Effect of Grout Properties on the Pull-out Load Capacity of Fully Grouted Rock Bolts

-

Upload

krainajacka -

Category

Documents

-

view

15 -

download

4

description

Transcript of Effect of Grout Properties on the Pull-out Load Capacity of Fully Grouted Rock Bolts

-

Tunnelling and Underground Space Technology 17 (2002) 355362

0886-7798/02/$ - see front matter 2002 Elsevier Science Ltd. All rights reserved.PII: S0886-7798 02 .00038-X

Effect of grout properties on the pull-out load capacity of fully groutedrock bolt

A. Klc, E. Yasar*, A.G. CelikDepartment of Mining Engineering, Cukurova University, 01330 Balcal, Adana, Turkey

Received 30 October 2001; received in revised form 30 April 2002; accepted 24 May 2002

Abstract

This paper represents the result of a project conducted with developing a safe, practical and economical support system forengineering workings. In rock engineering, untensioned, fully cement-grouted rock bolts have been used for many years. However,there is only limited information about the action and the pull-out load capacity of rock bolts, and the relationship between boltgrout or groutrock and the influence of the grout properties on the pull-out load capacity of a rock bolt. The effect of groutproperties on the ultimate bolt load capacity in a pull-out test has been investigated in order to evaluate the support effect of rockbolts. Approximately 80 laboratory rock bolt pull-out tests in basalt blocks have been carried out in order to explain and developthe relations between the grouting materials and untensioned, fully grouted rock bolts. The effects of the mechanical propertiesof grouting materials on the pull-out load capacity of a fully grouted bolt have been qualified and a number of empirical formulaehave been developed for the calculating of the pull-out load capacity of the fully cement-grouted bolts on the basis of the shearstrength, the uniaxial compressive strength of the grouting material, the bolt length, the bolt diameter, the bonding area and thecuring time of the grouting material. 2002 Elsevier Science Ltd. All rights reserved.

Keywords: Rock bolt; Grouting materials; Bolt pull-out load capacity; Bolt geometry; Mortar

1. Introduction

In rock engineering, rock bolts have been used tostabilise openings for many years. The rock boltingsystem may improve the competence of disturbed rockmasses by preventing joint movements, forcing the rockmass to support itself (Kaiser et al., 1992). The supporteffect of rock bolt has been discussed by many research-ers (e.g. Hyett et al., 1992; Ito et al., 2001; Reichert etal., 1991 and Stillborg, 1984). Rock bolt binds togethera laminated, discontinued, fractured and jointed rockmass. Rock bolting not only strengthens or stabilizes ajointed rock mass, but also has a marked effect on therock mass stiffness (Chappell, 1989). Rock bolts per-form their task by one or a combination of severalmechanisms. Bolts often act to increase the stress andthe frictional strength across joints, encouraging looseblocks or thinly stratified beds to bind together and actas a composite beam (Franklin and Dusseault, 1989).

*Corresponding author.E-mail address: [email protected] (E. Yasar).

Rock bolts reinforce rock through a friction effect,through a suspension effect, or a combination of two.For this reason, rock bolt technique is acceptable forstrengthening of mine roadway and tunnelling in alltype of rock (Panek and McCormick, 1973).Generally rock bolts can be used to increase the

support of low forces due to the diameter and thestrength of the bolt materials. They enable high anchor-ing velocity to be used at closer spacing between bolts.Their design provides either mechanical clamping orcement grouting against the rock (Aldorf and Exner,1986).Anchorage system of rock bolt is normally made of

solid or tube formed steel installed untensioned ortensioned in the rock mass (Stillborg, 1986). Rock boltscan be divided into three main groups according to theiranchorage systems (Franklin and Dusseault, 1989;Aldorf and Exner, 1986; Hoek and Wood, 1989; Cybul-ski and Mazzoni, 1989). First group is the mechanicallyanchored rock bolts that can be divided into two groups:slit and wedge type rock bolt, expansion shell anchor.

-

356 A. Klc et al. / Tunnelling and Underground Space Technology 17 (2002) 355362

They can be fixed in the anchoring part either by awedge-shaped clamping part or by a threaded clampingpart. Second group is the friction-anchored rock boltsthat can be simply divided into two groups: split-set andswellex. Friction-anchored rock bolts stabilise the rockmass by friction of the outer covering of bolt againstthe drill hole side. The last group is the fully groutedrock bolts that can also be divided into two groups:cement-grouted rock bolts, resin grouted rock bolts.A grouted rock bolt (dowel) is a fully grouted rock

bolt without mechanical anchor, usually consisting of aribbed reinforcing bar, installed in a drill hole andbonded to the rock over its full length (Franklin andDusseault, 1989). Special attention should be paid tocement-grouted bolts and bolts bonded (glued, resined)by synthetics resins for bolt adjustment. Grouted boltsfix the using of the coherence of the sealing cementwith the bolt rod and the rock for fastening the bolts.Synthetic resin (resined bolt) and cement mortar (rein-forced-concrete bolt) can be used for this type rock bolt.These bolts may be anchored in all type of rock.Anchoring rods may be manufactured of several mate-rials such as ribbed steel rods, smooth steel bars, cablebolts and other special finish (Aldorf and Exner, 1986).Grouted bolts are widely used in mining for the

stabilisation of tunnelling, mining roadway, drifts andshafts for the reinforcing of its peripheries. Simplicityof installation, versatility and relatively low cost ofrebars are further benefits of grouted bolts is comparisonto their alternative counterparts (Indraratna and Kaiser,1990).Bolts are self-tensioning when the rock starts to move

and dilate. They should therefore be installed as soonas possible after excavation, before the rock has startedto deform, and before it has lost its interlocking andshear strength.Although several grout types are available, in many

applications where the rock has a measure of short termstability, simple Portland cement-grouted reinforcingdowels are sufficient. They can be installed by fillingthe drill hole with lean, quickly set mortar into whichthe bar is driven. The dowel is retained in up holeseither by a cheap form of end anchor, or by packing thedrill hole collar with cotton waste, steel wool, or woodenwedges (Franklin and Dusseault, 1989).Concrete grouted bolts use cement mortar as a bond-

ing medium. In drill holes at minimum of 158 belowthe horizontal plane, the mortar can simply poured in,whereas in raising drill holes (roof anchoring) variousdesign of bolts or other equipment is used to preventthe pumped mortar from flowing out (Aldorf and Exner,1986).The load bearing capacity of fully cement-grouted

rock bolts depends on the bolt shape, the bolt diameter,the bolt length, rock and grout strength. The bondstrength of fully cement-grouted rock bolts is primarily

frictional and depends on the shear strength at the boltgrout or groutrock interface. Thus any changes in thisinterfaces shear strength must affect the bolt bondstrength and bolt load capacity.This laboratory testing program was executed to

evaluate the shear strength effect on the bond strengthof the boltgrout interface of a threaded bar and thelaboratory test results confirm the theory.

2. Previous solutions

The effectiveness of a grouted bolt depends on itslength relative to the extent of the zone of overstressedrock or yield zone. The shear and axial stress distribu-tions of a grouted bolt are also related to the bolt lengthbecause equilibrium must be achieved between the boltand the surrounding ground (Indraratna and Kaiser,1990).Bearing capacities of cement-grouted rock bolts (P )b

and their anchoring forces are a function of the cohesionof the bonding agent and surrounding rock, and thebolting bar. The ultimate bearing capacity of the bolt(P ) is expressed as follows (Aldorf and Exner, 1986):m1P spd l C yk (1)m s d 1 b

where k , safety coefficient (usually k s1.5); C , cohe-b b 1sion of the bonding material on bolting bar, l , anchoreddlength of the bolt, d , bolt diameter.s11P spd l C yk (2)m v d 2 b

where d , drill hole diameter; C , cohesion of thev 2bonding material with surrounding rock (carboniferousrocks and polyester resins C s3 MPa).2111P spd l C yk (3)m s d 3 b

where C , shearing strength of the bonding materi-3al.The maximum (ultimate) bearing capacity of the bolt

(P ) will be the lowest value from P to P .1 111m m mBearing capacities of all type bolts must also be

evaluated from the view point of the tensile strength ofthe bolt material (P ), which must not be lower thanmsthe ultimate bearing capacity resulting from the anchor-ing forces of bolts in drill holes (P ). It holds thatmP 0P (4)ms mwhere P , the ultimate bearing capacity of the boltmswith respect of the tensile strength of the bolt material;P , the ultimate bearing capacity of the bolt.m

3. Laboratory study

3.1. Experiments

The pull-out tests were conducted on rebars, groutedinto basalt blocks with cement mortar in laboratory. Therelations between bolt diameter (d ) and pull-out loadbof bolt (P ) (Fig. 2), bolt area (A ) and pull-out loadb b

-

357A. Klc et al. / Tunnelling and Underground Space Technology 17 (2002) 355362

Table 1Influence of the bolt diameter on the bolt strength

db dd Lb Ab Pb tb(mm) (mm) (cm) (cm )2 (kN) (MPa)

10 20 24.2 76 43.2 5.6812 22 24.2 91 54.7 6.0114 24 24.2 106 59.2 5.5816 26 24.2 122 73.6 6.0318 28 24.2 137 81.6 5.96

Rock: Basalt; curing time: 35 days; wycs0.40; t s8.15 MPa.g

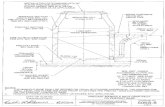

Fig. 1. Pull-out test set-up of rebar.

of bolt (P ) (Fig. 3), bolt length (L ) and pull-out loadb bof bolt (P ) (Fig. 5), water to cement ratio (wyc) andbbolt bond strength (t ) (Fig. 7), mechanical propertiesbof grout material and bolt bond strength (t ) (Fig. 9,bFigs. 10 and 11), and curing time (days) and boltstrength (Figs. 12 and 13) were evaluated by simplepull-out test programme.The samples consisted of rebars (ranging 1018 mm

diameters two by two) bonded into the basalt blocks.These basalt blocks used have a Youngs modulus of27.6 GPa and a uniaxial compressive strength (UCS )gof 133 MPa. Drilling holes which were 10 mm largerthan the bolt diameter, having a diameter of 2028 mmfor installation of bolts, were drilled up to 1532 cm indepth. The bolt was grouted with cement mortar. Thegrout was a mixture of Portland cement with a water tocement ratio of 0.34, 0.36, 0.38 and 0.40 cured for 28days. In order to obtain different grout types that havedifferent mechanical properties, siliceous sand N100 mm;500 mmM and fly ash N10 mm; 200 mmM were added ina proportion of 10% of cement weight and white cementwith a water to cement ratio of 0.40. The sand shouldbe well graded, with a maximum grain size of 2 mm(Schack et al., 1979). The Youngs modulus of thegrouts was measured during unconfined compressiontests and shear strength was calculated by means of ringshear tests.The test set-up is illustrated schematically in Fig. 1

and the procedure is explained below:

After filling prepared grout mortar into the hole, boltis inserted to the centre of drilling hole.

After curing time, the rebars in the rock were axiallyloaded and the load was gradually increased until thebolt failed.

The bond strength (t ) was then calculated by divid-bing the load (P ) by surface area (A ) of the bolt barb bin contact with the grout.

Pull-out tests were repeated for various grout types,bolt dimensions and curing times.The influence of the bolt diameter and the bond area

on the bond strength of a rock bolt can be formulatedas follows (Littlejohn and Bruce, 1975):t sP ypd l (5)b b b bwhere t , ultimate bolt bond strength (MPa); P , max-b bimum pull-out load of bolt (kN); d , bolt diameterb(mm); l , bolt length (cm); pd l , bonded area (cm ).2b b b

3.2. Analysis of laboratory test results

3.2.1. Influence of the bolt materialBolt diameters of 10, 12, 14, 16 and 18 mm were

used in pull-out tests. Typical results are represented inTable 1, Figs. 2 and 3. The most important observationswere:

(1) The maximum pull-out load (P ) increases line-barly with the section of the bolt while embedment lengthwas constant.

-

358 A. Klc et al. / Tunnelling and Underground Space Technology 17 (2002) 355362

Fig. 2. Influence of the bolt diameter on the pull-out load of bolt.

Fig. 3. Influence of the bond area on the pull-out load of bolt.

Table 2Influence of the bolt length on the bolt bond strength

Lb Ab Pb tb(cm) (cm )2 (kN) (MPa)

15.0 57 44.3 7.7724.7 93 72.8 7.8327.0 102 79.0 7.7530.0 113 90.2 7.9832.0 121 91.7 7.58

Rock: Basalt; d s12 mm; curing time: 21 days; t : 10.4 MPa;b gUCS s35.5 MPa; E s7.54 GPa.g g

Fig. 5. The relationship between bolt length and pull-out load.

Fig. 4. The pull-out test set-up of different bolt length.

(2) Bolt section depends upon bolt diameter. Therelation between bolt diameter and bolt bearing capacitycan be explained as follow empiric formulae (Fig. 2).

2P s4.785d y4.53R s0.9824 (6)b b

-

359A. Klc et al. / Tunnelling and Underground Space Technology 17 (2002) 355362

Fig. 6. The relationship between bolt bond area and pull-out load.

Table 3The influence of the water to cement ratio on the bolt bond strength

wyc UCSg tg Ab Pb tb(MPa) (MPa) (cm )2 (kN) (MPa)

0.34 42.0 11.9 102 80.9 7.930.36 38.9 11.3 102 79.0 7.750.38 33.3 10.7 102 77.4 7.590.40 32.0 10.3 102 75.3 7.38

Rock: Basalt; d 12 mm.bs

Fig. 7. The influence of water to cement ratio on the bolt bondstrength.

Fig. 8. The influence of water to cement ratio on the bolt pull-outload.

(3) The values of bolt bond strength were calculatedbetween 5.68 and 5.96 MPa (Table 1).Bolt lengths of 15.0, 24.7, 27.0, 30.0 and 32.0 cm

were used in pull-out tests as seen in Fig. 4. Typicalresults are represented in Table 2, and Figs. 5 and 6.The most important observations were:

(1) The pull-out force of a bolt increases linearlywith the embedded length of the bolt.

2P s2.8876L q1.2741R s0.9936 (7)b b(2) Maximum pull-out strength of a bolt is limited to

the ultimate strength of the bolt shank.

3.2.2. Influence of grouting materialThe water to cement ratio should be no greater than

0.40 by weight; too much water greatly reduces thelong-term strength. Because, part of the mixing water isconsumed by the hydration of cement used. Rest of themixing water evaporates and then capillary porositiesexist which results in unhomogenities internal structureof mortar. Thus, this structure reduces the long-termstrength by irregular stress distribution (Neville, 1963;Atis, 1997). To obtain a plastic grout, bentonit clay canbe added in a proportion of up to 2% of the cementweight. Other additives can accelerate the setting-time,improve the grout fluidity allowing injection at lowerwater to cement ratios, and make the grout expand andpressurize the drill hole. Additives, if used at all, shouldbe used with caution and in the correct quantities toavoid harmful side effect such as weakening and cor-rosion (Franklin and Dusseault, 1989).The water to cement ratio (wyc) in grouting materials

considerably affects pull-out strength of bolt. As seenin Table 3, UCS and shear strength (t ) of grout ing ghigh wyc ratio show lower values whereas in low wycratio higher values. The ratio between 0.34 and 0.40presents quite good results. Although the wyc ratio of0.34 gives the best bond strength, groutibility (pumpa-bility) decreases and a number of difficulties in appli-cation appear. In high wyc ratio, the pumpability of

-

360 A. Klc et al. / Tunnelling and Underground Space Technology 17 (2002) 355362

Table 4Influence of the mechanical properties of the grouting materials on the bolt load capacity

Grout UCSg Eg tg Pb Ab tb t ytb gtype (MPa) (GPa) (MPa) (kN) (cm )2 (MPa)

wycs0.40a 5.30 1.15 2.04 16.53 84 1.94 0.95wycs0.40b 12.84 2.74 4.99 43.75 84 5.20 1.04wycs0.40c 17.74 2.96 6.22 55.28 84 6.63 1.07wycs0.40d 20.80 3.39 7.95 57.59 84 6.83 0.86wycs0.40e 22.94 3.79 9.17 59.84 84 7.14 0.7810% sandf 31.60 6.22 6.73 55.45 83 6.73 1.0010% fly ashf 30.58 4.89 7.34 58.15 83 6.32 0.865% fly ashf 33.33 5.25 8.05 56.01 83 6.73 0.84White cementf 37.72 6.63 8.15 58.15 83 7.03 0.86wycs0.40f 32.01 7.40 10.30 75.26 102 7.34 0.71wycs0.38f 33.33 8.05 10.70 77.39 102 7.54 0.70wycs0.36f 38.94 9.12 11.30 78.99 102 7.75 0.68wycs0.34f 42.00 9.30 11.93 80.87 102 7.95 0.67

Curing time: 1 day; 3 days; 5 days; 7 days; 14 days; 21 days.a b c d e f

Fig. 9. The relationship between grout shear strength and bolt bondstrength.

Fig. 10. The relationship between UCS of grout materials and boltbond strength.

grouting materials into the drilling hole is easy but thebond strength of bolt decreases (Figs. 7 and 8).The bond strength of fully cement-grouted rock bolts

is primarily frictional and depends on the shear strengthat the boltgrout or groutrock interface. Thus anychange in this shear strength of interfaces affects thebolt bond strength and load capacity. The influences ofmechanical properties of grouting materials on the bear-ing capacity of bolt can be described as follows:

(1) The uniaxial compressive and shear strength ofthe grouting materials has an important role on thebehaviour of rock bolts. It was observed that increasingshear strength of the grouting material logarithmicallyincreases bolt bond strength as shown in Table 4 andFig. 9. The relation between grout shear strength andbolt bond strength was formulated as follows:

2t s3.2843ln(t )y0.0523R s0.9621 (8)b g

(2) Table 4 and Fig. 10 show that increasing groutcompressive strength considerable increases the bondstrength of the grouted bolts.

2t s2.4992ln UCS y1.4579R s0.8576 (9) .b g(3) In Fig. 11 and Table 4 show that there is another

relationship between Youngs modulus of grout and boltbond strength. Increasing the Youngs modulus increasesbolt bond strength.

2t s2.3137ln E q2.9394R s0.7882 (10) .b g

3.2.3. Influence of the curing timeAn important problem in the application of cement-

grouted bolts is the setting time of the mortar, whichstrongly affects the stabilizing ability of bolt. Cement-grouted dowels cannot be used for immediate supportbecause of the time needed for the cement to set andharden (Franklin and Dusseault, 1989).

-

361A. Klc et al. / Tunnelling and Underground Space Technology 17 (2002) 355362

Fig. 11. Changing of bolt bond strength due to Youngs modulus of grout.

Table 5The influence of the setting time on pull-out resistance

Curing time db Lb Ab Pb tb(days) (mm) (cm) (cm )2 (kN) (MPa)

1 12 24.2 91 17.64 1.943 12 24.2 91 43.75 4.795 12 24.2 91 56.83 6.227 12 24.2 91 71.25 7.8514 12 24.2 91 75.48 8.3621 12 24.2 91 76.55 8.4628 12 24.2 91 78.46 8.6635 12 24.2 91 80.06 8.77

Rock: Basalt; wycs0.40; d s22 mm.d

Fig. 12. Changing of pull-out load of bolt due to curing time.

Fig. 13. Changing of bolt bond strength due to curing time.

In the pull-out tests, eight group of bolts having samelength and mortar with a water to cement ratio of 0.4were used for determining the effects of curing time onthe bolt bond strength. Each group of rock bolt testingwas performed after different setting times (Table 5).

As can be seen in Figs. 12 and 13, the strength of boltbond increases rapidly in 7 days due to curing time.However, the bond strength of bolt continues to increaserather slowly after 7 days.Rock bolts may lose their supporting ability because

of yielding of bolt material, failure at the boltgrout orgroutrock interface, and unravelling of rock betweenbolts. However, laboratory tests and field observationssuggest that the most dominant failure mode is shear atthe boltgrout interface (Hoek and Wood, 1989). So,this laboratory study focussed on the interface betweenrock bolt and rock and the mechanical properties ofgrouting materials.

4. Conclusions

The laboratory investigation showed that the boltcapacity depends basically on the mechanical properties

-

362 A. Klc et al. / Tunnelling and Underground Space Technology 17 (2002) 355362

of grouting materials which can be changed by water tocement ratio, mixing time, additives, and curing time.Increasing the bolt diameter and length increases the

bolt bearing capacity. However, this increase is limitedto the ultimate tensile strength of the bolt materials.Mechanical properties of grouting materials have an

important role on the bolt bearing capacity. It is offeredthat the optimum water to cement ratio must be 0.340.4 and the mortar have to be well mixed before pouredinto drill hole. Improving the mechanical properties ofthe grouting material increases the bolt bearing capacitylogarithmically. The best relationship was observedbetween grout shear strength and bolt bond strength.Increasing the curing time increases the bolt bond

strength. Bolt bond strength of 19 kgycm in first day,277 kgycm in 7 days and 86 kgycm in 35 days was2 2determined respectively. The results show that bolt bondstrength increases quickly in first 7 days and then theincrease goes up slowly.Bond failure in the pull-out test occurred between the

bolt and cement grout, of which the mechanical behav-iour is observed by shear spring.This explains the development of bolt bond strength

and the failure at the boltgrout interface consideringthat the bond strength is created as a result of shearstrength between bolt and grout. This means that anychange at the grout strength causes to the changing ofbolt capacity. The failure mechanism in a pull-out testwas studied in order to clarify the bond effect of rockbolt. Thus one main bond effect was explained frombond strength of rock bolts.

Acknowledgments

The authors would like to thank the Research Fundof Cukurova University for supporting this research. No.FBE.2000.YL.50.

References

Atis, C.D., 1997. Design and properties of high volume fly ashconcrete for pavements. Ph.D. Thesis. The University of Leeds,UK, p. 342.

Aldorf, J., Exner, K., 1986. Mine Openings: Stability and Support.Elsevier, Oxford, Amsterdam, Tokyo.

Chappell, B.A., 1989. Rock bolts and shear stiffness in jointed rockmass. J. Geotech. Eng. 115.

Cybulski, J.A., Mazzoni, R.A., 1989. Roof support systems continueto evolve. 12th Annual Institute on Coal Mining Healthy, Safetyand Research, Blacksburg, Virginia, 147158.

Franklin, J.A., Dusseault, M.B., 1989. Rock Engineering. McGraw-Hill Publishing Company, New York.

Hoek, E., Wood, D.F., 1989. Rock Support. Min. Mag. 282287.Hyett, A.J., Bawden, W.F., Reichert, R.D., 1992. The effect of rockmass confinement on the bond strength of fully grouted cable bolts.Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 29, 503524.

Indraratna, B., Kaiser, P.K., 1990. Design for grouted rock bolts basedon the convergence control method. Int. J. Rock Mech. Min. Sci.Geomech. Abstr. 27, 269281.

Ito, F., Nakahara, F., Kawano, R., Kang, S., Obara, Y., 2001.Visualisation of failure in a pull-out of cable bolts using X-rayCT. Construction Build. Mater. 15, 263270.

Kaiser, P.K., Yazici, S., Nose, J., 1992. Effect of stress change on thebond strength of fully grouted cables. Int. J. Rock Mech. Min. Sci.Geomech. Abstr. 29, 293305.

Littlejohn, G.S., Bruce, D.A., 1975. Rock anchors-state of the art.Design Ground Eng. Part 1, 2548.

Neville, A.M., 1963. Properties of Concrete. Unwin Brothers Ltd,London, pp. 532.

Panek, L.A., McCormick, J.A., 1973. Roofyrock bolting. SMEMiningEngineering Handbook I, 13-125y13-135, New York.

Reichert, R.D, Bawden, W.F., Hyett, A.J., 1991. Evaluation of designbolt bond strength for fully grouted bolt. 93rd Annual Meeting ofCIM, Vancouver.

Schack, R., Garshol, K., Heltzen, A.M., 1979. Rock Bolting: APractical Handbook. Pergamon Press, Oxford, pp. 84.

Stillborg, B., 1986. Professional users for rock bolting. Ser. RockSoil Mech. 15.

Stillborg, B., 1984. Experimental investigation of steel cables forrock reinforcement in hard rock. Doctoral Thesis. 33 D, LuleaUniversity, Sweden.

Effect of grout properties on the pull-out load capacity of fully grouted rock boltIntroductionPrevious solutionsLaboratory studyExperimentsAnalysis of laboratory test resultsInfluence of the bolt materialInfluence of grouting materialInfluence of the curing time

ConclusionsAcknowledgementsReferences