Edo Bro Coe Cor Int Xxx 013 038 039 Rev a Aluminium Anodes

description

Transcript of Edo Bro Coe Cor Int Xxx 013 038 039 Rev a Aluminium Anodes

A 23.10.2013 ISSUED FOR INFORMATION AA ED ED

Rev. No.

Date Description Prepared Checked Contr. By Onay EDOPEC

ORIGINATOR

Published by

.

EDOPEC ENERJİ PETROL MÜHENDİSLİK SANAYİİ VE TİCARET

LİMİTED ŞİRKETİ

Document Title

ALUMİNUM ANODES Head Office : Palmiye Mah. Adnan

menderes Bulv. Oktay Sitesi No: 9/8

PK = 33100 Yenişehir /Mersin –

TURKEY

P:+90 324 3260595 F:+90 324

3260596

www.edopec.com. [email protected]

Document No.

EDO BRO COE COR INT XXX 013 038 039 Rev ACo. Org.

Cod

Doc

Type

Disc.

Code

Unit

Code

Prj.

type

Prj.

NO

Prıj.

Year

Pro.Doc.

Seq.No

DCC Seq.No

Page Scale

7

ALUMİNIUM ANODE

Page 2 of 7

Project: EDOPEC PRODUCT Proj. Identification:

Document Title: ALUMİNİUM ANODE Document No.: EDO-BRO-COE-COR-INT-XXX-013-038-039-REV-A-ALUMİNİUM ANODES

Revision: A Date: 23.10.2013

Corrosion When two dissimilar metals are connected in an electrolyte such as sea water, a corrosion cell is formed in which one metal becomes an anode and suffers corrosion while the other metal becomes the cathode and is preserved. Anodic and cathodic areas exist on the surface of all steel structures due to slight variations in material composition, local stresses, differences in coating condition and availability of oxygen. On a bare steel plate in sea-water, these areas form on what is apparently a uniform surface. Since corrosion will result in metal loss, roughening and wastage will occur on an uncoated plate. Where an imperfect coating exists, corrosion will take the form of accelerated pitting at the location of the bare spots and eventual breakdown of the coating. Whatever the circumstances, in the absence of cathodic protection, corrosion will eventually occur. Cathodic Protection The principle of cathodic protection involves the introduction into the electrical circuit of a metal that is more electro-negative than the existing anodic and cathodic areas. This additional metal becomes the anode and will corrode while providing current to the metal it is protecting, thereby overcoming the local anodic areas and making them cathodic. The classic cathodic protection solution to a galvanic corrosion problem is to introduce an

anode in a suitable alloy of magnesium, aluminium or zinc, which will suffer corrosion and so, be 'sacrificed' in protecting the cathode. This approach is used in Sacrificial Systems. As an alternative solution, the protective current needed to make the

structure fully cathodic may be obtained by applying low voltage DC derived from normal AC mains supply. This is achieved by transformer/rectifiers which supply DC to specially designed 'inert' anodes which will dissipate large currents without themselves suffering significant wastage. This approach is used in Impressed Current Systems. Cathodic Protection Systems whether of Sacrificial or Impressed Current type can be either used as the sole method of corrosion control, or in many instances, in conjunction with a coating. Protection even with the best and most expensive coatings alone is seldom adequate. Coatings are always vulnerable to damage and can only be as good as atmospheric and surface conditions permit at the time of their application. Cathodic Protection is therefore an essential ingredient in an overall corrosion controlm system for applications on ships as well as on off-shore structures, jetties, storage tanks and pipelines both underground and sub-sea.

ALUMİNIUM ANODE

Page 3 of 7

Project: EDOPEC PRODUCT Proj. Identification:

Document Title: ALUMİNİUM ANODE Document No.: EDO-BRO-COE-COR-INT-XXX-013-038-039-REV-A-ALUMİNİUM ANODES

Revision: A Date: 23.10.2013

Ship Hull Protection Hulls of ships are prone to corrosion of an aggressive nature in the form of pitting unless they are cathodically protected. Protection with the best and most expensive coating alone is not enough because the coating is vulnerable to mechanical damage at sea or in port and to imperfections at the time of application. For hull protection, zinc anodes with their high electrical efficiency, are of particular value when the aim is to restrict current output and so achieve a long system life from anodes of small bulk. Aluminium anodes combine high electrical capacity with light weight and offer a lower cost per ampere hour of available current and the need of fewer anodes. As an added benefit few anodes mean a reduced frictional resistance on the hull of the ship.

ALUMİNIUM ANODE

Page 4 of 7

Project: EDOPEC PRODUCT Proj. Identification:

Document Title: ALUMİNİUM ANODE Document No.: EDO-BRO-COE-COR-INT-XXX-013-038-039-REV-A-ALUMİNİUM ANODES

Revision: A Date: 23.10.2013

Ship Tank Protection The corrosion pattern in cargo tanks of crude oil carriers is very different from that on the ship's hull but can prove even more damaging and expensive. The cargo tanks are alternated with sea water and in this environment, the corrosion problem takes the form of pitting on horizontal surfaces such as the inner bottom shell plating, the upper surfaces of stringer platforms and the face plates of longitudinal and transverse members. Uniform wastage of vertical surfaces is inevitable. Pitting may also occur in lower areas where water may be present beneath oil cargoes and where residual ballast water is present in tanks which are supposed to be empty. The wastage of internal surfaces of 'permanent' ballast tanks is usually uniform in nature and can be inhibited by the installation of anodes distributed evenly throughout the internal structure. Corrosion of these types can be controlled simply and economically with either Zincalloy or Alalloy anodes or a combination of both, depending on the particular environmental conditions of each installation. Zincalloy can be invaluable in tank applications, particularly in the upper areas where the installation of aluminium alloy anodes is restricted while Alalloy provides the most effective and economical solution to the corrosion problem.

ALUMİNIUM ANODE

Page 5 of 7

Project: EDOPEC PRODUCT Proj. Identification:

Document Title: ALUMİNİUM ANODE Document No.: EDO-BRO-COE-COR-INT-XXX-013-038-039-REV-A-ALUMİNİUM ANODES

Revision: A Date: 23.10.2013

ALUMINIUM ALLOY ANODE (AL ALLOY) Characteristics Alalloy anodes are cast from -special aluminium alloys developed by Wilson Taylor. Suitably formulated for specific application, they are characterised by light weight , smooth corrosion pattern, high electrical capacity and stability. Fewer anodes may be used for a given installation compared with other materials and a substantially lower cost per installed system is achieved. Flexible Alalloy anode is extruded onto a mild steel core wire from a special patented aluminium alloy. The flexibility and light weight of this extruded anode, together with the method of clamping permits its use in applications where the use of cast block anodes may be difficult or uneconomic. Materials Different alloy formulations are available specially designed for different applications. Alalloy anodes are cast in alloys of aluminium and indium plus additions and have been developed specifically for use in sea-water. The materials are very stable in driving potential and efficiency even in electrolytes of varying conductivity and temperature. In normal sea-water having resistivity of about 25 ohm cm, approximately 2700 ampere hours of current are provided by each kilogram of alloy which will maintain a potential of - 1100 mV when measured against a silver/silver chloride reference half cell. Applications Alalloy anodes are suitable for a wide varity of applications including the hulls and tanks 5of ships, fixed off-shore structure, semi submersibles, storage tank bottom pipelines and jetties. Aluminum The theoretical electrochemical performance of aluminum makes it an attractive galvanic anode material, especially in low resistivity applications such as seawater and produced brines. Aluminum's lower driving potential (than magnesium) and high current capacity per pound are key aspects for its use in long life saline systems. For years, the low current efficiency of commercially available aluminum hindered industrial use in CP systems. The high efficiency alloy series were developed to correct this problem and become industry standard. Modern aluminum anodes stand out with respect to:

1. High Current Capacity Under Variable Conditions 2. Current Capacity Maintenance With Time 3. Desirable Operating Potential 4. Constant Potential With Time

Mercury activated anodes are typically specified for use in free flowing seawater where they provide the highest conversion efficiency of any sacrificial anode (1280 amp-hrs/lb.) when operated at current densities of 80 to 1400 mA/ft2 Indium activated anodes are recommended for use in seawater, saline mud, at both ambient and high temperatures, and in hot brines including most oil field brines. Aluminum Tank anodes are supplied in a variety of shapes and sizes with a number of different mounting cores. The Mercury activated alloy is recommended for seawater applications on platforms, docks, barges, etc., where the anode is exposed to a free flowing seawater environment.

ALUMİNIUM ANODE

Page 6 of 7

Project: EDOPEC PRODUCT Proj. Identification:

Document Title: ALUMİNİUM ANODE Document No.: EDO-BRO-COE-COR-INT-XXX-013-038-039-REV-A-ALUMİNİUM ANODES

Revision: A Date: 23.10.2013

The Indium activated tank anodes are recommended for use in hot brine and oil field brine applications. This alloy provides a longer life giving you more protection at a lower cost for tanks containing oil field brine. Aluminum anodes can be installed by suspending anodes from the deck of the tank from a deck mount or the anodes can be placed on concrete or tile blocks placed in the bottom of the tank. Welding or bolting the anode core to the structure can also install many of the anodes. In most cases it is recommended that the lead wire from the anodes be attached to the outside of the vessel. A shunt should be placed in series with the lead wire to measure the current out put in order to determine the life expectancy of the anodes. The Aluminum platform anodes are supplied in a variety of shapes and sizes for seawater applications. he Indium activated alloy is used in the same environments as the Mercury activated alloy or in applications where mercury activated anodes are prohibited. The Indium activated alloy is also used on offshore pipelines, bay platforms, etc., where the anodes are placed in the mud zone or where high resistivity conditions exist. The Aluminum Hull and condenser anodes are supplied in a variety of shapes and sizes with a number of different mounting cores. Application. The Mercury activated alloy hull anodes are recommended for seawater applications on boats, barges, docks, etc. where the anode is exposed to free flowing seawater. The Indium activated alloy hull anodes can be used in the same applications as the Mercury activated alloy. In many cases, as a result of the higher driving potential of the Indium activated alloy, fewer anodes may be required resulting in savings in installation costs. However, the life of the anodes is reduced by 20% due to the higher current output. The Indium activated alloy hull anodes are also used in ballast tanks, small oil field brine containing vessels, etc. The Indium activated alloy condenser anodes are used in condenser heads using seawater or low resistivity cooling waters, especially where the presence of mercury in a closed system is a problem.

ALUMİNIUM ANODE

Page 7 of 7

Project: EDOPEC PRODUCT Proj. Identification:

Document Title: ALUMİNİUM ANODE Document No.: EDO-BRO-COE-COR-INT-XXX-013-038-039-REV-A-ALUMİNİUM ANODES

Revision: A Date: 23.10.2013

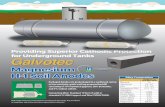

Bottom of Tank Aluminium Anode Leg

ALUMINIUM ANODE

ANODE PERFORMANCE VALUES

2965

90

2670

3.15

Ah/kg.

-

Ah/kg.

kg./Ayr

3.5

1.10

250

kg./Ayr.

V

mV

(According to Cu/CuSO4 electrode at sea water)

Electrode Potantial

True current capasity

True current capasity

Anode Efficiency (*) .%

According to Iron, closed circuit potantial

Teoretical current capasity

Teoretical current capasity

g/cm3Density 2.70

0.35-0.5

Al-Hg

0.25 max.

0.11-0.21

-

0.035-0.45

-

2.1-2.7

Al-Ýn

Element

Zinc

0.01-0.15

0.25 max.

-

Iron

Silicon

Mercury

Ýndium

Cadmium

Percent of Weight

0.003-0.032

0.017-0.024

CHEMICAL COMPOSITION

RemainingRemainingAluminium