EDT 310 - Chapter 41 Review - Linetypes Sacramento City College EDT 310.

EDT-GBtr

-

Upload

alistair-ciantar -

Category

Documents

-

view

125 -

download

4

description

Transcript of EDT-GBtr

-

Gardner Denver S.r.l. 21015 LONATE POZZOLO (VA) Italia Via Tevere, 6Tel: +39 0331 349411 Fax: +39 0331 349457

http://www.bottarini.it e.mail: [email protected]

is a brand of Gardner Denver Your Ultimate Source for Vacuum and PressureBottarini

EDT Energy savingrefrigeration dryers

-

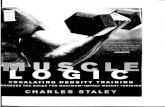

EDT: ENERGY SAVINGREFRIGERATION DRYERSWith the introduction of EDT, the new generation of energy-saving refrigeration dryers, our industry not only renews its product offering for the compressed air treatment but also reinterprets the concept of thermal storage operation, that made the international success of the EDT dryers. The new FlexiDry offers important advantages in terms of energy saving, reliability and operating costs as the EDT dryer is able to adapt itself to the real needs of the compressed air system. The regulation system of the dryer controls the dryer operation granting the most energetically effective method of compressed air drying, achieving high energy saving and ensuring at the same time an excellent dew point stability also in dynamic conditions.

New high efficiency heat exchanger Highest energy savings Minimum pressure drops Lowest environmental impact Reduced carbon footprint Easy installation Easy serviceability Maximum reliability

ENERGY SAVINGThis revolutionary design matches energy consumption to the work load to achieve energy savings while in operation.Thanks to some sensors placed on the refrigeration and on the compressed air circuits, the microprocessor controls the dryer operation granting the most energetically effective method of compressed air drying. For high/medium flows, the dryer applies the Impulse Technology to regulate its drying capacity. For low air flows, the dryer utilizes the thermal storage operation.

ENHANCED ENERGY SAVINGSNew 3-in-1 high efficiency heat exchanger with optimized fluid dynamics useful to keep the pressure drops to a minimum level. Advanced drying capacity control by im-pulses or by thermal storage effect. Enhanced energy savings (up to 80% compared with hot gas by-pass dryers).

HIGH OPERATING LIMITSHigh maximum inlet temperature +70 C (EDT 003-080) +60 C (EDT 100-270) and maximum ambient temperature (+50C) ensure a fail - safe operation at all times. High maximum operating pressure (16 barg).

RELIABLE DRYING & SEPARATIONThe stainless steel demister separator efficiently removes the condensed moisture at all airflows (unlike centrifugal separators). This ensures a high grade of drying all the time.

-

EDT

RELIABLE OPERATION The simple refrigeration circuit, without hot gas by-pass valve, and the careful selection of the mate-rials and components assure long, trouble free service life. The condenser coil is generously sized to maintain efficiency in all environments even at high ambient temperatures.

ROBUST DESIGNHeavy duty structure with panels protected by an epoxy polyester powder coating. Electrical panel (EDT 100 - 270) is IP54 compliant with EN 60204-1 and tested for electromagnetic compatibility in accordance with applicable EMC standards. Phase monitor standard EDT 165 - 270.

GUARANTED QUALITYAll models are individually tested: refrigerant charge and leakage control, microprocessor and safe-ty device setting verification. Leading brand components are used throughout, ensuring long term reliability.

EASY SERVICEABILITYRemovable frontal panel assures easy access to the main refrigeration components, thus facilitating maintenance operations also with dryer ON. There is no need of sea-sonal adjustments unlike hot gas by-pass dryers. Condenser filters standard (EDT 100-270) prevent mechanical equipment fouling by stopping debris.

USER FRIENDLY EDT automatically adapts itself to any operating condition, without any need to adjust or switch OFF the dryer. User friendly digital control is standard on all the models and shows all the main parame-ters, providing warnings and alarms to ensure correct dryer operation.

EASY INSTALLATIONAdvanced design makes this dryer extremely compact and lightweight. Small footprint and frontal access for all controls and refrigeration com-ponents save valuable plant floor space.

RESPECT OF ENVIRONMENTEDTs energy savings coupled with R134a and R404A non ozone depleting refrigerants, reduce the environment impact minimizing the energy waste. Recyclable and high qual-ity materials ensure respect of environment. and reduced carbon footprint.

Maintenance is as easy as ever.

FAST AND EASY SERVICEThese compressors are designed to ensure easy access to maintenance points.All panels on the structure can be easily removed to allow full access to all service points. Also, the limited number of moving parts reduces service costs.

SERVICE NETWORKOur large network of approved Gardner Denver dealers is always at your service to ensure the smooth running of your compressor. Gardner Denver can ensure the swift supply of replacement parts to respond to different system needs.

AFTER-SALES SERVICEGardner Denver offers a full range of after-sales services to fulfil all client needs. Using original spare parts will allow customers to save time and money in the long run.

-

Gardner Denver S.r.l. 21015 LONATE POZZOLO (VA) Italia Via Tevere, 6Tel: +39 0331 349411 Fax: +39 0331 349457

http://www.bottarini.it e.mail: [email protected]

is a brand of Gardner Denver Your Ultimate Source for Vacuum and PressureBottarini

Data refers to the following working conditions: air FAD 20 C / 1bar A, pressure 7 bar(g), ambient temperature 25 C, air inlet temperature 35 C, pressure dew point 3 C, according to ISO 8573.1 standard humidity class 4.Weights are net (without packing and for timed drain confirguration). Refrigerant fluids: R134a (EDT 5-80), R404A (EDT 100-270). Protection class IP22.Maximum working pressure 16 bar(g); maximum ambient temperature 50 C; maximum inlet temperature +70 C (EDT 5-80), +60 C (EDT 100-270).The correction factors in the following table should be used as a guide only; for accurate selection at conditions differing from the above the selection software should be utilised.CAPACITY correction factors (indicative values): CAPACITY = RATED VALUE 7 bar(g) x K1 x K2 x K3 x K4.

7 BAR KW DimensionsMOD. REF. m3/min cfm Nom. Volt/Hz IN/OUT A B C D E F KGEDT 5 CC1112237 0,50 17,65 0,16

230/1/50

3/8"319 298 390 70 32 353 18

EDT 7 CC1112238 0,70 24,72 0,18 319 298 390 70 32 353 19EDT 9 CC1112236 0,90 31,78 0,18

1/2"359 298 415 70 32 367 22

EDT 12 CC1112239 1,20 42,37 0,22 359 298 415 70 32 367 22EDT 18 CC1116033 1,80 63,56 0,38

1"

380 514 625 70 76 480 35EDT 26 CC1116034 2,60 91,81 0,49 380 514 625 70 76 480 39EDT 32 CC1116035 3,20 113,00 0,59 380 514 625 70 76 480 42EDT 40 CC1116036 4,00 141,25 0,74 680 511 860 80 79 685 68EDT 50 CC1116037 5,00 176,57 0,81

1-1/2"680 511 860 120 96 646 75

EDT 60 CC1116038 6,00 211,88 0,84 680 511 860 120 96 646 76EDT 80 CC1116039 8,00 282,51 1,10 755 555 995 150 104 751 94EDT 100 CC1116040 10,00 353,14 1,53

2"1031 799 1039 150 143 747 180

EDT 120 CC1116041 12,00 423,77 1,85 1031 799 1039 150 143 747 190EDT 140 CC1116043 14,00 494,40 2,21

2-1/2"

1170 939 1180 200 165 840 235EDT 165 CC1116044 16,50 582,69 2,24

400/3/50

1170 939 1180 200 165 840 246EDT 190 CC1116045 19,00 670,97 2,55 1170 939 1180 200 165 840 246EDT 230 CC1116046 23,00 812,23 2,97 1170 939 1180 200 165 840 268EDT 270 CC1116048 27,00 953,49 3,33 1170 939 1180 200 165 840 272

Technical data

pressure dew point C 3 5 7 9correction factor K4 1,00 1,12 1,24 1.38

working pressure bar (g) 3 4 5 6 7 8 9 10 11 12 13 14 15 16correction factor K1 0,71 0,82 0,90 0,96 1,00 1,04 1,07 1,09 1,11 1,13 1,15 1,16 1,18 1,19

air inlet temperatur C 30 35 40 45 50 55 60 65 70correction factor K2 1,23 1,00 0,81 0,66 0,57 0,52 0,48 0,44 0,40

ambient temperature C 20 25 30 35 40 45 50correction factor K3 1,05 1,00 0,95 0,89 0,84 0,78 0,72

EDT 18 - 32A B

C

D

F

E

EDT 5 - 12A D

FC

E B

EDT 40 - 80

A B

C

D

E

F

EDT 100 - 270A B

C

D

F

E