Dyeing & Printing

-

Upload

yuganshu-soni -

Category

Documents

-

view

244 -

download

1

Transcript of Dyeing & Printing

-

8/13/2019 Dyeing & Printing

1/33

1

Dyeing

Dyeing is the process of adding color

totextileproducts likefibers,yarns,andfabrics.

Dyeing is normally done in a

specialsolution containingdyesand

particularchemical material.After dyeing,

dyemolecules haveuncutChemical bond with

fiber molecules. Thetemperature and time

controlling are two key factors in dyeing. There

are mainly two classes of dye,natural andman-made.

Acrylic fibers are dyed with basic dyes, Nylon and protein fibers such as wool and

silk are dyed with acid dyes, polyester yarn is dyed with disperse dyes. Cotton is

dyed with a range of dye types, including vat dyes, and modern synthetic reactive

and direct dyes.

Direct dyeing

Direct dyes, a class of dyes largely for dyeing cotton, are water soluble and can be

applied directly to the fiber from an aqueous solution. Most other classes of

synthetic dye, other than vat and surface dyes, are also applied in this way.This

dyeing is normally carried out in a neutral or slightlyalkaline dye bath, at or

nearboiling point, with the addition of eithersodium chloride (NaCl) orsodium

sulphate (Na2SO4). Direct dyes are used oncotton, paper,leather, wool, silk

andnylon.They are also used aspH indicators and asbiological stains

Yarn dyeing

There are many forms of yarn dyeing. Common forms are the at package form and

the at hanks form. Cotton yarns are mostly dyed at package form, and acrylic or

wool yarn are dyed at hank form. In the continuous filament industry, polyester or

http://en.wikipedia.org/wiki/Textilehttp://en.wikipedia.org/wiki/Fiberhttp://en.wikipedia.org/wiki/Yarnhttp://en.wikipedia.org/wiki/Fabrichttp://en.wikipedia.org/wiki/Solutionhttp://en.wikipedia.org/wiki/Dyehttp://en.wikipedia.org/wiki/Materialhttp://en.wikipedia.org/wiki/Moleculeshttp://en.wikipedia.org/wiki/Chemical_bondhttp://en.wikipedia.org/wiki/Temperaturehttp://en.wikipedia.org/wiki/Natural_dyeshttp://en.wikipedia.org/wiki/Dyeshttp://en.wikipedia.org/wiki/Dyeshttp://en.wikipedia.org/wiki/Alkalinehttp://en.wikipedia.org/wiki/Boiling_pointhttp://en.wikipedia.org/wiki/Sodium_chloridehttp://en.wikipedia.org/wiki/Sodium_sulfatehttp://en.wikipedia.org/wiki/Sodium_sulfatehttp://en.wikipedia.org/wiki/Cottonhttp://en.wikipedia.org/wiki/Leatherhttp://en.wikipedia.org/wiki/Nylonhttp://en.wikipedia.org/wiki/PH_indicatorhttp://en.wikipedia.org/wiki/Staining_(biology)http://en.wikipedia.org/wiki/Staining_(biology)http://en.wikipedia.org/wiki/PH_indicatorhttp://en.wikipedia.org/wiki/Nylonhttp://en.wikipedia.org/wiki/Leatherhttp://en.wikipedia.org/wiki/Cottonhttp://en.wikipedia.org/wiki/Sodium_sulfatehttp://en.wikipedia.org/wiki/Sodium_sulfatehttp://en.wikipedia.org/wiki/Sodium_chloridehttp://en.wikipedia.org/wiki/Boiling_pointhttp://en.wikipedia.org/wiki/Alkalinehttp://en.wikipedia.org/wiki/Dyeshttp://en.wikipedia.org/wiki/Dyeshttp://en.wikipedia.org/wiki/Natural_dyeshttp://en.wikipedia.org/wiki/Temperaturehttp://en.wikipedia.org/wiki/Chemical_bondhttp://en.wikipedia.org/wiki/Moleculeshttp://en.wikipedia.org/wiki/Materialhttp://en.wikipedia.org/wiki/Dyehttp://en.wikipedia.org/wiki/Solutionhttp://en.wikipedia.org/wiki/Fabrichttp://en.wikipedia.org/wiki/Yarnhttp://en.wikipedia.org/wiki/Fiberhttp://en.wikipedia.org/wiki/Textile -

8/13/2019 Dyeing & Printing

2/33

2

polyamide yarns are always dyed at package form, while viscose rayon yarns are

partly dyed at hank form because of technology.

Dyes

A dye is acolored substance that has anaffinity to thesubstrate to which it is beingapplied. The dye is generally applied in anaqueous solution, and may require

amordant to improve the fastness of the dye on the fiber.

Types of dyes:

Natural dyes

The majority of natural dyes are from plant sources like roots,

berries,bark,leaves, andwood,fungi, andlichens. Plant-based dyes suchasindigo,saffron,andmadder were raised commercially and were important trade

goods in the economies of Asia and Europe. Across Asia and Africa, patterned

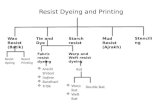

fabrics were produced usingresist dyeing techniques to control the absorption of

color in piece-dyed cloth.

Synthetic dyes

They are human-made (synthetic)organic dye like mauveine.Synthetic dyes have

quickly replaced the traditional natural dyes. They cost less, they offered a vast

range of new colors, and they impart better properties to the dyed materials.

Dyes are also classified according to how they are used in the dyeing process:

Acid dyes:arewater-solubleanionic dyes that are applied

tofibers such assilk,wool,nylon and modifiedacrylic

fibers using neutral to acid dye baths. Attachment to the fiber

is attributed, at least partly, to salt formation between anionic

groups in the dyes andcationic groups in the fiber. Acid dyesare not substantive tocellulosic fibers. Most synthetic food

colors fall in this category.

Basic dyes:are water-solublecationic dyes that are mainly applied toacrylic

fibers,but find some use for wool and silk. Usuallyacetic acid is added to the dye

http://en.wikipedia.org/wiki/Colorhttp://en.wikipedia.org/wiki/Chemical_affinityhttp://en.wiktionary.org/wiki/substratehttp://en.wikipedia.org/wiki/Aqueous_solutionhttp://en.wikipedia.org/wiki/Mordanthttp://en.wikipedia.org/wiki/Roothttp://en.wikipedia.org/wiki/Berryhttp://en.wikipedia.org/wiki/Barkhttp://en.wikipedia.org/wiki/Leafhttp://en.wikipedia.org/wiki/Woodhttp://en.wikipedia.org/wiki/Fungihttp://en.wikipedia.org/wiki/Lichenhttp://en.wikipedia.org/wiki/Indigo_dyehttp://en.wikipedia.org/wiki/Trade_and_use_of_saffronhttp://en.wikipedia.org/wiki/Rubiahttp://en.wikipedia.org/wiki/Resist_dyeinghttp://en.wikipedia.org/wiki/Organic_compoundhttp://en.wikipedia.org/wiki/Mauveinehttp://en.wikipedia.org/wiki/Acid_dyehttp://en.wikipedia.org/wiki/Acid_dyehttp://en.wikipedia.org/wiki/Waterhttp://en.wikipedia.org/wiki/Solublehttp://en.wikipedia.org/wiki/Anionichttp://en.wikipedia.org/wiki/Fiberhttp://en.wikipedia.org/wiki/Silkhttp://en.wikipedia.org/wiki/Woolhttp://en.wikipedia.org/wiki/Nylonhttp://en.wikipedia.org/wiki/Acrylic_fiberhttp://en.wikipedia.org/wiki/Acrylic_fiberhttp://en.wikipedia.org/wiki/Cationichttp://en.wikipedia.org/wiki/Cellulosehttp://en.wikipedia.org/wiki/Cationichttp://en.wikipedia.org/wiki/Acrylic_fiberhttp://en.wikipedia.org/wiki/Acrylic_fiberhttp://en.wikipedia.org/wiki/Acetic_acidhttp://en.wikipedia.org/wiki/Acetic_acidhttp://en.wikipedia.org/wiki/Acrylic_fiberhttp://en.wikipedia.org/wiki/Acrylic_fiberhttp://en.wikipedia.org/wiki/Cationichttp://en.wikipedia.org/wiki/Cellulosehttp://en.wikipedia.org/wiki/Cationichttp://en.wikipedia.org/wiki/Acrylic_fiberhttp://en.wikipedia.org/wiki/Acrylic_fiberhttp://en.wikipedia.org/wiki/Nylonhttp://en.wikipedia.org/wiki/Woolhttp://en.wikipedia.org/wiki/Silkhttp://en.wikipedia.org/wiki/Fiberhttp://en.wikipedia.org/wiki/Anionichttp://en.wikipedia.org/wiki/Solublehttp://en.wikipedia.org/wiki/Waterhttp://en.wikipedia.org/wiki/Acid_dyehttp://en.wikipedia.org/wiki/Mauveinehttp://en.wikipedia.org/wiki/Organic_compoundhttp://en.wikipedia.org/wiki/Resist_dyeinghttp://en.wikipedia.org/wiki/Rubiahttp://en.wikipedia.org/wiki/Trade_and_use_of_saffronhttp://en.wikipedia.org/wiki/Indigo_dyehttp://en.wikipedia.org/wiki/Lichenhttp://en.wikipedia.org/wiki/Fungihttp://en.wikipedia.org/wiki/Woodhttp://en.wikipedia.org/wiki/Leafhttp://en.wikipedia.org/wiki/Barkhttp://en.wikipedia.org/wiki/Berryhttp://en.wikipedia.org/wiki/Roothttp://en.wikipedia.org/wiki/Mordanthttp://en.wikipedia.org/wiki/Aqueous_solutionhttp://en.wiktionary.org/wiki/substratehttp://en.wikipedia.org/wiki/Chemical_affinityhttp://en.wikipedia.org/wiki/Color -

8/13/2019 Dyeing & Printing

3/33

3

bath to help the uptake of the dye onto the fiber. Basic dyes are also used in the

coloration ofpaper.

Mordant dyes: require amordant,which improves the fastness of the dye against

water,light andperspiration.The choice of mordant is very important as different

mordants can change the final color significantly. Most natural dyes are mordant

dyes. The most important mordant dyes are the synthetic mordant dyes, or chrome

dyes, used for wool; these comprise some 30% of dyes used for wool, and are

especially useful for black and navy shades. The mordant,potassium dichromate,

is applied as an after-treatment.

Vat dyes:are essentially insoluble in water and incapable of

dyeing fibres directly. However, reduction inalkaline

liquorproduces the water solublealkalimetalsalt of the dye,

which, in this leuco form, has an affinity for the textile fibre.

Subsequentoxidation reforms the original insoluble dye. The

color of denim is due to indigo, the original vat dye.

Reactive dyes: utilize achromophore attached to asubstituent that is capable of

directlyreacting with the fibre substrate. Thecovalentbonds that attach reactive

dye to natural fibers make them among the most permanent of dyes. "Cold"

reactive dyes, such asProcion MX,Cibacron F,andDrimarene K,are very easy touse because the dye can be applied at room temperature. Reactive dyes are by far

the best choice for dyeingcotton and othercellulose fibres.

Disperse dyes: were originally developed for the dyeing ofcellulose acetate,and

are water insoluble. The dyes are finely ground in the presence of a dispersing

agent and sold as a paste, or spray-dried and sold as a powder. Their main use is to

dyepolyesterbut they can also be used to dye nylon,cellulose triacetate, and

acrylic fibres.

Sulfur dyes:are two part "developed" dyes used to dyecotton with dark colors. The initial bath imparts a yellow or

palechartreuse color, This is after treated with a sulfur

compound in place to produce the dark black we are familiar

with in socks for instance. Sulfur Black 1 is the largest selling

dye by volume.

http://en.wikipedia.org/wiki/Paperhttp://en.wikipedia.org/wiki/Mordanthttp://en.wikipedia.org/wiki/Lighthttp://en.wikipedia.org/wiki/Perspirationhttp://en.wikipedia.org/wiki/Potassium_dichromatehttp://en.wikipedia.org/wiki/Vat_dyehttp://en.wikipedia.org/wiki/Vat_dyehttp://en.wikipedia.org/wiki/Alkaline_liquorhttp://en.wikipedia.org/wiki/Alkaline_liquorhttp://en.wikipedia.org/wiki/Alkalihttp://en.wikipedia.org/wiki/Salthttp://en.wikipedia.org/wiki/Oxidationhttp://en.wikipedia.org/wiki/Reactive_dyeshttp://en.wikipedia.org/wiki/Reactive_dyeshttp://en.wikipedia.org/wiki/Chromophorehttp://en.wikipedia.org/wiki/Substituenthttp://en.wikipedia.org/wiki/Chemical_reactionhttp://en.wikipedia.org/wiki/Covalenthttp://en.wikipedia.org/wiki/Procion_MXhttp://en.wikipedia.org/w/index.php?title=Cibacron_F&action=edit&redlink=1http://en.wikipedia.org/w/index.php?title=Drimarene_K&action=edit&redlink=1http://en.wikipedia.org/wiki/Cottonhttp://en.wikipedia.org/wiki/Cellulosehttp://en.wikipedia.org/wiki/Cellulose_acetatehttp://en.wikipedia.org/wiki/Polyesterhttp://en.wikipedia.org/wiki/Cellulose_triacetatehttp://en.wikipedia.org/wiki/Sulfur_dyehttp://en.wikipedia.org/wiki/Sulfur_dyehttp://en.wikipedia.org/wiki/Chartreuse_(color)http://en.wikipedia.org/wiki/Chartreuse_(color)http://en.wikipedia.org/wiki/Sulfur_dyehttp://en.wikipedia.org/wiki/Cellulose_triacetatehttp://en.wikipedia.org/wiki/Polyesterhttp://en.wikipedia.org/wiki/Cellulose_acetatehttp://en.wikipedia.org/wiki/Cellulosehttp://en.wikipedia.org/wiki/Cottonhttp://en.wikipedia.org/w/index.php?title=Drimarene_K&action=edit&redlink=1http://en.wikipedia.org/w/index.php?title=Cibacron_F&action=edit&redlink=1http://en.wikipedia.org/wiki/Procion_MXhttp://en.wikipedia.org/wiki/Covalenthttp://en.wikipedia.org/wiki/Chemical_reactionhttp://en.wikipedia.org/wiki/Substituenthttp://en.wikipedia.org/wiki/Chromophorehttp://en.wikipedia.org/wiki/Reactive_dyeshttp://en.wikipedia.org/wiki/Oxidationhttp://en.wikipedia.org/wiki/Salthttp://en.wikipedia.org/wiki/Alkalihttp://en.wikipedia.org/wiki/Alkalihttp://en.wikipedia.org/wiki/Alkaline_liquorhttp://en.wikipedia.org/wiki/Alkaline_liquorhttp://en.wikipedia.org/wiki/Vat_dyehttp://en.wikipedia.org/wiki/Potassium_dichromatehttp://en.wikipedia.org/wiki/Perspirationhttp://en.wikipedia.org/wiki/Lighthttp://en.wikipedia.org/wiki/Mordanthttp://en.wikipedia.org/wiki/Paper -

8/13/2019 Dyeing & Printing

4/33

4

Textile Dyes used for cellulosic Fibres

Cellulose fibers include cotton, linen, rayon, hemp, ramie, lyocell (Tencel),

bamboo, and pineapple plant fiber.

Fiber Reactive Dyes

The best dyes, by far, to use for cotton and other cellulose fibers are the fiber

reactive dyes. They are much brighter, longer-lasting, and easier-to-use than all-

purpose dyes.

How to Use Fiber Reactive Dye

Cool water fiber reactive dyes can be used normally. It can also be used according

to the Low Water Immersion, or even in a washing machine.They work especially

well on cotton, and on any other cellulose fiber.

Types of Fiber Reactive Dye

ProcionMX : Many people feel quite strongly that the best dye choice for the

beginner, as well as for many experienced dyers, is Procion MX, because this dye

is very easy to work with. You never need to steam or otherwise heat-set the fabric,

when you are using Procion MX type fiber reactive dyes, and the dyes are

relatively non-toxic. Other advantages include the remarkable washfastness found

in all fiber-reactive dyes.

Optimum reaction temperatures for Procion MX dyes are between 95 and 105F =35 to 41C (except for turquoise, which prefers up to 130F = 55C). Do not use

at temperatures below 70F.If the temperature is lower than that, pop each piece

into a separate plastic bag or bucket and take them to a warmer place overnight to

react.

-

8/13/2019 Dyeing & Printing

5/33

5

Cibacron F: Another very good fiber reactive dye for artists and crafters to use is

the Cibacron F line. Like Procion MX dyes, Cibacron F dyes can be used in warm

water, instead of extremely hot water like some dyes. Its advantages over

ProcionMX dyes are that it 'keeps' better in solution, so one can store and possibly

even buy it already in solution (liquid form), avoiding the safety hazard ofbreathing dye powder; it is also easier to wash the excess unattached dye out of the

fabric when using Cibacron F dyes than when using Procion MX. However, the

Cibacron F line has one major drawback when compared to the Procion MX line:

there is not as wide a choice of colors, whether one buys primaries to mix your

own, or buys pre-made mixes from the dye supplier.

Optimum temperatures for Cibacron F dyes are slightly higher than for Procion

MX dyes. Ciba said 55 to 65C (130 to 150F).

Drimarene K:This is the more of a "warm water" dye than a "cool water" dye. It

requires higher temperatures still than Cibacron F, but does not require steaming.

They are very similar in action to MX type dyes, except for requiring a minimum

temperature of 35C (or 95F). The greatest drawback, besides the need to find a

warm place for the dye reaction to occur, is the lack of a truly rich red. This is,

however, another excellent line of dye for home.Drimarene K has optimum

temperatures around 60C (140F) for most colors, 80C (176F) for turquoise and

a couple of others.Remazol or vinyl sulfone dyes: are usually used for silk painting and fixed by

steaming, but, like Procion H dyes, may be fixed to cotton using a high-pH

solution such as sodium silicate at room temperature, or by moderate heating. They

work well between 104F and 140F (40C-60C). To use it for cotton, use it with

TSP instead of soda ash, in low water immersion dyeing, with just a little heating,

by floating the buckets in a sinkful of hot water, or by using a microwave oven to

heat the dyebath. Vinyl sulfone dyes are particularly useful for chemical resist

dyeing (PDF), in which two different types of fiber reactive dyes are used to printforeground and background in different colors. Remazol dyes are more suitable for

dyeing for later discharge (bleaching) than are other fiber reactive dyes.

Levafix: Their temperature optimum is around 50C (122F). This is lower than

the optimum temperature of 60 to 80 C. for the Drimarene K dyes, which can be

-

8/13/2019 Dyeing & Printing

6/33

6

used in "cold" dyeing, but higher than the optimum temperature of about 35 to

40C (95 to 105F) for Procion MX. As with all of these dyes, it is not necessary

to get quite as high as the optimal temperature in order to have acceptable results.

Procion H and H-E dyes: are hot water dyes. They are usually used for silkpainting; they require steaming or simmering to fix to cotton or silk. Procion H

dyes are chemically similar to Procion MX dyes, being monochlorotriazines, but

they are far less reactive, and will not work at all well at room temperature. They

can be purchased in the form of powdered dye or dissolved in water; the latter

removes the dangers associated with breathing dye powder. Immersion dyeing

works best at 175F (80C).

Direct Dyes

Direct dyes are a class of hot water dyes for use on cellulose

fibers, such as cotton. It is one of the two types of dyes that are

mixed in 'all purpose dyes' such as Rit, Tintex Hot Water dye,

and Dylon Multi-purpose Dye. (The other type in the mixture

is an acid dye, which will not stay in any cellulose fiber for

long.) In most cases, better results will be obtained, often with

versatile and easier-to-use cool water methods,if one uses fiberreactive dye instead of direct dye. However, there are some

cases in which direct dye is preferred.

They areduller in color and poorly washfast.The colors of most direct dyes tend to

be duller than those provided by fiber reactive dyes, especially after fading in the

laundry. The washfastness of direct dyes is poor: expect anything dyed with them

to 'bleed' forever. They lack the permanence of the cold water fiber reactive dyes

which most hand-dyers prefer for use on cellulose fibers. As a result, clothing dyed

with direct dyes should be laundered in cool water only, with closely similarcolors. The washfastness problem can be reduced by following dyeing with the use

of a cationic after-treatment such as Retayne.

-

8/13/2019 Dyeing & Printing

7/33

7

They are inexpensive.The main reason why direct dyes are used is because of cost.

Direct dyes are sold alone and purchased in bulk and are among the cheapest of all

dyes.

They need a single dye bath.Direct dyes are applied in hot water, typically between175F and 200F. They can be applied in the same boiling-water dyebath with acid

dyes (whether for same-color effects, as in all-purpose dyes, or contrasting effects,

as in the case of AlterEgo brand dyes).

Direct dyes are not generally more lightfast than fiber reactive dyes.Many direct

dyes are less resistant to light than similarly-hued fiber reactive dyes, and both tend

to be less lightfast than vat dyes. There are just a few cases in which a particular

direct dye may be more lightfast than similar shades of fiber reactive dye.

Direct dyes are only loosely associated with the fiber molecule through the

property called substantivity, which is the tendency of the dye to associate with the

dye without strong bonds. This substantivity is increased by increasing the size of

the dye molecule, so direct dyes tend to be large. Small dye molecules tend to be

bright, while large dye molecules tend to be duller (as there are more parts that can

absorb additional wavelengths of light), so direct dyes are generally much less

bright in color than fiber reactive dyes. Substantivity is said to result from a

combination of the relatively weak Van der Waals forces and some hydrogen

bonding.

Suppliers

Dharma's Industrial dyes are eight different colors of direct dyes"not as

washfast or as bright as our other dyes, but easy & cheap". They are very

inexpensive to use, costing as little as 6 cents per pound of fabric to be dyed. A

pound of Dharma's Industrial Dye costs only $6.

PRO Chemical & Dye until recently sold an inexpensive line of nine different

direct dye colors under the name "Diazol Direct Dyes". Dyeing one pound of fabric

to a medium shade requires only 2.25 grams of dye, less than is required for most

dye types. This means that a pound of dye would be sufficient to dye more than

200 pounds of cotton fabric. The different colors have different costs, with prices

-

8/13/2019 Dyeing & Printing

8/33

8

being set lower for the less expensive dyes, rather than all being set to the same

price as the most expensive color, as in many brands.

Aljo Mfg. sells the same direct dyes that ProChem used to, by Color Index

Number, as well as blended colors. They may supply their dyes in a differentstrength, but you can ask for 100% of standard strength.

Jacquard Productshas introduced a line of direct dyes called iDye, to go with

their line of low-energy disperse dyes called iDye Poly. The two kinds of dyes may

be mixed in order to dye cotton/polyester blends in a single dyebath. iDye is much

more expensive per use than Industrial Dyes or Diazol Direct Dyes, as it is

packaged in individual-use packets like Rit or Tintex all-purpose dye.

Cushing sells a line containing many different pre-mixed colors of direct dyes; no

information is available on which direct dyes are included. There are two groups of

primary colors: the lighter set is Scarlet, Light Blue or Copenhagen Blue, and

Yellow, while the darker would be Blue, Cardinal and Canary. They are designed

to be used directly, however, not for color mixing; thus, there are forty different

colors available. Half an ounce of Cushing Direct Dye is sufficient to dye two

pounds of cellulose fiber, such as cotton, and costs $3.65. Rit brand's Proline Bulk

Dye consists of only direct dye, with no acid dye included, but apparently with a

considerable amount of salt included, so a given weight of dye will not go nearly

as far as with ProChem'sDiazol Direct dyes or Dharma's Industrial dyes.

Vat Dyes

Vat dyes are an ancient class of dye, based on the original natural dye, Indigo,

which is now produced synthetically, and its close chemical relative, historic

TyrianPurple. Both cotton and wool, as well as other fibers, can be dyed with vat

dyes.

"Vat dyeing" means dyeing in a bucket or vat. It can be done whenever a solideven shade, the same color over the entire garment, is wanted, using almost any

dye, including fiber reactive dye, direct dye, acid dye, etc. The opposite of vat

dyeing is direct dye application, such as, for example, tie dyeing.

Vat Dyes

-

8/13/2019 Dyeing & Printing

9/33

9

Most vat dyes are less suitable for the home dyer, as they are difficult to work

with; they require a reducing agent to solubilize them. The dye is soluble only in

its reduced (oxygen-free) form. The fiber is immersed repeatedly in this oxygen-

free dyebath, then exposed to the air, whereupon the water-soluble reduced form

changes color as oxygen turns it to the water-insoluble form. Indigo is an exampleof this dye class; it changes from yellow, in the dye bath, to green and then blue as

the air hits it.

Light fastness of Vat dyes

Vat dyes are, as a class, the most light-fast of all dyes. However, not all individual

vat dyes are equally resistant to light. The following are lightfastness ratings for

the unmixed vat dyes :

ColorName Colour Index name Lightfastnessrating (out of8)

VD01 Yellow vat yellow 2 5

VD02 Orange vat orange 2 5

VD03 Red vat red 13 7

VD04 Blue vat blue 6 7-8

VD08 Violet vat violet 1 6

Instructions for dyeing with vat dyes

Vat dyes must be solubilized before use. They are not soluble in their oxidized

form. The process requires the use of lye (sodium hydroxide), which must be used

with due care, including the use of goggles.

Indigo is subject to major crocking (rubbing off of the dye onto other items) unless

it is applied carefully. This means use a weaker dyebath, and dipping many times,

rather than a single strong dipping.

To solubilize vat dyes, use a mixture of sodium hydroxide (caustic soda, or lye)

and the reducing agent sodium dithionite (also known as sodium hydrosulfite, and

found in Rit Color Remover.

-

8/13/2019 Dyeing & Printing

10/33

10

Light-oxidized Vat Dyes

Inko-dye is a brand of solubilized reduced vat dye esters, which uses light rather

than oxygen to 'fix' the dye, with a inspirationally wide variety of possible effects.

Instead of being applied in an oxygen-free bath and being developed in the fabricby exposure to oxygen, Inkodyes are painted onto the fabric and then developed by

light. Unlike the Setacolor fabric paints used in sun printing, Inkodyes are true

dyes. (A dye actually itself attaches to the fabric; fabric paint includes a glue-like

binder, which imparts a stiffer feeling to the fabric.

Suppliers

The only retail source of Inkodye is Dharma Trading Company. There are many

textile industry sources for Indigosol dyes, which are the same type of dye used in

Inkodye, but these large companies tend to be less suitable for small-scale users

such as textile artists.

Naphthol Dyes

Cotton, rayon, and other celluosic fibers, as well as silk, can also be dyed withazoic or naphthol dyes. Naphthol dyes are true cold water dyes. The "cold" water

used in fiber reactive dyes such as Procion MX dyes should, ideally, be between

95 and 105F. (35 to 41C), although temperatures as low as 70F. (21C) may

be used. In contrast, naphthol dyes may be used in ice water. Both fiber reactive

and naphthol dyes are suitable for use in batik, since they do not require heat that

would melt the wax to set the dye.

Naphthol dyes include more hazardous chemicals than fiber reactive dyes, which

makes them less appropriate for home use.

The way naphthol dyes are used is fascinating. Two different types of chemicals

are mixed in the fiber, the diazo salt and the naphthol; the specific combination

determines the color obtained. An advantage of this sort of dye is that contrasting

colors may be placed adjacent to each other on fabric without color bleeding from

-

8/13/2019 Dyeing & Printing

11/33

11

one to the other. As with vat dyes, the final color is provided by insoluble particles

of dye that are stuck within the fiber; only the components that react together to

form these compounds are themselves soluble in water.

All Purpose Dyes

All-purpose dye is a hot water dye. It contains a mixture of dyes which will work

on many different kinds of fabric and yarn, but not particularly well on any of

them. It is often used in situations when another kind of dye would perform better,

largely because many people are unaware that there are higher quality dyes that

they could use.Theyare a mixture of Acid dye, of the leveling acid type, for dyeing

wool and other animal (protein) fibers, as well as nylon, and Direct dye, for dyeing

cellulose fibers such as cotton, rayon, linen, etc. In some cases it may contain an

acid dye that also happens to work pretty well as a direct dye. All-purpose dye

cannot be used to dye polyester or acrylic, and it cannot be used in cold water.

Great for Dyeing Fiber Blends

All purpose dye is most useful when coloring a blend of protein fiber (or nylon)

with a cellulose fiber such as cotton or rayon. Both fibers can be dyedapproximately the same color, at the same time. Some examples of such blends

include linsey-woolsey, Nycott (unless treated with Teflon, which makes it

undyeable), and any cotton or rayon garment with nylon lace trim. Both of the

kinds of dye in all-purpose dye tend to bleed and fade in the laundry, but a

commercial dye fixative can be used to improve performance.

Wasteful for Single Fibers

However, when dyeing a pure fiber of any sort, or a mixture of a pure fiber withundyeable synthetics such as polyester or acrylic (which require entirely different

dyes), this mixture of dyes represents a waste of dye and money. While dyeing

pure cotton, the acid dye brightens the dyed item up only until it is washed for the

first time, whereupon all of the acid dye disappears into the sewage system.

-

8/13/2019 Dyeing & Printing

12/33

12

Conversely, while dyeing wool or nylon alone, the direct dye is wasted, and ends

up down the drain.

In addition, the formulas for all-purpose dye generally contain a lot of salt. Salt is

cheap, but it makes the package appear to contain more dye than it really does. Saltis useful in dyeing solid colors, but causes problems for specialized dyeing

techniques in which the dye is painted on the material.

Suppliers

All-purpose dye is sold under a number of brand names, including Rit brand dye,

Dylon Multi-purpose dye (Dylon also sells fiber reactive dyes, in their Cold

Water and Washing Machine lines of dye), DEKA L Hot Water Dyes, andTintex Fabric Dyes. The old Cushing Union dye was also an all-purpose dye,

but they have since switched to selling their acid dye and direct dye separately.

The single most popular dye sold for home use in the US is Rit brand all-purpose

dye. The reason for its popularity is its ubiquity: nearly every grocery store and

pharmacy in the US sells an assortment of Rit brand dye on a rack.

Use the Correct Technique

To dye cellulosic fabric like cotton with all-purpose dye, you must use heat, and

plenty of time. Submerging the garment to be dyed in Rit brand dye and

simmering hot water will produce pastels after five minutes, or deeper, more

intense shades after half an hour. The ideal temperature is far hotter than tap water

can reach, at least 190F (or 87C).

Do not add soda ash when dyeing with all-purpose dye. Soda ash is used only

when dyeing with fiber reactive dye. It will not act as a dye fixative for all-purpose

dye.

Each packet of all-purpose dye contains only enough dye for 4 to 8 ounces of

material (100 to 200 grams). Black requires two to four times as much dye as other

colors. Smaller amounts of dye will result in paler colors.

Use an After-Treatment to Prevent Bleeding

-

8/13/2019 Dyeing & Printing

13/33

13

While dyeing cotton with all purpose dyes, the only portion of the dye that actually

does anything is the direct dye. Direct dye tends to be poor at surviving washing; it

tends to wash out gradually, bleeding on other fabrics. The solution to this

problem, which is widely employed by the textile industry, is to apply a cationic

dye fixative afterwards which seals the dye into the fiber. Do not use vinegar to tryto make all-purpose dye more permanent.

Conclusions

Use all-purpose dye if you want to use a single step to dye a garment that is a

mixture of a cellulose fiber, such as cotton or rayon, with either wool, another

animal fiber, or nylon. It is actually possible to dye both cotton and nylon in a

mixed-fiber garment with the same fiber reactive dye, but this requires a two-step

process with two different pH levels. Wool can be dyed with fiber reactive dyes ata pH of 8 or 9, but nylon requires an acid pH.

Otherwise, whenever possible, avoid all purpose dye, in favor of a specific acid or

direct or fiber reactive dye that specifically matches your fiber and meets your

needs. If you want an acid dye that is washfast, use a different type of acid dye,

such as Lanaset dye. If one wants a cotton dye that is washfast, choose a fiber

reactive dye. For dyeing large quantities of cotton cheaply, mail-order direct dye in

bulk.

Textile dyes for wool

Wool is a fiber made from the hair of sheep. Other animal hair fibers, such as

angora, mohair, cashmere, and camel's hair, are in most respects dyed the same as

wool. All animal fibers are made of a class of chemicals known as protein.

Proteins are made out of different combinations of the twenty essential amino

acids. They are more complex than cellulose, which is made out of repeating units

of a sugar, glucose, and thus there are more ways in which different dye chemicalscan attach to them. There are, therefore, many more different substances which can

be used to dye protein fibers.

All animal hair fibers, such as wool, are sensitive to high pHs. To dye wool,one

must avoid the high pH of the soda ash recipes used to dye cotton. Most wool-

-

8/13/2019 Dyeing & Printing

14/33

14

dyeing recipes call for an acid such as acetic acid, white vinegar (which naturally

contains acetic acid), or citric acid.

Dyes for Wool

Acid dyes are the most popular dyes used on wool, and comprise a very wide

range of different dyes. Some of the many different available acid dyes include

food dyes, Metal Complex (or premetallized) Acid Dyes, Washfast Acid dyes,

Acid Leveling dyes, and One Shot dyes. Fiber reactive dyes such as Procion MX,

Cibacron F, and Drimarene K can also be used as acid dyes on wool.

Natural dyes: Many natural dyes work very well on protein fibers, such as wool.

Most will require a mordant, such as alum, copper, tin, or iron, so they are not

necessarily more on-toxic than synthetic dyes.

Lanaset dyes: The longest lasting, most wash-resistant, richest of hand dyes

available for dyeing wool in the US are the Lanaset dyes. The Lanaset dyes

comprise a selection of both acid dyes and fiber reactive dyes that are designed for

wool. Unlike other dyes for wool, Lanaset dyes can be washed in hot water without

fading badly. They are often difficult to obtain other countries in quantities small

enough for hand dyeing.

Lanaset dyes can be used to dye all polyamide fibers: silk, wool, angora, mohair,

and nylon. Lanaset dyes include two or three entirely different classes of dye. They

all attach to wool under similar conditions.

Lanaset dyes are considerably more washfast than most dyes available for use on

wool; they are significantly more permanent than the less washfast members ofProChem'sWashFast Acid dyes or Jacquard's Acid Dyes, and certainly far more

washfast than the strong acid (Kiton) dyes. No other group of dyes that is suitable

for hand dyeing is more washfast on wool. Unlike other acid dyes, Lanaset dyes

are tested in hot water, at 140F, conditions under which many acid dyes will wash

out or bleed.

-

8/13/2019 Dyeing & Printing

15/33

15

The main disadvantage of Lanaset dyes is that they are more expensive than other

acid dyes (though lower than all-purpose dyes

How to use

Lanaset/Sabraset dyes are used at a mildly acid pH; for example, for one pound

(0.5 kg) of fiber in 3 gallons (12 liters) of water, use 2 cups (0.5 liter) of distilled

white vinegar. Glauber's salt (sodium sulfate) is often used to help level the dye,

that is, to produce a smooth single color on the entire batch of wool, instead of

coloring some parts strongly and others weakly; typically one cup per pound of

fiber in 3.5 gallons of water is recommended. In addition, sodium acetate may be

used as a pH buffer, to maintain acidity, at a rate of 2 grams per liter (0.5 to 1

ounce per 3.5 gallon dyebath). Albegal SET is a three-product mix that aids in

leveling, to get a smooth solid color. Heat is the final requirement.

Vinyl sulfonedyes :also known as Remazol dyes, are a type of fiber reactive dye

that is often used in silk painting. Unlike Procion MX dyes, they can be applied to

wool under acid conditions as true fiber reactive dyes, rather than as acid dyes.

Note that ProChem sells these under the name "Liquid Reactive Dyes", Dharma

Trading Company as "Vinyl Sulphon", and other suppliers as "Remazol" dyes.

Vat Dyes: such as indigo, can also be used to dye wool and other protein fibers,

but the recipe must be modified to avoid pHs high enough to damage the wool.

All purpose dyes: can be used to dye protein fibers, because they include an acid

dye in their mixture.The color might be slightly different than expected, and theexpense is higher than with other dyes.

How to use the different dyes

The different types of dyes used on wool are not interchangeable. All require a

mild acid, such as vinegar, citric acid, ammonium sulfate, or sodium acetate, but

-

8/13/2019 Dyeing & Printing

16/33

16

not necessarily in the same quantities, and some require additional chemicals such

as salt, Albegal SET, or sodium sulfate (Glauber's salt). Some dyes require a

significantly lower (more acidic) pH than others; using a pH that is too low or too

high for some specific dye will reduce the success in dyeing. After selecting the

dye, find a wool-dyeing recipe that specifies that particular sort of dye.

Suppliers

PRO Chemical & Dye, which sells most of these types of dye, has a full

range of reliable instruction sheets for each of many different types of dye.

Dharma Trading Company provides Instructions and Tutorials.

Jacquard Products has a page listing different Product Instructions.

Batik Oetoro in Australia gives instructions for different dyes on a single

Directions page.

Kraftkolour in Australia has a wonderful selection of Instruction Sheets for

many different dyes including Acid Milling Dyes, Lanaset and Lanasol dyes.

Fibrecrafts in the UK lists pages of instructions in their Fact File.

Although they're not a supplier for hand dyers, it's interesting to look at the

industrial recipes provided by Town End Colours in the UK for each of their

classes of dyes.

Suppliers of Lanaset dyes

Lanaset dyes are sold by several dye suppliers, including Paradise Fibers and PRO

Chemical and Dye under their name of Sabraset. They are also sold under the

brand name Telana. They are manufactured by Huntsman Textile Effects, which

purchased the global Textile Effects business of Ciba Specialty Chemicals Inc. in

2006.

-

8/13/2019 Dyeing & Printing

17/33

17

Textile Dyes used for silk

Acid dyesare used to dye protein fibers such as wool, angora, cashmere, and silk,

as well the milk protein fiber called Silk Latte, the soy protein fiber called Soy

Silk, and the synthetic polyamide fiber nylon.

Acid dyes sound scary to some novices, who imagine that the dyes themselves arecaustic strong acids. In fact, the dyes are non-caustic, are in some cases non-toxic,

and are named for the mild acid (such as vinegar) used in the dyeing process, and

for the types of bonds they form to the fiber. Some of them are significantly more

toxic than fiber reactive dyes, while others are even safe enough to eat, and are

sold as food coloring.

Marabou silk colour hand dyeSilk fabrics can be dyed very easily and individually with Marabu-Silk Color. The

versatile selection of colours offers both up to the minute fashionable shades andclassic basic shades.

Silk dyed with Marabu-Silk Color will have exceptional colour brilliance,permanent light fastness and incredibly soft feel. Marabu-Silk Color is extremelywash-resistant when washed by hand and also dry-clean-resistant directly after thedyeing process. In combination with Marabu-Contours & Effects, Marabu-VelvetTouch (as photo) and thickened Marabu-Silk, which are applied after dyeing, brandnew dimensions in silk fabric design can be created. With the help of Marabu-Stencils and Marabu-Design Stamps creating something individual is very easy.

-

8/13/2019 Dyeing & Printing

18/33

18

Definition of Auxiliaries

A chemical or formulated chemical product which enables aprocessing operation in preparation, dyeing, printing or finishing to be carriedout more effectively, or whichis essential if a given effect is to be obtained.

Necessity of auxiliaries in textile dyeing

(a) To prepare or improve the substrate in readiness for coloration byscouring,bleaching and desizingwettingenhancing the whiteness by a fluorescent brightening effect

(b)To modify the sorption characteristics of colorants byaccelerationretardation

creating a blocking or resist effectproviding sites for sorptionunifying otherwise divergent rates of sorptionimproving or resisting the migration of dyes

(c) To stabilize the application medium byimproving dye solubilitystabilizing a dispersion or solutionthickening a print paste or pad liquorinhibiting or promoting foamingforming an emulsionscavenging or minimizing the effects of impuritiespreventing or promoting oxidation or reduction

(d) To protect or modify the substrate bycreating or resisting dye abilitylubricating the substrateprotecting against the effects of temperature and other processing conditions

-

8/13/2019 Dyeing & Printing

19/33

19

(e) To improve the fastness of dyeing, as in the after treatment of direct orreactive dyesthe after treatment of acid dyes on nylonthe chroming of mordant dyes on wool or nylon

inhibitors of gas-fume fadingback-scouring or reduction clearing

(f)To enhance the properties of laundering formulations (fluorescentbrighteningagents).

Auxilliaries used with different dyes

Dyes for Cellulosic Fibers

Direct Dyes (Anionic) :They can be dyed directly on cellulosic fibers.Without the presence of salt, whenthe fibers are immerged in water, it will showanionic cha rge which repel s th edyes. Addi ng sa lt into the dye bath, it wil l reduce anionic on the fibers sothe dyes can get closer and adsorb into the fibers.

Advantage: cheap, easily dyed on fibersDisadvantage: poor wet fastness and some dyes have poor light fastness.

Textile Auxiliaries:1. Salt - reduce negative charges on the fibers2. Water - dyeing media3. FixingAgent - enhance wet fastness but usually reduce light fastness

Dyeing Conditions:(Exhaustion): dyeing lOOoC x 30-90 mm fixing 6OoC x 20 mm.(Continuous) pad--> dry --> steam --> wash --> soap --> dry

Reactive Dyes (Anionic):

They can be dyed on cellulosic fibers. The mechanism isnearly the same asdescribed in direct dyes.

Advantage:

high wet fastness due to covalent bonding (Chemical Bonding) betweenfibers anddyes, easily dyed on fibers.

-

8/13/2019 Dyeing & Printing

20/33

20

Disadvantage:

Expensive.

Dyeing Conditions:

1. Continuous Process:1.1Pad-dry-bake This is very easy method for cotton or cotton blends fibers.1.2Pad-dry-Pad (Chemical)-Steam This will give brighter and moreintense color than method 1.1.1.3Pad-batch This will put the goods into the dye solution and squeeze with 2

rubber rollers to get rid of excess water and then batch at room temperature for 1-2days.2. Exhaustion Process:

This method will be used in small factory. Dyeing conditionswill be 40-8OoC for30-90 mm depending to the types and structures of the dyes.Textile Auxiliaries:1. Salt - reduce negative charges on the fibers2. Water - dyeing media.3. Soda Ash - excite the dye to link with the fibers with covalent bonding.Therefore it enhances wet fastness4. Fixing Agent - enhances wet fastness for heavy shade but usuallyreduce lightfastness.Vat Dye (Anionic when soluble):The dye is named from the container (Vat) that used for rotting thed y e w i t h a l k a l i s o l u t i o n . T h i s c r u c i a l p r o c e s s w i l l r e d u c e t h edye from insoluble to soluble dye(suitable for exhaustion in thecellulosic fibers). Now the manufacturer cansynthesizeman-made vat dye.

Dyeing Process:

1. Dissolve dye into water (insoluble dye)2. Vatting process by reducing the insoluble dye in alkali condition. (Soluble dye)3. Absorb into fibers (soluble dye)4. After dyeing, oxidize the dye with oxidizing agent (insoluble dye)5. Wash andsoap the goods

-

8/13/2019 Dyeing & Printing

21/33

21

Dyeing Conditions:1. Continuous Process

1.1 Pad-dry-Pad (Chemical):The solution of the dye is prepared without addingreducing agent toensure leveling dyeing. After that, the goods are passed to chemical bath toreduce the dye into soluble dye and fix within the goods. Oxidizingagent isadded to the goods and converted to insoluble dyes.

1.2 Pad-oxidize-pad-oxidize (many times):This will put the goods into the dyesolution and squeeze with 2 rubber rollers toget rid of excess water, oxidize with theair and then immerse into the dye solutionagain and again to allow the dye penetrateinto the goods.

Textile Auxiliaries

1. Salt - reduce the negative charges on the fibers

2 . Sodium hydroxide - adjusts pH to the dyeing bath and makes the

suitableconditions for reducing agent.

3. Sodium hydrosulfite - reducing agent for the vat dyes.

4. Water - dyeing media

5. Oxidizing agents - (Hydrogen peroxide or Acetic acid or Air) oxidize the solubletoinsoluble dye

Acid Dye (Anionic):

The dye is called acid because it needs acidic dyeing condition.It can be dyed onprotein fibers (silk, wool, and other animal fibers) and on polyamidefibers. Acidic

condition will give the fibers showing positive charge. As the negativecharge willattach directly to positive charge, and penetrate into the fibers.

Dyeing conditions:

l00 x 30-60 mm

Textile Auxiliaries:

-

8/13/2019 Dyeing & Printing

22/33

22

1. Leveling agent - for levelness dyeing.2. Retarding agent - for inhibiting the dye not attach to fibers too fast.3. Acid - adjust the dyeing condition and make the fibers to show positive charges.4. Water - dyeing media.

Basic Dye (Cationic)The dye shows positive charge. Normally, the dye can be applied onwool, silk and poly-acrylonitrile (acrylic).Dyeing Conditions:l00oC x 30-60 mmDyes Dyeing Condition (pH)Acid (Wool) 2-4, 4-6, 6-8 (depends on types ofdyes)Acid (Nylon) 4.5-5.5, on types of dyes)Basic 3.5-4Direct 7.0Disperse(Polyester) 5-6Disperse (Acetate) 6.5-7.0Disperse (Triacetate) 4.5-6.5Reactive 7.0(Exhaustion)11.0 (Fixing)

Textile Auxiliaries:

1. Leveling agent - for levelness dyeing.2. Retarding agent - for inhibiting the dye not attach to fibers too fast.

3. Acid - adjust the dyeing condition and make the fibers to show negativecharges.

4. Water - dyeing media.

S yn th e s i s o f R e ac t i ve A u x i l i ar i e s for D ye R e s i s t

Treatment of Wool

Auxiliary products of various types are commonly used in the dye bath during the

lowtemperature dyeing of wool. Such chemicals are used to promote dye

bathexhaustion and to achieve level dyeing . A resist process may be defined asonewhich modifies a textile fiber in such away that when the resist treated fiber

issubsequently dyed, it absorbs dye to a lesser extent or at a slower rate than

untreatedfiber. Various treatments have been proposed for imparting dye resist

effects to wool,for example, sulphonation,acetylation, glyoxylation, deposition of

polymers, alkalinechlorination and treatment with formaldehyde,sulphamic acid,

-

8/13/2019 Dyeing & Printing

23/33

23

tannic acid/metalsalts, synthetic tanning agents and also colourless

reactive compound.Among them reactive dye resist agents are

preferred due to their easy handling andapplication. A viable dye resist

agent must be completely cured and bound firmlyto the wool substrate in order to

achieve satisfactory dye resist effects. Increasingthe substantivity between thesubstrate and the dye resist agents is one of the mostimportant factors needed to

improve dye resist effects.In order to increase thissubstantivity one possible

effective dye resist method would be to covalently bind thedye resist agents to the

wool substrate using suitable fiber reactive groups. In thiswork we synthesized

three reactive auxiliaries containing s-triazine based reactivegroups which were

used for treating wool. Three acid dyes containing differentnumber of sulphonic

acid groups were used for dyeing treated wool

Three acid dyes which have different numbers of sulphonate groups were used are

in table 1. The commercial names and color Index names for these

dyes are given in table 2:

-

8/13/2019 Dyeing & Printing

24/33

24

-

8/13/2019 Dyeing & Printing

25/33

25

List OfSuppliers

Adhik Chemicals - Manufacturer and exporter osolvents, dyes, pigment, and intermediates.

Airedale Chemical Co. Ltd. - Supplier of dyes,dyestuffs, and chemical products for the textiles,

agricultural, and aluminium industries.

Alabama Pigments Company - Producer of blackand natural red iron oxide pigments.

ALPS Industries - Manufactures natural dyes,cotton products, dye fibres, and yarns.

Ama Herbal Laboratories - Manufacturer ofextracts of eco-friendly natural dyes for textile andhair.

Amantech - Importer of Indian pigments, dyes,food colours, and raw materials for the coatings

industry.

Ambuja Intermediate Products Pvt. Ltd. -Manufacturer of dye intermediates, dyestuffs, and

pigments.

American Colors, Inc. - Coloration systems forthe plastics and coatings industries.

Amichem Corporation - Manufactures metallicsalts, organic, inorganic, and basic chemicals.

Anar Chemicals - Manufactures synthetic organicdyes, pigments, and intermediates.

Apollo Chemical Corporation - Supplier oftextile chemicals.

ArunChemi-Dyes - Manufacturer and exporter ofsodium naphthionate, betahydroxynapthoic acid,

bon acid, and parachloro aniline.

Asian Dyestuff Industries - Manufacturesreactive, direct, and acid dyes and pigment

powders.

Atlas Dye-Chem Industries- Manufactures

http://www.adhikchemicals.com/index.htmhttp://www.adhikchemicals.com/index.htmhttp://www.airedalechemical.co.uk/http://www.alabamapigments.com/http://www.alpsind.com/http://www.alpsind.com/http://www.amaherbal.com/http://www.amantech.com/http://www.ambujaindia.com/http://www.americancolors.com/http://www.americancolors.com/http://www.amichemcorp.com/http://www.anarchem.com/http://www.apollochemical.com/http://www.apollochemical.com/http://www.arunchemi.com/http://www.asian-dyes.com/http://www.asian-dyes.com/http://www.atlasdye-chem.com/http://www.atlasdye-chem.com/http://www.atlasdye-chem.com/http://www.asian-dyes.com/http://www.arunchemi.com/http://www.apollochemical.com/http://www.anarchem.com/http://www.amichemcorp.com/http://www.americancolors.com/http://www.ambujaindia.com/http://www.amantech.com/http://www.amaherbal.com/http://www.alpsind.com/http://www.alabamapigments.com/http://www.airedalechemical.co.uk/http://www.adhikchemicals.com/index.htm -

8/13/2019 Dyeing & Printing

26/33

26

reactive dyes.

B.R. Group - Distributing pigments, dyes, andother chemical products.

Bajaj Group of Companies - Manufactures dyesand dyes intermediates, as well as roasted peanutsand peanut butter.

CDR Pigments & Dispersions - Manufacturescolorants and varnishes for ink, plastic and paint

applications.

Chemco India - Manufacturer and exporter ofbasic, solvent, and acid dyes, as well as food

colours.

Chemical Factory Triade - Makes dyestuffs andpigments for the textile, paper, and leather

industries.

Chemrez - Manufacturer of paints and coatings,inks, resins, and colorants.

China Wellton Chemical Co. Ltd. - Providingorganic pigment, pigments printing paste,

dispersion dye, and more.

Cleveland Pigment & Color Co. - Processespigments for rubber, plastics, and other industries.

ColoresNaturales de Chile - Producing andmanufacturing cochineal extracts and derived

carmines for the food and cosmetic industries.

Colorwen International Corp. - Serves domesticand international markets with dry pigments,

presscake, water-based ink, colour paste,

colourmasterbatch, pigment flush, and inkjet inks.

Coltech Chemicals - Manufactures copperphthalocyanine green.

Coral Group - Iron oxide red and blackmanufacturer.

Creanova, Inc. - Provides tinters, inks, biocides,raw materials, and additives to industry.

http://www.thebrgroup.com/http://www.bajajgroups.com/http://www.cdrpigments.com/http://www.cdrpigments.com/http://www.chemcoindia.com/http://www.chemcoindia.com/http://www.triade.nl/http://www.triade.nl/http://www.chemrez.com/http://www.wtchem.com/http://www.wtchem.com/http://www.clevelandpigment.com/http://www.cochineal.cl/http://www.colorwen.com/http://www.colorwen.com/http://www.coltech.com/http://www.coralchem.com/http://www.coralchem.com/http://www.creanovainc.com/http://www.creanovainc.com/http://www.creanovainc.com/http://www.coralchem.com/http://www.coltech.com/http://www.colorwen.com/http://www.cochineal.cl/http://www.clevelandpigment.com/http://www.wtchem.com/http://www.chemrez.com/http://www.triade.nl/http://www.chemcoindia.com/http://www.cdrpigments.com/http://www.bajajgroups.com/http://www.thebrgroup.com/ -

8/13/2019 Dyeing & Printing

27/33

27

Daemyung Industry - Producing dyeing, printing,pretreatment, and sizing chemicals for the textile

trade.

Deepak Chemicals Group - Manufacturespigments, dyes, and dye intermediates.

Delta Colours - Colour pigments for the paint,plastics, ink, and construction industries.

Devarsons Industries Limited - Makes pigmentsand dyes.

Dyetex Corporation - Manufactures synthetic,intermediate, coaltar, and colorant dyes.

Elian - Masterbatch and colorant manufacturer forplastics coloration.

Farbenchem International - Marketing dyes, dyeintermediates, pigments, and pigment intermediates.

Gopal Chemicals - Manufacturing food colours. Gwalior Oil Mills - Makers of oil, paints, resins,

and pigments.

Hangzhou Pigment Chemicals Plant - Exporterand manufacturer of organic pigment,

anthraquinone and h-acid.

Hastand - Offer a range of chemicals, includingpigments, dyestuffs, and pharmaceutical raw

materials.

Hebei Jiehong Dyestuff Chemical Corporation -Tianjin Dept.@

HebeiLuquanXingyu Chemical Factory -Manufacturer of dyestuffs including basic red, basic

violet, monochloroacetic acid, fluorescent

brighteners, thiourea dioxide, and 6-chloro-2-hexanone.

HebeiQuzhouChenguang Natural PigmentCo.,Ltd - Manufacturer of natural pigment for

foodstuffs including red chillicolour, extract,

chilliflavouring essence, xanthophylls, and more.

http://www.daemyung-ind.com/http://www.daemyung-ind.com/http://www.deepakchemicals.com/http://www.deltacolours.com/http://www.deltacolours.com/http://www.devarsons.com/http://www.dyetexcorp.com/http://www.elian-britishvita.com/http://www.elian-britishvita.com/http://www.farbenchem.com/http://www.farbenchem.com/http://www.foodcolourindia.com/http://www.foodcolourindia.com/http://www.gomindia.com/http://www.gomindia.com/http://www.chinapigment-dye.com/http://www.chinapigment-dye.com/http://www.hastand.com/http://in.dir.yahoo.com/Regional/Countries/China/Business_and_Economy/Business_to_Business/Chemicals_and_Allied_Products/Pigments_and_Dyes/Hebei_Jiehong_Dyestuff_Chemical_Corporation___Tianjin_Dept_/http://in.dir.yahoo.com/Regional/Countries/China/Business_and_Economy/Business_to_Business/Chemicals_and_Allied_Products/Pigments_and_Dyes/Hebei_Jiehong_Dyestuff_Chemical_Corporation___Tianjin_Dept_/http://in.dir.yahoo.com/Regional/Countries/China/Business_and_Economy/Business_to_Business/Chemicals_and_Allied_Products/Pigments_and_Dyes/Hebei_Jiehong_Dyestuff_Chemical_Corporation___Tianjin_Dept_/http://in.dir.yahoo.com/Regional/Countries/China/Business_and_Economy/Business_to_Business/Chemicals_and_Allied_Products/Pigments_and_Dyes/Hebei_Jiehong_Dyestuff_Chemical_Corporation___Tianjin_Dept_/http://in.dir.yahoo.com/Regional/Countries/China/Business_and_Economy/Business_to_Business/Chemicals_and_Allied_Products/Pigments_and_Dyes/Hebei_Jiehong_Dyestuff_Chemical_Corporation___Tianjin_Dept_/http://www.dyestuff-china.com/http://www.dyestuff-china.com/http://www.hdchenguang.com/http://www.hdchenguang.com/http://www.hdchenguang.com/http://www.hdchenguang.com/http://www.hdchenguang.com/http://www.hdchenguang.com/http://www.dyestuff-china.com/http://in.dir.yahoo.com/Regional/Countries/China/Business_and_Economy/Business_to_Business/Chemicals_and_Allied_Products/Pigments_and_Dyes/Hebei_Jiehong_Dyestuff_Chemical_Corporation___Tianjin_Dept_/http://in.dir.yahoo.com/Regional/Countries/China/Business_and_Economy/Business_to_Business/Chemicals_and_Allied_Products/Pigments_and_Dyes/Hebei_Jiehong_Dyestuff_Chemical_Corporation___Tianjin_Dept_/http://www.hastand.com/http://www.chinapigment-dye.com/http://www.gomindia.com/http://www.foodcolourindia.com/http://www.farbenchem.com/http://www.elian-britishvita.com/http://www.dyetexcorp.com/http://www.devarsons.com/http://www.deltacolours.com/http://www.deepakchemicals.com/http://www.daemyung-ind.com/ -

8/13/2019 Dyeing & Printing

28/33

28

HebeiWuqiangRuixin Chemical Co. -Manufacturer of organic pigment and intermediates,

including basic green, basic orange, and others.

HebeiXihai Dyestuff Group Co., Ltd. - Offeringintermediates, direct dyes, reactive dyes, and more.

Hema Chemical - Manufactures organic dyes andintermediates.

Holland Colours - Produces pigments and pigmentdispersions mainly for the plastics industry

worldwide.

Indo Colchem Ltd. - Manufactures dyes andintermediates.

Industrial Colours and Chemicals Limited -Supplier of dyes and pigments to manufacturing

industries such as, paint and coating, graphic arts,

plastics and rubber, paper, and more.

JagsonColchem - Makes reactive dyes includingacids and direct dyes.

JyotiColours - Manufacturer and exporter oorganic and inorganic pigments, dyes, metallic

powder, oils, and resins. Based in Bangalore, India.

Karnavati Chemicals - Manufactures monochloroacetic acid.

Kerr-McGee Corporation - Energy and inorganicchemical company with worldwide operations.

Kiburn Chemicals - Manufactures titaniumdioxide, ferrous sulphateheptahydrate, mixed

sulphate salt, and ferro gypsum.

Kromachem - Chemicals and pigments for thecoatings industries and silicone rubber for mouldmaking.

Kronos, Inc. - Hightstown, NJ - Anatase/rutiletitanium dioxide pigment for whiteness, brightness

and opacity in paints, coatings, plastics, paper, ink,

fibres and ceramics.

Kumar Textile Industries - Products include

http://www.basic-green.com/http://www.basic-green.com/http://www.xihai-dyestuffs.com/http://www.hemachem.com/http://www.hemachem.com/http://www.hollandcolours.com/http://www.indocol.com/http://www.indocol.com/http://www.iccbram.com/http://www.jagson.com/http://www.jyoticolors.com/http://www.karnavatichemicals.com/http://www.karnavatichemicals.com/http://www.kerr-mcgee.com/http://www.kerr-mcgee.com/http://www.kilburnchemicals.com/http://www.kilburnchemicals.com/http://www.kromachem.co.uk/http://www.nl-ind.com/http://www.nl-ind.com/http://www.kumartextile.com/http://www.kumartextile.com/http://www.kumartextile.com/http://www.nl-ind.com/http://www.kromachem.co.uk/http://www.kilburnchemicals.com/http://www.kerr-mcgee.com/http://www.karnavatichemicals.com/http://www.jyoticolors.com/http://www.jagson.com/http://www.iccbram.com/http://www.indocol.com/http://www.hollandcolours.com/http://www.hemachem.com/http://www.xihai-dyestuffs.com/http://www.basic-green.com/ -

8/13/2019 Dyeing & Printing

29/33

29

direct, reactive, acid, and basic dyes.

LuenShing Company - Hong Kong-basedenterprises specialising in auxiliary, dyestuff, and

chemical products for the fur and leather industries.

Magruder Color Company - Manufacturer of dryand flushed pigments for sheetfed, web offset,

heatset, news, aqueous and solvent inks.

Mahavir Chemicals - Exporter of acid, pigment,leather, and non bezidine dyes.

Manan Ceramic Colours - Manufacturers andsuppliers of zirconium oxide, high and low

temperature ceramic colours, glass colours, reactive

frit, and related glazes.

Meilida Pigment Industry Company -Manufactures organic pigment and intermediates,

mainly phthalocyanine blue series products.

Nanjing New Chemicals Import and ExportCorporation - Manufacturer and exporter o

disperse dyestuffs, solvent dyestuffs, chemical

intermediates, and pigments.

Narayan Group of Industries - Offers pigments,copper salts, and more.

Neelikon Food Dyes & Chemicals - Makeswriting ink, fluorescent pigments, and colours for

food, pharmaceuticals, and cosmetics.

Ningbo Huajie Chemical - Manufacturer andexporter of disperse dyes, pigments, intermediates,

and other chemical products.

Nova Dyestuff Industries - Manufactures andexports dyes, auxiliaries, intermediates, and more.

Novasoft Systems - Manufacturing natural andsynthetic dyes.

Organic Dyestuffs, Inc. - Manufacturers of dyesand auxiliaries for all industries.

Orient Corporation of America - Manufacturerof dyes and pigments for plastics, inks, toners,

http://www.luenshingfurdye.com/http://www.luenshingfurdye.com/http://www.magruder.com/http://www.magruder.com/http://www.mahavirchem.com/http://www.mahavirchem.com/http://www.ceramiccoloursindia.com/http://www.ceramiccoloursindia.com/http://www.meilidapigment.com/http://www.newnjchem.com/http://www.newnjchem.com/http://www.newnjchem.com/http://www.newnjchem.com/http://www.newnjchem.com/http://www.narayan-pigments.com/http://www.narayan-pigments.com/http://www.neelikon.com/http://www.huajiechem.com/http://www.huajiechem.com/http://www.novadyestuff.com/http://www.novadyestuff.com/http://www.dyesonline.com/http://www.dyesonline.com/http://www.organicdye.com/http://www.orient-usa.com/http://www.orient-usa.com/http://www.orient-usa.com/http://www.organicdye.com/http://www.dyesonline.com/http://www.novadyestuff.com/http://www.huajiechem.com/http://www.neelikon.com/http://www.narayan-pigments.com/http://www.newnjchem.com/http://www.newnjchem.com/http://www.meilidapigment.com/http://www.ceramiccoloursindia.com/http://www.mahavirchem.com/http://www.magruder.com/http://www.luenshingfurdye.com/ -

8/13/2019 Dyeing & Printing

30/33

30

charge control agents, leather, and anodized

aluminium.

Parikh Enterprises Limited - Manufacturers andexporters of copper fungicides, copper chemicals,

copper pigments, cpc blue like copper sulphate, andbordeaux.

Plasticolors, Inc. - Supplier of colorants andchemical dispersions for the plastics industry.

Prem Dye Chem Industries - Manufactures acid,direct, and leather dyes.

Recent Laboratories - Manufacturer of alkalicyanates. Offers indigeniously developed products.

Renshel Exports - Manufactures aleuritic acid andshellac products.

Ritchemie - Manufacturers and suppliers of dyes. Rossari - Products include dyes, intermediates,

and enzymes for textiles and leather.

Sajjan India Ltd. - Manufacturing and exportingdyes and dye intermediates.

Sanyo Color Works, Ltd. - Manufacturingpigments, dyes, functional pigments, cationic

pigment-dyes, pigment dispersions, and more.

Saraf Chemical Industries - Processes andexports granite blocks, slabs, tiles, marble, slate,

and sandstone as well as reactive, acid, and direct

dyes.

Sarichem Dyestuff - Offers a wide range odyestuff.

ShidimoInteraux - Manufacturer and exporter oacid , acid milling, metal complex, and solventdyes. Also, dye intermediates, and textile

auxiliaries.

Shree Polymers - Manufactures pigmentemulsions and binders.

Shreenath Dye Chem Industries - Manufactures

http://www.parikhenterpriseslimited.com/http://www.parikhenterpriseslimited.com/http://www.plasticolors.com/http://www.plasticolors.com/http://www.bicserve.com/htm/premdye/http://www.recentlab.com/http://www.recentlab.com/http://www.renshel.com/http://www.renshel.com/http://www.angelfire.com/in/ritchemie/http://www.rossari.com/http://www.sajjan.com/http://www.sanyocolor.jp/http://www.saraf-group.com/http://www.saraf-group.com/http://www.sarichem.com/http://www.sarichem.com/http://www.shidimo.com/http://www.shidimo.com/http://www.shreepigment.com/http://www.shreepigment.com/http://www.shreenathdyechem.com/http://www.shreenathdyechem.com/http://www.shreenathdyechem.com/http://www.shreepigment.com/http://www.shidimo.com/http://www.sarichem.com/http://www.saraf-group.com/http://www.sanyocolor.jp/http://www.sajjan.com/http://www.rossari.com/http://www.angelfire.com/in/ritchemie/http://www.renshel.com/http://www.recentlab.com/http://www.bicserve.com/htm/premdye/http://www.plasticolors.com/http://www.parikhenterpriseslimited.com/ -

8/13/2019 Dyeing & Printing

31/33

31

vat pastes, pigments, emulsions, and textile

auxilaries.

Sinlai Industries Corp. - Colours (dye/pigment),fine and speciality chemicals and pharmaceuticals

suppliers. Soujanya Enterprises - Specialists in pigments

and pigment dispersion for use in paint, soap,

detergent and printing ink.

Sparkle India - Manufactures pigments, dyes, andcolours for plastics, paints, leather, textiles, and

printing inks.

Specialised Industrial Chemicals Ltd - Suppliesspeciality inks and chemicals to British and

European industries covering the automotive,

electronics, marine, and engineering sectors.

Spectra Colors Corporation - Industrial inks,dyes and colorants for all needs.

Spectrum Dyes & Chemicals Pvt. Ltd. -Manufacture disperse dyes for use in the textile

industry.

Stallion Impex, Ltd. - Manufactureres of reactive,direct and acid dyestuffs.

Standardcon - Manufacturers and exporters oaluminium lake and food colours.

Stoopen&Mee S.A. - Pigments and dyes forwoods, cement, plastics, printing, food, and more,

specially formulated by request.

Sudarshan Chemical Industries - Manufacturesand markets a range of paint, plastic, and ink

pigments as well as agricultural chemicals and

environmental products

Sun Chemical - Manufacturer of printing inks,coatings and organic pigments.

Sunbelt Corporation Tabercolor - Printing inks for paper and PVC

http://www.sicchem.com/http://www.soujanya.com/http://www.soujanya.com/http://www.sparklecolour.com/http://www.sparklecolour.com/http://www.sic.mcmail.com/http://spectracolors.com/http://spectracolors.com/http://www.spectrumdyes.com/http://www.stallionimpex.com/http://www.stallionimpex.com/http://www.standardcon.com/http://www.standardcon.com/http://www.dragoncolors.com/http://www.sudarshan.com/http://www.sunchemical.com/http://www.sunchemical.com/http://www.sunbeltcolors.com/http://www.tabercolor.com/http://www.tabercolor.com/http://www.tabercolor.com/http://www.sunbeltcolors.com/http://www.sunchemical.com/http://www.sudarshan.com/http://www.dragoncolors.com/http://www.standardcon.com/http://www.stallionimpex.com/http://www.spectrumdyes.com/http://spectracolors.com/http://www.sic.mcmail.com/http://www.sparklecolour.com/http://www.soujanya.com/http://www.sicchem.com/ -

8/13/2019 Dyeing & Printing

32/33

32

surfaces, pigment dispersions, and more.

Texchem - Manufacturers of chemical products fortextile dyeing and finishing.

Thirumalai Chemicals - Manufactures andmarkets industrial chemicals for the plastics, paints,resin industries, and additives for the food and feed

industry.

TOR Minerals International - Markets andmanufactures pigments for paints, plastics, and

other products that require colorization.

U H International - Chemical company in India,developing and suppling food colours, dyes,

flavours, and fragrances globaly.

Ushanti - Offers dyestuff, pigment, colourmatching, and intermediate processes.

Vidhi Dyestuffs Manufacturing Ltd. -Manufacturers and exporters of food colours.

Vinayak Corporation - Manufacturers omenthol, food colours, essential oils, aromatic

chemicals, and dyes.

Vipul Dye Chem Limited - Manufacturespigment emultions, solvent colours and acid dyes.

Zhe Jiang Wan Tong Chemical - Manufacturerand exporter of disperse dyes. Includes company

profile and online inquiry form.

Zydex Industries - Supplies textile polymers,printing thickeners, coatings, dispersants, and other

finishing chemicals.

http://www.texchem.co.uk/http://www.thirumalaichemicals.com/http://www.torminerals.com/http://www.torminerals.com/http://www.uhintl.com/http://www.uhintl.com/http://www.ushanti.com/http://www.ushanti.com/http://vidhifoodcolours.com/http://vidhifoodcolours.com/http://www.vinayakcorporation.com/http://www.vinayakcorporation.com/http://vipuldyes.com/http://vipuldyes.com/http://www.sxdyes.com/http://www.zydexindustries.com/http://www.zydexindustries.com/http://www.zydexindustries.com/http://www.sxdyes.com/http://vipuldyes.com/http://www.vinayakcorporation.com/http://vidhifoodcolours.com/http://www.ushanti.com/http://www.uhintl.com/http://www.torminerals.com/http://www.thirumalaichemicals.com/http://www.texchem.co.uk/ -

8/13/2019 Dyeing & Printing

33/33

Biblography

Books referred:

1. B.P.Corbman2. Chemistry of dyes & principles of dyeing3. V.A.Shenai4. Tortora5. Hurst6.NCUTE Progress series

Websites referred:1. www.wikipidea.com2. file:///I:/dnp/Paula%20Burch's%20About%20Dyes.htm3. file:///I:/dnp/Rainbow%20Silks%20%20%20Fabric%20Dyes.htm4. file:///I:/dnp/Process%20for%20dyeing%20cellulosic%20...%20-

%20Google%20Patents.htm#v=onepage&q=Textile%20dyes%20and%20auxiliaries%20for%20cellulosic%20materials&f=false

5. file:///I:/dnp/DyStar%20-%20World%20of%20Textiles.htm6. file:///I:/dnp/Dyeing%20Auxiliaries,Textile%20Dyeing%20Auxiliaries,Dyei

ng%20Auxiliaries%20Importers%20India.htm

7. file:///I:/dnp/Clariant%20Textile%20Chemicals%20-%20-%20Special%20Dyes.htm

8. file:///I:/Aurora%20Silk%20-%20Natural%20&%20Plant%20Dyes.htm9. file:///I:/Yahoo!%20India%20Directory%20%20%20Pigment%20and%20D

ye%20Manufacturers%20and%20Distributors.htm10.A study of textile Dyeing Auxiliaries.htm

http://www.wikipidea.com/http://i/dnp/Paula%20Burch's%20About%20Dyes.htmhttp://i/dnp/Rainbow%20Silks%20%20%20Fabric%20Dyes.htmhttp://i/dnp/Process%20for%20dyeing%20cellulosic%20...%20-%20Google%20Patents.htm%23v=onepage&q=Textile%2520dyes%2520and%2520auxiliaries%2520for%2520cellulosic%2520materials&f=falsehttp://i/dnp/Process%20for%20dyeing%20cellulosic%20...%20-%20Google%20Patents.htm%23v=onepage&q=Textile%2520dyes%2520and%2520auxiliaries%2520for%2520cellulosic%2520materials&f=falsehttp://i/dnp/Process%20for%20dyeing%20cellulosic%20...%20-%20Google%20Patents.htm%23v=onepage&q=Textile%2520dyes%2520and%2520auxiliaries%2520for%2520cellulosic%2520materials&f=falsehttp://i/dnp/Process%20for%20dyeing%20cellulosic%20...%20-%20Google%20Patents.htm%23v=onepage&q=Textile%2520dyes%2520and%2520auxiliaries%2520for%2520cellulosic%2520materials&f=falsehttp://i/dnp/Process%20for%20dyeing%20cellulosic%20...%20-%20Google%20Patents.htm%23v=onepage&q=Textile%2520dyes%2520and%2520auxiliaries%2520for%2520cellulosic%2520materials&f=falsehttp://i/dnp/DyStar%20-%20World%20of%20Textiles.htmhttp://i/dnp/Dyeing%20Auxiliaries,Textile%20Dyeing%20Auxiliaries,Dyeing%20Auxiliaries%20Importers%20India.htmhttp://i/dnp/Dyeing%20Auxiliaries,Textile%20Dyeing%20Auxiliaries,Dyeing%20Auxiliaries%20Importers%20India.htmhttp://i/dnp/Dyeing%20Auxiliaries,Textile%20Dyeing%20Auxiliaries,Dyeing%20Auxiliaries%20Importers%20India.htmhttp://i/dnp/Dyeing%20Auxiliaries,Textile%20Dyeing%20Auxiliaries,Dyeing%20Auxiliaries%20Importers%20India.htmhttp://i/dnp/Clariant%20Textile%20Chemicals%20-%20-%20Special%20Dyes.htmhttp://i/dnp/Clariant%20Textile%20Chemicals%20-%20-%20Special%20Dyes.htmhttp://i/dnp/Clariant%20Textile%20Chemicals%20-%20-%20Special%20Dyes.htmhttp://i/dnp/Clariant%20Textile%20Chemicals%20-%20-%20Special%20Dyes.htmhttp://i/Aurora%20Silk%20-%20Natural%20&%20Plant%20Dyes.htmhttp://i/Yahoo!%20India%20Directory%20%20%20Pigment%20and%20Dye%20Manufacturers%20and%20Distributors.htmhttp://i/Yahoo!%20India%20Directory%20%20%20Pigment%20and%20Dye%20Manufacturers%20and%20Distributors.htmhttp://i/Yahoo!%20India%20Directory%20%20%20Pigment%20and%20Dye%20Manufacturers%20and%20Distributors.htmhttp://i/Yahoo!%20India%20Directory%20%20%20Pigment%20and%20Dye%20Manufacturers%20and%20Distributors.htmhttp://i/Yahoo!%20India%20Directory%20%20%20Pigment%20and%20Dye%20Manufacturers%20and%20Distributors.htmhttp://i/Yahoo!%20India%20Directory%20%20%20Pigment%20and%20Dye%20Manufacturers%20and%20Distributors.htmhttp://i/Aurora%20Silk%20-%20Natural%20&%20Plant%20Dyes.htmhttp://i/dnp/Clariant%20Textile%20Chemicals%20-%20-%20Special%20Dyes.htmhttp://i/dnp/Clariant%20Textile%20Chemicals%20-%20-%20Special%20Dyes.htmhttp://i/dnp/Dyeing%20Auxiliaries,Textile%20Dyeing%20Auxiliaries,Dyeing%20Auxiliaries%20Importers%20India.htmhttp://i/dnp/Dyeing%20Auxiliaries,Textile%20Dyeing%20Auxiliaries,Dyeing%20Auxiliaries%20Importers%20India.htmhttp://i/dnp/DyStar%20-%20World%20of%20Textiles.htmhttp://i/dnp/Process%20for%20dyeing%20cellulosic%20...%20-%20Google%20Patents.htm%23v=onepage&q=Textile%2520dyes%2520and%2520auxiliaries%2520for%2520cellulosic%2520materials&f=falsehttp://i/dnp/Process%20for%20dyeing%20cellulosic%20...%20-%20Google%20Patents.htm%23v=onepage&q=Textile%2520dyes%2520and%2520auxiliaries%2520for%2520cellulosic%2520materials&f=falsehttp://i/dnp/Process%20for%20dyeing%20cellulosic%20...%20-%20Google%20Patents.htm%23v=onepage&q=Textile%2520dyes%2520and%2520auxiliaries%2520for%2520cellulosic%2520materials&f=falsehttp://i/dnp/Rainbow%20Silks%20%20%20Fabric%20Dyes.htmhttp://i/dnp/Paula%20Burch's%20About%20Dyes.htmhttp://www.wikipidea.com/