Effect of two-stage injection dwell angle on engine combustion … · aSchool of Mechanical...

Transcript of Effect of two-stage injection dwell angle on engine combustion … · aSchool of Mechanical...

Contents lists available at ScienceDirect

Fuel

journal homepage: www.elsevier.com/locate/fuel

Full Length Article

Effect of two-stage injection dwell angle on engine combustion andperformance characteristics of a common-rail diesel engine fueled withcoconut oil methyl esters-diesel fuel blends

Y.H. Teoha,⁎, H.H. Masjukib,⁎, H.G. Howb,c,⁎, M.A. Kalamb, K.H. Yub, A. Alabdulkaremd

a School of Mechanical Engineering, Universiti Sains Malaysia, Engineering Campus, 14300 Nibong Tebal, Penang, Malaysiab Centre for Energy Sciences, Faculty of Engineering, University of Malaya, 50603 Kuala Lumpur, Malaysiac Department of Engineering, School of Engineering, Computing and Built Environment, KDU Penang University College, 32, Jalan Anson, 10400 Georgetown, Penang,MalaysiadMechanical Engineering Department, College of Engineering, King Saud University, 11421 Riyadh, Saudi Arabia

A R T I C L E I N F O

Keywords:Diesel engineNOx

Injection timingDwell angleBiodiesel

A B S T R A C T

Diesel engine is widely used as prime mover due to its high thermal efficiency. Usage of renewable biodiesel indiesel engine is also widely studied due to its potential in reducing emission and as a replacement of conven-tional diesel. Biodiesel performance could be improved by blending it with petroleum diesel besides introducingappropriate injection strategies. In this experiment, the effect of percentage of biodiesel blends and injectionstrategies such as variations in start of injection (SOI) timing and dwell angle on diesel engine performance wereinvestigated. The test engine used is four-stroke turbocharged direct injection diesel engine. Results show thatexhaust emissions, engine performance and combustion characteristics are substantially affected by biodieselblending ratio and SOI timing but slightly influenced by two-stage injection dwell angle. Biodiesel blends per-centage could be raised to improve NOx and smoke emissions. Even though SOI performed at a later timing couldreduce NOx emission, smoke emission increased. Dwell angle between two successive injections could be pro-longed to lower the effect of the increase in smoke emission. It could also be inferred that by setting a proper SOItiming and dwell angle under two-stage injection scheme when suitable biodiesel blend is used, the engineperformance could be optimized.

1. Introduction

Diesel engine is ubiquitously used as primary mover by virtue of itshigh efficiency. It has been used in many areas such as transportation,power generation, irrigation and construction equipment. However, theuse of diesel fuel has posed two main problems – fossil fuel depletionand air pollution issues. The demand of liquid fuels is expected to in-crease in the near future as depletion problem may worsen. Besides,usage of diesel engine has caused emission of air pollutants. Nitrogenoxides (NOx) (nitric oxide and nitrogen dioxide), carbon monoxide (CO)and unburned hydrocarbons (HC) are some of the main components ofair pollutants produced when diesel engine is used [1]. The air pollu-tants may cause various health problems, formation of acid rain, de-struction of ozone layer, etc. Steps have to be taken to overcome theproblems due to the usage of diesel engine.

Biodiesel fuel is one of the alternatives to solve the diesel depletionproblem. It can be derived from plants and animals such as coconut,rapeseed, soybean, animal fats, etc [2]. It is nontoxic, renewable andbiodegradable [3]. Emission characteristics of biodiesel fuel are dif-ferent from conventional diesel. Combustion of biodiesel emits a lowerlevel of CO, smoke and particulate matter concentration due to thehigher oxygen content in it [4]. According to Shivakumar et al. [5], NOx

emission of waste cooking oil biodiesel blends is higher than conven-tional diesel. However, the smoke emission of waste cooking oil bio-diesel blends is less than conventional diesel. Ganapathy et al. [6]studied about the emission of Jatropha biodiesel. They found that Ja-tropha biodiesel always exhibits a higher NOx emission compared toconventional diesel. The smoke density observed when Jatropha bio-diesel is used is lower than conventional diesel. Brake thermal effi-ciency (BTE) of Jatropha biodiesel is lower than conventional diesel.

https://doi.org/10.1016/j.fuel.2018.07.036Received 7 April 2018; Received in revised form 4 July 2018; Accepted 7 July 2018

⁎ Corresponding authors at: School of Mechanical Engineering, Universiti Sains Malaysia, Engineering Campus, 14300 Nibong Tebal, Penang, Malaysia (Y.H.Teoh). Centre for Energy Sciences, Faculty of Engineering, University of Malaya, 50603 Kuala Lumpur, Malaysia (H.G. How and H.H. Masjuki).

E-mail addresses: [email protected] (Y.H. Teoh), [email protected] (H.H. Masjuki), [email protected] (H.G. How),[email protected] (M.A. Kalam), [email protected] (K.H. Yu).

Fuel 234 (2018) 227–237

Available online 11 July 20180016-2361/ © 2018 Elsevier Ltd. All rights reserved.

T

Raheman and Ghadge [7] investigated the performance of diesel enginewhen Mahua biodiesel was used. They showed that the brake specificfuel consumption (BSFC) increased while the brake thermal efficiency(BTE) decreased when the percentage of biodiesel blend increased. TheNOx and smoke emission trends are the same as what were observedwhen waste cooking oil biodiesel blend and Jatropha biodiesel wereused.

In order to improve the performance and emission characteristics ofdiesel engine when biodiesel is used to replace conventional diesel, amore advanced injection strategies have to be carried out. Multiple-injection strategy has been proposed as one of the methods to reducethe air pollutants emitted by diesel engine. Generally, two kinds ofmultiple-injection schemes which are pilot injection and split injectionare applied in diesel engine. Pilot and split injections are distinguishedby the injection quantity of the first injection. Usually, in pilot injection,a relatively small quantity of first injection fuel is introduced before thesecond main injection. While in split injection, the injection of fuel isdivided into two or more equal portions, where each portion is injectedconsecutively but non-continuously. One of the purposes is to ensurethat before main combustion occurs, a highly premixed fuel can beformed. The benefits of multiple-injections, which includes pilot andsplit injections, have been studied by many researchers before [8–14].Jafarmadar and Nemati [15] applied the split injection scheme in anindirect injection diesel engine to study the exergetic performanceusing three-dimensional CFD code. The first injection pulse was alteredfrom 75% to 90% and the duration of the dwelling angle was main-tained at 20° crank angle. As the results showed, with longer first in-jection pulse, the heat loss, work, and fuel burn exergies as well as theexergy efficiency increased. Besides, Choi and Reitz [16] noted the NOxsuppression effects with both late and split injection strategies whenusing biodiesel in a single-cylinder heavy-duty diesel engine. In the caseof double injection strategies, the first injection pulse and dwell timewere fixed at 50% and 0.97ms for low load and at 61% and 1.18ms forhigh load conditions. The authors found that these injection schemesreduced the burning rate during premixed combustion phase, therebylowered in-cylinder combustion temperatures. Another study [17] usedneat biodiesel from soybean oil for the study of the effect of injectiontiming and exhaust gas recirculation (EGR) rate on the combustion andemissions. The results showed that biodiesel exhibited lower NOx withsplit injection strategy at retarded SOI timing. Also, the BSFC wasslightly increased with retarded SOI. The testing was carried out withsmall fuel quantity of the first injection compared to the second injec-tion (main injection) on the Ford Lion V6 DI diesel engine. This injec-tion technique was rather common but no in-depth studies were con-ducted on the effect of same fuel injection quantities for the first andsecond injection. Kim et al. [18] experimentally assessed split injectionon engine performance, exhaust emissions and soot particulates onsingle-cylinder common-rail injection diesel engine fueled with neatbiodiesel derived from soybean. The results indicated that the split in-jection reduced NOx emissions remarkably without a significant in-crease in soot emissions. The benefits of split injection for NOx reduc-tion were further affirmed by Stringer and co-worker [19] using anoptical access research engine. Additionally, post injection appliedduring split injection serves to reduce the amount of smoke, particulatematter and unburned hydrocarbon [20]. The parameters in split in-jection can be changed and improved to produce a better effect on theperformance and emissions characteristics of diesel engine. Theseparameters include injection timing, dwell angle between injections,mass injected, mass ratio of injections, number of injections, injectionpressure and others. Recently, the authors of this paper [21] examinedthe effects of combining biodiesel blended fuels and split injection (i.e.single, double and triple injection) in a four-cylinder common-raildiesel engine at various SOI and reported simultaneous decrement ofNOx and smoke emissions with a drop in performance. Besides, theoutcomes also suggested that the dwell angle between consecutive in-jections for double injection scheme could be further optimized for

obtaining a much cleaner exhaust emissions and engine performance. Inthis study, effect of different start of injection timing and dwell anglebetween injections in two-stage injection scheme on the performanceand emission characteristics will be investigated and discussed.

Start of injection timing is one of the factors which greatly affectdiesel engine performance and emission characteristics. Shivakumaret al. [5] found that NOx emitted was reduced when waste cooking oilbiodiesel blends were used when SOI is retarded while advanced SOIcaused reduction in amount of smoke emitted. The same results wereobtained by Sayin et al. [22] using C18.08H34.86O2 biodiesel and Gana-pathy et al. [6] using Jatropha biodiesel. According to Jeon and Park[23], when pilot injection was applied, the retardation of SOI of pilotinjection caused higher emission of NOx compared to single injectionscheme. Adam et al. [24] used gasoline and soy methyl ester biodieselin investigating engine performance and emission characteristics. Theyfound that with retarded injection timing, gas temperature and HRRincreased, leading to rise in NOx emission amount.

Besides SOI, dwell angle is also an important factor. According toCung et al. [25], when the dwell angle was reduced, the penetrationrate was increased. However, a dwell angle which is too short will causethe soot to increase. With a longer dwell angle, the peak heat releaserate (PHRR) and total heat released were increased. Rohani and Bae[26] found that longer dwell angle of about 30°CA produced a morepremixed charge. In split injection with five times of injection, Mathi-vanan et al. [27] discovered that smoke level was the lowest when thedwell angle between the fourth injection and the last injection was thelongest. Liu and Song [28] found that cylindrical pressure decreasedwith increasing dwell angle under constant fuel quantity in double in-jection scheme. When the post injection was retarded and the dwellangle was increased, NOx emission could be reduced. A shorter dwellangle causes limitation in oxidation of CO and hydrocarbon (HC) due toinsufficient mixing time. Using Karanja biodiesel as fuel, Dhar andAgarwal [29] found that NOx emission decreased with retarding start ofmain injection timing for every start of pilot timing. However, at fixedstart of main injection, NOx emission was almost constant with thechange in start of pilot injection.

Some studies about impacts of biodiesel blends, start of injection(SOI) timing and multiple injection dwell angle on efficiency and ex-haust emission of diesel engine have been carried out as stated above.However, the study on the combination effect of these three factors isless. In fact, most of them have been carried out on single-cylinderresearch engine, which is not a practical representative of the produc-tion multi-cylinder engine adopted in commercial vehicles. This mightbe due to single-cylinder engine that essentially differs from multi-cy-linder engine in term of rotational dynamics, gas intake dynamics, heattransfer dynamics, dynamic coupling between cylinders, and in otheraspects [30]. For instance, the difference in gas intake dynamics arisesespecially in the case of turbocharged engines, which can significantlyalter the in-cylinder intake air charge motion and momentum, thusimpacting on in-cylinder emission production due to the differences inheat transfer. Consequently, there is a research gap existing in thesedisciplines. Hence, the topic will be explored in the present paper. Inthis study, effects of start of injection timing and dwell angle on dieselengine performance and characteristics emission will be investigated byusing biodiesel blended fuels in multi-cylinder turbocharged dieselengine. Combination of different parameters will be carried out to un-derstand the combination which can lead to optimum performance andemission characteristics of diesel engine.

2. Experimental apparatus and procedure

2.1. Apparatus setup

Table 1 shows the specifications of the engine used in this experi-ment. The experimental setup was the same as that described in [31].Four-stroke diesel engine with turbocharger was used instead of single-

Y.H. Teoh et al. Fuel 234 (2018) 227–237

228

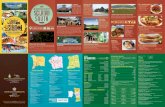

cylinder diesel engine due to its more common usage in real world. Byusing Delphi common–rail fuel injection system, it was possible tocontrol the injection parameter electronically to manipulate the com-bustion condition. High pressure direct fuel injection was able to beperformed. Other devices were also connected to test engine or inter-connected with each other to implement corresponding function ac-cording to Fig. 1. Eddy current dynamometer with absorption power of150 kW was connected to the engine shaft to provide constant load andengine angular velocity. The dynamometer was controlled by a dy-namometer controller while hot-wire air mass sensor was used tomeasure the mass flow rate of air which entered the engine.

Pressure developed in cylinder during combustion was monitoredby using Kistler 6058A piezoelectric sensor. The pressure sensor wasmounted on engine by using glow plug adapter while charge amplifier,DAQ-Charge-B was utilized to amplify the signal from pressure sensor.Based on the pressure data obtained, the corresponding HRR andtemperature values could be calculated using law of thermodynamics.Incremental encoder was also used so that at every interval of0.125°CA, the in-cylinder gas pressure reading could be taken. Theengine was started and run steadily for a certain amount of time, beforethe taking of pressure readings began. The pressure data of 100 con-secutive cycles was taken and the average pressure of each data pointwas obtained. The signals produced by the encoder and pressure sensorwere feed into a high-speed data acquisition system. Other lower speeddata acquisition system and engine control module (ECM) were in-house built by utilizing Arduino microcontrollers. Three I/O pins onArduino were connected to incremental encoder and camshaft to act asreceiver. Arduino was linked to a personal computer, where a graphicuser interface (GUI) developed using LabVIEW was employed to set the

injection parameters and engine parameters. By employing a closed-loop feedback of engine speed via incremental encoder, the period ofinjection could be determined for ECM to send appropriate signal toinjector. In this way, the angular velocity of engine could be keptconstant. Disturbance and steady state error which occurs during theexperiment could be alleviated by implementing proportional-integralcontrol loop. To avoid injector from being heated up, which wouldsubsequently affect the fuel temperature and engine performance, peakand hold method was applied to trigger the solenoid type fuel injectors.

Aside from combustion characteristics, engine performance andexhaust emission were also investigated in this experiment. In order toquantify the efficiency of engine, the quantity of fuel used had to bedetermined. Kobold fuel flow meter was used to measure the quantityof fuel consumed during the combustion. On the other hand, exhaustemission could be studied by using Bosch BEA 350 gas analyzer, AVLDICOM 4000 gas analyzer and smoke opacity meter. K-type thermo-couples was employed to measure the temperature of surrounding air,lubricant oil, exhaust gas and engine coolant.

2.2. Experimental methods and procedures

The engine operating conditions were fixed as shown in Table 2throughout this experiment. Load which was lower than the maximumvalue was applied by dynamometer to the engine as vehicles normallywork under part load condition. It could be seen that two-stage injec-tion strategy was carried out for all test cases. The mass ratio of firstinjection to second injection was 50:50 as depicted in Fig. 2, where thequantity of fuel injected during first injection was same as that ofsecond injection. Two-stage injection strategy was investigated due toits advantage in improving the exhaust emissions. By dividing fuel to beintroduced into cylinder via two injections, the maximum temperatureachieved can be reduced owing to the longer combustion period andbetter fuel air mixture can be formed. First injection combustion cancreate a suitable environment with higher temperature for the com-bustion of second injection to occur effectively. Late injection com-bustion serves to promote complete reaction between fuel and air.

According to Table 3, test cases examined in this research are de-signed by manipulating biodiesel blending ratios, SOI timings and dwellangles. Different fuel types contain different biodiesel composition andthis will greatly affect the exhaust emission. On the other hand, changein SOI timings cause the start of combustion to happen at differentposition with corresponding condition and the ignition delay to belengthened or shortened. Dwell angles affect the combustion

Table 1Key information and specifications of test engine.

Type of engine Four-cycle, turbocharged, direct injection dieselengine

Injection system High-pressure (over 140MPa) common-railCylinder number 4Valve number per cylinder 2Bore diameter 76.0 mmStroke length 80.5 mmLength of connecting rod 135mmCompression ratio 18.25:1Displacement 1461 cm3

Maximum torque 160 Nm at 2000 rpmMaximum power output 48 kW at 4000 rpm

Fig. 1. Apparatus setup schematic diagram.

Y.H. Teoh et al. Fuel 234 (2018) 227–237

229

characteristics and engine performance in about the same way as SOItiming where the position of start of combustion is change. Hence, thestudy of simultaneous effects of these three parameters had to be doneto optimize the engine performance. A test case consisted of a combi-nation of three levels, where each level originated from correspondingvariable parameter was carried out. All possible combinations wereinvestigated in this experiment. First, combination of baseline dieseland dwell angle of 12°CA was fixed in studying the effect of variation inSOI timings. Then, dwell angle was changed and the steps were re-

peated. When all dwell angles and SOI timings have been tested usingbaseline diesel, the entire procedures were repeated using B20 and B50biodiesel respectively.

2.3. Biodiesel property test

In this experiment, the biodiesel used was produced in laboratoryrather than purchased in market in which the biodiesel does not havestandard composition. Transesterification was carried out to converttriglycerides in coconut oil into methyl ester so that viscosity of coconutoil could be reduced to make it a suitable fuel to be used in dieselengine. After the process was implemented, various tests were con-ducted to obtain neat coconut oil biodiesel (COB) properties. The neatCOB produced had to fulfill ASTM standard. The properties of neatCOB, ASTM D6751 standard and baseline diesel properties were listedin Table 4. It can be seen that all the properties of neat COB satisfied thestandard employed in this experiment. Distillation characteristics canbe discovered from Table 4. Furthermore, the physicochemical prop-erties of the baseline diesel fuels were also measured and comparedwith those reported in literature. It appeared that most of the physi-cochemical properties of baseline diesels were in good agreement withthe results from literature. To optimize the properties of biodiesel, neatCOB had to be blended with petroleum diesel. In this experiment, B20blend (80:20 petroleum diesel-biodiesel ratio) and B50 blend (50:50petroleum diesel-biodiesel ratio) were suggested and prepared. Theproperties of petroleum diesel, B20 blend, B50 blend and neat COBwere obtained by carrying out ASTM and EN ISO test methods, as

shown in Table 5. It was observed that calorific value decreased withincreasing percentage of biodiesel blends. Low calorific value fuel wasnot preferable since more fuel will be consumed to produce sameamount of energy. Neat COB also had a higher density compared toconventional diesel. When the biodiesel percentage rises, the flash pointwas observed to be elevated and favorable for the usage in engine.Besides, blends with higher percentage of biodiesel were more likely tobe subjected to oxidation.

2.4. Statistical and equipment uncertainty analysis

Research measurements always subject to uncertainty, which mustbe considered when analytical results are used as part of a basis forcomparing experimental numbers. All experimental measured resultreported should be accompanied by an explicit uncertainty estimate.For the present study, the summary of the equipment used and thecorresponding measurement range and accuracy of the instruments istabulated in Table 6. Uncertainty evaluation is crucial to verify theaccuracy of the experiments. Hence, the percentage uncertainties ofbrake specific fuel consumption (BSFC) and brake thermal efficiency(BTE) were determined based on the percentage uncertainties of theinstruments used in the experiments. The uncertainty analysis wasperformed using the method described by [21,34]. The overall experi-mental uncertainty was determined using the following equation:

= + + + + +

+ = ±

Square root of [(0.5) (1.5) (1.7) (1.3) (1) (0.5)

(0.03) ] 2.9%

2 2 2 2 2 2

2

3. Results and discussion

3.1. Performance characteristics

The data obtained had been plotted in graph form. The performanceand emission characteristics variations of diesel engine with the per-centage of biodiesel blend, start of injection timing (SOI) and dwellangle change are analyzed based on the graphs plotted. In this section,the effects of the stated engine parameters on brake thermal efficiency(BTE) and brake specific fuel consumption (BSFC) will be examined.Fig. 3 shows the BTE and BSFC of diesel engine when the parameters asshown were varied. It can be seen that BTE of biodiesel is always lowerthan diesel engine at any SOI timing and dwell angle. By focussing ontest case with SOI timing of -6°ATDC and dwell angle of 12°CA, com-parison can be made where the BTE values were 30.6%, 30.5% and30.4% for petroleum diesel, B20 and B50 blends respectively. More-over, the results suggest that SOI timing is one of the key factors whichaffect BTE. When SOI timing is advanced, the BTE of all type of fuelimproves. This is discovered for different dwell angles. This is becausewhen the SOI is advanced, the ignition delay of the first injection willincrease, causing more homogeneous mixture to form. This leads to amore complete combustion. Besides, according to Fig. 6, the peak heatrelease rate (PHRR) occurred nearest to top dead center (TDC) at the

Table 2Engine operating condition.

Fixed parameter Value

Engine angular velocity 2000 rpmTorque 60 NmFuel injection strategy Two-stageMass ratio (first: second) 50:50

Fig. 2. Timing chart at three different dwell angle and with first SOI of-6°ATDC.

Table 3Test cases.

Variable parameter Level

Types of fuel Baseline diesel, B20, and B50First injection SOI timings (°ATDC) −12, −10, −8, −6, −4, −2, 0, 2Dwell angles (°CA) 12, 15, 18

= +

+ + +

+ +

Overall experimental uncertainty Square root of [(uncertainty of Fuel Flow Rate)(uncertainty of BSFC) (uncertainty of BTE) (uncertainty of NO ) (uncertainty of Smoke)

(uncertainty of pressure sensor) (uncertainty of crank angle encoder) ]

2

2 2x

2 2

2 2

Y.H. Teoh et al. Fuel 234 (2018) 227–237

230

most advanced SOI. This will produce higher effective pressure toperform greater useful work [35]. Nevertheless, for the correspondingSOI timing, slight fall of BTE level occurred with a value of 0.1% and1.6% for the case of dwell angles of 15°CA and 18°CA, respectively, incomparison with that of baseline diesel at 12°CA dwell angle. Peakpressure might decrease when dwell angle is increased where the usefulwork done on the piston drops [20,28]. Besides, heat loss might in-crease with longer combustion process for dwell angles of 15°CA and18°CA. The energy which is converted into useful mechanical work may

be less. Another possible explanation is that at retarded crank angle,cylinder expansion cooling effect may take place. The volume of cy-linder will increase quickly where the increment rate of pressure will belower. Effective pressure which is lower can be achieved and this pro-duces a lower power output [36]. On the other hand, by zeroing in ontest case with SOI of -6°ATDC and dwell angle of 12°CA, it can be seenthat increasing percentage of biodiesel blend reduced the BTE level.This phenomenon is observed in test case with different SOI timings anddwell angles and the trend is also reported by other researchers[5,7,37]. One of the reasons may be that the properties of biodiesel wasdifferent from baseline diesel. Diesel engine used was not specificallytailored to be operated with biodiesel. Furthermore, oxygen content ofbiodiesel blends was higher than that of pure diesel. This might affectbiodiesel blends in such a way that the fuel’s calorific value will belower compared to that of pure diesel as indicated in Table 5. Lowerpart of Fig. 3 depicts the variation of BSFC with changing engineparameters. When B20 or B50 biodiesel blend was used to run dieselengine, the BSFC value obtained was invariably larger than that ofpetroleum diesel across every SOI timing and dwell angle. This phe-nomenon is aligned with Atul Dhar et al. [29], H. Raheman et al. [7],Cenk Sayin et al. [22] and T. Ganapathy [6]. When higher BSFC isobserved, more fuel is necessary to maintain the same power output.

Table 4Chemical and physical properties of baseline diesel and neat COB.

Chemical/Physical Properties Units Standards COB Biodiesel Limit (ASTM D6751) Diesel Diesel [32,33]

Kinematic viscosity at temperature 40 °C mm2/s ASTM D445 4.02 1.9–6.0 2.99 2.91Flash point °C ASTM D93 145.5 130min 71.5 71.5Density at 40 °C kg/m3 ASTM D1298 856.0 – 825.6 839.0Pour point °C ASTM D97 3 Not specified 0 1.0Cloud point °C ASTM D2500 4 Not specified 3 2.0Acid value mg KOH/g ASTM D664 0.05 0.5 max – 0.17Cold filter plugging point °C ASTM D6371 7 Not specified 5 −8.0Calorific/Heating value MJ/kg ASTM D240 39.92 – 45.21 45.825Oxidation stability H EN ISO 14112 15.8 3min > 100.0 23.70Carbon content %wt ASTM D 5291 73.2 – 86.1 88.5Hydrogen content %wt 12.5 – 13.8 13.5Nitrogen content %wt < 0.1 – < 0.1 –Oxygen content %wt Calculation 14.3 – 0.1 0.0Water content %wt EN ISO 12937 0.021 < 500 ppm 0.012 0.0038Copper Strip Corrosion (3 h @ 50 °C) – ASTM D 130 1a 1 1a 1aDistillation: °C D86 Distillation temperature, 90% recovered (T90)=360 °C maxInitial boiling point 192 165.5 182.75% recovery 240 220 212.410% recovery 249 240 225.520% recovery 260 262.5 246.130% recovery 269 276.5 261.040% recovery 276 288.5 274.650% recovery 284 298.5 286.960% recovery 294 309 299.470% recovery 312 320 312.780% recovery 321 333 327.890% recovery 324 351 346.1Final boiling point 324 374 366.0

Table 5Notable chemical and physical properties of baseline diesel, COB, B20 and B50.

Physical/ChemicalProperties

Units Diesel COB B20 B50 Test method

Calorific/HeatingValue

MJ/kg 45.21 39.92 44.60 42.79 ASTM D240

Density at 40 °C kg/m3 825.6 856.0 831.3 840.1 ASTM D1298Flash Point °C 71.5 145.5 74 80.5 ASTM D93Kinematic viscosity

at 40 °Cmm2/s 2.985 4.02 3.204 3.491 ASTM D445

Oxidation Stability h >100.0 15.8 89.48 51.44 EN ISO14112

Table 6Summary of measurement range, accuracy and percentage uncertainties.

Measurement Measurement range Accuracy Measurement techniques % Uncertainty

Load ± 600 Nm ±0.1 Nm Strain gauge type load cell ± 0.25Speed 0–10,000 rpm ±1 rpm Magnetic pick up type ±0.1Time – ±0.1 s – ±0.2Fuel flow measurement 0.5–36 L/h ±0.04 L/h Positive displacement gear wheel flow meter ±0.5NOx 0–5000 ppm ±1 ppm Electrochemical ± 1.3Smoke 0–100% ±0.1% Photodiode detector ±1Pressure sensor 0–25,000 kPa ±10 kPa Piezoelectric crystal type ±0.5Crank angle encoder 0–12,000 rpm ±0.125° Incremental optical encoder ±0.03

ComputedBSFC – ±5 g/kWh – ±1.5BTE – ±0.5% – ±1.7

Y.H. Teoh et al. Fuel 234 (2018) 227–237

231

This is not surprising in view of the lower calorific value of B20 and B50biodiesel blends in comparison with that of baseline diesel, which isapproximately 1.4% and 5.4%, respectively lower. In addition, changesin injection timing may influence the BSFC profoundly. Advancing SOItiming from crank angle of 2°ATDC to -12°ATDC occasioned the re-duction in BSFC when different fuels were tested. This is in accordancewith results obtained by M. Badami et al. [38]. According to S. KevinChen [39], by performing the first injection earlier, it is possible toreduce BSFC. The occurrence may be explained by the fact that whenSOI is carried out earlier, there is a constant refinement in the effec-tiveness and quality of combustion. With the same magnitude of brakepower output, the decreasing BSFC implies that less fuel was supplied toenable a more effective combustion process to occur. Besides, for mostof the SOI timings, the BSFC elevated with the larger dwell angles forevery type of fuel. These outcomes are congruous with other re-searchers’ observations [17,38–40]. At retarded SOI timing of secondinjection due to large dwell angle, turbulence effect may be low. Theless enhanced mixing of air and fuel might result in incomplete com-bustion where energy produced might be lower. Besides, at retardedcrank angle, expansion cooling effect may take place and result in lowerrate of combustion. Another reasonable explanation is that the longercombustion period might have increased the amount of heat loss whendwell angle is increased. As a consequence, BSFC had to be greater togenerate more energy.

3.2. Emissions characteristics

Impacts of percentage of biodiesel blends, SOI timing and dwellangle on NOx and smoke emissions are analyzed in the section below.The NOx amount released when different test fuels were utilized atvarying SOI timings and dwell angles is delineated in Fig. 4. The graphshows that advancing SOI timing gave rise in NOx level for every testfuel and dwell angle. Research by Atul Dhar et al. [29] also showed thatNOx emission amount increased with advancing injection timing. Theincreasing pattern in NOx indicates that with SOI implemented earlier,the mixture of air and fuel can be ignited and burnt in advance,therefore causing early formation of pressure peak near TDC. Thisbrings a greater combustion temperature and aids in thermal or Zel-dovich NOx formation. Moreover, according to Wenyi Liu et al. [28],when late second injection was carried out due to retarded SOI, thecylinder volume expansion and heat transfer reduced the temperature,causing NOx emission amount to decrease. The outcome also pointedout that both of the B20 and B50 biodiesel blends showed a tendency to

reduce the NOx released across every SOI timing and dwell angle. Be-sides, the B20 and B50 biodiesel blends have a lower calorific value andgreater cetane number in comparison with that of baseline diesel. As aresult, lower heat release rate (HRR) and peak mean gas temperature(PMGT) may develop during premix combustion stage. This finding canbe explained by observing the peak mean gas temperature (PMGT) datatabulated in Fig. 6. Moreover, a considerably low level of NOx near110 ppm was achievable via late SOI timing for fuel operations con-ducted using B20 or B50 biodiesel blends with dwell angle 18°CA. Theincrease in dwell angle caused slight decrease in NOx emission for allfuels and SOI cases. The observation is compatible with the researchresults of B. Yang et al. [41], Wenyi Liu et al. [28], Atul Dhar et al. [29],S. Kevin Chen [39] and Donghui Qi et al. [17]. With retarded injection,the combustion phase occurs late and may be located in expansionstroke, away from TDC. This phenomenon results in decreased tem-perature of combustion and less NOx formation. Besides, the con-centration of oxygen is lower at retarded crank angle. Less oxygenatoms were available to react with nitrogen atoms to form NOx mole-cules. In addition, according to M. Pontoppidan et al. [42], the rise oftemperature with respect to single injection containing both first andsecond injection, occurs at a higher level, if the first injection is keptclose to the second injection. However, if the second injection is per-formed further from first injection, the total duration for the wholeprocess to occur will increase. The injected mass fraction during eachinjection will be reduced, leading to a leaner mixture burnt at a lowertemperature. As a result, NOx emission amount will decrease. Accordingto G.M. Bianchi et al. [43], when dwell angle between two injections isreduced, the mass of fuel burnt at high temperature will increase,causing the NOx emission amount to increase. Smoke formation hap-pens due to ineffective combustion of hydrocarbon and partial reactionof carbon content in diesel. The smoke amount released for test caseswith different fuels at various SOI timings and dwell angles is displayedin Fig. 4. Overall, it can be observed that amount of smoke emitted waslower when B20 or B50 biodiesel blend is employed at different SOItimings. Ji Zhang et al. [44] and Shivakumar et al. [5] discovered thatthe amount of soot which leads to smoke of biodiesel is less thanbaseline diesel. According to Joonho Jeon et al. [23], even though sootparticles are formed at high production rate when biodiesel is burnt, thesoot is eliminated by the active oxidation process. Lower smoke level ofcombustion of biodiesel is attributed to more oxygen, less carboncontent and non-existing or low quantity of aromatic compound inbiodiesel [45,46]. Moreover, when SOI is retarded, the smoke emissionamount generally increased for all fuels across all dwell angle. This

Fig. 3. BTE and BSFC data for different biodiesel blends, SOI timings and dwell angles.

Y.H. Teoh et al. Fuel 234 (2018) 227–237

232

result is compatible with findings of Shivakumar et al. [5], T. Gana-pathy et al. [6], S. Saravanan et al. [47] and Takeshi Hashizume et al.[48]. Advanced SOI timing may increase in-cylinder gas temperatures.This enhances the chemical reaction between fuel and oxygen, subse-quently giving rise to less smoke emitted. A second possible reason isthe fact that sufficient time may be available for the evaporation andmixing of fuel with air to happen, resulting in more effective mixingand combustion. In addition, when SOI of first injection was retarded,the injection was performed nearer to TDC where the piston wall wascloser to the injector. The fuel injected may be impinged on the pistonwall easily, causing the quenching of fuel by wall to occur [42]. Thisreduces the temperature of fuel and cause incomplete combustion.When SOI is more than -2°ATDC onwards, the smoke emission amountexhibited a decreasing trend for most of the SOI and fuels when dwellangle was increased. The observation is in accordance with Cheol-woong Park et al. [20], Takeshi Hashizume et al. [48] and Khanh Cunget al. [25] research. When the dwell angle between two injections issmall, the ignition delay for second injection will be short. The dieselinjected during second injection may not have enough time to mix withthe air. Besides, the diesel might be injected directly at the flame pro-duced via first injection. The combustion during first injection may belack of oxygen because the diesel from second injection entrains theburnt gas of first injection. This causes low heat release rate and tem-perature, resulting in large amount of smoke released. When the in-jection strategy employing B50 biodiesel blends and 18°CA dwell anglewas conducted, smoke emission amount decreased while showing areduction in NOx at the same time. The results indicate that with re-tardation of SOI, a low NOx emission of 110 ppm was achieved withsmoke emission level still remained below 6%. Hence, simultaneousNOx and smoke amount decrement compared to that of petroleumdiesel is viable with the application of B50 biodiesel blend and im-plementation of retarded SOI timing and larger dwell angle of 18°CA inthe test engine.

3.3. Combustion characteristics

Using pressure sensor, pressure developed in cylinder can be ob-tained and recorded for 100 successive cycles. The average value ofpressure was calculated for each crank angle. Subsequently HRR wasevaluated from pressure value. Fig. 5 depicts the combustion pressurecurve, HRR curve and profile of injector current of test engine run usingpetroleum diesel at -6°ATDC SOI timing with varying dwell angles. It isclearly shown by the Fig. 5 that every test case investigated involved

two similar injection pulses. Due to longer combustion period, heat losswhen longer dwell angle was applied was more and greater amount offuel was injected to compensate the energy loss. This resulted in longerinjection current and injector activation timing. It can be observed thatdifference in dwell angles affects the combustion characteristics. Thepressure peak increased with increasing dwell angles. After the peakpressure occurs, the rate of decrease in pressure was higher with longerdwell angle, where the pressure when dwell angle was set as 12°CA wasthe highest after 15°ATDC. The starts of combustion (SOC) of all testcases conducted happened at the same crank angle. One of the factorswhich influences SOC timing is the quantity of fuel injected. If a largeamount of fuel is introduced, a longer air-fuel mixing time might berequired and this will cause a retarded SOC timing. Since the amount offuel injected were similar for every test case implemented, the SOCoccurred at the same crank angle. Two noteworthy HRR peaks can benoticed for every dwell angle. First peaks of HRR of different test caseswere formed at almost the same crank angle due to the equal amount offuel injected at the same SOI timing. However, the second peaks of HRRwere located at different crank angles when different dwell angles wereapplied. The shorter the dwell angles, the more advanced the secondpeak of HRR was. Ignition delay_1 is longer than ignition delay_2 whenthe dwell angle was set as 12°CA and 15°CA. This is due to the highcylinder temperature when second injection is performed. The injectionof fuel towards main combustion zone which formed during the first

Fig. 4. NOx and smoke emission data for different biodiesel blends, SOI timings and dwell angles.

Fig. 5. Combustion pressure, HRR and injector current data for test case em-ploying baseline diesel with different dwell angles at -6°ATDC SOI.

Y.H. Teoh et al. Fuel 234 (2018) 227–237

233

injection causes the fuel to burn immediately. Comparing ignitiondelay_2 of test cases with different dwell angle, it is observed that thegreater the dwell angle, the longer the ignition delay_2. This is attri-butable to the lower cylinder temperature achieved after passing alonger dwell angle. Larger heat loss and expansion cooling effect mayhave taken place where low temperature results in longer time requiredto heat up the fuel.

Influences of percentage of biodiesel blend, SOI timing and dwellangle on peak mean gas temperature (PMGT) and peak heat release rate(PHRR) are examined in section below. Fig. 6 shows the changes inPMGT with various SOI timings and dwell angles of test engine fuelledwith baseline diesel, B20 and B50 biodiesel blends. There was noconsistent trend observed with increasing percentage of biodieselblends. However, the variation in SOI timing did give rise to con-siderably constant pattern. For every type of fuel and injection dwellangle tested, it was discovered that initially PMGT decreased with re-tarding SOI timing until a minimum PMGT value was reached aroundSOI timing of -6°ATDC. Then, with SOI performed later, PMGT rose.The initial decrement in PMGT value can be attributed to the lowerpeak pressure developed nearer to TDC when SOI timing was retardedbased on Fig. 7. Due to the low peak pressure, PMGT achieved will belower. With retarding SOI timing from -12°ATDC to -6°ATDC, the peakpressure may occur at late crank angle and decrease on account of thecylinder expansion, causing a decrease in temperature. The elevation ofPMGT with retarding SOI timing when SOI is perform late at the rangeof -6°ATDC to 2°ATDC can be explained by observing BSFC trend fromFig. 3 and HRR curve from Fig. 7. With late SOI timing, combustionoccurs at crank angle when the volume of cylinder is large and rate ofexpansion is rapid. In order to develop ample pressure to produce en-ough effective work done to maintain equal power output, temperatureachieved in cylinder has to be high. Combustion of larger amount offuel is evident by observing Fig. 3 where BSFC increased with retardingSOI timing. This may lead to a higher HRR peak as delineated in Fig. 7,which subsequently resulted in higher PMGT. On the other hand, it canbe seen that when dwell angle is fixed as 18°CA, the PMGT values at-tained for most of the test cases associated were lower than theircounterparts when dwell angle was 12°CA or 15°CA. This may indicatethat longer dwell angle will cause a decrease in PMGT developed. Thesame observation was reported by Takeshi Hashizume et al. [48] too.When dwell angle is increased, combustion will continue for a longerduration. The fuel burnt per unit time will reduce, where the rate ofrising of temperature will be lower. Expansion cooling effect also fur-ther promotes the decrement in cylinder temperature. As a result,

Fig. 6. Peak mean gas temperature (PMGT) and peak heat release rate (PHRR) for different fuels, SOI timings and dwell angles.

Fig. 7. In-cylinder gas pressure and HRR curves for dwell angle of a) 12°CA, b)15°CA, and c) 18°CA under different SOI timings using baseline diesel.

Y.H. Teoh et al. Fuel 234 (2018) 227–237

234

PMGT achieved will be lower. Peak HRR (PHRR) is also one of thenoteworthy variables associated with combustion characteristics. FromFig. 6, it is delineated that B20 and B50 biodiesel blends exhibit PHRRwhich was constantly less than that of pure diesel when different SOItimings and dwell angles were tested. The trend was observed by SeungHyunYoon et al. [49], Ji Zhang et al. [44] and T. Ganapathy et al. [6] intheir studies. The trend occurs primarily owing to the greater cetanenumber of biodiesel in comparison with that of petroleum diesel, thusleading to shorter ignition delay and smaller PHRR, as described insection before. When SOI is retarded, PHRR during the premixedcombustion phase may increase when different biodiesel blends areused at any dwell angle. This observation is compatible with Cheol-woong Park et al.’s [20] and S. Kevin Chen’s [39] findings where heatrelease increases when pilot injection is performed nearer to TDC. Thecombustion phase may occur at a more retarded crank angle which isfurther away from TDC when injection is performed at a later timing.The pressure produced will then be lower due to cylinder volume ex-pansion process. The useful work done on the piston will be lower. Tocompensate the decrease in work done, BSFC increases as higheramount of fuel is injected according to Fig. 3. As a result, the com-bustion will continue for a longer time where HRR can rise to a highervalue before the fuel is burnt out. Also, it can be seen that PHRR in-creased slightly when dwell angle is increased from dwell angle of12°CA to 15°CA. This trend happened for most of the SOI applied. At adwell angle equals to 12°CA, the interval between two injections maybe too short [20]. The second injection might be introduced to theflame produced by the combustion of first injection. The fuel injectedduring second injection will entrain the burnt gas, reducing the amountof oxygen required for combustion. As a result, PHRR achieved whendwell angle was fixed as 12°CA was lower. When dwell angle was in-creased from 15°CA to 18°CA, PHRR decreased slightly at most of theSOI tested. Combustion duration may increase with increasing dwellangle. Amount of fuel burnt per unit time might decrease, causingPHRR to drop.

Dwell angle is one of the parameters which can be adjusted to im-prove the NOx and smoke emission amount. Fig. 7 displays the data ofcombustion pressure and HRR for dwell angles of 12°CA, 15°CA and18°CA at different SOI timings when baseline diesel is utilized. Theinfluences of dwell angle on in-cylinder gas pressure and HRR areanalyzed here by directly comparing outcomes of corresponding SOItimings under dwell angle subgroups. The comparison enables one topoint out the differences in the combustion events that are responsiblefor results observed in NOx and smoke emissions. The HRR data col-lected signified that the two combustion events began to deviate as thefirst fuel injection pulse of double injection had been stopped after apremixed combustion of about the similar intensity, which can beevidently observed in Fig. 5. Combustion process which occurred afterthe premixed combustion phase during the duration between SOI_1 andSOI_2 featured a high initial in-cylinder gas temperature by virtue of theburning of a huge amount of fuel injected during the first injection. Forthis reason, the second injection fuel was combusted in the form ofdiffusion flame. Only a very short ignition delay was available for themixing process of fuel and hot gases to transpire. The successive fuelinjection led to another lower HRR peak and rise in flame temperature,which happened for approximately 20° CA in combustion cycle. Theoccurrence enabled lower quantity of NOx to be produced. Thus, fur-ther optimization of multiple injection scheme in the context of NOxand smoke emissions amount was achieved by employing a larger dwellangle.

From Fig. 7, it is observed that peak pressure increased with ad-vancing SOI when baseline diesel was used. This observation was ob-tained for different dwell angles. Atul Dhar et al. [29], T. Ganapathyet al. [6], Joonho Jeon et al. [23] and Hongyuan Wei et al. [50] dis-covered the same trend in their research. According to heat release ratecurve, when SOI was advanced, the start of combustion happenednearer to TDC. This produces a higher pressure at TDC and creates a

larger useful work done. Retarding SOI may cause the combustion tooccur at a later timing, where cylinder volume expansion happens. Thepeak pressure achieved will be lower and the useful work done will bereduced. Besides, when SOI is advanced, a longer ignition delay will beavailable before the pressure and temperature is high enough to initiatecombustion [4]. The air-fuel mixing time will be longer to enable amore complete combustion to occur and thus leads to a higher tem-perature and pressure. Therefore, advancing SOI can cause the peakpressure and PHRR to occur at an earlier crank angle [50].

Referring to Fig. 8, when dwell angle was set as 12°CA and SOI wasfixed as -6°ATDC, the start of combustion was advanced when thepercentage of biodiesel blends increased. On dwell angle equal to 15°CAand 18°CA, the same trend was observed. The result is compatible withJi Zhang et al. [44], T. Ganapathy et al. [6] and Seung Hyun Yoon et al.[49] research finding. This is because biodiesel has a higher cetanenumber, bulk modulus, sound velocity and viscosity [46,51–53]. Itsignition delay is shorter, causing it to burn earlier. However, PHRRdecreases with increasing percentage of biodiesel blends [49]. The ig-nition delay of biodiesel is shorter, resulting in less air-fuel mixing time.The combustion of the biodiesel will be less intense compared tobaseline diesel, thus producing a lower PHRR. Besides, the calorificvalue of biodiesel is also less than baseline diesel [44]. With same

Fig. 8. In-cylinder gas pressure and HRR curves for dwell angle of a) 12°CA, b)15°CA, and c) 18°CA using different fuels at SOI of -6°ATDC.

Y.H. Teoh et al. Fuel 234 (2018) 227–237

235

amount of fuel burnt, the heat released by biodiesel will be lesser. WhenPHRR is lower, the heat released will be lower. Thus, the peak pressuredeveloped by burning biodiesel at any dwell angle was smaller, asshown in Fig. 8 [49]. It is observed that the start of combustion ofsecond injection was slightly advanced for baseline diesel compared tobiodiesel even though the SOI of second injection was fixed at 6°ATDCwhen dwell angle was 12°CA. This can be due to the higher PHRRachieved during the first injection by using baseline diesel. The gastemperature after the combustion of the first injection of baseline dieselis higher. This condition reduces the ignition delay of second injection,leading to an advanced start of combustion of baseline diesel.

Referring to Fig. 9, when baseline diesel was used at SOI equals-6°ATDC, the heat release rate when dwell angle was 12°CA dropped ata higher rate after the first PHRR was reached compared to dwell anglesof 15°CA and 18°CA. This happened to B20 and B50 biodiesel as well.When a shorter dwell angle is used, the second injection will be in-troduced to the flame produced by the combustion of first injection. Thegas temperature and the oxygen amount available for combustion de-creases due to the second injection diesel vaporization. As a result, thesecond injection which is close to the combustion of first injection willinterrupt with the combustion and causes the rapid drop in heat releaserate [38]. The earlier reduction in heat release rate will also cause thepeak pressure to decrease due to less energy produced near TDC. This

explains the lower peak pressure achieved when shorter dwell anglewas set. In addition, it is found that PHRR of second injection com-bustion was higher when dwell angle of 12°CA was applied compared todwell angle of 15°CA and 18°CA. Smaller dwell angle may shorten thecombustion duration, causing the same amount of fuel to be burnt at ashorter time interval, hence increasing HRR of second peak. Whendwell angle increases, the second injection will be performed at a re-tarded timing further away from TDC. Expansion of cylinder volumewill cause reduction in pressure and gas temperature, therefore low-ering the rate of combustion of second injection diesel. Besides, a longerdwell angle may increase the heat loss during the entire period ofcombustion process [29]. Moreover, the direct comparison of variousdwell angles under SOI timing of -6°ATDC also showed slight differencein the peak pressure and second PHRR. Combustion phasing is one ofthe factors which responsible for diesel engine smoke emissions. Thediesel combustion with longer dwell angle can be performed to enable alonger ignition delay for better air-fuel mixing. This enables a sufficientoxidation of air-fuel mixture to happen. The favorable impact of sootoxidation in the last combustion phase could be noticed when smokeemission becomes lower, as what is displayed in Fig. 4 when longerdwell angle of 18°CA was applied compared to dwell angle of 15°CAand 12°CA.

4. Conclusion

The engine operating parameters such as biodiesel blend ratios, SOItiming and dwell angle have been investigated in this paper. Differentcombinations of the parameters have been implemented to understandtheir impacts on the characteristics of combustion. Via this study, theoptimum conditions where the pollutant emissions highlighted arelessened simultaneously have been inferred. Conclusions on the opti-mized injection strategies are made as follow:

1. Biodiesel blend ratio and SOI timing affect exhaust emissions, en-gine performance and combustion characteristics significantly whiledwell angle causes a slight variation in the outcome studied.

2. Increase in percentage of biodiesel blends causes reduction in NOx

and smoke emission amount.3. Retarded SOI timing improves NOx emission but this occurs in the

expense of increasing smoke emission.4. By retarding SOI timing in conjunction with long dwell angle, it is

possible to reduce NOx emission without causing much increase insmoke emission.

Acknowledgments

The authors would like to acknowledge the Ministry of HigherEducation (MOHE) of Malaysia, Universiti Malaya, KDU PenangUniversity College Internal Research Grant and Universiti SainsMalaysia (BRIDGING research grant scheme-304/PMEKANIK/6316119) for financial support towards this research project.

References

[1] Heywood J. Internal combustion engine fundamentals. McGraw-Hill Education;1988.

[2] Demirbas A. Importance of biodiesel as transportation fuel. Energy Policy2007;35(9):4661–70.

[3] Ma F, Hanna MA. Biodiesel production: a review1Journal Series #12109,Agricultural Research Division, Institute of Agriculture and Natural Resources,University of Nebraska-Lincoln. 1. Bioresour Technol 1999;70(1):1–15.

[4] Mohamed Shameer P, et al. Effects of fuel injection parameters on emission char-acteristics of diesel engines operating on various biodiesel: a review. Renew SustainEnergy Rev 2017;67:1267–81.

[5] Shivakumar, Srinivasa Pai P, Shrinivasa Rao BR. Artificial Neural Network basedprediction of performance and emission characteristics of a variable compressionratio CI engine using WCO as a biodiesel at different injection timings. Appl Energy2011;88(7):2344–54.

[6] Ganapathy T, Gakkhar RP, Murugesan K. Influence of injection timing on

Fig. 9. In-cylinder gas pressure and HRR curves using a) baseline diesel, b) B20,and c) B50 with different dwell angles at SOI of -6°ATDC.

Y.H. Teoh et al. Fuel 234 (2018) 227–237

236

performance, combustion and emission characteristics of Jatropha biodiesel engine.Appl Energy 2011;88(12):4376–86.

[7] Raheman H, Ghadge SV. Performance of compression ignition engine with mahua(Madhuca indica) biodiesel. Fuel 2007;86(16):2568–73.

[8] Park SH, Yoon SH, Lee CS. Effects of multiple-injection strategies on overall spraybehavior, combustion, and emissions reduction characteristics of biodiesel fuel.Appl Energy 2011;88(1):88–98.

[9] Roh HG, Lee D, Lee CS. Impact of DME-biodiesel, diesel-biodiesel and diesel fuels onthe combustion and emission reduction characteristics of a CI engine according topilot and single injection strategies. J Energy Inst 2015;88(4):376–85.

[10] Suh HK. Investigations of multiple injection strategies for the improvement ofcombustion and exhaust emissions characteristics in a low compression ratio (CR)engine. Appl Energy 2011;88(12):5013–9.

[11] Allocca L, et al. Evaluation of RME (rapeseed methyl ester) and mineral diesel fuelsbehaviour in quiescent vessel and EURO 5 engine. Energy 2014;77:783–90.

[12] Iannuzzi SE, Valentino G. Comparative behavior of gasoline–diesel/butanol–dieselblends and injection strategy management on performance and emissions of a lightduty diesel engine. Energy 2014;71:321–31.

[13] Alptekin E. Emission, injection and combustion characteristics of biodiesel andoxygenated fuel blends in a common rail diesel engine. Energy 2017;119:44–52.

[14] Anand K, Reitz RD. Exploring the benefits of multiple injections in low temperaturecombustion using a diesel surrogate model. Fuel 2016;165:341–50.

[15] Jafarmadar S, Nemati P. Numerical investigation of the effect split injection schemeon exergy terms in an IDI (indirect injection) diesel engine by three dimensionalmodeling. Energy 2015;93:2280–91.

[16] Choi CY, Reitz RD. An experimental study on the effects of oxygenated fuel blendsand multiple injection strategies on DI diesel engine emissions. Fuel1999;78(11):1303–17.

[17] Qi D, et al. Effect of EGR and injection timing on combustion and emission char-acteristics of split injection strategy DI-diesel engine fueled with biodiesel. Fuel2011;90(5):1884–91.

[18] Kim MY, Yoon SH, Lee CS. Impact of split injection strategy on the exhaust emis-sions and soot particulates from a compression ignition engine fueled with neatbiodiesel. Energy Fuels 2008;22(2):1260–5.

[19] Stringer VL, et al. Combustion and emissions of biodiesel and diesel fuels in directinjection compression ignition engines using multiple injection strategies. SAETechnical Paper. 2008-01-1388. doi: 10.4271/2008-01-1388.

[20] Park C, Kook S, Bae C. Effects of multiple injections in a HSDI diesel engineequipped with common rail injection system. SAE Technical Paper. 2004-01-0127.doi: 10.4271/2004-01-0127.

[21] How HG, et al. Influence of injection timing and split injection strategies on per-formance, emissions, and combustion characteristics of diesel engine fueled withbiodiesel blended fuels. Fuel 2018;213:106–14.

[22] Sayin C, Gumus M. Impact of compression ratio and injection parameters on theperformance and emissions of a DI diesel engine fueled with biodiesel-blendeddiesel fuel. Appl Therm Eng 2011;31(16):3182–8.

[23] Jeon J, Park S. Effects of pilot injection strategies on the flame temperature and sootdistributions in an optical CI engine fueled with biodiesel and conventional diesel.Appl Energy 2015;160:581–91.

[24] Adams CA, et al. Effects of biodiesel–gasoline blends on gasoline direct-injectioncompression ignition (GCI) combustion. Fuel 2013;111:784–90.

[25] Cung K, et al. Spray–combustion interaction mechanism of multiple-injection underdiesel engine conditions. Proc Combust Inst 2015;35(3):3061–8.

[26] Rohani B, Bae C. Effect of exhaust gas recirculation (EGR) and multiple injectionson diesel soot nano-structure and reactivity. Appl Therm Eng 2017;116:160–9.

[27] Mathivanan K, Mallikarjuna JM, Ramesh A. Influence of multiple fuel injectionstrategies on performance and combustion characteristics of a diesel fuelled HCCIengine – an experimental investigation. Exp Therm Fluid Sci 2016;77:337–46.

[28] Liu W, Song C. Effect of post injection strategy on regulated exhaust emissions andparticulate matter in a HSDI diesel engine. Fuel 2016;185:1–9.

[29] Dhar A, Agarwal AK. Experimental investigations of the effect of pilot injection onperformance, emissions and combustion characteristics of Karanja biodiesel fuelledCRDI engine. Energy Convers Manage 2015;93:357–66.

[30] Malouf FTC, Bauer SM, Moskwa TJJ. A second generation heat transfer simulatorfor single-cylinder engines to replicate multi-cylinder engine dynamics. IFAC-

PapersOnLine 2015;48(15):30–7.[31] How HG, et al. An investigation of the engine performance, emissions and com-

bustion characteristics of coconut biodiesel in a high-pressure common-rail dieselengine. Energy 2014;69:749–59.

[32] Silitonga AS, et al. Experimental study on performance and exhaust emissions of adiesel engine fuelled with Ceiba pentandra biodiesel blends. Energy ConversManage 2013;76:828–36.

[33] Teoh YH, et al. Effect of injection timing and EGR on engine-out-responses of acommon-rail diesel engine fueled with neat biodiesel. RSC Adv2015;5(116):96080–96.

[34] How HG, et al. An investigation of the engine performance, emissions and com-bustion characteristics of coconut biodiesel in a high-pressure common-rail dieselengine. Energy 2014;69(Supplement C):749–59.

[35] Bari S, Yu CW, Lim TH. Effect of Fuel injection timing with waste cooking oil as afuel in a direct injection diesel engine. Proc Inst Mech Eng, Part D: J AutomobileEng 2004;218(1):93–104.

[36] Hampson GJ, Reitz RD. Two-color imaging of in-cylinder soot concentration andtemperature in a heavy-duty di diesel engine with comparison to multidimensionalmodeling for single and split injections. SAE Technical Paper. 980524. doi: 10.4271/980524.

[37] Yehliu K, Boehman AL, Armas O. Emissions from different alternative diesel fuelsoperating with single and split fuel injection. Fuel 2010;89(2):423–37.

[38] Badami M, et al. Influence of multiple injection strategies on emissions, combustionnoise and BSFC of a DI common rail diesel engine. SAE Technical Paper. 2002-01-0503. doi: 10.4271/2002-01-0503.

[39] Chen SK, Simultaneous reduction of NOx and particulate emissions by using mul-tiple injections in a small diesel engine. SAE Technical Paper. 2000-01-3084. doi:10.4271/2000-01-3084.

[40] d’Ambrosio S, Ferrari A. Potential of multiple injection strategies implementing theafter shot and optimized with the design of experiments procedure to improvediesel engine emissions and performance. Appl Energy 2015;155:933–46.

[41] Yang B, Mellor AM, Chen SK. Multiple injections with EGR effects on NOx emissionsfor DI diesel engines analyzed using an engineering model. SAE Technical Paper.2002-01-2774. doi: 10.4271/2002-01-2774.

[42] Pontoppidan M, et al. Study of the impact of variations in the diesel-nozzle geo-metry parameters on the layout of multiple injection strategy. SAE Technical Paper.2002-01-0217. doi: 10.4271/2002-01-0217.

[43] Bianchi GM, et al. Numerical analysis of passenger car HSDI diesel engines with the2nd generation of common rail injection systems: the effect of multiple injections onemissions. SAE Technical Paper. 2001-01-1068. doi: 10.4271/2001-01-1068.

[44] Zhang J, et al. Soot temperature and KL factor for biodiesel and diesel spraycombustion in a constant volume combustion chamber. Appl Energy2013;107:52–65.

[45] Canakci M, Erdil A, Arcaklioğlu E. Performance and exhaust emissions of a biodieselengine. Appl Energy 2006;83(6):594–605.

[46] Lapuerta M, Armas O, Rodríguez-Fernández J. Effect of biodiesel fuels on dieselengine emissions. Prog Energy Combust Sci 2008;34(2):198–223.

[47] Saravanan S, et al. Theoretical and experimental investigation on effect of injectiontiming on NOx emission of biodiesel blend. Energy 2014;66:216–21.

[48] Hashizume T, et al. Combustion and emission characteristics of multiple stage dieselcombustion. SAE Technical Paper. 980505. doi: 10.4271/980505.

[49] Yoon SH, Suh HK, Lee CS. Effect of spray and EGR rate on the combustion andemission characteristics of biodiesel fuel in a compression ignition engine. EnergyFuels 2009;23(3):1486–93.

[50] Wei H, et al. Experimental investigations of the effects of pilot injection on com-bustion and gaseous emission characteristics of diesel/methanol dual fuel engine.Fuel 2017;188:427–41.

[51] Alam M, et al., Combustion and emissions performance of low sulfur, ultra lowsulfur and biodiesel blends in a DI diesel engine. SAE Technical Paper. 2004-01-3024. doi: 10.4271/2004-01-3024.

[52] Szybist JP, et al. Evaluation of formulation strategies to eliminate the biodiesel NOxeffect. Fuel Process Technol 2005;86(10):1109–26.

[53] Monyem A, Van Gerpen H, Canakci M. The effect of timing and oxidation onemissions from biodiesel-fueled engines. Trans ASAE 2001;44(1):35.

Y.H. Teoh et al. Fuel 234 (2018) 227–237

237