Ejector Pins - KALLER · 2017-05-04 · kaller.com Ejector Pin (EP) gas springs are designed to...

Transcript of Ejector Pins - KALLER · 2017-05-04 · kaller.com Ejector Pin (EP) gas springs are designed to...

Would you like to order this product? All available information at www.kaller.com.

Ejector Pins EP3 16 EP2 24 EPS2 24

Product Series Gas Springs including Standard Mounts

kaller.com

The highly appreciated non-re-pairable EP se-ries gas springs for the tool and die industry have been on the market since the early 2000s. It goes without saying, but since the introduction the EP series – naturally like all KALLER gas springs – has undergone continuous and consistent design changes to meet customer expectations for reliability, safety and service lifetime.

Safety updates approved and appreciatedThe new EP3 16 series bears the resemblance of the sealed rod, compact and fully adjustable R12 series. The major difference is that the EP3 16 models come with a rounded piston rod top and a threaded sleeve. Safety updates approved and appreciated by KALLER customers and distributors! Like the EP2 16 the new EP3 16 series con-sists of six gas spring models available in each thread size. Five preset models and one adjus-

To meet customer expectations

“Living up to safety and reliability”

Per-Åke Lundgren, R&D Manager,

Lidhs Verktyg AB, Sweden

table model. The pre-charging of the adjustable model is 5-10 bar, designed for the customer to adjust the gas charge pressure.

Purchasing plenty of gas springsLidhs Verktyg AB, the leading Swedish tool manufacturer of advanced tools for sheet metal forming, has been in business since 1969. Per-Åke Lundgren, Lidhs’s R&D Manager, has all the best to say when asked about the KALLER gas springs in general, and he has very good KALLER knowledge from purchasing plenty of gas springs over the years. “At Lidhs we have a saying: ‘our experience is the customer’s security for reliable production’. To live up to this we need to work with contrac-tors who can live up to catchwords like ‘safety’ and ‘reliability’. KALLER is definitely among those contractors,” Mr. Lundgren concludes.

FEATURES & BENEFITS | EP3 16 • EP2 24 • EPS2 24

They come in the same stroke

length. The total length is similar.

Now abandoning Ejector Pin

EP2 16 gas springs to introduce

the EP3 16 series, an unexperienced

eye would probably say that KALLER

has changed nothing in design.

But as always when KALLER

introduces new or

updated products,

there is a major

focus on safety

updates. Perhaps

not visible to a

layman but

undoubtedly

crystal clear to a

trained technician.

kaller.com

Ejector Pin (EP) gas springs are designed to

replace mechanical spring plungers/lifters.

EP gas springs have a partially threaded

M16x1.5, M16x2 or M24x1.5 body.

Compared to conventional mechanical

spring plungers/lifters EP gas springs

provide a fully adjustable and superior

lifting force and better service life.

EP3, EP2 and EPS2 gas springs

are color-coded for easy force

identification. The gas springs

can be adjusted and

recharged to meet

individual force

requirements.

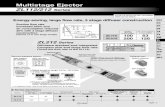

Features and benefits Ejector Pins EP3 16, EP2 24 and EPS2 24 - color-coded gas springs for easy force identification

Safety Reliability

Need additional information on KALLER features? Refer to the back cover of this brochure or visit www.kaller.com/FAQ

KALLER - THE SAFER CHOICE

FEATURES & BENEFITS | EP3 16 • EP2 24 • EPS2 24

We reserve the right to add, delete or modify components without notification. All dimensions are stated in mm. All dimensions are nominal unless tolerance is stated.

kaller.com

TECHNICAL FACTS | EP3 16 • EP2 24 • EPS2 24

S Stroke

L ±0.25 L min

Gas vol.( l )

Weight (kg)

10 65 55 0.002 0.06

20 85 65 0.003 0.07

30 105 75 0.003 0.07

40 125 85 0.004 0.08

50 145 95 0.005 0.08

60 165 105 0.005 0.09

70 185 115 0.006 0.10

80 205 125 0.006 0.11

100 245 145 0.008 0.11

125 295 170 0.010 0.13

Model

Force in Nat +20°C

Color

Chargingpressure

(bar)

End force in N at + 20°C,

at full strokeInitial

EP3 16x2 40 Purple 12 64

EP3 16x1.5/x2 57 Green 20 91

EP3 16x1.5/x2 110 Blue 40 180

EP3 16x1.5/x2 210 Red 75 335

EP3 16x1.5/x2 420 Yellow 150 670

EP3 16x1.5/x2 XX* 20-420 Black 6-150 32-670

R3

L

1

S

Lm

in

5

35

M6 charge port

Thr

ead

lock

ing

elem

ent

HEX10

Ø 6

M16x2M16x1.5

Stroke Length (mm)

EP3 16x1.5 - 10 - Blue

(10, 20, 30, 40, 50, 60, 70, 80, 100, 125)

How to order

Model:

Thread: x1.5 = M16x1.5 x2 = M16x2

Force: Purple, Green, Blue, Red, Yellow, Black

HEX10

HEX17

Installation Tool, Order No. 3021000

Pressure medium......................... Nitrogen Max. charging pressure................ 150 bar Min. charging pressure................. 12 bar Operating temperature................. 0 - +80°C Force increase by temperature..... ± 0.3%/°C Recommended max. strokes/min.. ~ 100 (at 20°C) Max. piston rod velocity................. 1.6 m/sNeed additional information? See KALLER catalog.

AF 24

8

EP3 16 is available with shoulder and stroke 15 mm as per GM Standard. Contact your local distributor or Strömsholmen AB for more information.

S

L

Lm

in

5

35

M16x1.5

R3

3

20

HEX 9.5

Ø

Ø 6

Thr

ead

lock

ing

elem

ent

S

L

Lm

in

5

35

M16x1.5

R3

3

20

HEX 9.5

Ø

Ø 6

Thr

ead

lock

ing

elem

ent

Lock nut

Order No. Thread 503681 M16x1.5 503722 M16x2

* Force to be set by customer. Delivered with a pre-charge of 5-10 bar.

2 million

APPROVED

97/23/EC

EP3 16 with adjustable and superior lifting force

Basic informationMounting possibilities

We reserve the right to add, delete or modify components without notification. All dimensions are stated in mm. All dimensions are nominal unless tolerance is stated.

kaller.com

EP3 16 • EP2 24 • EPS2 24 | TECHNICAL FACTS

Pressure medium......................... Nitrogen Max. charging pressure................ 150 bar Min. charging pressure................. 6 bar Operating temperature................. 0 - +80°C Force increase by temperature..... ± 0.3%/°C Recommended max. strokes/min.. ~ 30-80 (at 20°C) Max. piston rod velocity................. 1.6 m/sNeed additional information? See KALLER catalog.

* Force to be set by customer. Delivered with a pre-charge of 5-10 bar.

Limited features for EP2 24 and EPS2 24.

S Stroke

L ±0.25 L min

Gas vol.( l )

Weight (kg)

10 65 55 0.05 0.13

20 85 65 0.07 0.15

30 105 75 0.10 0.17

40 125 85 0.12 0.19

50 145 95 0.14 0.21

60 165 105 0.17 0.23

70 185 115 0.19 0.25

80 205 125 0.22 0.27

100 245 145 0.26 0.31

125 295 170 0.32 0.35

AF 36

Lock nut Order No. 503928

10

Model

Force in Nat +20°C

Color

Char-ging

pressure (bar)

End force in N at + 20°C,at full strokeInitial

EPS2 24 07 65 Orange 6 110

EPS2 24 11 110 Purple 10 190

EP2/EPS2 24 230 Green 20 390

EP2/EPS2 24 450 Blue 40 800

EP2/EPS2 24 850 Red 75 1500

EP2/EPS2 24 1700 Yellow 150 2900

EP2/EPS2 24 XX* 65-1700 Black 6-150 110-2900

Ø 12

M24x1.5

1

S

5

R8

35

L

Lm

in

M6 charge port

Thr

ead

lock

ing

elem

ent

HE

X17

Stroke Length (mm)

EP2 24 20-Red

(10, 20, 30, 40, 50, 60, 70, 80, 100, 125)

How to order

Model: Force: Purple, Green, Blue, Red, Yellow, Black

Ø 12

M24x1.5

1

S

8

R8

35

L

Lm

in

M6 charge port

Thr

ead

lock

ing

elem

ent

HE

X25

HE

X17

Stroke Length (mm)

EPS2 24 20-Green

(10, 16, 20, 25, 30, 38, 40, 50, 60, 70, 80, 100, 125)

How to order

Model: Force: Orange, Purple, Green, Blue, Red, Yellow, Black

S Stroke

L ±0.25 L min

Gas vol.( l )

Weight (kg)

10 65 55 0.05 0.15

16 77 61 0.06 0.16

20 85 65 0.07 0.17

25 95 70 0.08 0.18

30 105 75 0.10 0.19

38 121 83 0.11 0.21

40 125 85 0.12 0.21

50 145 95 0.14 0.23

60 165 105 0.17 0.25

70 185 115 0.19 0.27

80 205 125 0.22 0.29

100 245 145 0.26 0.33

125 295 170 0.32 0.37

EP2 24 EP2 24 EPS2 24

Basic informationMounting possibilities

EP2 24 and EPS2 24 for individual force requirementsØ 12

M24x1.5

1

S

5

R8

35

L

Lm

in

M6 charge port

Thr

ead

lock

ing

elem

ent

HE

X17

We reserve the right to add, delete or modify components without notification. All dimensions are stated in mm. All dimensions are nominal unless tolerance is stated.

kaller.com

The Safer Choice

Dual Seal

Over-Stroke Protection System

SAFETY. When a gas spring is over-stroked, this helps reduce the risk of tool damage or injury.

PED approved for 2 million strokes

RELIABILITY. Our 2 million stroke PED approval ensures safer component cycle life.

Overload Protection System

SAFETY. Jammed cam or tool part being forced by gas springs? This will help reducing such risks.

Overpressure Protection System

SAFETY. Vents the spring if the internal gas pressure exceeds the maximum allowable limit to prevent accidents.

Flex GuideTM System

RELIABILITY. Prolongs service life, life, allows more strokes per minute, and offers greater tolerance to lateral tool movements.

Dual SealTM Link Systems

RELIABILITY. Fewer production interruptions due to leakage caused by vibration. Simplified installation thanks to the non-rotation feature.

KALLER Training Program

TRAINING. Without doubt the KALLER Training Program is the best and most creative way to fully understand and appreciate the importance of the safety and reliability features.

Introduced in 1983, the KALLER gas spring technology quickly led to world-wide demand. The Safer Choice - Training, Safety and Reliability - has always been a KALLER top priority for providing the safer working environment. We recommend looking through all available KALLER features when selecting gas springs and gas or hose linked systems.

8100

-251

3-07

© S

TR

ÖM

SH

OLM

EN

AB

, Prin

ted

in S

wed

en 2

011