Cover slab openings and block-outs around columns to prevent water penetration of moisture barrier.

3.06 STEEL REINFORCEMENTA. General: Comply with CRSI's "Manual of Standard Practice" for placing reinforcement.

1. Do not cut or puncture vapor retarder. Repair damage and reseal vapor retarder before placing concrete.2. Clean reinforcement and remove loose dust and mill scale, earth, oil, and other materials which reduce

bond or destroy bond with concrete.3. Position, support, and secure reinforcement against displacement by forms, construction, and the

concrete placement operations. Provide metal chairs, dobies, or other aids manufactured for this purpose.4. Place reinforcement to obtain the required concrete coverages for concrete protection.

3.07 JOINTSA. General: Construct joints true to line with faces perpendicular to surface plane of concrete.B. Construction Joints: Install so strength and appearance of concrete are not impaired, at locations indicated or

as approved by Architect.C. Contraction Joints in Slabs-on-Grade: Form weakened-plane contraction joints, sectioning concrete into areas

as indicated. Construct contraction joints for a depth equal to at least one-inch as follows:1. Grooved Joints: Form contraction joints after initial floating by grooving and finishing each edge of joint to

a radius of 1/8 inch. Repeat grooving of contraction joints after applying surface finishes. Eliminate groover tool marks on concrete surfaces.

2. Sawed Joints: Form contraction joints with power saws equipped with shatterproof abrasive or diamond-rimmed blades. Cut 1/8-inch wide joints into concrete when cutting action will not tear, abrade, or otherwise damage surface and before concrete develops random contraction cracks. Saw cut slab as soon as surface has hardened to where it can support the equipment and operator, normally within 2 hours after finishing. Use saw which is specially designed for cutting fresh concrete, such as “Soff-Cut” or equal.a. Depth of cut: 1/3 depth of slab, 1 inch min.

D. Doweled Joints: Install dowel bars and support assemblies at joints where indicated. Lubricate one-half of dowel length to prevent concrete bonding to one side of joint.

3.08 CONCRETE PLACEMENTA. Before placing concrete, verify that installation of formwork, reinforcement, and embedded items is complete

and that required inspections have been performed.B. Do not add water to concrete during delivery, at Project site, or during placement unless approved by

Architect.C. Deposit concrete continuously in one layer or in horizontal layers of such thickness that no new concrete will

be placed on concrete that has hardened enough to cause seams or planes of weakness. If a section cannot be placed continuously, provide construction joints as indicated. Deposit concrete to avoid segregation.1. Deposit concrete in horizontal layers of depth to not exceed formwork design pressures and in a manner

to avoid inclined construction joints.2. Consolidate placed concrete with mechanical vibrating equipment according to ACI 301.3. Do not use vibrators to transport concrete inside forms. Insert and withdraw vibrators vertically at

uniformly spaced locations to rapidly penetrate placed layer and at least 6 inches into preceding layer. Do not insert vibrators into lower layers of concrete that have begun to lose plasticity. At each insertion, limit duration of vibration to time necessary to consolidate concrete and complete embedment of reinforcement and other embedded items without causing mixture constituents to segregate.

D. Deposit and consolidate concrete for floors and slabs in a continuous operation, within limits of construction joints, until placement of a panel or section is complete.1. Consolidate concrete during placement operations so concrete is thoroughly worked around reinforcement

and other embedded items and into corners.2. Maintain reinforcement in position on chairs during concrete placement.3. Screed slab surfaces with a straightedge and strike off to correct elevations.4. Slope surfaces uniformly to drains where required.5. Begin initial floating using bull floats or darbies to form a uniform and open-textured surface plane, before

excess bleedwater appears on the surface. Do not further disturb slab surfaces before starting finishing operations.

E. Cold-Weather Placement: Comply with ACI 306.1 and as follows. Protect concrete work from physical damage or reduced strength that could be caused by frost, freezing actions, or low temperatures.1. When average high and low temperature is expected to fall below 40 deg F for three successive days,

maintain delivered concrete mixture temperature within the temperature range required by ACI 301.2. Do not use frozen materials or materials containing ice or snow. Do not place concrete on frozen

subgrade or on subgrade containing frozen materials.3. Do not use calcium chloride, salt, or other materials containing antifreeze agents or chemical accelerators

unless otherwise specified and approved in mixture designs.F. Hot-Weather Placement: Comply with ACI 301 and as follows:

1. Maintain concrete temperature below 90 deg F at time of placement. Chilled mixing water or chopped ice may be used to control temperature, provided water equivalent of ice is calculated to total amount of mixing water. Using liquid nitrogen to cool concrete is Contractor's option.

2. Fog-spray forms, steel reinforcement, and subgrade just before placing concrete. Keep subgrade uniformly moist without standing water, soft spots, or dry areas.

3.09 FINISHING FORMED SURFACESA. Rough-Formed Finish: As-cast concrete texture imparted by form-facing material with tie holes and defects

repaired and patched. Remove fins and other projections that exceed specified limits on formed-surface irregularities.1. Apply to concrete surfaces not exposed to public view.

B. Smooth-Formed Finish: As-cast concrete texture imparted by form-facing material, arranged in an orderly and symmetrical manner with a minimum of seams. Repair and patch tie holes and defects. Remove fins and other projections that exceed specified limits on formed-surface irregularities.1. Apply to concrete surfaces exposed to public view, to receive a rubbed finish, to be covered with a coating

or covering material applied directly to concrete.C. Rubbed Finish: Apply the following to smooth-formed finished as-cast concrete.

1. Smooth-Rubbed Finish: Not later than one day after form removal, moisten concrete surfaces and rub with carborundum brick or another abrasive until producing a uniform color and texture. Do not apply cement grout other than that created by the rubbing process.

D. Related Unformed Surfaces: At tops of walls, horizontal offsets, and similar unformed surfaces adjacent to formed surfaces, strike off smooth and finish with a texture matching adjacent formed surfaces. Continue final surface treatment of formed surfaces uniformly across adjacent unformed surfaces unless otherwise indicated.

3.10 FINISHING FLOORS AND SLABSA. General: Comply with ACI 302.1R recommendations for screeding, restraightening, and finishing operations

for concrete surfaces. Except as may be shown otherwise on the drawings, provide the following finishes at the indicated locations.

B. Scratch Finish: While still plastic, texture concrete surface that has been screeded and bullfloated or darbied. Use stiff brushes, brooms, or rakes to produce a profile amplitude of 1/4 inch in one direction.1. Apply scratch finish to surfaces that are to receive concrete floor toppings or mortar setting beds for

bonded cementitious floor finishes.C. Float Finish: Consolidate surface with power-driven floats or by hand floating if area is small or inaccessible to

power driven floats. Restraighten, cut down high spots, and fill low spots. Repeat float passes and restraightening until surface is left with a uniform, smooth, granular texture.1. Apply float finish to surfaces to receive trowel finish and to be covered with fluidapplied or sheet

waterproofing, built-up or membrane roofing, or sand-bed terrazzo.D. Trowel Finish: After applying float finish, apply first troweling and consolidate concrete by hand or power-

driven trowel. Continue troweling passes and restraighten until surface is free of trowel marks and uniform in texture and appearance. Grind smooth any surface defects that would telegraph through applied coatings or floor coverings.1. Apply a trowel finish to surfaces exposed to view or to be covered with resilient flooring, carpet, ceramic or

quarry tile set over a cleavage membrane, paint, or another thin-film-finish coating system.2. Finish and measure surface so gap at any point between concrete surface and an unleveled,

freestanding, 10-ft. long straightedge resting on two high spots and placed anywhere on the surface does not exceed 1/8 inch.

3. The contractor shall anticipate that grinding will be required as a result of curling or other slab defects. Grinding required to bring the slab surface into acceptable tolerances for finished flooring installation shall be included as part of the Work.

E. Trowel and Fine-Broom Finish: Apply a first trowel finish to surfaces where ceramic or quarry tile is to be installed by either thickset or thin-set method. While concrete is still plastic, slightly scarify surface with a fine broom.1. Comply with flatness and levelness tolerances for trowel-finished floor surfaces.

F. Broom Finish: Apply a broom finish to exterior concrete platforms, steps, ramps, and elsewhere as indicated.

3.11 CONCRETE PROTECTING AND CURINGA. General: Protect freshly placed concrete from premature drying and excessive cold or hot temperatures.

Comply with ACI 306.1 for cold-weather protection and ACI 301 for hotweather protection during curing.B. Vertical and decorative concrete shall be sacked and patched and receive an anti-graffiti coating.C. Finishes: Medium broom finish or top-cast etching at horizontal concrete.D. Evaporation Retarder: Apply evaporation retarder to unformed concrete surfaces if hot, dry, or windy

conditions cause moisture loss approaching 0.2 lb/sq. ft. x h before and during finishing operations. Apply according to manufacturer's written instructions after placing, screeding, and bull floating or darbying concrete, but before float finishing.