EASA SUPPLEMENT. Paul EASA... · EASA Supplement to FAA 14 CFR 145 Accepted Repair Station Quality...

Transcript of EASA SUPPLEMENT. Paul EASA... · EASA Supplement to FAA 14 CFR 145 Accepted Repair Station Quality...

EASA Supplement to FAA 14 CFR 145 Accepted Repair Station Quality Manual (RSQM) Reissue Date: 15-Aug-2012

Cover Issue 1, Revision 2 15-Oct-2013

EASA SUPPLEMENT

to the

FAA 14 CFR 145 Repair Station Quality Manual (RSQM) (ref: MAG, Change 2)

Dallas Airmotive, Inc. City, State FAA# EASA # St. Paul, MN YRR0491L 145.5596

This supplement is applicable to the above listed EASA Repair Station.

Compliance with the FAA accepted supplement together with the FAA 14 CFR Part 145 RSQM forms the basis of the European Aviation Safety Agency (EASA) Part-145 approval.

This supplement forms part of the DAI’s obligations for EASA Part-145 approval as specified in the guidance.

This supplement does not form part of the FAA 14 CFR Part 145 RSQM.

EASA Supplement to FAA 14 CFR 145 Accepted Repair Station Quality Manual (RSQM) Reissue Date: 15-Aug-2012

1. LIST OF FFECTIVE PAGES Page Issue, Revision Date Cover Issue 1, Revision 2 15-Oct-2013

Page 1 Issue 1, Revision 2 15-Oct-2013

Page 1 Issue 1, Revision 2 15-Oct-2013 Page 2 Issue 1, Revision 2 15-Oct-2013 Page 3 Issue 1, Revision 2 15-Oct-2013 Page 4 Issue 1 15-Aug-2012 Page 5 Issue 1 15-Aug-2012 Page 6 Issue 1, Revision 2 15-Oct-2013 Page 7 Issue 1 15-Aug-2012 Page 8 Issue 1 15-Aug-2012 Page 9 Issue 1 15-Aug-2012 Page 10 Issue 1, Revision 1 31-May-2013 Page 11 Issue 1, Revision 1 31-May-2013 Page 12 Issue 1 15-Aug-2012 Page 13 Issue 1 15-Aug-2012 Page 14 Issue 1 15-Aug-2012 Page 15 Issue 1, Revision 2 15-Oct-2013 Page 16 Issue 1, Revision 1 31-May-2013 Page 17 Issue 1, Revision 1 31-May-2013 Page 18 Issue 1 15-Aug-2012 Page 19 Issue 1 15-Aug-2012 Page 20 Issue 1 15-Aug-2012 Page 21 Issue 1, Revision 1 31-May-2013 Page 22 Issue 1, Revision 1 31-May-2013 Page 23 Issue 1, Revision 1 31-May-2013 Page 24 Issue 1 15-Aug-2012 Page 25 Issue 1, Revision 2 15-Oct-2013 Page 26 Issue 1 15-Aug-2012 Page 27 Issue 1 15-Aug-2012 Page 28 Issue 1 15-Aug-2012 Page 29 Issue 1 15-Aug-2012 Page 30 Issue 1, Revision 1 31-May-2013 Page 31 Issue 1, Revision 2 15-Oct-2013 Page 32 Issue 1 15-Aug-2012 Page 33 Issue 1 15-Aug-2012 Page 34 Issue 1 15-Aug-2012 Page 35 Issue 1 15-Aug-2012 Page 36 Issue 1, Revision 2 15-Oct-2013 Page 37 Issue 1, Revision 1 31-May-2013 Page 38 Issue 1, Revision 1 31-May-2013 Page 39 Issue 1, Revision 1 31-May-2013 Page 40 Issue 1, Revision 1 31-May-2013 Page 41 Issue 1, Revision 1 31-May-2013 Page 42 Issue 1, Revision 1 31-May-2013 Page 43 Issue 1, Revision 1 31-May-2013 Page 44 Issue 1, Revision 1 31-May-2013 Page 45 Issue 1, Revision 1 31-May-2013 Page 46 Issue 1, Revision 1 31-May-2013 Page 47 Issue 1, Revision 1 31-May-2013 Page 48 Issue 1 15-Aug-2012 Page 49 Issue 1 15-Aug-2012 Page 50 Issue 1 15-Aug-2012 Page 51 Issue 1 15-Aug-2012

EASA Supplement to FAA 14 CFR 145 Accepted Repair Station Quality Manual (RSQM) Reissue Date: 15-Aug-2012

DISTRIBUTION AND APPLICABILITY All DAI Employees have access to this manual via docTrack. Additional copies will be distributed as listed in the following table. Distributed copies will be on CD-ROM with documents in Adobe Acrobat format.

Issue Number Issue Owner Contact Information

FAA (by DAI RS Number) FAA (by FSDO location) Reference “FAA-PMI Name & Address List by DAI

Location” in docTrack

Page 2 Issue 1, Revision 2 15-Oct-2013

EASA Supplement to FAA 14 CFR 145 Accepted Repair Station Quality Manual (RSQM) Reissue Date: 15-Aug-2012

This Supplement is applicable to the following DAI facility whose addresses may be found in the Dallas Airmotive Repair Station and Quality Manual: Dallas Airmotive Inc – St. Paul, MN FAA Repair Station YRR0491L EASA Accepted Maintenance Organization 145.5596

Page 3 Issue 1, Revision 2 15-Oct-2013

EASA Supplement to FAA 14 CFR 145 Accepted Repair Station Quality Manual (RSQM) Reissue Date: 15-Aug-2012

2. AMENDMENT PROCEDURE

2.1. The processes and procedures for revision of this supplement are similar to those contained in the FAA 14 CFR Part 145 Repair Station Quality Manual (RSQM), Paragraph 10.0.

2.2. This supplement is revised as necessary to ensure continuing compliance with current EASA regulations and continuous improvement.

2.2.1. This supplement is maintained in an electronic format and therefore every page is reproduced at each revision.

2.2.2. Revisions to this supplement are noted by “red bars” in the left margin of the revised paragraph(s) except when it is a Issue in which case there will not be any revision bars.

2.3. Responsibilities

2.3.1. The Chief Technical and Regulatory Officer or designee; shall manage the revision process to include:

2.3.1.1. Revisions to this manual;

2.3.1.2. Quality review of revisions to this manual;

2.3.1.3. Approval of revisions to this manual;

2.3.1.4. Ensuring such revisions are submitted to the FSDO having jurisdiction over the facility;

2.3.1.5. Ensuring such revisions are accepted by the FSDO having jurisdiction over the facility.

2.4. DAI provides a copy of this supplement to the FAA in a format preferred by the local FSDO (typically a CD-ROM with documents in Adobe Reader format).

2.4.1. Should the FAA find a revision unacceptable, DAI expects the FSDO will follow FAA guidance with respect to manual rejection.

NOTE: Failure to ensure that the 14 CFR Part 145 RSQM and this EASA Supplement are kept up to date in respect of regulatory changes and that the repair station staff comply with the procedures therein could invalidate the EASA Approval.

Page 4 Issue 1 15-Aug-2012

EASA Supplement to FAA 14 CFR 145 Accepted Repair Station Quality Manual (RSQM) Reissue Date: 15-Aug-2012

3. INTRODUCTION

3.1. The FAA and EASA have established the differences between EASA Part-145 and Title 14 of US Code of Federal Regulations, Part 145 (hereinafter referred to as 14 CFR Part 145) and these differences are listed in the Maintenance Annex Guidance (MAG) as agreed between the FAA and the EU. These differences are identified as special conditions.

3.2. EASA has agreed that the FAA is a recognized authority by means of a bilateral aviation safety agreement (BASA).

3.3. A 14 CFR Part 145 repair station can be EASA Part-145 accepted when the repair station complies with the maintenance special conditions as detailed in this procedure and in addition to complying with 14 CFR Parts 145 and 43.

3.4. This supplement is intended to indicate that this Repair Station Organization is working in accordance with their EASA Part-145 acceptance and to identify the differences from 14 CFR Part 145 that need to be taken into account.

3.5. Dallas Airmotive Inc.’s primary business is the maintenance of turbine engines, accessories, components, and airframes (limited) and the distribution of turbine parts, accessories and components. All personnel, regardless of the products maintained and capability, are required to adhere to the policies and procedures set forth in this manual as appropriate.

3.6. This manual is issued on the authority of the President of Dallas Airmotive Inc., and is maintained by the Chief Technical and Regulatory Officer who is responsible for interpreting the quality policies when clarification is necessary

3.7. All employees are encouraged to contribute to the Dallas Airmotive Inc. quality system. Our success is based on participation by employees in every aspect of the system.

3.8. The following documents (as applicable) are refered and adapted to this supplement and are available to internal and external parties, including certification bodies, for review:

3.8.1. The RSQM (which is accepted by the FAA)

3.8.2. The Training Manual, OP620-1 (which is Approved by the FAA)

3.8.3. The Subcontract Functions List for non-FAA approved subcontractors (which is Approved by the FAA for some, but not all, DAI locations)

3.8.4. The Master Roster

3.8.5. The DAI Approved Subcontractor List (ASL)

3.8.6. The Forms Manual, OP424-1

3.8.7. Procedures for Work Performed at Another Location, OP 750-1

3.8.8. Initiation of Field Service, WI 420

3.8.9. Field Service Representatives, WI 424

Page 5 Issue 1 15-Aug-2012

EASA Supplement to FAA 14 CFR 145 Accepted Repair Station Quality Manual (RSQM) Reissue Date: 15-Aug-2012

Page 6 Issue 1, Revision 2 15-0ct-2013

4. ACCOUNTABLE MANAGER'S COMMITMENT STATEMENT

"This supplement in conjunction with the accepted 14 CFR Part 145 RSQM defines the organisation and procedures upon which EASA approval is based."

"These procedures are approved by the undersigned, and must be adhered to, as applicable, when maintenance work/orders are being performed under the conditions of the EASA Part-145 approval."

"It is accepted that the repair station's procedures do not override the necessity of complying with any additional requirements formally published by the EASA and notified to this organisation from time to time."

"It is understood that the EASA shall issue an Approval Certificate and list this repair station in an EASA published list as long as the EASA is satisfied that the procedures are being followed and work standards maintained. It is further understood that EASA reserves the right to revoke the Approval Certificate if EASA considers that procedures are not followed or standards not upheld."

SIGNED:

II DATED: 15-0ct-2013

w. Ian Cheyne Chief Technical and Regulatory Officer For and on behalf of Dallas Airmotive, Inc.

Reference Maintenance Annex Guidance, Appendix 1, paragraph 4. b): The accountable manager is normally intended to mean the chief executive officer of the organization, who, by virtue of position, has overall responsibility (including appropriate financial authority) for running the organization. When the accountable manager is not the chief executive officer, he must have direct access to the chief executive officer and have a sufficiency of maintenance funding allocation.

EASA Supplement to FAA 14 CFR 145 Accepted Repair Station Quality Manual (RSQM) Reissue Date: 15-Aug-2012

5. APPROVAL BASIS AND LIMITATION

5.1. EASA approval is based upon compliance with 14 CFR Parts 145 and 43 except where varied by the special conditions specified in the Maintenance Annex and associated guidance. However, this approval must not exceed the ratings permitted by Commission Regulation (EC) No. 2042/2003.

5.2. The approval of maintenance work is limited to the scope of work permitted under the current certificate issued by the FAA to DAI in accordance with 14 CFR Part 145 for work carried out within the United States. Deviations have to be agreed on a case-by-case basis by the JMCB.

Page 7 Issue 1 15-Aug-2012

EASA Supplement to FAA 14 CFR 145 Accepted Repair Station Quality Manual (RSQM) Reissue Date: 15-Aug-2012

6. ACCESS BY EASA AND FAA

6.1. EASA, or FAA staff acting on behalf of EASA, are allowed access to DAI for the purpose of ascertaining compliance with 14 CFR Part 145, the EASA Special Conditions, procedures and standards and to investigate specific problems.

6.2. In accordance with paragraph 2.1 of Appendix 1 to Annex 2 of the Agreement, DAI confirms that it will accept investigation and enforcement action that may be taken by EASA in accordance with any relevant EU regulations and EASA procedures and that DAI will cooperate with these actions.

Page 8 Issue 1 15-Aug-2012

EASA Supplement to FAA 14 CFR 145 Accepted Repair Station Quality Manual (RSQM) Reissue Date: 15-Aug-2012

7. WORK ORDERS/CONTRACTS

7.1. The customer is responsible for:

7.1.1. Correctly informing DAI of required “Dual Release”.

7.1.2. Correctly informing DAI of all required maintenance and alterations.

7.1.3. Correctly informing DAI of all required EASA Airworthiness Directives.

7.2. Customer Service, Sales, Operations, Engineering, Contracts and Quality personnel (as required) are responsible to review all proposed customer contract or purchase order requirements.

7.3. This review is to evaluate customer requirements and the resources required. The contract review includes the following:

7.3.1. Customer specified requirements, including delivery and service.

7.3.2. Requirements not specified by the customer but necessary for the intended application.

7.3.3. Regulatory requirements to include a review of applicable Airworthiness Directives.

7.3.4. Other requirements as determined by DAI review personnel.

7.3.5. Comparing proposed requirements with the final order/contract for differences. Any differences are resolved with the customer prior to acceptance.

7.3.6. Ensuring that DAI has the capability to meet requirements and that risk assessment has been performed (i.e. turn time, new equipment).

7.3.7. Ensuring that the contract identifies the required work scope, additional technical publications, and/or subcontract requirements.

7.3.8. Documentation of verbal commitments from the customer prior to acceptance of the contract / purchase order.

7.3.9. Additional review of requirement changes that occur during the life of the contract. Typically those reviews are made by Engineering and communicated to other affected functions via amendment notifications. This includes dispositions for out-of-scope defects discovered during maintenance.

7.3.10. A post maintenance review to ensure completeness of and compliance with the customers’ requirements.

7.4. The Program Managers are responsible for keeping records of contract reviews that affect their programs.

7.5. A Customer Service Representative (CSR) provides primary contact while the work is in progress.

7.6. The CSR annotates on the Sales Order work instructions, any special customer requirements, including country of registry, military affiliation, public aircraft and any other data pertinent to the work to be performed.

7.7. During the course of the workflow, the CSR communicates with the customer to advise of changes and/or amendments including identification of discrepancies outside the proposed work scope.

7.8. Engineering or CSR authors a Condition Report when required by the customer.

Page 9 Issue 1 15-Aug-2012

EASA Supplement to FAA 14 CFR 145 Accepted Repair Station Quality Manual (RSQM) Reissue Date: 15-Aug-2012

8. APPROVED DESIGN AND REPAIR DATA

8.1. Changes to the type design: Major Changes, Minor Changes, STCs.

The EASA-approved design engineering data is normally data supplied by an EASA Design Organisation Approval (DOA) holder, or data approved by the National Aviation Authority of the Type Certificate Holder (or equivalent), or data supplied by the customer and approved by the EASA. In all cases, the customer is responsible for confirmation of data approval. Details for the acceptance and /or validation of FAA approved changes to the type design by EASA are contained in Annex 1 to the Agreement and in the Technical Implementation Procedures (TIP).

NOTE: EASA defines “design change” as a change to the type design. EASA does not automatically accept alterations that affect type design.

8.2. Repairs

8.2.1. FAA shall approve design data in support of major repairs in accordance with FAA Order 8110.4, Type Certification; FAA Order 8110.37, Designated Engineering Representative Guidance Handbook; FAA Order 8100.15, Organization Designation Authorization Procedures; and FAA Order 8900.1, Flight Standards Information Management System. Minor repairs are made in accordance with “acceptable” data, in accordance with 14 CFR part 43.

8.2.2. EASA shall approve design data in support of repairs in accordance with EASA Part 21 Subpart M-Repairs and EASA’s procedure Type Certificate Change and Repair Approval.

8.3. EASA Acceptance of FAA Repair Design Data.

Non-Critical Components

8.3.1. EASA shall accept data used in support of major repairs regardless of the State of Design of the product, part or appliance, if:

8.3.1.1. EASA has certificated/validated the product or appliance,

8.3.1.2. The FAA is the authority of the State of Design for the repair design data, and

8.3.1.3. The FAA repair design data approval is substantiated via an FAA letter or FAA Form 8110-3, FAA Form 8100-9, properly executed FAA Form 337, or a signed cover page of a repair specification.

8.3.2. EASA shall also accept data used in support of minor repairs when:

8.3.2.1. (i) EASA has certificated/validated the product or appliance,

8.3.2.2. (ii) The FAA is the authority of the State of Design for the repair design data, and

8.3.2.3. (iii) The repair design data has been provided by a U.S. TC/STC or TSOA holder, or

8.3.2.4. (iv) For minor repairs from other than a U.S. TC/STC or TSOA holder, the determination that data are acceptable (under 14 CFR Part 43) has been made by a U.S. maintenance organization under FAA’s authorized system,

NOTE: An EU company must use EASA Part 21 for the approval of repair data for use on an EU-registered aircraft. Unless the minor repair data has been previously used on an N-registered aircraft, an EU company cannot determine any data to be acceptable data under 14 CFR Part 43 for use on an EU-registered aircraft.

Page 10 Issue 1, Revision 1 31-May-2013

EASA Supplement to FAA 14 CFR 145 Accepted Repair Station Quality Manual (RSQM) Reissue Date: 15-Aug-2012

8.3.3. In these circumstances, repair design data are considered to be EASAapproved following its approval or acceptance under FAA’s system. This process does not require application to EASA or compliance findings to the EASA certification basis.

Critical Components

NOTE: A critical component is defined as a part identified as critical by the design approval holder during the validation process, or otherwise by the exporting authority. Typically, such components include parts for which a replacement time, inspection interval, or related procedure is specified in the Airworthiness Limitations section or certification maintenance requirements of the manufacturer’s maintenance manual or Instructions for Continued Airworthiness.

8.3.4. EASA shall accept any critical component repair design data from a TC/STC holder, regardless of the State of Design of the product, if.

8.3.4.1. EASA has certificated/validated the product, and

8.3.4.2. The FAA is the authority of the State of Design for the repair design data.

8.3.4.3. In these circumstances, repair design data are considered to be EASA approved following its approval under FAA’s system. This process does not require application to EASA or compliance findings to the EASA certification basis.

8.3.5. Repair design data on critical components, developed by organizations/persons that are not the TC/STC Holder, shall be submitted to the Agency for approval following the standard application procedure, with an EASA Form 31. Applicants do not need to hold a DOA if the repair data has been approved by the FAA.

Page 11 Issue 1, Revision 1 31-May-2013

EASA Supplement to FAA 14 CFR 145 Accepted Repair Station Quality Manual (RSQM) Reissue Date: 15-Aug-2012

9. AIRWORTHINESS DIRECTIVES

9.1. Responsibilities:

9.1.1. The customer remains responsible for correctly informing DAI of all required maintenance and alterations, including EASA Airworthiness Directives.

9.1.2. The Chief Technical and Regulatory Officer is responsible for ensuring that all employees involved in the process understand and comply with this process.

9.1.3. DAI receives EASA Airworthiness Directives (AD’s) from EASA via the internet and the EASA website http://ad.easa.europa.eu/.

9.1.4. Document Control / Publications is responsible for routing EASA ADs for review/acknowledgement and placing in docTrack and/or CD Server.

9.1.5. Product Line Engineers are responsible for review/acknowledgement of all AD’s and assuring all paperwork is updated to reflect any new requirements.

9.1.6. Chief Inspector/Quality Manager is responsible for assuring all QC and Inspection personnel are aware of the EASA AD’s and implementing necessary actions.

9.1.7. Service Managers, General Managers, and Production Supervisors are responsible for ensuring all personnel are notified of the EASA AD’s.

9.2. DAI ensures that EASA airworthiness directives the customer requires are embodied and understands that it may be necessary to confer with the customer for supply of data.

9.2.1. Review of applicable EASA Airworthiness Directives.

9.2.2. The CSR annotates on the Sales Order work instructions, any special customer requirements, including country of registry, military affiliation, public aircraft, EASA Airworthiness Directives and any other data pertinent to the work to be performed.

9.2.3. The Program Managers are responsible for keeping records of contract reviews that affect their programs and to ensure that the customer remains responsible for correctly informing DAI of all required maintenance and alterations, including EASA Airworthiness Directives.

9.3. DAI assures that the customer supplies such EASA Airworthiness Directives as required to maintain their aircraft or part thereof. This information must be specified on the customer repair order and transcribed to the DAI Work Order. Such publications will be kept in the customer file as evidence of the work performed.

9.4. If DAI does not comply with an applicable EASA AD, its non-compliance must be recorded in the item’s maintenance records.

9.4.1. The non-compliance of apllicable EASA AD’s will also be recorded in Block 13 of the FAA Form 8130-3 as “EASA Airworthiness Directives not complied with” (including Amendment, Effective Date, and other international authority AD’s as required).

Page 12 Issue 1 15-Aug-2012

EASA Supplement to FAA 14 CFR 145 Accepted Repair Station Quality Manual (RSQM) Reissue Date: 15-Aug-2012

10. RELEASE AND ACCEPTANCE OF COMPONENTS

NOTE: At the time of drafting of this guidance, the FAA and EASA are considering a future change to the FAA Form 8130-3 and EASA Form 1, which will affect the numbering of the blocks. The references to the blocks in this section are based on the 2007 forms and guidance. The repair station should complete the appropriate blocks of the form by following the latest guidance published relating to the completion of the form.

FAA 8130-3/EASA Form One GENERAL PROCEDURE:

10.1. Any authorized person having access to the electronic form or hard copy reproduction may prepare a Return to Service document.

10.2. The standard electronic form is accessible to authorized personnel in docTrack or via the network. These forms are preprinted with the appropriate FAA Repair Station Number and Address and EASA Statement. Other International Release data is entered into block 13 if applicable.

10.3. Each form is personalized with the appropriate FAA Repair Station Number and Address, and EASA Repair Station Number. These forms may be downloaded by all facilities and authorized personnel as necessary to their operation.

10.4. Only FAA Certificated personnel authorized as signatories on the Master Roster for DAI may affix their signature to a Return to Service document.

BLOCK-BY-BLOCK INSTRUCTIONS:

Block 1: Approving National Aviation Authority/Country: - Preprinted on both computer generated and paper copies

Block 2: Authorized Release Certificate: - Preprinted on both computer generated and paper copies

Block 3: Form Tracking Reference Number: - All DAI Maintenance facilities enter work order/sales order number. In the case of multiple parts a unique tracking number is assigned allowing traceability of work performed.

Block 4: Issuing Organization - Preprinted for Dallas Airmotive Inc. facilities. Includes name, address and repair station number.

Block 5: Work Order, Contract, Repair or Sales Order Number - as pertinent to customer requirements.

Should it be necessary to attach additional documentation (life limited card, AD status, this block will also be used to record number of pages attached) Or: Block 13 if the attached shipment list contains the information required in Blocks 6 through 12

Block 6: Item - Several items may be sent on 1 (one) Return to Service document. Single item number or multiple item numbers (e.g., same item with different serial numbers) may be used for the same part number. However, Dallas Airmotive Maintenance facilities will only send one item (i.e., one part number) per form. For example, we may have 23 each part number xxxxxxx blades, but we will only have one Item. Blades with another part number would be entered on another Return to Service document.

Block 7: Part Name - Enter the name of the part as per the Manufacturers Parts Catalog, overhaul manual or work order.

Block 8: Part Number - Enter the manufacturer’s part number. Ensure that any part number change required by modification has been accomplished and is recorded.

Block 9: Eligibility –“NA” is pre-printed on all 8130’s used for approval for return to service (maintenance release) in accordance with FAA Order 8130-21 (as revised).

Note: if required, engine type / model may be annotated in block 13.

Block 10: Quantity - Enter number of parts.

Block 11: Serial/Batch Number - Enter the serial/batch number of the part(s). If there is no serial/batch number, enter "N/A"

Page 13 Issue 1 15-Aug-2012

EASA Supplement to FAA 14 CFR 145 Accepted Repair Station Quality Manual (RSQM) Reissue Date: 15-Aug-2012

Block 12: Status/work performed - Enter any of the following descriptions as applicable (must be in ALL CAPS):

REPAIRED MODIFIED OVERHAULED INSPECTED

The entry must reflect the majority of the work performed. Only one item may be entered in Block 12.

Block 13: For Repaired, Overhauled, or Inspected parts:

10.5. The following information must be filled out in Block 13 when approving for return to service after maintenance: 10.5.1. Enter Time/Cycle information in the preprinted blocks as applicable. Should time/cycle

information be unknown, enter UNK. If time/cycle information is not required, enter “NA”

Note: Life limited parts are not released with Unknown times and/or cycles unless received only for a repair process such as X-ray. In this instance, it is permissible to enter “UNK” in the time/cycle information blocks.

For parts received individually, time and cycle information may only be entered in block 13 when the repair station records contain a signed letter from the LAST OPERATOR or an adequate logbook entry attesting to the accuracy of the cycles and times supplied.

Parts to be installed at the repair station must have documents regarding the current time status of the part.

10.5.2. Work scope and reference documents. Must include document or manual part number, revision status and date if available.

10.5.3. PMA parts installed in engines/modules must be listed separately from OEM references in block 13 by part number, serial number, part name and must include document or manual part number, revision status and/or date from the PMA manufacturer.

Note: Commercially, Dallas Airmotive discourages the use of PMA parts. However, at the customer’s written request, Dallas Airmotive will install the requested PMA parts if the PMA parts are accepted as detailed in EASA Part-21 or in Annex 1 of the Agreement.

10.5.4. Service Bulletins accomplished: (List of service bulletins by manufacturer)

10.5.5. FAA and EASA Airworthiness Directives complied with (and not complied with if applicable), including Amendment, Effective Date and other international authority AD’s if required.

10.5.6. Enter the engine/airframe/accessory S/N item was removed from if available. If a Life Limited part, this information is required. Additional information, such as logbook entries, life card, or customer statement may be attached to the Return to Service (number of pages to be referenced in Block 5)

10.5.7. Enter repair/overhaul maintenance data including reference to technical data, manual revision number and revision date. Service Bulletins, and FAA and EASA Airworthiness Directives and should be entered if not attached to the Return to Service.

Examples:

Repaired for lightning strike with reference to the PWC overhaul manual P/N__________ rev. # ______ rev date

Repaired with reference to American Airlines ESO XXXXXX Rev. rev date

Welded with reference to Beech Operations Manual number _____ revision __ rev date

Accomplished Airworthiness Directive 96-00-00 Amend. 1 paragraph B and Service Bulletin 10000.

Accomplished Major Repair of ____________ with reference to the approved data.

Modified with reference to (OEM) service bulletin 00000.

Page 14 Issue 1 15-Aug-2012

EASA Supplement to FAA 14 CFR 145 Accepted Repair Station Quality Manual (RSQM) Reissue Date: 15-Aug-2012

Inspected with reference to Spey Overhaul Manual number ______ revision __ rev date_________

Note: removed from engine model ________ serial number _______

10.5.8. Block 13 Shall also contain the following statement:

“Certifies that the work specified in block 12/13 was carried out in accordance with EASA Part-145 and in respect to that work the component is considered ready for release to service under EASA Part-145 Approval Number: “EASA 145.5596”.

10.5.9. NOTE: In the case of maintenance carried out by a U.S.-based EASA Part-145 approved organisation subject to the Agreement, EASA only recognises the dual release FAA Form 8130-3 for component, engine, or propeller maintenance.

Block 14-18: Note: In no case should blocks 14 through 18 be completed.

Block 19: Return to service - Pre-printed return to service statement (maintenance release) in accordance with 14 CFR Part 43 and 14 CFR Part 145 or other International regulations. In the case of EASA, both blocks will always be checked except for the following deviations:

Deviations: (1) The case where all required maintenance was not carried out. In this case, list the

maintenance not carried out in Block 13 and/or attachments.

(2) The case where the particular maintenance requirement was only EASA-approved and not FAA-approved. Example: an EASA Airworthiness Directive not approved by the FAA.

Block 20: Signature - Legible ink signature of the individual authorized by DAI to perform final inspection and approval for return to service as prescribed in 14 CFR Part 43. This signature will be entered in permanent blue or black ink.

Block 21: Certificate number – Preprinted Facility FAA certificate number.

Block 22: Name - Clearly printed or typed name of authorized individual approving product for return to service.

Block 23: Date (Mmm dd yyyy) – The Date to be entered in Block 23 for approval for return to service will be the date on which the original work was completed ( refer to § 43.9). The date must be in the following format: first three letters of the month, two-digit day, and four-digit year, for example, Feb 03 2008.

If the 8130 is a duplicate, the date the part was returned to service will be entered in Block 13.

10.6. The staff authorized to issue the FAA Form 8130-3 on behalf of the repair station are identified in the Master Roster, as revised.

10.7. Component means any component part of an aircraft up to and including a complete powerplant and any operational or emergency equipment.

10.8. Only the following new and used components may be fitted during maintenance:

10.8.1. New Components

10.8.1.1. New components should be traceable to the OEM as specified in the Type Certificate (TC) holder’s Parts Catalogue and be in a satisfactory condition for installation. A release document issued by the OEM or Production Certificate (PC) holder should accompany the new component. The release document should clearly state that it is issued under the approval of the relevant AA under whose regulatory control the OEM or PC holder works.

10.8.1.2. For U.S. OEMs and PC holders release should be on the FAA Form 8130-3 as a new part.

Page 15 Issue 1, Revision 2 15-Oct-2013

EASA Supplement to FAA 14 CFR 145 Accepted Repair Station Quality Manual (RSQM) Reissue Date: 15-Aug-2012

10.8.1.3. For all EU States OEMs and PC holders release should be in accordance with EASA Part-21 on EASA Form 1 as a new part.

10.8.1.4. For Canadian OEMs and PC holders release should be on the Canadian Form One as a new part.

10.8.1.5. Standard parts are exempt from the forgoing provisions, except that such parts should be accompanied by a conformity statement and be in a satisfactory condition for installation.

NOTE: EASA Standard Parts Definition: Per AMC M.A.501(c), “Standard Parts are: parts manufactured in complete compliance with an established industry, Agency, competent authority or other Government specification which includes design, manufacturing, test and acceptance criteria, and uniform identification requirements. The specification should include all information necessary to produce and verify conformity of the part. It should be published so that any party may manufacture the part. Examples of specifications are National Aerospace Standards (NAS), Army-Navy Aeronautical Standard (AN), Society of Automotive Engineers (SAE), SAE Sematec, Joint Electron Device Engineering Council, Joint Electron Tube Engineering Council, and American National Standards Institute (ANSI), EN Specifications etc…”

10.8.1.6. PMA parts may only be accepted as detailed in EASA Part-21 or in Annex 1 of the Agreement.

10.8.1.7. Engines rebuilt by the production approval holder can be accepted as specified in the Technical Implementation Procedures for Airworthiness and Environmental Certification (TIP- paragraph 5.1.4).

10.8.2. Used Components

10.8.2.1. Used components shall be traceable to maintenance organisations and repair stations approved by the authority who certified the previous maintenance, and in the case of life limited parts, certified the life used. The used component must be in a satisfactory condition for installation and be eligible for installation as stated in the TC holders Parts Catalogue.

10.8.2.2. An FAA Form 8130-3 issued as a dual maintenance release must accompany used components from EASA-approved U.S.-based 14 CFR Part 145 repair stations.

10.8.2.3. Used components from a 14 CFR Part 145 repair station not EASA-approved will not be used even if accompanied by an FAA Form 8130-3.

10.8.2.4. An EASA Form 1 issued as a maintenance release shall accompany used components from EASA Part-145 approved maintenance organizations not located in the U.S.

10.8.2.5. A Canadian Form One issued as a maintenance release should accompany used components from a Canadian EASA-approved maintenance organisation.

NOTE: Canadian EASA-approved maintenance organizations will specify the EASA release statement and their EASA approval number in the remarks block of Canadian Form One.

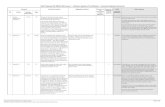

NOTE: Please reference “DUAL RELEASE DECISION FLOW DIAGRAM” on next page.

Page 16 Issue 1, Revision 1 31-May-2013

EASA Supplement to FAA 14 CFR 145 Accepted Repair Station Quality Manual (RSQM) Reissue Date: 15-Aug-2012

DUAL RELEASE DECISION FLOW DIAGRAM

Page 17 Issue 1, Revision 1 31-May-2013

Do ALL

serviceable

parts issued have

FAA/EASA Dual

Release tags?

YES

NO

Do 1 or more

serviceable parts issued

have a FAA 8130-3

single release tag?

NO

Do 1 or more

serviceable parts issued

have a EASA Form 1

single release tag?

YES

When can I issue a FAA/EASA Dual Release?

You must inspect the part for

airworthiness and fully document

the inspection, and;

The inspection document must

be attached to the Release

Form of the part / article and

kept with the job package, and;

Attach a properly completed

FAA 8130-3 Dual Release tag

with block 3 showing ‘Inspected’.

(Part may be “issued” or “stocked”)

Is your

Repair Station

rated by FAA/EASA to

return the part / article

to service?

YES

NO

Issue of

FAA/EASA

Dual Release

NOT possible

Issue of

FAA/EASA

Dual Release

NOT possible

Issue of

FAA/EASA

Dual Release

possible

YES

1 or more

serviceable parts issued

has a EASA Form 1

single release tag

1 or more

serviceable parts issued

has a FAA 8130-3

single release tag

NO

Issue of FAA 8130-3

Single Release

possible(must use standard FAA

8130-3)

Issue of 8130-3 Single

Release possible.(must use the “Single

Release EASA ONLY”

release tag in docTrack)

EASA Supplement to FAA 14 CFR 145 Accepted Repair Station Quality Manual (RSQM) Reissue Date: 15-Aug-2012

Example completed FAA Form 8130-3 dual release.

Page 18 Issue 1 15-Aug-2012

EASA Supplement to FAA 14 CFR 145 Accepted Repair Station Quality Manual (RSQM) Reissue Date: 15-Aug-2012

11. CERTIFICATE OF AIRWORTHINESS (C of A) VALIDITY

11.1. After performing maintenance under a limited airframe rating on EU registered aircraft, and before

returning the aircraft to service, the 'airworthiness review certificate' must be reviewed to ensure it is still valid.

11.1.1. If the certificate is valid the aircraft may be released to service as per paragraph 13 of this supplement.

11.1.2. If the certificate is not valid then the customer must be informed before releasing the aircraft for service and the communication should be documented in writing.

NOTE: Although EU aircraft have indefinite C of As, the C of A’s validity period is verified by means of an “Airworthiness Review Certificate” (ARC). The EASA Operator or owner is responsible for ensuring the C of A remains valid but the repair station should ensure that the C of A is valid from the expiry date as detailed on the ARC before issue of a release to service as specified in Section B Appendix 1 paragraph 12. If the ARC has expired, inform the customer before issue of a release to service as specified in paragraph 12.

Page 19 Issue 1 15-Aug-2012

EASA Supplement to FAA 14 CFR 145 Accepted Repair Station Quality Manual (RSQM) Reissue Date: 15-Aug-2012

12. RELEASE OF AIRCRAFT AFTER MAINTENANCE

12.1. DAI releases aircraft back to service in accordance with 14 CFR Part 43 and this supplement. At the completion of maintenance the following certification should be made in the aircraft maintenance record:

12.1.1. Return to Service in Accordance with 14 CFR Part 43.9 and the following “Certifies that the work specified; except as otherwise specified, was carried out in accordance with FAA airworthiness regulations, and in respect to that work the aircraft is considered ready for release to service.”

NOTE: Reference to Paragraphs 7 – 10 and 12 must be adhered to in the performance of a proper EASA Release to Service.

12.1.2. Please note that the sub clause “except as otherwise specified” is intended for use with two types of deviations as follows:

12.1.2.1. The case where all required maintenance was not carried out. In this case, list the maintenance not carried out on the 14 CFR Part 43.9 Return to Service and/or attachments.

12.1.2.2. The case where the particular maintenance requirement was only EASA-approved and not FAA-approved. Example: an EASA Airworthiness Directive not approved by the FAA.

12.1.3. Where the customer Operator requires his/her paperwork to be signed, the following alternate certification can be made. The following is only applicable to repair stations with airframe and/or limited airframe rating.

12.1.3.1. Release to Service in Accordance with EASA Part-145.A.50:

“Certifies that the work specified, except as otherwise specified, was carried out in accordance with EASA Part-145 and in respect to that work the aircraft is considered ready for release to service.”

12.1.3.2. In all cases, the repair station must issue the certification when all required maintenance has been carried out, except that if it was not possible to complete all maintenance actions requested, then details of the work not performed must be endorsed on the Release to Service and the Operator informed.

12.1.3.3. Quote the EASA Part-145 Approval Certificate Number and the FAA 14 CFR Part 145 Certificate Number in all cases.

NOTE: Reference to Paragraphs 7 – 11 must be adhered to in the performance of a proper EASA Release to Service.

Page 20 Issue 1 15-Aug-2012

EASA Supplement to FAA 14 CFR 145 Accepted Repair Station Quality Manual (RSQM) Reissue Date: 15-Aug-2012

13. REPORTING OF UNAIRWORTHY CONDITIONS

13.1. When serious defects are found in EU regulated aircraft or components, then such facts are reported

to the customer/operator, EASA, the aircraft design organization.

13.2. Responsibility

13.2.1. The following positions shall ensure serious unairworthy condition reports are made to the authorities and customer in the most expeditious manner possible:

13.2.2. The Chief Technical and Regulatory Officer; or

13.2.3. The Facility/EASA Accountable Manager; or

13.2.4. The Quality Manager/Chief Inspector

13.3. Reporting requirements

13.3.1. The reporting is done within three days (72 hours) of discovery.

13.3.2. EASA Form 44, Occurrence Reporting Form will be sent via facsimile and/or electronic mail.

13.3.3. When reporting to the EASA, the identity of the customer must be included to allow follow up action.

NOTE: EASA Part-145 occurrence reporting requirements include SUP reporting requirements.

Page 21 Issue 1, Revision 1 31-May-2013

EASA Supplement to FAA 14 CFR 145 Accepted Repair Station Quality Manual (RSQM) Reissue Date: 15-Aug-2012

14. QUALITY ASSURANCE SYSTEM (QAS)

14.1. The Quality Assurance System (QAS) of DAI is based on ISO 9001 and is detailed in the Quality Manual at paragraph 8.0. The QAS specifies criteria for monitoring the quality system including external maintenance providers. The established QAS together with this supplement assures that DAI can provide an airworthy product and maintain compliance with 14 CFR Parts 43 and 145 and the EASA Special Conditions. Highlights are provided as follows:

14.1.1. An independent, internal audit system

14.1.2. A sample audit schedule is included as Appendix A.

14.1.3. The independent audit system is a process of sample audits of all aspects of DAI’s ability to carry out all maintenance to the required standards. It represents an overview of the complete maintenance system. It does not replace the need for mechanics to ensure that they carry out maintenance to the required standard nor does it replace any associated inspection/quality control system. Independence is established by ensuring that audits are not carried out by the personnel responsible for the function, procedure, or product being audited.

14.1.4. The internal audit system contains the following:

14.1.4.1. Procedural audits. The audits monitor compliance with required aircraft/aircraft component standards and adequacy of the maintenance procedures to ensure that such procedures invoke good maintenance practices and airworthy aircraft/aircraft components.

14.1.4.2. Product audits. The sample check of a product means to witness any relevant testing and visually inspect the product and associated documentation. The sample check should not involve repeat disassembly or testing unless the sample check identifies findings requiring such action.

14.1.5. It is acceptable to use personnel from one section/department to audit the work and products of another section/department in accordance with paragraph 14.2 which defines the audit programme.

14.1.6. The process of sample audits may be carried out once per year as a single exercise (feasible at smaller facilities) or conducted in segments during a period of one year in accordance with the audit programme contained in this Supplement (applicable to larger facilities). All applicable 14 CFR Parts 43 and 145 provisions and the EASA Special Conditions as detailed in this guidance should be checked at least once per year against each primary product line.

14.1.7. A primary product line is any one aircraft, engine or mechanical product line where the systems and procedures are very similar throughout that product line.

14.1.8. A management/control and follow up system

14.1.9. The management control follow up system, which is not to be contracted to outside persons, consists of the Corrective Action Request (CAR) system which operates at all levels and the Corrective Action Board (CAB) which may operate on a product or facility level or both, as needed. These systems ensure that all findings/discrepancies resulting from any audits are corrected in a timely manner and to enable the accountable manager to remain informed of the state of compliance and any safety issues.

14.1.10. The facility accountable manager or designee holds routine CAB metings to check the progress on clearing outstanding CAR’s, except that in the larger repair stations such meetings may be delegated on a day to day basis to the Quality Manager as long as the accountable manager meets at least once per year with the senior staff involved to review the overall performance.

Page 22 Issue 1, Revision 1 31-May-2013

EASA Supplement to FAA 14 CFR 145 Accepted Repair Station Quality Manual (RSQM) Reissue Date: 15-Aug-2012

14.1.11. CAR’s or orther issues that cannot, for any reason, be resolved at the local or CAB level

are escalated to senior management for review.

14.1.12. The quality monitoring system as specified in paragraph 14 extends to include the Field Service organization where that organization operates under an EASA 145 repair station.

14.1.12.1. Field Service will be audited by the same audit programme as described in paragraph 14.2.

14.1.13. One example of the particular product line shall be used as the basis of each audit, except in the case of stores audits when a random selection of parts should be used for the audit.

14.2. Audit Programme/Schedule

14.2.1. A sample audit schedule is included as Appendix A.

14.2.2. Auditor independence is established by ensuring that audits are not carried out by personnel responsible for the function, procedure, or product being audited.

14.2.3. All processes required to be audited are audited at least once per year over the course of the year.

14.2.4. Processes may be audited separately to maximize coverage and minimize production disruptions.

14.2.5. Processes to be audited include all processes required in the performance of turbine engine maintenance, accessory maintenance and aircraft maintenance (all as specified by Operations Specification and/or Capability Lists).

14.2.6. The Special Conditions of EASA, which may be combined with the standard audit checklists as applicable for all processes audited as 14 CFR Part 145 and Part 43 are part of both the regular and EASA audit schedule of DAI.

14.2.7. Primary product lines as defined in paragraph 14.1.7. required to be audited are audited at least once per year.

14.2.8. Product audits will include:

14.2.8.1. Witnessing any relevant testing.

14.2.8.2. Visually inspect the product.

14.2.8.3. Visually inspect the associated product documentation.

14.2.8.4. A product audit may occur over the course of a year

14.2.9. A product should be selected in each hangar and/or each facility and the sample audit programme conducted at least once per year except that in the case of procedures which are common throughout the repair station, the procedure need only be audited once per year if there are no problems.

14.2.10. An audit report is prepared for each internal audit carried out. The report describes what standards, procedures and/or processes were checked, results of reviews of any previous non-conformanaces for effectivity of corrective actions; and any resulting non-conformances, observations, and/or opportunities.

14.2.11. A copy of the report is sent to the process owner and the General or Operations Manager, as applicable.

14.2.12. All non-conformances are loaded into a Corrective Action database and assigned to a responsible person for corrective action including target completion dates.

Page 23 Issue 1, Revision 1 31-May-2013

EASA Supplement to FAA 14 CFR 145 Accepted Repair Station Quality Manual (RSQM) Reissue Date: 15-Aug-2012

14.2.12.1. The responsible person is required to determine the root cause, correct the

non-conformance and complete the Corrective Action form (online).

14.2.12.2. The department manager may then approve or reject the Corrective Action report.

14.2.12.3. Following manager approval, the Corrective Action administrator may approve or reject the Corrective Action.

14.2.12.4. At this point, the administrator may also assign a follow-up action item.

14.2.13. All findings not considered non-conformances are added to the agenda of the CAB meeting for discussion and disposition.

14.3. Sub-contracted maintenance provider Audits

14.3.1. The Chief Technical and Regulatory Officer is responsible for the Subcontractor Maintenance Program. Corporate Quality Assurance personnel maintain the list of approved subcontractors.

14.3.2. Corporate Quality Assurance is responsible for submitting subcontracted maintenance functions lists to the FSDO. These lists are provided to the applicable Principle Inspector upon request.

14.3.3. DAI maintains and the FAA (i.e. the appropriate FSDO for each DAI certificated repair station) approves a list of maintenance functions subcontracted to non-certificated subcontractors. DAI will not subcontract a maintenance function to a non-certificated subcontractor without prior FAA approval.

14.3.4. DAI maintains and makes available to its FSDOs a list of DAI approved subcontract maintenance providers, the ‘Approved Subcontract List’. This list includes the maintenance functions subcontracted, the name of each outside facility, and the type of certificate and ratings held by each facility.

14.3.5. The procedure for approving and maintaining repair subcontractors, including non-certificated subcontractors, is documented in paragraph 16 of this supplement.

Page 24 Issue 1 15-Aug-2012

EASA Supplement to FAA 14 CFR 145 Accepted Repair Station Quality Manual (RSQM) Reissue Date: 15-Aug-2012

15. PROVISION OF HANGAR SPACE FOR AIRCRAFT MAINTENANCE DAI maintains adequate hangar space for all aircraft operated under the regulatory control of a EU Member State. DAI hangars are located at:

Love Field, Dallas, TX

New London, NC

Millville, NJ In the case of field service work, DAI technicians ensure that the customer’s hangar space is adequate for the work to be performed prior to commencing work.

Page 25 Issue 1, Revision 2 15-Oct-2013

EASA Supplement to FAA 14 CFR 145 Accepted Repair Station Quality Manual (RSQM) Reissue Date: 15-Aug-2012

16. CONTRACTED MAINTENANCE

NOTE 1: When part of the maintenance is contracted to another organisation, the repair station must ensure that the other organisation is approved to EASA Part-145 for the maintenance they carry out. If maintenance is contracted to a non-EASA-approved organisation then this is considered to be a Non–certificated Facility. In such a case, the repair station returning the product to service is fully responsible for ensuring its airworthiness.

NOTE 2: To prevent duplication with the FAA Repair Station Manual and the EASA Supplement, it is permissible to make a cross reference to the RSM procedures in the EASA Supplement making a clear reference to where the information is to be found.

An EASA-approved Part-145 repair station may contract a maintenance work pertaining to an article to an outside source (contracting is some times referred to as subcontracting. For the purposes of this section the term contracting includes subcontracting). There are two elements to the contracting provisions of the MAG.

16.1. Listing Subcontractors

16.1.1. EASA recognizes 14 CFR Part 145 requirements for the Repair Station Manual to contain a list of all contractors utilized by the Repair Station and approved by the FAA as part of the Repair Station Manual.

16.1.2. The DAI Approved Subcontractor List (ASL) list contains the name, address, and certificate and rating if applicable of each organization to which DAI subcontracts maintenance.

16.1.3. Those subcontractor(s) DAI uses to support maintenance activities for aircraft registered in the EU or aeronautical products to be installed on such aircraft are identified by their EASA Part-145 Certificate Number and are also made available to EASA on request.

16.1.4. When DAI uses subcontractor(s) that are NOT EASA Part-145 Certificated to support maintenance activities for aircraft registered in the EU or aeronautical products to be installed on such aircraft, DAI will have responsibility for ensuring its airworthiness.

16.2. Qualifying Subcontractors

16.2.1. Approved subcontractors are identified by inclusion on the DAI ASL.

16.2.2. Personnel desiring to have a new subcontractor approved fill out Form FC-301 and submit to Quality Assurance for review (example attached).

16.2.3. Prior to acceptance either initial or recurrent, QA requests from the subcontractor the completion of Form QA-2002 (example attached) and the following as applicable:

16.2.3.1. FAA Certificate and complete Operations Specification.

16.2.3.2. Drug / Alcohol Plan FAA Approval Letter if A-449 is not included in Op Specs.

16.2.3.3. EASA Acceptance letter and Approval Certificate

16.2.3.4. ISO9001/AS9100/AS9110 Registration Certificate

16.2.3.5. Certificate of Insurance

16.2.3.6. A completed W-9

16.2.3.7. Federal Tax ID Number

16.2.4. If the requested subcontractor is not FAA (or other NAA) approved:

NOTE: Maintenance functions intended to be subcontracted to non FAA (or other NAA) approved organizations must be approved by the FAA prior to being considered for inclusion on the DAI ASL.

16.2.4.1. A physical audit is required of all facilities not certificated by the FAA (or other NAA).

Page 26 Issue 1 15-Aug-2012

EASA Supplement to FAA 14 CFR 145 Accepted Repair Station Quality Manual (RSQM) Reissue Date: 15-Aug-2012

16.2.4.2. Non-EASA approved organizations may be approved for inclusion on the ASL

in coordination with Quality Assurance, Engineering, Customer Service, Purchasing and/or Quality Control.

16.2.4.3. DAI will not approve any non-EASA subcontractor to perform any maintenance on EASA articles for which DAI itself is not rated.

16.2.4.4. DAI will have responsibility for the EASA airworthiness of maintenance subcontracted to a non-EASA approved subcontractor which is included on the DAI ASL.

16.3. Subcontracting to EASA approved organizations.

16.3.1. DAI requires all subcontractors to meet DAI quality system requirements. In addition, this requirement applies to the extent necessary to ensure that characteristics not verifiable upon receipt are adequately controlled by the subcontractor to include compliance with:

16.2.1.1. Operators’ Manuals;

16.2.1.2. Manufacturers’ Manuals; and

16.2.1.3. Instructions for Continued Airworthiness.

NOTE: Any changes that DAI becomes aware of regarding Operators’ Manuals, Manufacturers’ Manuals and/or Instructions for Continued Airworthiness will be informed to the subcontractor by providing a copy of the revised manuals and/or instructions.

16.3.2. Subcontractors must treat repair data (Technical Instructions, drawings, and specifications) provided by DAI as proprietary. They will not divulge, copy, or give DAI proprietary repair data to any third party without written permission from a DAI company officer.

16.3.3. Subcontractors must contractually agree to allow the FAA and EASA access to their facilities or any other place necessary to assess the quality of subcontracted work during maintenance. The customer must also be allowed access to the subcontractor’s facility. DAI reserves the right to visit each subcontractor’s facility as needed to satisfy FAA, EASA and/or customer requirements.

16.4. Subcontracting to non-EASA approved organizations.

16.4.1. DAI will have responsibility for the EASA airworthiness of maintenance subcontracted to a non-EASA approved subcontractor which is included on the DAI ASL.

16.4.2. DAI requires all subcontractors to meet DAI quality system requirements.

16.4.3. The specific requirements are listed on the Purchase Order to the subcontractor.

16.4.4. This requirement applies to the extent necessary to ensure that characteristics not verifiable upon receipt are adequately controlled by the subcontractor.

16.4.5. DAI must inspect each item on which subcontracted work has been performed for compliance with this supplement.

16.4.6. If DAI cannot determine the quality of the subcontracted work and the contracted item must be disassembled by DAI to determine the quality of the work performed then it should not be contracted to a that non-EASA approved organization.

Page 27 Issue 1 15-Aug-2012

EASA Supplement to FAA 14 CFR 145 Accepted Repair Station Quality Manual (RSQM) Reissue Date: 15-Aug-2012

16.5. Auditing Subcontractors

16.5.1. The subcontractor re-approval period for EASA Approved subcontractors is two years. The approval period is from the date the subcontractor is initially added to the ASL or re-approved to the end of the month the re-approval is due.

16.5.2. Auditing for re-approval of subcontractors is accomplished as listed in paragraph 16.2. if there have been no quality issues reported.

16.5.3. If quality issues have been reported, DAI may elect to complete an on-site audit depending upon the criticality of the quality issue.

16.5.4. Records of subcontractor audits are assembled as a single “pdf” file consisting of those items listed in paragraph 16.2., as applicable, and stored in an electronic database (docTrack).

16.5.5. Records of audits are maintained on file for a period no less than 4 years.

16.6. Receiving Inspections

16.6.1. If DAI subcontracts functions to another organisation that is EASA approved, that organization is responsible for approving the return to service for each item on which it has worked.

16.6.2. DAI verifies at receiving inspection that maintained articles and documents received from EASA approved, ASL subcontractors conform to the requirements specified on the Purchase Order.

16.6.3. The Receiving Clerk inspects subcontracted material to ensure P/N, S/N, and quantity received is correct and part is received undamaged.

16.6.4. The Receiving Clerk ensures certification and test reports received with an item, remain with the item.

16.6.5. Subcontracted items are receipt inspected by the appropriate inspection department prior to further repair or completion of process. Inspector ensures conformance to contract requirements, certification and test reports are received and are checked for completeness and correctness, and final inspect components/parts for serviceability as necessary. All inspections are signed off on the component/parts repair tag/router inspection block.

NOTE: Reference paragraph 10.8.2. of this supplement for EASA Certification requirements for subcontracted work.

16.6.6. The Chief Technical and Regulatory Officer determines the need for additional testing or laboratory analysis, based on previous failures, laboratory history, inadequate marking, trend analysis, and any other questions regarding material conformance to specification.

16.6.7. The Receiving Clerk records the results of inspection on a computer terminal, which produces a Receiving Form. The Receiving Clerk attaches a copy to the outside of the package, retains a copy for receiving records, and places a copy inside the packing with the part.

16.6.8. All technical training, including training receiving inspection personnel who inspect contracted work, is documented in the FAA Approved Training Manual, OP620-1, as revised.

16.6.9. Records of subcontracted work received through the receiving process are maintained on file for a minimum of two (2) years.

Page 28 Issue 1 15-Aug-2012

EASA Supplement to FAA 14 CFR 145 Accepted Repair Station Quality Manual (RSQM) Reissue Date: 15-Aug-2012

Example of Form FC-301

Page 29 Issue 1 15-Aug-2012

EASA Supplement to FAA 14 CFR 145 Accepted Repair Station Quality Manual (RSQM) Reissue Date: 15-Aug-2012

Example of Form QA-2002

Page 30 Issue 1, Revision 1 31-May-2013

EASA Supplement to FAA 14 CFR 145 Accepted Repair Station Quality Manual (RSQM) Reissue Date: 15-Aug-2012

17. HUMAN FACTORS

17.1. DAI requires Human Factors training each two years at a minimum with the initial Human Factors training assigned by hire date +30 days.

17.2. DAI uses various methods to train the workforce regarding Human Factors.

17.3. Subscription Services:

17.3.1. Blue Tuna, an FAA-recognized vendor for the online delivery of Human Factors (HF) courses.

17.3.2. Business and Legal Resources (BLR) for Health, Safety and Environmental (HSE) courses.

17.3.3. FedReady for FAA Drug and Alcohol Testing Program training.

17.4. Additional resources and methods employed include, but are not limited to:

17.4.1. Computer-Based Training (CBT):

17.4.2. “Tech Talks”, internally-developed informational documents.

17.4.3. Blue Tuna which includes topics that vary according to our needs and assigned to personnel who maintain or supervise maintainers.

17.4.4. BLR for assigning applicable HSE courses to employees.

17.4.5. FedReady, for FAA Drug and Alcohol Testing Program training for supervisors of employees in safety-sensitive positions.

17.4.6. Other communication/training resources employed include:

17.2.1.1. Newsletters

17.2.1.2. DAI’s intranet homepage

17.2.1.3. All-Hands briefings

17.2.1.4. Shop video monitors

17.2.1.5. “Tool Box” talks

17.2.1.6. Facility Safety Committee meetings

17.2.1.7. Instructor-led courseware

17.4.7. DAI Executive leadership and/or Director of Quality and Continuous Improvement briefings

17.4.7.1. Ethics Policies

17.4.7.2. Facility Policies

17.4.7.3. Safety Policies

17.4.7.4. Near-Miss reporting processes

17.4.7.5. Job Hazard Analysis

17.4.7.6. Root Cause Analysis

Page 31 Issue 1, Revision 2 15-Oct-2013

EASA Supplement to FAA 14 CFR 145 Accepted Repair Station Quality Manual (RSQM) Reissue Date: 15-Aug-2012

18. LINE STATIONS DAI is not FAA authorized (D107) for line maintenance so this section does not apply.

Page 32 Issue 1 15-Aug-2012

EASA Supplement to FAA 14 CFR 145 Accepted Repair Station Quality Manual (RSQM) Reissue Date: 15-Aug-2012

19. WORK AWAY FROM A FIXED LOCATION

DAI may be requested to perform maintenance on an EU registered aircraft or articles away from our fixed location. These requests are initiated through our Field Service group. DAI may work away from its fixed location as follows:

19.1. On a recurring basis when necessary:

19.1.1. Subject to the approval contained in the FAA Operations Specification D100, and;

19.1.2. Only as necessary to perform emergency or non-routine maintenance limited to urgent defect rectification, or repair work on an EU Registered aircraft, or articles intended for installation on EU registered aircraft.

19.1.3. DAI will follow all existing procedures in its current Repair Station Manual and this EASA Supplement.

19.1.4. When the work requested is to be performed within the territory of the United States or its territories, the responsible PMI shall be informed and EASA notification is not required.

19.1.5. When the work requested is to be performed outside the territory of the United States or its territories, the responsible PMI shall be informed and EASA will be notified using electronic mail at [email protected].

Field Service Overview

19.2. When DAI performs work away from its fixed location, it refers to that as Field Service.

19.3. DAI maintains a group dedicated to field service work to support customers with engine and/or engine related airframe work, for example engine removals and installations or engine mounted accessory replacement.

19.4. Field Service work may be performed in any DAI hangar or the customer’s facility as necessary.

19.5. Regardless of location, this work is performed following the procedures in the DAI RSQM, section 6.0 of the Repair Station Manual and this supplement.

19.5.1. The DAI RSQM refers to OP 750-1, Procedures for Work Performed at Another Location; WI 420, Initiation of Field Service; and WI 424, Field Service Representatives

19.5.2. The remaining portions of this supplement chapter 19 were adapted from these procedures and instructions.

19.6. The repair station Chief Inspector/Quality Manager is responsible for ensuring that all maintenance is performed in accordance with this supplement, applicable DAI procedures and all regulatory requirements. He or she may delegate this oversight to qualified personnel, but this does not relieve him or her from overall responsibility.

19.7. Unique tooling, maintenance records and procedures required to perform field work are subject to the same approvals and controls specified by the RSQM for work within the repair station and meet the requirements of the manufacturer’s instructions for continued airworthiness or other data acceptable to the pertinent regulatory authority.

19.8. DAI personnel are not dispatched to a work site unless arrangements have been made to ensure the work is done in accordance with this supplement. The necessary tooling, training and data must be available for the work to be accomplished.

Field Service Personnel

19.9. All DAI Field Service personnel are certificated under 14 CFR Part 65 or perform maintenance under the direct supervision of a technician certificated under 14 CFR Part 65.

19.10. DAI may use or contract non-DAI personnel to assist DAI Field Service Representatives. These persons do not inspect or approve any article for return to service under the certificated repair station authorization.

Page 33 Issue 1 15-Aug-2012

EASA Supplement to FAA 14 CFR 145 Accepted Repair Station Quality Manual (RSQM) Reissue Date: 15-Aug-2012

19.11. Non-DAI personnel work under the direct supervision of certificated DAI personnel.

19.12. Field Service personnel listed on the repair station’s Master Roster with authority to return articles to service are qualified to perform and inspect their own work (except when R.I.I. is required) based on the following criteria:

19.12.1. When inspecting their own work they assume the responsibilities of an inspector with a reporting line to the Field Service Quality Manager or Chief Inspector.

19.12.2. Maintenance records, including inspection and sign-off, are maintained current with the work in progress.

19.12.3. The general requirements of the DAI quality system with respect to the methods used to record and approve maintenance are followed.

19.12.4. When two or more Field Service Representitives are assigned to the job, each may perform inspection duties for the other(s).

Field Service Work

19.13. Technical Data

19.13.1. DAI Field Service Representatives have access to current technical data when performing maintenance. This is obtained via:

19.13.1.1. Customer manuals/data

19.13.1.2. Electronic means

19.13.1.3. Current data provided by DAI

19.13.1.4. Field Service Representatives record the specific technical data, revision number and Sales Order in the maintenance record.

19.14. Tools and Equipment

19.14.1. Tools and equipment shipped to Field Service Representatives are inspected for serviceability and current calibration, as applicable, by DAI personnel prior to use.

19.14.2. Field Service Representatives may use tools, equipment or measuring devices furnished by the customer at the work site provided tools/equipment are inspected to ensure suitability for intended use and, where applicable, valid calibration and maintenance status.

19.15. Handling of Parts

19.15.1. Parts and assemblies from any source used at a remote work site are inspected by DAI personnel for damage and proper documentation before installation.

19.15.2. When unacceptable parts are received at the remote work site from any source, the Field Service Representitive immediately notifies the Field Service Quality Manager and supplies the following:

19.15.2.1. Part Name

19.15.2.2. Part Number

19.15.2.3. Manufacturer

19.15.2.4. Serial Number

19.15.2.5. Supply Source

19.15.2.6. Any other pertinent data

(NOTE: If the part(s) are suspected to be unapproved (SUP), then reference RSM 11.5 for additional guidance)

19.15.3. Non-conforming parts are segregated and then disposition is determined by DAI’s Chief Inspector/Quality Manager on a case-by-case basis.

Page 34 Issue 1 15-Aug-2012

EASA Supplement to FAA 14 CFR 145 Accepted Repair Station Quality Manual (RSQM) Reissue Date: 15-Aug-2012

19.15.4. Documentation for parts embodied becomes part of the Sales Order.

19.15.5. Parts removed by Field Service Representitives from the article undergoing maintenance are properly tagged and returned to the Materials Department, or the customer. The appropriate tag, (serviceable, repairable, or rejected), is signed and securely attached to each article.

19.16. Forms and Control

19.16.1. Sales Order Assignment

19.16.1.1. Upon receipt of a request for maintenance, the responsible manager creates a Sales Order or Work Order.

19.16.1.2. A Sales Order or Work Order is prepared that, at a minimum, specifies the following: Repair station name, address and certificate number, unique identifier number, date of preparation, customer name, customer contact information, article model to be worked on, article serial number (where applicable) and a description of the initial work to be accomplished.

19.16.1.3. The description of work provides clear and unambiguous instructions for the technician performing the work.

19.16.1.4. Changes to the scope of work required, based on customer requests, results of preliminary inspections or the initial work; are documented.

19.16.1.4.1. When necessary, due to remote location or time constraints, these revisions are hand written on the original Sales Order or applicable Field Service form. The notations are signed and dated by the technician (and / or initials and employee number) performing the work. These changes are written in English, using a permanent pen, and are legible and clear in meaning and content. This document is retained as part of the maintenance record held on file at the repair station under the unique identifier number.

19.16.1.4.2. Hand written changes may be transferred to a system generated revision upon completion of the job.

19.17. Field Service Representatives’ Responsibilities:

19.17.1. Perform the work described on the Sales Order in accordance with the approved data including, when applicable, the Operators’ Approved Maintenance Program (i.e. the Operators’ FAA / NAA Approved General Maintenance Manual).

Note: When an Operator has an Approved Aircraft Inspection Program (AAIP) other than that specified by the manufacturer, or has additional requirements based on an AAIP (such as R.I.I. etc.) it is a regulatory requirement for the Operator to provide DAI with a copy of the relevant sections of his manual. No work should be performed on the aircraft / engine until the manual has been reviewed and the requirements understood.

19.17.2. Perform and record a preliminary inspection (reference RSM 11.3) and, if necessary, a hidden damage inspection (reference RSM 11.4). This inspection(s) is documented on form FS-ALL-9000. A sample may be found in the Forms Manual OP 424-1, as revised.

19.17.3. Notify the appropriate manager when revised instructions are required. The Sales Order is revised to incorporate the revision.

19.17.4. Use initials and employee number or stamp to sign off work accomplished on applicable forms.

19.17.5. Complete maintenance records and sign for approval for return to service with reference to paragraph 12 of this supplement.

19.17.6. Notify the responsible manager regarding completion of Sales Order.

Page 35 Issue 1 15-Aug-2012

EASA Supplement to FAA 14 CFR 145 Accepted Repair Station Quality Manual (RSQM) Reissue Date: 15-Aug-2012

19.18. Maintenance Documentation

19.18.1. Field Service uses various forms to document maintenance performed, including hand-written discrepancy logs (for simple tasks) and pre-printed abbreviated checklists (for more complex tasks). Alternatively, pages from the applicable technical manuals may be copied and used by technicians as checklists for any task.

19.18.2. Maintenance record entries provide the following information:

19.18.2.1. A description of work performed.

19.18.2.2. Reference to the applicable instructions for continued airworthiness.

19.18.2.3. The date of completion of the work performed.

19.18.2.4. The name of the person performing the work.

19.18.2.5. The signature (if other than the person who performed the work), the DAI EASA Approved Repair Station number and the FAA Certificated Repair Station Number.

The signature of the authorized DAI Technician certifying the article/item for release to service in respect to that work performed

NOTE: Reference to Paragraphs 7-10 and 12 must be adhered to in the performance of a proper EASA Release to Service.

19.2.1.1. If applicable, the signature of the person performing Required Inspection Items (R.I.I.).

19.18.3. Approval for Release to Service - Example

This certifies that the work requested by the customer and described on the Sales Order listed below was carried out and inspected in accordance with EASA Part-145 and in respect to that work the aircraft is considered ready for release to service. Pertinent details of this maintenance are on file at this EASA Approved / FAA Certificated Repair Station.

Sales Order No.: ____________________ Date: _______________ Signed: ______________________________________________________ For Dallas Airmotive, Inc. EASA.145.5596 FAA YRR0491L 330 Bravo Lane St. Paul, MN 55107

19.18.4. In all cases, the repair station must issue the certification when all required maintenance has been carried out, except that if it was not possible to complete all maintenance actions requested, then details of the work not performed must be endorsed on the Release to Service and the Operator informed.

19.18.5. Quote the EASA Part-145 Approval Certificate Number and the FAA 14 CFR Part 145 Certificate Number in all cases.

NOTE: Reference to Paragraphs 7 – 10 and 12 must be adhered to in the performance of a proper EASA Release to Service.

19.18.6. In the absence of a DAI preprinted maintenance release label; the authorized inspector duplicates the wording on the label (stated above) for the logbook entry. This maintains a standard logbook entry that meets the requirements of the pertinent parts of EASA Part-145 and 14 CFR Parts 43 and 145.

Page 36 Issue 1, Revision 2 15-Oct-2013

EASA Supplement to FAA 14 CFR 145 Accepted Repair Station Quality Manual (RSQM) Reissue Date: 15-Aug-2012

Page 37 Issue 1, Revision 1 31-May-2013

EASA Supplement to FAA 14 CFR 145 Accepted Repair Station Quality Manual (RSQM) Reissue Date: 15-Aug-2012

Page 38 Issue 1, Revision 1 31-May-2013

EASA Supplement to FAA 14 CFR 145 Accepted Repair Station Quality Manual (RSQM) Reissue Date: 15-Aug-2012

Page 39 Issue 1, Revision 1 31-May-2013

EASA Supplement to FAA 14 CFR 145 Accepted Repair Station Quality Manual (RSQM) Reissue Date: 15-Aug-2012

Page 40 Issue 1, Revision 1 31-May-2013

EASA Supplement to FAA 14 CFR 145 Accepted Repair Station Quality Manual (RSQM) Reissue Date: 15-Aug-2012

Page 41 Issue 1, Revision 1 31-May-2013

EASA Supplement to FAA 14 CFR 145 Accepted Repair Station Quality Manual (RSQM) Reissue Date: 15-Aug-2012

Page 42 Issue 1, Revision 1 31-May-2013

EASA Supplement to FAA 14 CFR 145 Accepted Repair Station Quality Manual (RSQM) Reissue Date: 15-Aug-2012

Page 43 Issue 1, Revision 1 31-May-2013

EASA Supplement to FAA 14 CFR 145 Accepted Repair Station Quality Manual (RSQM) Reissue Date: 15-Aug-2012

Page 44 Issue 1, Revision 1 31-May-2013

EASA Supplement to FAA 14 CFR 145 Accepted Repair Station Quality Manual (RSQM) Reissue Date: 15-Aug-2012

Page 45 Issue 1, Revision 1 31-May-2013

EASA Supplement to FAA 14 CFR 145 Accepted Repair Station Quality Manual (RSQM) Reissue Date: 15-Aug-2012

Page 46 Issue 1, Revision 1 31-May-2013

EASA Supplement to FAA 14 CFR 145 Accepted Repair Station Quality Manual (RSQM) Reissue Date: 15-Aug-2012

Page 47 Issue 1, Revision 1 31-May-2013

EASA Supplement to FAA 14 CFR 145 Accepted Repair Station Quality Manual (RSQM) Reissue Date: 15-Aug-2012

Appendix A – Sample Audit Schedule

Page 48 Issue 1 15-Aug-2012

EASA Supplement to FAA 14 CFR 145 Accepted Repair Station Quality Manual (RSQM) Reissue Date: 15-Aug-2012

Page 49 Issue 1 15-Aug-2012

EASA Supplement to FAA 14 CFR 145 Accepted Repair Station Quality Manual (RSQM) Reissue Date: 15-Aug-2012

Page 50 Issue 1 15-Aug-2012